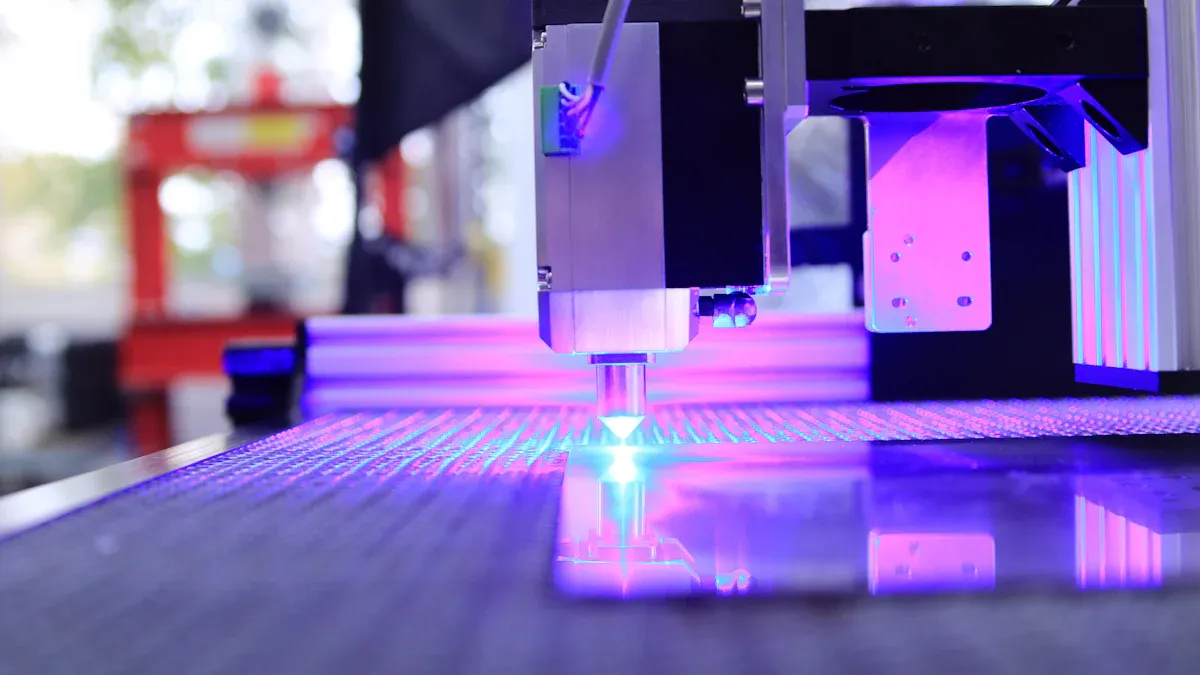

I’ve always been fascinated by how sheet metal laser cutting has revolutionized modern manufacturing. This manufacturing process stands out because of its unmatched precision, efficiency, and versatility. For example, advanced laser cutting machines operate at 10 kW, making them far more energy-efficient than traditional methods that use up to five times more energy. The precision is equally impressive, with machines achieving an accuracy of 0.003 mm, compared to traditional tools with tolerances of 1 to 3 mm. Additionally, laser cutting’s ability to create custom shapes and sizes allows manufacturers to craft intricate and complex components with ease. These qualities have made this technique indispensable across industries like automotive, construction, and even the military, where exact specifications are critical.

Key Takeaways

Laser cutting is very precise, with accuracy up to ±0.003 mm. It works well for industries needing exact measurements.

This method uses less material, saving resources and cutting costs. This helps make production more eco-friendly.

Laser cutting speeds up production and increases output. It helps companies finish work on time without lowering quality.

It can cut many materials like metal and plastic. This makes it useful for many industries and jobs.

Buying laser cutting machines can save money over time. It lowers running costs and skips extra finishing steps.

Industries That Use Sheet Metal Laser Cutting

Automotive Industry

The automotive industry relies heavily on sheet metal laser cutting for its precision and efficiency. This technology plays a vital role in producing components that meet exact specifications. For instance, the positioning error for laser cutting is only ±0.1mm. This level of accuracy is essential for crafting complex details in automotive parts, such as engine components and body panels.

Laser cutting ensures that every part fits perfectly, reducing the need for adjustments during assembly.

The impact of laser cutting on automotive manufacturing is evident in its ability to improve cost and efficiency. Here's a quick overview of some key statistics:

These benefits make laser cutting indispensable in automotive manufacturing, where precision and efficiency are paramount.

