Sheet metal CNC Punching has transformed the way we work with sheet metal. It enables us to create parts with exceptional accuracy and speed, which is crucial in today’s fast-paced manufacturing environment. Even complex designs can be easily produced using this method. Recent statistics highlight its increasing significance:

The CNC Sheet Metal Press Machines market is projected to grow from $2.5 billion in 2024 to $4.5 billion by 2033.

It is anticipated to expand at a rate of 7.5% annually from 2026 to 2033.

The metal fabrication industry is growing at 5% each year, indicating a rising demand for tools like sheet metal CNC Punching.

Sheet metal CNC Punching is capable of tackling challenging tasks. It’s not merely a tool; it’s revolutionizing the way we manufacture today.

Key Takeaways

CNC punching improves precision, with tolerances as small as ±0.1 mm. This ensures parts fit well for great results.

It makes production faster, reaching up to 1,000 hits per minute. This helps finish work on time without losing quality.

CNC punching allows creative designs, making complex shapes in one step. This makes it useful for many industries.

Smart programming reduces wasted materials, cutting costs and helping the environment.

Keeping tools in good shape is important for CNC punching. Regular care ensures it lasts long and works well.

Understanding Sheet Metal CNC Punching

What is CNC Punching in Sheet Metal Fabrication

CNC punching is a modern way to shape sheet metal. It uses a computer-controlled machine to punch holes or make designs. This method ensures parts are made with the same quality every time. It’s especially useful for big projects.

The machine presses a tool into the metal to form shapes. These shapes can be circles, squares, or detailed patterns. CNC punching is great for making complex designs easily. For example, it can create vents, countersinks, or ribs in one step. This makes it popular in industries like cars, buildings, and electronics.

The demand for CNC punching is growing fast worldwide. By 2033, the market could reach $2.6 billion. This growth is due to its use in cars and new investments in developing countries. It shows how important CNC punching is for modern manufacturing.

How CNC Punching Works for Precision Sheet Metal Fabrication

CNC punching combines smart technology with precise mechanics. The machine has a turret punch press with many tools for different shapes. A computer program controls the machine to make sure every punch is exact.

The process starts with a digital design. The design is uploaded to the machine, which plans its movements. The machine adjusts based on the metal’s thickness and type. It works with materials from 0.5 mm to 6 mm thick and is very accurate.

Here’s a simple breakdown of its performance:

CNC punching reduces waste by making clean cuts. This saves money and helps the environment. Its speed, accuracy, and flexibility make it essential for creating top-quality metal parts.

Key Benefits of Sheet Metal CNC Punching

Ensuring Accuracy and Consistency

Accuracy is very important in making sheet metal parts. Even small mistakes can ruin parts or waste materials. CNC punching fixes this by using computers to make exact punches. It can achieve tight tolerances of ±0.1 mm. This ensures every part fits perfectly, even for tricky designs.

CNC punching also makes parts the same every time. Unlike hand methods, it gives identical results for all pieces. Whether making one item or many, the quality stays consistent. This is crucial for industries like aerospace and electronics, where precision is key.

Enhancing Efficiency and Speed

Speed is a big advantage in making metal parts. Old methods often need manual work, which takes longer and costs more. CNC punching works nonstop and automates the process. This helps finish projects faster without losing quality.

Here’s a simple comparison of CNC punching and older methods:

This speed saves time and cuts costs. By reducing mistakes and increasing output, CNC punching helps meet tight deadlines with great results.

Supporting Versatility in Design

CNC punching is great for making detailed designs. Whether it’s a simple part or a complex one, the machine adjusts easily. Its turret punch press can create many features, making it very flexible.

Here are some things CNC punching can do:

Make holes for screws and wires.

Add vents for airflow and style.

Cut spaces for handles and panels.

Create raised designs for labels and logos.

Drill mounting holes for HVAC systems.

Shape speaker and control panel openings.

This flexibility allows for endless design options. Even the most detailed ideas can be made with CNC punching, always giving excellent results.

Addressing Sheet Metal Fabrication Challenges with CNC Punching

Overcoming Challenges of Sheet Metal Fabrication

Making sheet metal parts can be tricky and needs precision. A big problem is keeping quality the same for large orders. Small mistakes can cause parts to not fit or work right. With CNC punching, I can make parts with great accuracy every time. The computer controls remove human mistakes, ensuring tight tolerances of ±0.1 mm. This is very important for industries like aerospace and electronics, where details matter a lot.

Another issue is meeting tight deadlines. Old methods are slow, especially for complex designs. CNC punching solves this with fast turret punch presses. These machines can punch up to 1,000 times per minute. At Foxsen, we’ve improved our process to deliver parts in 7-14 days, even for big orders. This speed helps us meet deadlines without losing quality.

