UV printing, including Sheet Metal UV Printing, uses special light to dry ink quickly, resulting in bright and long-lasting prints. This modern technique allows for high-quality designs to be printed directly on metal sheets. Sheet Metal UV Printing also ensures that designs are tough and accurate, even on challenging surfaces.

Many industries now utilize Sheet Metal UV Printing. For example:

The UV printing market grew from $0.35 billion in 2019 to $1.71 billion by 2027, with an annual growth rate of 21.7%.

UV printer sales, particularly in the realm of Sheet Metal UV Printing, may reach $6.5 billion by 2033 due to advancements in technology.

Sheet Metal UV Printing is known for its strength and flexibility, making it a preferred choice for many professionals.

Key Takeaways

UV printing uses UV light to dry ink quickly. This makes prints bright and long-lasting on sheet metal.

This method is better for the environment. It uses less energy and releases fewer harmful chemicals than older methods.

UV printing is very precise and detailed. It’s great for making sharp designs on many materials, like metal.

The process saves money and time. It also reduces waste, helping businesses work more efficiently.

UV printing can be used in many industries. These include automotive, signs, and custom products.

What is UV Printing?

Definition and Overview

UV printing is a modern way to print using ultraviolet light. The light dries the ink right away, making prints bright and strong. This method works on many materials like sheet metal, plastic, glass, and wood. It’s great for projects needing clear details and lasting results.

Unlike older printing methods, UV printing doesn’t need drying time. This makes it quicker and more effective. It also uses special inks that are safe for the environment. Industries like car-making, advertising, and factories use UV printing because it’s flexible and creates sharp designs.

Key Features of UV Printing Technology

UV printing has special features that make it stand out. Here are some key points:

Instant Drying: The ink dries fast with UV light, stopping smudges and saving time.

Eco-Friendly Process: It releases fewer harmful chemicals, helping the environment.

Versatility: UV printing works on many surfaces like metal, plastic, and ceramics.

Energy Efficiency: It uses less energy than older printing methods.

Studies show LED UV systems use 50% to 80% less energy. This saves money and helps the planet. UV printing also creates sharp images and shiny finishes, perfect for eye-catching designs.

Comparison to Traditional Printing Methods

UV printing has many benefits over older printing styles, especially for sheet metal.

Production Efficiency: No drying time means projects finish faster.

Enhanced Durability: Prints last longer and resist damage or fading.

Energy Consumption: It uses up to 80% less energy than older methods.

Environmental Benefits: It cuts harmful emissions by over 90%.

Versatility in Substrates: It works on materials like metal, plastic, and glass.

Older methods often use inks with harmful chemicals and need more drying time. UV printing uses safer inks and reduces waste. Its bright colors and clear details make it perfect for signs and custom items.

