Sheet metal machine enclosures are important for protecting machines and electronics. They help keep equipment safe and make it last longer. New ways of making these enclosures have improved their design and use.

Custom-made sheet metal enclosures now follow strict industry rules, like NEMA standards.

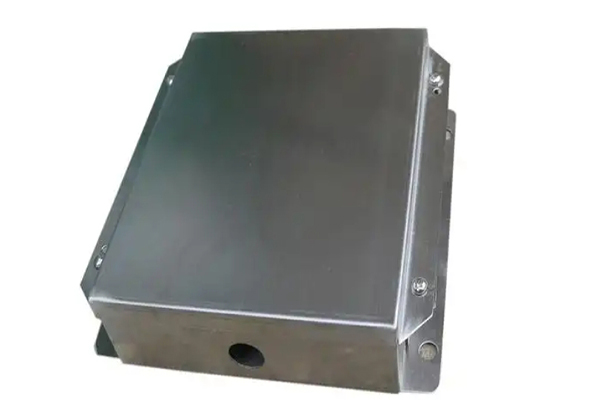

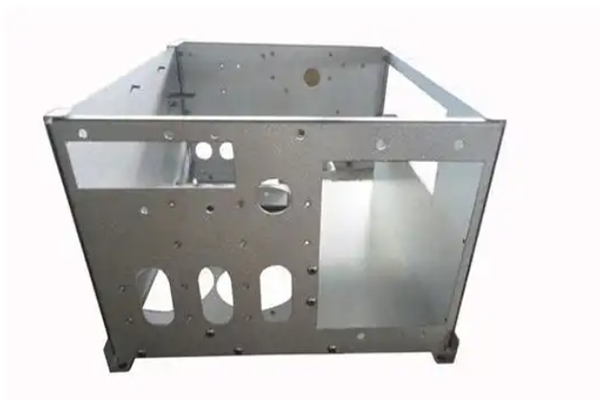

Electrical boxes, panels, cabinets, and machine covers are used to give strong protection.

These changes make them very useful in areas like factories, green energy, and technology.

As industries change, enclosures must improve too. In 2025, they will be stronger, more eco-friendly, and more flexible.

Key Takeaways

Sheet metal enclosures keep machines safe from harm, dirt, and water. This helps machines last longer.

Special designs make enclosures fit industry needs, improving work in factories and other places.

Using green materials and methods is important to protect nature.

Smart enclosures with IoT check conditions, stopping problems and making work smoother.

Modular designs are flexible, letting enclosures change quickly for new machine needs.

Overview of Sheet Metal Machine Enclosures

What Are Sheet Metal Enclosures?

Sheet metal enclosures are covers that protect machines and electronics. They keep parts safe from damage, weather, and electrical problems. These covers are very important for keeping factories running smoothly. They can be made for use indoors or outdoors. For example, Types 1, 2, 5, 12, 12K, and 13 are for indoor use. Types 3, 3X, 3R, 3RX, 3S, 3SX, 4, 4X, 6, and 6P are made for outdoor conditions.

Why Are Metal Enclosures Important in Factories?

Metal enclosures are very useful in factories and workplaces. They stop dust, water, and chemicals from damaging machines. They also protect people from touching live wires and prevent electrical fires. These enclosures help organise wires and keep machines cool by spreading heat. They also block magnetic fields, which is important for delicate electronics. This makes them a key part of industries that need precise equipment.

Materials Used for Custom Sheet Metal Enclosures

The material used for enclosures affects how strong and long-lasting they are. Stainless steel, aluminium, and galvanised steel are popular choices. Stainless steel doesn’t rust and works well in wet or chemical-heavy places. Aluminium is light but strong, so it’s good for portable uses. Galvanised steel is cheaper and resists rust well. When picking a material, think about the environment, stress, and heat or electricity needs. This helps make sure the enclosure works as it should.

Stainless steel: Strong and doesn’t rust easily.

Aluminium: Light, strong, and spreads heat well.

Galvanised steel: Affordable and resists rust effectively.

Key Uses of Sheet Metal Enclosures in 2025

Factories and Automated Production

Factories in 2025 use sheet metal enclosures to protect machines. These enclosures are key in automated production lines for smooth work. They keep dust, dirt, and vibrations away from delicate parts. This helps machines run without stopping.

Custom enclosures are very useful in factories. They can be made to fit specific machines and needs. Modular designs allow quick changes, perfect for busy production lines.

Industries like mining and construction also need strong metal parts. New cutting and welding methods make better enclosures. Companies like Foxsen now create tough and flexible solutions for heavy machines.

Green Energy Systems

Green energy systems use sheet metal enclosures to stay reliable. These enclosures hold parts like inverters and control panels. They protect them from heat, moisture, and sunlight in solar and wind setups.

Special designs, like double-layered walls, save energy and improve performance. Airflow, shape, and heat control are important for these systems. Picking the right enclosure keeps your equipment working well for longer.