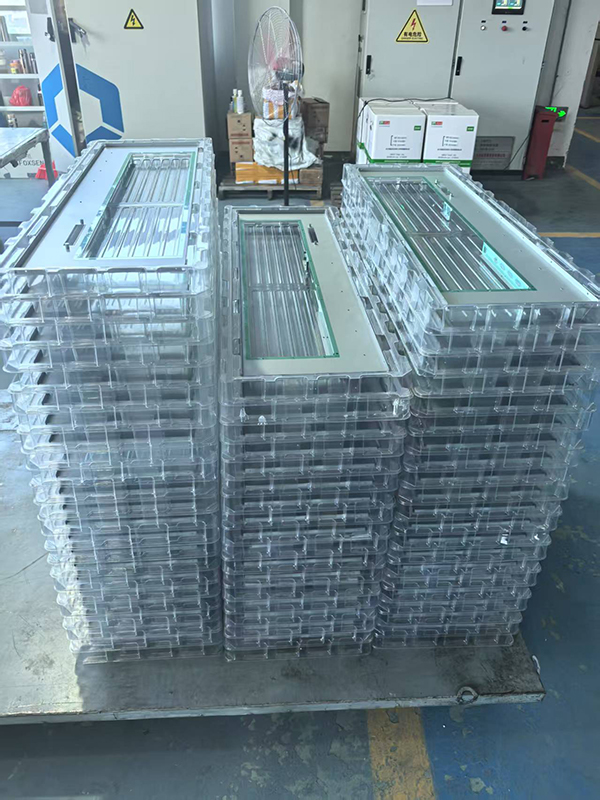

Wasting material is also a common problem. Cutting metal poorly can create a lot of scrap, which costs more and harms the environment. CNC punching uses smart programming to cut metal efficiently. At Foxsen, we go further by checking customer designs and improving layouts to save material. This reduces waste, lowers costs, and helps the planet.

Solving Customer Challenges in Precision Sheet Metal Fabrication

When helping customers, I often see unique problems needing special fixes. Some customers are new to precision metalwork and don’t know what’s possible. I guide them, showing how CNC punching can turn their ideas into real parts. By explaining the process, I help them understand what works best.

Tight schedules are another common issue. Customers want parts fast but worry about losing quality. I suggest ways to speed up production without errors. For example, Foxsen’s CNC punching can handle detailed designs in one go, saving time and keeping quality high.

Sometimes, customer designs don’t fit well with sheet metal rules. This can make parts hard or impossible to make. I work with them using Design for Manufacturability (DFM) support. Together, we adjust designs to ensure the final product fits and works perfectly. This teamwork avoids problems and builds trust in our skills.

Handling Complex and Intricate Designs

Complicated designs can be hard to make with old methods. These methods may fail to create detailed patterns or features. CNC punching is different and handles these challenges well. It can make things like vents, countersinks, and ribs in one step. This opens up many creative design options.

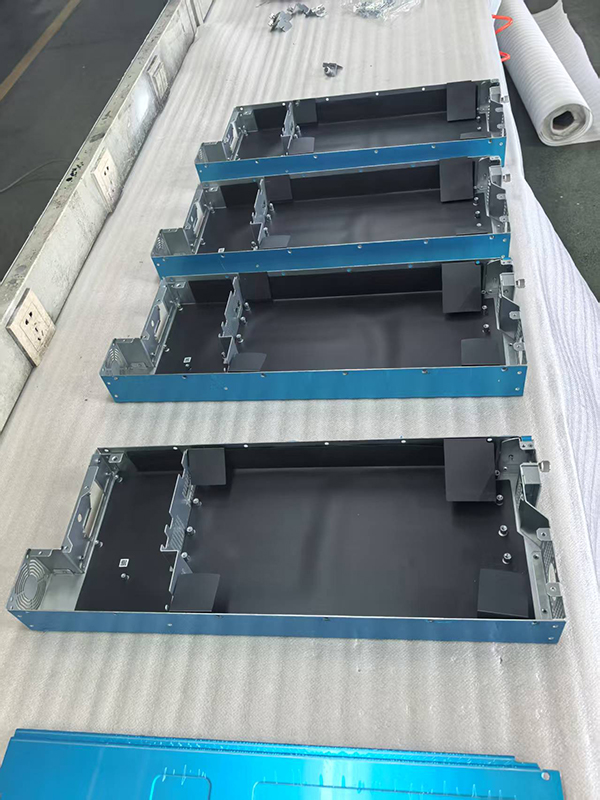

For example, I’ve worked on projects needing precise holes for control panels and speaker grilles. Using Foxsen’s advanced machines, I made clean, accurate cuts that matched the customer’s needs. These detailed designs not only look good but also work as planned.