Medical Industry

The medical field demands high precision and cleanliness, making laser cutting an ideal choice for manufacturing medical equipment. This technology enables the creation of extremely small and precise cuts, which are crucial for devices like flexible catheter shafts and custom stents. The intricate designs required for these tools would be impossible to achieve with traditional methods.

Laser cutting is also used to produce medical stents, needles, and other intricate instruments. Here are some key points:

Laser cutting machines achieve an accuracy of up to 0.0005 inches.

This precision is critical for producing complex parts in medical devices.

Consistent and accurate cuts lead to reduced waste and improved manufacturing efficiency.

The ability to create intricate designs with such precision has revolutionized the production of medical equipment, ensuring better outcomes for patients and healthcare providers.

Construction and Architecture

In construction and architecture, laser cutting has transformed how sheet metal is used. Architects and builders now have the freedom to create intricate designs that were once considered impossible. From decorative panels to structural components, laser cutting allows for unparalleled creativity and precision.

One of the most significant advantages of laser cutting in this industry is its ability to handle various materials, including steel, aluminum, and copper. This versatility ensures that architects can bring their visions to life without compromising on quality or durability.

Laser cutting not only enhances the aesthetic appeal of buildings but also improves the efficiency of construction processes.

By reducing material waste and speeding up production, laser cutting has become a cornerstone of modern construction and architectural design.

Electronics and Technology

The electronics industry has embraced laser cutting as a cornerstone of modern manufacturing. I’ve seen firsthand how this technology enables the creation of intricate designs and small-scale components that are essential for devices like circuit boards and connectors. High-precision laser systems make it possible to achieve miniaturization without compromising accuracy.

Key Advantages in Electronics Manufacturing:

High-precision laser systems allow for intricate designs and micro-machining techniques.

Laser cutting is essential for producing tiny features with exceptional accuracy.

The ability to create complex shapes ensures compatibility with advanced electronic devices.

Implementing laser cutting in electronics production has also proven to be economically beneficial. Companies benefit from increased efficiency and reduced material waste, which lowers operating costs. The long service life of laser cutting machines further enhances their cost-effectiveness.

The growth of the laser market underscores its importance in this sector. From $11 million in 1963 to over $16 billion in 2022, the industry has seen a compound annual growth rate of 9%. This consistent expansion highlights the transformative impact of laser cutting on electronics manufacturing.

Aerospace and Defense

In the aerospace and aviation industry, precision is non-negotiable. I’ve observed how laser cutting has revolutionized the production of aircraft components and defense equipment. This technology ensures exact dimensions and angles, producing parts without variation or tool marks.

Benefits for the Defense Industry:

High throughput and shorter lead times improve production efficiency.

The concentrated heat of the laser minimizes distortion, preserving material integrity.

Optimized material usage reduces waste, making the process both cost-effective and sustainable.

Laser cutting’s ability to handle complex geometries and high-strength materials makes it indispensable in aerospace applications. Manufacturers rely on this technology to produce lightweight yet durable components that meet stringent safety standards.

The defense industry also benefits from laser cutting’s speed and versatility. Multiple parts can be cut from a single sheet in record time, ensuring rapid production cycles. This efficiency has made laser cutting the preferred method for fabricating critical components in defense manufacturing.

Agricultural and Packaging Industries

Laser cutting has brought remarkable improvements to agricultural equipment manufacturing and packaging solutions. I’ve noticed how its integration into automated workflows enhances productivity by enabling high-speed cutting tasks.

Advantages in Agricultural Equipment Manufacturing:

High precision ensures smooth parts without burrs, maintaining the integrity of the workpiece.

Faster cutting speeds reduce production cycles, boosting efficiency.

Automation lowers labor costs and optimizes raw material usage, minimizing waste.

In packaging, laser cutting offers unparalleled customization. Manufacturers can create flexible designs without the constraints of molds, catering to specific customer needs. The technology’s adaptability to various materials, including paper and plastic, further enhances its versatility.

Key Benefits in Packaging:

Precision cutting minimizes material waste, making the process eco-friendly.

Fast integration into automated lines reduces turnaround times.

Personalized packaging solutions meet diverse consumer demands.

Laser cutting’s ability to deliver high-quality results while maintaining worker safety and environmental standards has made it a game-changer in these industries.