As green energy grows, more precise enclosures are needed. Companies like Foxsen lead this trend with eco-friendly designs. They make strong enclosures for the unique needs of green energy projects.

Data Centres and IT Systems

Data centres need strong enclosures to protect servers and devices. These enclosures stop overheating, magnetic problems, and physical damage.

Custom designs are important for IT setups. You can choose enclosures with cable organisers, better airflow, and noise control. These features make data centres work better and more reliably.

Small-scale manufacturing has made custom enclosures more affordable. Whether for big data centres or small IT setups, companies like Foxsen provide exact solutions. Good enclosures ensure your IT systems run smoothly in 2025 and beyond.

Transportation and Automotive Industry

The transport and car industries use sheet metal enclosures a lot. These enclosures keep important parts like control units and batteries safe. They protect from dust, water, and shaking, ensuring systems work well.

By 2025, electric cars (EVs) and self-driving cars need more enclosures. EV batteries need strong covers to stop damage and control heat. Self-driving cars have sensors and processors that need careful protection to work properly.

Custom designs are very important in this field. Enclosures can be made to fit specific cars or systems. Lightweight materials like aluminium are popular as they cut weight but stay strong. This helps save fuel and supports eco-friendly goals.

Modular designs are also becoming common in car-making. These let makers quickly adjust enclosures for different car types. For example, one design can fit both hybrid and electric engines. This saves time and money in production.

Tip: Choose enclosures with strong materials, good heat control, and rust resistance. These features make them last longer and work better.

Medical Devices and Healthcare Equipment

In healthcare, sheet metal enclosures are key for protecting equipment. Machines like MRI scanners and ventilators need covers to block damage and magnetic problems. This keeps them working accurately in hospitals.

Making these enclosures needs high precision for detailed medical designs. They can be shaped into complex forms, fitting many medical uses. Their strength means they handle tough hospital conditions well.

Eco-friendly materials are now used to make these enclosures. This lowers the environmental impact of making medical tools. It matches the global move towards greener practices.

Hygiene is also vital when designing medical enclosures. Smooth, rust-proof materials like stainless steel are best. They are easy to clean and meet strict health rules. This keeps patients and staff safe.

Note: High-quality enclosures last longer and work better. They improve patient care by keeping medical devices reliable.

Innovations and Trends in Sheet Metal Machine Enclosures

Smart Enclosures with IoT and Sensor Integration

By 2025, smart technology is making metal enclosures more advanced. With IoT devices and sensors, these enclosures now monitor conditions live. They can check temperature, moisture, and vibrations inside the enclosure. This helps machines work better and avoid breakdowns.

For example, sensors can warn you about overheating or dampness. This early warning stops damage to important parts. IoT-enabled enclosures also let you control settings remotely. This is very helpful for places like data centres and green energy systems, where constant operation is vital.

These smart enclosures also save energy. Sensors collect data to find where energy is wasted. You can then fix these issues to lower costs and help the environment.

Tip: Pick enclosures with advanced sensors that match your current systems. This ensures smooth use and full benefits of IoT features.

Modular and Flexible Designs for Customisation

Custom enclosures are becoming popular, leading to modular designs. These designs let you adjust enclosures for specific needs without losing strength.

New fabrication methods make this possible. For instance:

Aluminium or stainless steel ensures both flexibility and durability.

CNC bending creates precise shapes with high accuracy.

Rebound compensation keeps dimensions stable under different conditions.

Continuous bending makes strong frames for heavy loads.

These modular enclosures are great for industries like manufacturing and cars. You can change or expand them easily for new equipment. Features like ventilation slots and heat control improve their use for electronics.

They are also cost-effective. Integrated bending reduces welding, cutting production costs. This makes them a smart choice for businesses balancing quality and budget.

Note: Modular enclosures combine flexibility with strength. They are ideal for industries needing frequent updates or changes.

Eco-Friendly and Sustainable Materials in Fabricated Metal Enclosures

In 2025, sustainability is a big focus for metal enclosures. Makers now use eco-friendly materials to lower environmental harm. Recyclable metals like aluminium and stainless steel are common. These materials last long and resist rust while reducing waste.

Galvanised steel is another option. It is affordable and lasts longer due to its protective coating. This means fewer replacements, which lowers its carbon footprint.

Modern production methods also support sustainability. Laser cutting and CNC machining reduce material waste. Powder coating avoids harmful chemicals, making the process safer for the planet.

Choosing eco-friendly enclosures helps fight climate change. They meet green building standards and may even earn certifications like LEED.

Tip: Choose enclosures made from recyclable materials and eco-friendly processes. This helps the planet and boosts your company’s responsible image.

Stronger and Better-Looking Enclosures

Strength and looks are very important for sheet metal enclosures. By 2025, new ways of making these enclosures have made them tougher and nicer to look at. This makes them more useful for factories and businesses.

Stronger Enclosures

Today’s enclosures can handle tough conditions and hard use. They protect machines from damage, rust, and wearing out over time. Makers now use better methods to make sure enclosures stay strong, even in harsh situations.