Another benefit of CNC punching is its ability to work with many materials. Whether it’s aluminum, stainless steel, or galvanized steel, I can adjust the process for each type. This is helpful for projects with different materials or thicknesses. By using CNC punching, I can create amazing solutions for even the toughest designs.

Pro Tip: Think about the material type and thickness early when designing. This helps get the best results and avoids changes later.

Best Practices for Precision Sheet Metal CNC Punching

Selecting the Right Tooling and Materials

Picking the right tools is key for good fabrication. I use strong punches and dies to make accurate cuts and bends. Good tools stop wear and misalignment, which can cause problems. Checking tools often helps me spot issues early and keep them working well.

Choosing the right material is also very important. I think about thickness, type, and if it works with the tools. For custom projects, I suggest aluminum or stainless steel because they are strong and flexible. Lining up materials correctly before punching avoids mistakes and keeps things running smoothly.

To make work easier, I follow these tips:

Oil moving parts often to avoid friction.

Train workers to solve problems and handle tools safely.

Plan regular maintenance to catch problems early.

These steps help me meet unique needs and deliver custom solutions quickly.

Optimizing Maintenance for Consistent Performance

Taking care of machines is crucial for smooth fabrication. I use systems that predict problems to avoid sudden breakdowns. Sharpening tools automatically makes them last longer and reduces delays. Watching machine performance remotely helps me fix issues before they get worse.

Fault detection tools are very helpful. They collect data, so I can plan repairs better. Managing tools wisely ensures they work well for a long time.

By focusing on maintenance, I speed up production without losing quality. This shows my skill in providing precise cutting and bending services.

Minimizing Material Waste and Improving Efficiency

Cutting waste is a big goal in fabrication. I use smart design methods to reduce scrap and improve layouts. Checking customer designs helps me find better ways to use materials.

CNC punching programs help me make clean cuts and waste less. I adjust tools to use as much of the sheet as possible. Smoothing edges after cutting makes parts safer to handle.

These methods save money and support eco-friendly practices. By solving material problems, I create solutions that are good for both budgets and the planet.

Pro Tip: Check designs early to match manufacturing rules. This saves time and avoids costly changes later.

Real-World Applications of CNC Punching

Case Studies in Solving Sheet Metal Fabrication Challenges

CNC punching helps solve big problems in many industries. I’ve seen how it improves manufacturing by making parts precise and fast. Here are some real examples showing its benefits:

These cases show how CNC punching fixes issues like poor quality, slow work, and worn-out tools. By using smart tools and tech, I’ve helped clients improve their manufacturing.

Examples of Precision Sheet Metal Fabrication Success

CNC punching is great for making accurate parts for industries like cars and electronics. I’ve worked on projects where speed and detail were very important. For example, one electronics client needed control panels with many holes. CNC punching made parts with tight tolerances of ±0.1 mm, fitting perfectly.

Another project was for HVAC systems needing thousands of identical parts. The client wanted ventilation louvers in each piece. CNC punching made all the parts in one go, saving time and money. It also cut down on waste, helping the client’s eco-friendly goals.

These stories show how CNC punching handles tough designs and tight schedules. It’s a reliable way to get high-quality results every time.

Pro Tip: Use CNC punching for detailed designs and large orders. It saves time and ensures great results.

CNC punching has changed how we make precise sheet metal parts. It solves problems like accuracy, speed, and tricky designs, making it a game-changer.

CNC machines can work with tolerances as small as ±0.005 mm. For large projects, sheet metal fabrication with ±0.2 mm tolerances saves money and reduces waste.

The use of CAD software and automated tools shows the need for better methods.

Using CNC punching, I’ve noticed businesses finish jobs faster with better quality. It’s a smart way to improve sheet metal work.

Pro Tip: Use CNC punching for detailed designs and big projects to save time and ensure accuracy.

FAQ

What materials are best for CNC punching?

Materials like aluminum, stainless steel, and galvanized steel work well. They are strong and flexible, making them great for precise work. For metal thinner than 2.5 mm, CNC punching is fast and affordable.

How precise is CNC punching?

CNC punching is very precise, with tolerances as small as ±0.1 mm. This means parts fit perfectly, even for detailed designs. It’s a trusted method for making high-quality parts.

Can CNC punching make complex designs?

Yes, CNC punching is great for detailed designs. It can create vents, ribs, and countersinks in one step. This makes it perfect for tricky projects with special features.

How does CNC punching save material?

Smart programming helps use materials wisely and reduce waste. By improving layouts and checking designs, CNC punching cuts costs and helps the environment.

Which industries use CNC punching the most?

Industries like aerospace, cars, electronics, and HVAC use it a lot. CNC punching makes accurate parts for things like control panels and vents.