Sheet metal CNC punching is a computer-run method to shape metal sheets. It employs machines to create holes, slots, or designs in metal. This process is highly accurate and produces consistent results every time.

Industries such as aerospace and electronics utilise sheet metal CNC punching to manufacture strong, lightweight components. These parts must adhere to stringent regulations. The machines operate continuously without fatigue, resulting in fewer mistakes. This also aids in conserving materials and reducing costs. Sheet metal CNC punching has become essential for producing high-quality products at lower expenses.

Key Takeaways

CNC punching uses machines to shape metal sheets quickly and accurately.

This process lowers mistakes made by humans and saves time.

Car and plane industries use CNC punching to make strong, light parts.

These parts must follow strict rules for quality and safety.

Picking the right metal and thickness is very important.

It helps tools last longer and makes stronger products.

Better designs for CNC punching can speed up production.

Using sharp tools and setting cutting tools correctly are helpful tips.

CNC punching saves money on big projects by reducing waste.

It also removes the need for costly moulds.

What Is Sheet Metal CNC Punching?

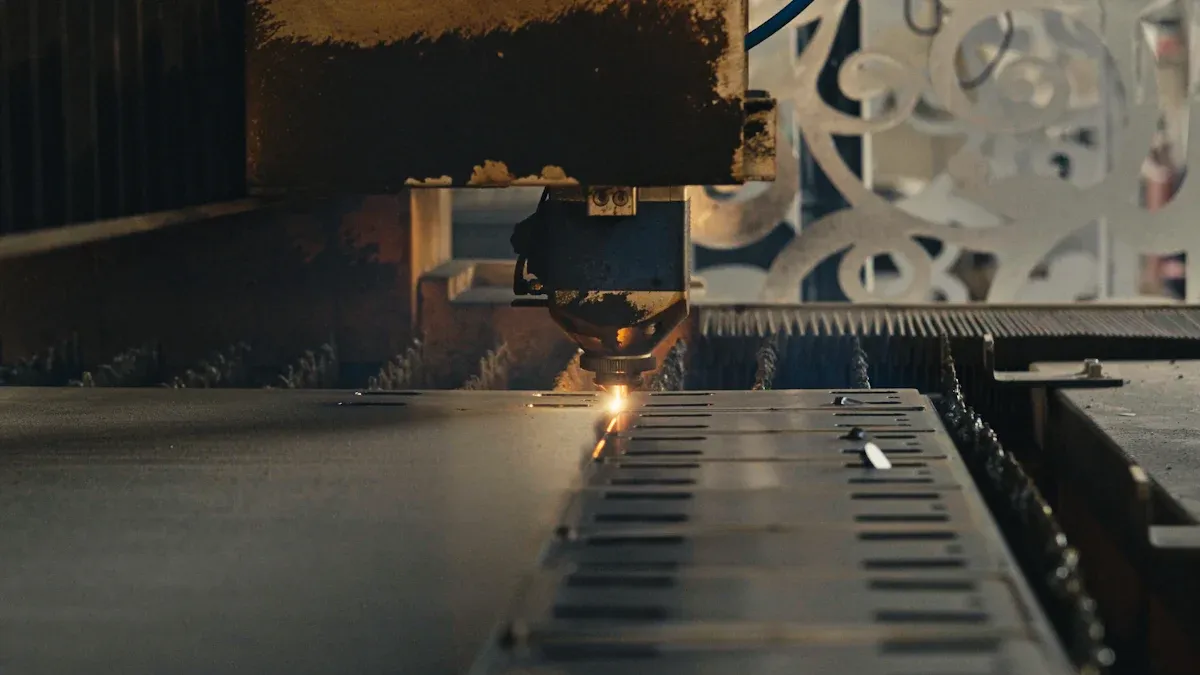

Definition and basic concept

Sheet metal CNC punching is a way to shape metal sheets. It uses machines controlled by computers to make exact designs. These machines work with materials like stainless steel, aluminium, and even plastic. The thickness of the material can range from 0.5mm to 6mm.