Benefits of Sheet Metal Laser Cutting

High Precision and Accuracy

I’ve always been impressed by the level of precision that laser cutting achieves. Industrial laser cutters can produce high-precision cuts with tolerances typically ranging from ±0.1 mm to ±0.5 mm. For thinner metals, the accuracy can be even higher. This capability makes laser cutting ideal for applications requiring intricate designs and tight tolerances.

One of the most remarkable aspects of laser cutting is its ability to create clean, burr-free edges. This eliminates the need for secondary finishing processes, saving both time and resources. For example:

Laser cutting ensures consistent accuracy, outperforming traditional cutting methods.

It produces intricate designs with exceptional detail, which is crucial for industries like aerospace and the defense industry.

This level of precision is not just about aesthetics. It directly impacts the functionality and reliability of components, especially in sectors where even the smallest error can lead to significant issues.

Tip: High precision in laser cutting reduces errors, ensuring components fit perfectly during assembly.

Reduced Material Waste

One of the key benefits of laser cutting is its ability to minimize material waste. I’ve seen how traditional cutting methods often generate over 15% scrap material, which can significantly increase production costs. Laser cutting, on the other hand, optimizes material usage through efficient nesting techniques.

For instance:

A manufacturer saved €95,200 annually on raw materials by switching to a coil-fed punch/laser production line.

By reducing scrap material, laser cutting helps lower overall production costs.

This efficiency is particularly valuable in industries like the defense industry, where raw materials are expensive and waste reduction is critical. The ability to maximize material usage not only saves money but also supports sustainability efforts by reducing environmental impact.

Note: Laser cutting’s precision and efficiency make it an eco-friendly choice for modern manufacturing.

Cost-Effectiveness

The cost-effectiveness of laser cutting is another reason why it has become a preferred method in manufacturing. I’ve noticed that machining costs account for only 14% of the total product cost, while raw materials make up 86%. By reducing material waste, laser cutting significantly lowers overall expenses.

Here’s how laser cutting proves to be cost-effective:

Traditional methods often require additional finishing processes, which add to the cost. Laser cutting eliminates this need.

The speed and efficiency of laser cutting reduce production times, leading to quicker project completion.

Manufacturers benefit from lower operational costs and faster returns on investment.

These financial advantages make laser cutting an attractive option for industries like aerospace, electronics, and the defense industry. Its versatility also allows manufacturers to handle a wide range of projects without investing in multiple tools or machines.

Callout: Laser cutting combines precision, efficiency, and cost savings, making it a game-changer in modern manufacturing.

Versatility in Design and Application

I’ve always admired how laser cutting adapts to a wide range of projects, from simple prototypes to large-scale production runs. This technology handles diverse project sizes and complexities with ease. For example, industrial laser cutters can produce intricate designs like holes, tabs, and custom shapes without requiring additional tools or setup changes. This flexibility allows manufacturers to switch between projects seamlessly, saving time and resources.

One of the most impressive aspects of laser cutting is its ability to handle intricate designs. I’ve seen how it creates complex patterns and features that would be nearly impossible with traditional methods. The automation involved in laser cutting ensures uninterrupted production, eliminating the need for manual adjustments. This makes it an ideal choice for industries requiring rapid prototyping solutions or custom components.

Tip: Laser cutting’s adaptability makes it perfect for applications in industries like automotive, electronics, and construction.

This versatility has transformed modern manufacturing. Whether it’s crafting decorative architectural panels or producing precise medical instruments, laser cutting delivers consistent quality and efficiency. Its ability to work with various materials, including steel, aluminum, and copper, further highlights its unmatched flexibility.

Faster Production Times

Speed is another reason why I believe laser cutting stands out in manufacturing. This process handles materials quickly, especially thin sheets, which significantly boosts production efficiency. I’ve noticed how manufacturers use real-time data to process more quotes per day, reducing errors and improving customer responsiveness.

Here are some key time-saving benefits of laser cutting:

Real-time data integration enhances efficiency by 10% to 35%, enabling more accurate quoting and fewer errors.

Thin materials are processed rapidly, reducing lead times for manufacturing.

Automation ensures faster transitions between projects, minimizing downtime.

These advantages make laser cutting an essential tool for industries that prioritize quick turnaround times. For example, in the electronics sector, where demand for components is high, laser cutting ensures that production schedules stay on track.

Callout: Faster production times mean businesses can meet tight deadlines without compromising on quality.

By combining speed with precision, laser cutting not only accelerates production but also maintains the high standards required in modern manufacturing. This balance of efficiency and quality is why I consider it a game-changer for industries worldwide.