Main features that make them strong include:

Rust Resistance: Metals like stainless steel and galvanised steel don’t rust easily. They are great for wet or chemical-heavy places.

Impact Protection: Thicker metal and stronger designs keep machines safe from hits.

Heat Control: Good metals spread heat well, stopping machines from overheating.

For areas like transport and green energy, strength is a must. You can pick enclosures made for special needs, like high moisture or changing temperatures.

Tip: Look for enclosures with extra coatings like powder coating. These add more protection against damage and weather.

Better Looks

Besides being strong, enclosures now look better too. A good-looking enclosure not only protects but also makes workspaces look neat. In 2025, you can find many styles to match different needs.

Common design features include:

Custom Colours: Powder-coated finishes come in many colours and textures. These can match your brand or workspace.

Smooth Shapes: New methods create clean edges and seamless joints for a sleek look.

Space-Saving Designs: Compact enclosures fit into small spaces without losing their usefulness.

Better designs are especially helpful in places like hospitals and IT centres. Here, equipment needs to look tidy and fit well into organised spaces.

Note: Choosing stylish enclosures can make workplaces feel better and impress visitors.

Combining Strength and Style

The best enclosures mix strength with good looks. They protect machines while also improving how a place looks. Thanks to new methods, these enclosures are both useful and attractive, making them a smart choice for modern industries.

Benefits and Challenges of Sheet Metal Enclosures

Advantages: Protection, Longevity, and Customisation

Sheet metal enclosures are great for protecting equipment in many industries. They are strong and can handle tough conditions like water, dust, and heat. This makes them perfect for outdoor use where weather can be harsh.

These enclosures are light but still very durable. For example, aluminium enclosures don’t rust and are strong for their weight. This makes them useful in cars and planes. You can also easily change their design to fit specific needs, like adding vents or access points.

Key Benefits:

Protects electronics from damage caused by the environment.

Resists rust, making them last longer.

Can be customised for different industry needs.

Challenges: Cost, Maintenance, and Material Limitations

Even with their benefits, sheet metal enclosures have some problems. Thin metal can break if not designed well. For instance, placing holes in the wrong spots can make them weaker.

Choosing the right material is also tricky. Steel is strong but heavy, which isn’t good when weight matters. Aluminium is lighter but not as tough as steel. Also, bending the metal depends on its type and thickness, which can make production harder.

Following rules and standards can also be hard. Some designs may not meet industry requirements, so staying updated is important.

Solving Industry Needs with Custom Sheet Metal Enclosures

Custom enclosures solve specific problems in different fields. In electronics, special designs with vents and access points help devices work better and last longer. Telecom companies use modular enclosures that fit various sites and save money.

Car makers use enclosures to protect parts like batteries and control units. These designs meet safety rules and are built to last. In aerospace, enclosures must follow strict safety and performance standards.

By choosing custom enclosures, industries can meet their exact needs. This improves how well equipment works and lasts over time.

Sheet metal machine enclosures are key for protecting equipment. They also help industries work better and more efficiently. In 2025, new trends like smart designs, modular setups, and eco-friendly materials are changing how they are used. These updates make enclosures more useful and support global green goals.

The market for these enclosures is growing fast.

Future ideas like AI, automation, and 3D printing are shaping the industry. Smart enclosures with sensors can predict problems and allow remote checks. This keeps machines running smoothly. Eco-friendly materials and energy-saving designs also lower harm to the planet while meeting industry needs.

Better ways of making enclosures have made them lighter and stronger. From 2025 to 2032, the industry is expected to grow by 12.2% each year. This growth is driven by new metal-making methods and more automated factories.

Even with challenges like material limits and costs, these enclosures are very flexible. They can be customised for many uses, making them essential. Whether in cars, hospitals, or green energy, they protect equipment and improve efficiency.

Note: Choosing strong, custom enclosures ensures they last longer and match future needs.

FAQ

Which industries use sheet metal enclosures the most?

Many industries depend on sheet metal enclosures. These include factories, green energy, IT, cars, and healthcare. Enclosures keep equipment safe from harm and improve efficiency. Their flexibility makes them useful in many areas.

How can you pick the best material for an enclosure?

Think about where it will be used and its strength needs. Stainless steel doesn’t rust, aluminium is light, and galvanised steel is cheap and resists rust. Choose the material that fits your needs for the best results.

Tip: Use rust-proof materials for outdoor enclosures.

Can sheet metal enclosures be customised?

Yes, you can design enclosures to match your needs. Options include adjustable sizes, air vents, and access points. Custom designs make sure the enclosure works perfectly for your tasks.

What makes smart enclosures special?

Smart enclosures have IoT sensors to check conditions like heat and dampness. They send live data, allowing remote control and early problem fixes. This technology boosts efficiency and prevents breakdowns.

How do eco-friendly enclosures help the planet?

Eco-friendly enclosures use recyclable metals like aluminium and stainless steel. Modern methods cut waste and save energy. These choices lower harm to the environment and support global green goals.