This process is mostly automated, making it fast and accurate. For instance, industries like automotive and aerospace use it to make detailed parts. Examples include air vent louvres and dimples for positioning. In construction, it helps make slide rail bridges. Architects use it for items like ventilation grilles and LED panels.

Key components of CNC punching machines

CNC punching machines have important parts that ensure accuracy and speed. A turret punch press is a common type. It has a rotating turret holding many tools for punching. These tools can make shapes like holes, slots, and raised designs.

The machines are run by computer systems, giving consistent results. They use CAD files like DXF or DWG to guide the process. This helps choose the right tools for the job. Machines can have different frames, like C frame or portal frame, depending on their use.

Difference between manual and CNC punching

Manual punching needs people to operate the machines, which can cause mistakes and slow work. CNC punching, however, automates the process, making it much faster.

Production Speed: CNC punching makes detailed patterns in seconds, unlike manual methods.

Accuracy and Precision: Computers remove human errors, ensuring perfect results.

Labour Costs: Automation means fewer workers are needed, saving money.

Material Waste: CNC punching uses materials efficiently, reducing waste and costs.

Workflow Optimisation: Automated setups and tool changes save time and improve workflows.

The benefits of CNC punching make it the best choice for industries needing precise and affordable sheet metal work.

How CNC Punching Works

Overview of the punching process

CNC punching is a mix of accuracy and speed. It starts with a flat metal sheet placed on the machine's table. A computer program controls the tools that punch the metal. These tools make shapes like holes, slots, or raised designs.

The machine ensures every punch is exact and error-free. It can repeat patterns many times without mistakes. This makes it great for making lots of identical parts. The process also saves material, which lowers costs.

Types of CNC punching machines

There are different kinds of CNC punching machines for various jobs. One common type is the turret punching machine. It has a spinning turret holding many tools. This lets the machine switch tools quickly for complex designs. Industries like air conditioning often use turret machines.

Another type is the linear rail punching machine. It moves tools in straight lines for precise work. These machines are perfect for tasks needing high accuracy. Both types show how CNC punching is useful in many industries.

Role of software in CNC punching

Software is key to CNC punching. It acts like the machine's brain. It turns design files, like CAD drawings, into instructions for the machine. These instructions tell the tools how to punch the metal.

Advanced software makes tool paths faster and saves time. It can also test the process to spot problems before starting. This ensures the final product is made perfectly. Without software, CNC punching wouldn't be as accurate or efficient.

Applications of CNC Punching in Sheet Metal Manufacturing

Industries that use CNC punching

CNC punching has changed many industries by being precise and fast. The car industry depends on it for making body parts and brackets. These parts are made with great accuracy. The aerospace industry also uses CNC punching a lot. It helps make strong but light parts that meet strict rules.

Studies show the CNC punching market will grow quickly. It is expected to rise from USD 2.8 billion in 2023 to USD 4.5 billion by 2032. This shows more industries are using this technology.

Other fields, like construction and electronics, also use CNC punching. In building, it makes things like air vents and strong parts. Electronics companies use it to make small, detailed parts for gadgets. At Foxsen, we’ve seen how useful this technology is for many jobs. It’s now a key part of modern manufacturing.

Types of features created

CNC punching is great for making different shapes in metal sheets. It can make holes, slots, and raised designs with precision. These shapes are important for many uses. Holes and slots help in putting parts together. Raised designs make the metal stronger or look better.

The machines work very fast and can make many parts without errors. This is important for industries like cars and planes, where quality matters. Also, CNC punching wastes less material. This saves money and supports eco-friendly manufacturing.

Examples of products made using CNC punching

CNC punching is used to make many different products. In cars, it helps create door panels, brackets, and exhaust parts. For planes, it makes detailed parts for interiors and strong outer parts.

In construction, it’s used for things like metal stairs, railings, and wall panels. Electronics companies use it to make cases, heat sinks, and shields for circuits. At Foxsen, we’ve worked on projects like LED panels and air vents. This shows how flexible CNC punching is.