Types of Laser Cutting Technologies

CO2 Laser Cutting

CO2 laser cutting stands out as one of the most widely used laser cutting technologies. I’ve seen how its efficiency makes it ideal for high-volume production. This method uses a gas mixture, primarily carbon dioxide, to generate the laser beam. It excels at cutting non-metallic materials like wood, acrylic, and plastics, but it also handles metals effectively.

One of the reasons manufacturers prefer CO2 laser cutting is its cost-effectiveness. Although the initial investment in equipment is higher, the long-term savings are significant. Shorter production times and reduced labor costs lower the cost per part, especially in large-scale operations. Additionally, its ability to minimize material waste further enhances its appeal.

Tip: CO2 laser cutting is perfect for industries requiring high-speed production with consistent quality.

Fiber Laser Cutting

Fiber laser cutting has gained popularity due to its energy efficiency and versatility. I’ve noticed how this technology uses optical fibers to amplify the laser beam, making it highly effective for cutting metals like steel, aluminum, and copper. Its ability to handle reflective materials without damaging the equipment sets it apart from other methods.

Here are some performance statistics that highlight its advantages:

Modern fiber laser systems consume 50-70% less energy than CO2 lasers.

Fiber lasers use up to 80% less energy than plasma cutting for materials under 10 mm thickness.

High-brightness fiber lasers achieve wall-plug efficiencies exceeding 40%, compared to 10-15% for CO2 lasers.

Fiber laser cutting’s energy efficiency not only reduces operational costs but also supports sustainability efforts. Its speed and precision make it a preferred choice for industries like aerospace and electronics.

Nd:YAG Laser Cutting

Nd:YAG laser cutting, which stands for Neodymium-doped Yttrium Aluminum Garnet, is a specialized technology I’ve seen used for applications requiring high power density. This method is particularly effective for cutting thick metals and welding tasks. Its ability to focus the laser beam into a small area allows for precise cuts, even on challenging materials.

Nd:YAG lasers are often used in industries like automotive and aerospace, where durability and precision are critical. Their versatility extends to engraving and marking applications, making them a multi-functional tool in manufacturing. While the equipment cost is higher, the quality and reliability of the results justify the investment.

Note: Nd:YAG laser cutting is ideal for projects requiring high power and precision, especially in demanding environments.

Comparison of Laser Types

When comparing different laser cutting technologies, I’ve noticed that each has unique strengths and applications. Fiber laser cutting, CO2 laser cutting, and Nd:YAG laser cutting all serve specific purposes, but their differences in precision, cost, and material compatibility make them suitable for distinct industries.

Fiber laser cutting stands out for its precision and efficiency, especially when working with thin to medium-thick materials. Its lower operating costs make it a popular choice for industries like electronics and aerospace. On the other hand, CO2 laser cutting offers versatility. It handles a wide range of materials, including non-metals like wood and acrylic. However, its maintenance and operating costs tend to be higher than those of fiber lasers. Nd:YAG laser cutting excels in high-power applications, such as cutting thick metals or performing welding tasks. While it’s less common, its ability to handle challenging materials makes it indispensable in industries like automotive and defense.

Here’s a quick comparison of these technologies:

Each laser cutting technology offers unique benefits. I’ve found that choosing the right one depends on the specific needs of the project. For example, if cost efficiency is a priority, fiber lasers are often the best choice. For versatility, CO2 lasers shine. Understanding these differences helps manufacturers optimize their processes and achieve better results.

Tip: Always consider the material type and project requirements when selecting a laser cutting technology.

How Laser Cutting Works

Overview of the Laser Cutting Process

I’ve always found the laser cutting process fascinating because of its precision and efficiency. The process begins with a high-powered laser beam directed at the material. This beam, focused through a lens, generates intense heat that melts, burns, or vaporizes the material. A jet of gas, such as nitrogen or oxygen, clears away the molten material, leaving a clean and precise cut.

What makes this process so efficient is its ability to handle multiple operations simultaneously. For example:

It can cut, engrave, and mark materials in one seamless operation.

The non-contact nature ensures minimal wear on tools, reducing maintenance downtime.

The concentrated heat minimizes material distortion, resulting in smooth edges.

This combination of speed, precision, and cost-effectiveness makes laser cutting a cornerstone of modern manufacturing.

Key Components of a Laser Cutting Machine

The performance of a laser cutting machine depends on its key components. Each part plays a critical role in ensuring precision and efficiency.

Cutting Heads: These are optimized for specific environments, ensuring reliable operation and excellent cutting quality.