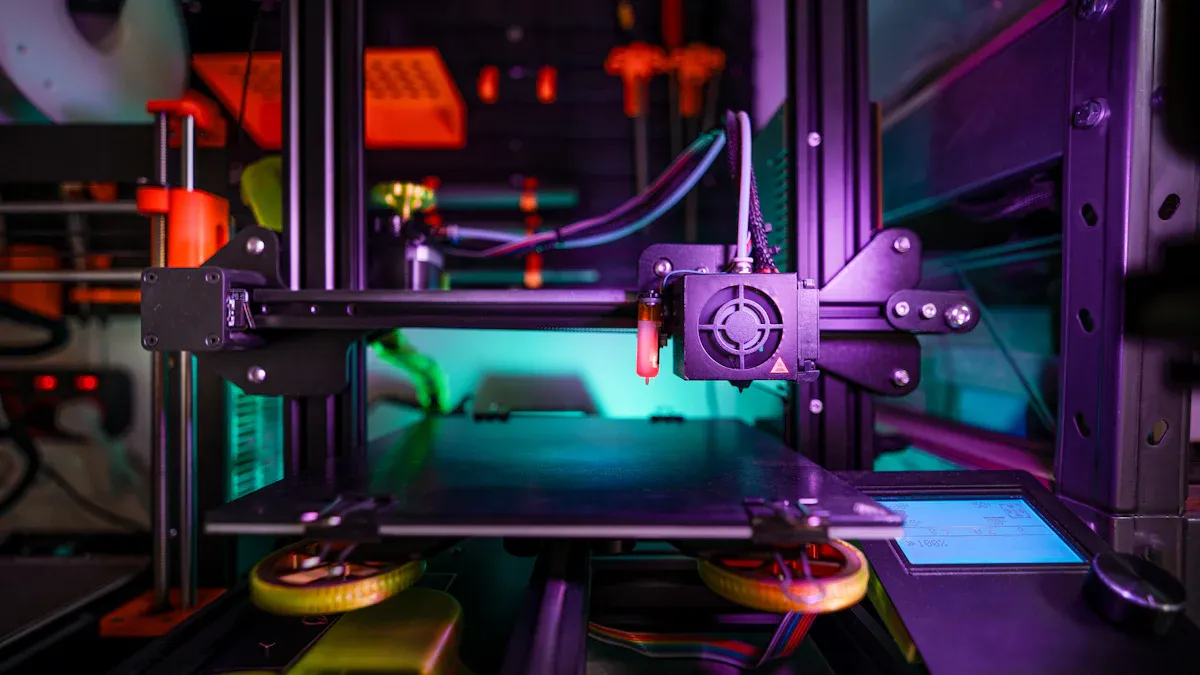

How UV Printing Works on Sheet Metal

The UV Printing Process Explained

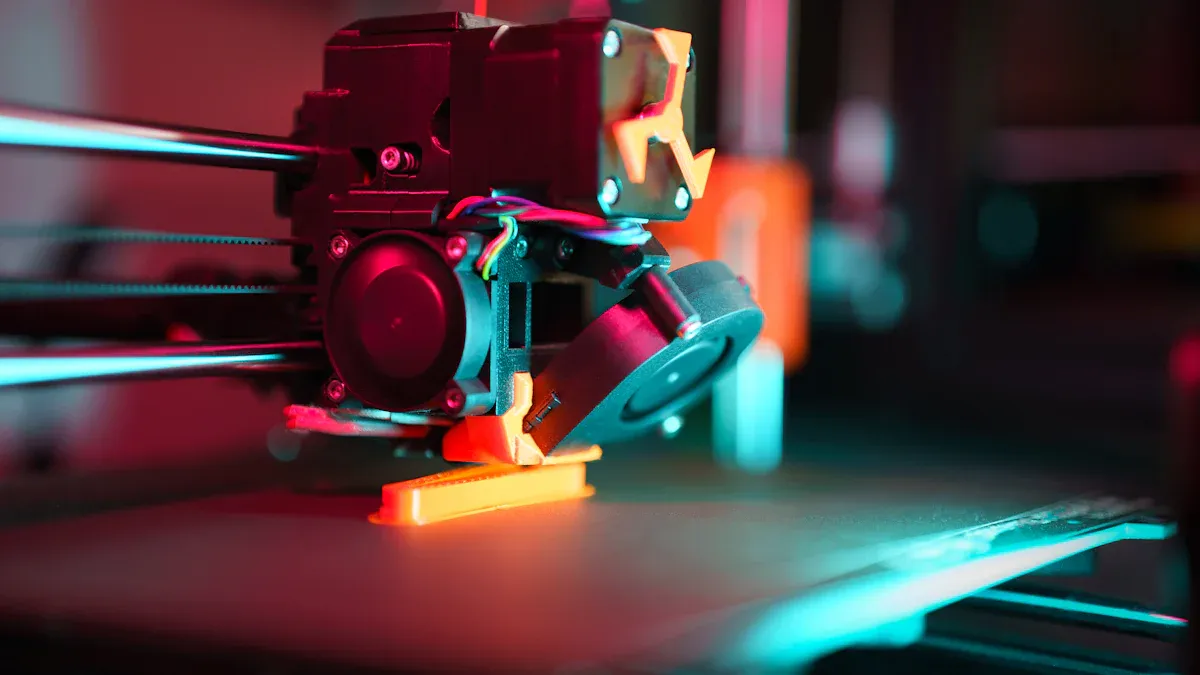

UV printing on sheet metal is a simple and fast process. First, clean the metal to remove dirt or grease. This helps the ink stick better. Then, a UV printer sprays ink directly onto the metal. The ink has special chemicals that react to UV light. When the light shines on the ink, it dries instantly, making the print strong and colorful.

Unlike older methods, UV printing doesn’t need drying time. This makes it faster and prevents smudges. It also creates clear and detailed designs. Whether it’s logos, patterns, or text, UV printing ensures accuracy and quality every time.

Materials and Equipment Used

UV printing uses special tools and materials for the best results. The main tool is the UV inkjet printer. It has advanced nozzles to place ink perfectly on the metal. UV lamps or LED lights are used to dry the ink right away.

Many materials can be printed with UV technology, but sheet metal works best. Here’s a comparison of materials:

Sheet metal is ideal because it’s smooth and strong. It shows bright colors and sharp details, making it great for signs, nameplates, and labels.

Challenges and Solutions in Printing on Sheet Metal

Printing on sheet metal has some challenges. One problem is getting the ink to stick. Metal can be slippery, so pre-treating it by sanding or priming helps. These steps make the ink stay longer.

Another issue is heat from UV lamps. Heat can bend thin metal sheets. Using LED UV lights lowers heat while still drying the ink. This keeps the metal flat and undamaged.

Lastly, keeping prints consistent on big projects can be hard. Differences in surface texture or ink can affect the print. Regularly checking the printer and doing quality tests help keep results even. By solving these problems, UV printing on sheet metal can give you great results for many uses.

Benefits of Sheet Metal UV Printing

Strong and Long-Lasting Designs