CNC punching works with many materials and designs. It is a key tool in modern manufacturing. Its accuracy and speed ensure top-quality products for all industries.

Advantages and Limitations of CNC Punching

Advantages

CNC punching has many benefits for shaping sheet metal. It is very precise, with accuracy up to 0.1 mm. This means all parts are made the same every time. The machines are also very fast. They can punch 500 to 900 times in one minute, making them great for large jobs.

It also saves money by reducing wasted material. The process uses flat sheets and smart tool paths to cut costs. In some cases, it removes the need for expensive moulds, saving even more money.

These features make CNC punching a top choice for industries needing fast, accurate, and affordable production.

Limitations

CNC punching also has some downsides. Complicated die designs can take longer to set up. This makes it less ideal for projects with tight deadlines. The tools needed for complex shapes can also be expensive.

Complicated dies take longer to prepare, slowing work.

Special tools are needed for tricky designs, adding costs.

High tool costs make it less efficient for small jobs.

Even with these issues, new tools are improving CNC punching. This makes it more flexible and useful over time.

Comparison with other sheet metal processes

CNC punching and laser cutting each have their own strengths. CNC punching is better for making lots of parts quickly. It can punch and shape metal in one step, which lasers cannot do. But laser cutting is more precise and handles detailed designs without needing moulds.

For big projects, CNC punching is often faster and cheaper than laser cutting. The best choice depends on what the project needs.

Optimising Designs for CNC Punching

Tips for optimising designs for CNC punching

Planning is key to getting the best results with CNC punching. Follow these simple tips:

Tool Selection: Use sharp tools for smooth cuts and fewer burrs.

Cutting Parameters: Adjust speed and feed for good efficiency and finish.

Deburring Techniques: Add a final step to smooth edges and improve looks.

It's important to balance speed, feed, and cutting depth. For example, brass works well at 6,000–10,000 RPM and 15–25 inches per minute. Using special tools with a high rake angle can also improve the finish. These changes help save material and ensure accuracy.

Material selection and thickness considerations

Picking the right material and thickness is crucial for success. Each material needs specific die clearance and force. The table below shows these details:

Choosing the right thickness helps tools last longer and keeps parts strong. For example, mild steel is great for sturdy parts, while aluminium is better for lightweight items.

Common design mistakes to avoid

Avoiding mistakes can make production smoother and better. Here are some common errors and their effects:

Poor hole quality often leads to more waste and higher costs. Using proper lubrication and keeping clearances correct can stop this. Fixing these mistakes helps manufacturers make better products and save money.

CNC punching has changed how sheet metal is made. It creates neat, exact holes, perfect for making many parts quickly. It works with different materials to make vents, holes, panels, and control parts.

New technologies like AI and smart machines are improving CNC punching. These tools make work faster and cheaper. In building, prefabrication needs CNC punching for custom parts. As factories focus on speed and accuracy, CNC punching will stay important in modern manufacturing.

FAQ

What materials can CNC punching handle?

CNC punching works with many materials like steel, aluminium, brass, and plastic. Each material needs specific settings for the tools. For instance, aluminium is light and easy to punch, but stainless steel needs more force because it is stronger.

How accurate is CNC punching?

CNC punching is very precise, with accuracy up to 0.1 mm. This means every part is made exactly the same. The computer controls remove human mistakes, making it great for jobs needing perfect results.

Can CNC punching create complex designs?

Yes, CNC punching can make detailed patterns with special tools and software. But it works best on flat surfaces and simpler shapes. For very detailed or curved designs, laser cutting might be a better choice.

Is CNC punching cost-effective for small projects?

CNC punching is better for big jobs because it is fast and efficient. For smaller tasks, the setup and tool costs might be too high. It’s important to check the project size before deciding.

How does CNC punching support eco-friendly manufacturing?

CNC punching reduces waste by using materials smartly and cutting efficiently. This means less scrap and lower costs. It also uses less energy than some other methods, making it better for the environment.