Nozzle: Maintains the correct distance from the workpiece, improving cutting speed and protecting the lens.

Focusing Lens: Focuses the laser beam for efficient cutting. Its quality and protection are crucial for longevity.

Focus Tracking System: Adjusts the laser head position in real-time, maintaining consistent focus on uneven surfaces.

Servo Motor: Controls speed and accuracy, ensuring precise cutting and positioning.

Speed Reducer: Matches power and speed, providing torque and precise control for improved accuracy.

Cooling System: Stabilizes performance by cooling critical components.

Machine Bed: Constructed from high-quality materials to enhance stability and maintain accuracy.

These components work together to deliver the high performance that makes laser cutting machines so effective.

Materials Suitable for Laser Cutting

One of the reasons I admire laser cutting is its versatility with different materials. From metals to plastics, this process handles a wide range of materials with ease.

Each material offers unique characteristics that make it suitable for specific applications. For example, titanium’s strength-to-weight ratio makes it ideal for medical implants, while acrylic’s polished edges are perfect for decorative items. This adaptability highlights the versatility of laser cutting in various industries.

Safety Considerations in Laser Cutting

Safety plays a critical role in laser cutting operations. I’ve seen how following proper safety protocols not only protects workers but also ensures smooth and efficient processes. Laser cutting involves high-powered beams, which can pose risks if not handled correctly. Understanding and implementing safety measures is essential for preventing accidents and maintaining a secure work environment.

Laser Classifications and Risks

Laser systems are classified based on their potential hazards. I always emphasize the importance of knowing these classifications:

Class 1 lasers are safe under normal conditions.

Class 2 lasers are safe for brief exposure but require caution.

Class 3B lasers can cause permanent eye damage with direct or reflected exposure.

Class 4 lasers pose significant risks, including fire hazards and severe injuries, necessitating stringent safety protocols.

Knowing the laser class helps operators take appropriate precautions, especially when working with high-risk systems like Class 4 lasers.

Essential Safety Practices

I’ve learned that effective safety practices revolve around preparation and vigilance. Here’s a table summarizing key measures:

These practices create a safer environment and reduce the likelihood of accidents.

Emergency Preparedness

Emergencies can happen, even with the best precautions. I always stress the importance of staying calm and following these steps:

Keep calm during an emergency.

Assess the condition and severity of the situation.

Inform the emergency response team or call emergency services.

Evacuate to a safe area quickly.

Take appropriate measures, such as using a fire extinguisher.

Being prepared for emergencies ensures quick and effective responses, minimizing harm and damage.

Tip: Always wear proper PPE and follow operational guidelines to reduce risks during laser cutting.

By prioritizing safety, laser cutting becomes a reliable and efficient process that benefits both workers and manufacturers.

Sheet metal laser cutting has redefined manufacturing in different industries by delivering high precision, efficiency, and versatility. I’ve seen its impact firsthand in sectors like automotive, medical, and electronics. For instance, the global sheet metal fabrication market, valued at USD 15 billion in 2023, is projected to reach USD 25 billion by 2032. This growth reflects the increasing demand for precision engineering. The automotive industry alone produced over 90 million vehicles in 2024, relying on laser cutting for precise parts. As technology advances, its role in shaping industries like the aerospace and aviation industry will only grow.

FAQ

What materials can be cut using laser cutting?

Laser cutting works on metals like steel, aluminum, and copper. It also handles non-metals such as acrylic, wood, and plastics. I’ve seen it used for both industrial-grade materials and delicate items like jewelry, showcasing its versatility.

How does laser cutting compare to traditional cutting methods?

Laser cutting offers higher precision, faster speeds, and less material waste. Traditional methods often require secondary finishing, but laser cutting produces clean edges. I’ve noticed that it’s also more cost-effective for complex designs.

Is laser cutting environmentally friendly?

Yes, laser cutting minimizes waste by optimizing material usage. It also consumes less energy compared to older methods. I’ve observed how manufacturers use it to reduce their environmental footprint while maintaining efficiency.

Can laser cutting handle intricate designs?

Absolutely! Laser cutting excels at creating intricate patterns and detailed shapes. I’ve seen it produce designs that would be impossible with traditional tools. Its precision ensures every detail is accurate.

What industries benefit the most from laser cutting?

Industries like automotive, aerospace, electronics, and medical rely heavily on laser cutting. I’ve noticed its impact in creating precise components, from car panels to medical stents. Its versatility makes it valuable across many sectors.