UV printing makes designs on metal that last a long time. The ink sticks firmly to the metal, so it doesn’t scratch or fade easily. It also resists damage from weather like rain or sunlight. For example, outdoor signs stay bright and clear for years. This strength makes UV printing great for industries where metal surfaces face heavy use.

Clear and Detailed Prints

UV printing creates very detailed and sharp designs. The printers place ink with high accuracy, capturing every small detail. Whether it’s tiny text, complex logos, or fine patterns, the results are always clean. There’s no smudging or uneven prints. This is perfect for making nameplates, labels, or decorative items that need to look flawless.

Creative and Colorful Options

UV printing allows for many creative choices. You can pick from lots of colors and designs. The prints are bright and strong, fitting many uses:

Industrial signs show logos and important details clearly.

Architects use UV printing to add cool designs to buildings.

Metal crafts like trophies can have special patterns and words.

This flexibility lets you design metal for both useful and decorative purposes. Whether you want bold ads or fancy gifts, UV printing helps bring your ideas to life.

Cost-Effectiveness and Efficiency

UV printing on sheet metal is a budget-friendly option for projects. It skips drying time, so work finishes faster. This saves both time and money. The quick drying also avoids waste from smudged or ruined prints.

This method handles many designs without extra setups. Whether it’s one item or many, the process stays simple. You can meet deadlines while keeping quality high. For example, making nameplates or labels is faster and cheaper than older methods.

UV printers use energy wisely. LED UV lamps need less power than older systems. This cuts costs and helps the environment. Over time, these savings grow, making UV printing a smart choice for businesses.

The prints are also very strong. You won’t need to replace or fix them often. Colors stay bright, and details stay clear, even in tough conditions. This means your designs look great and last a long time.

Choosing UV printing gives you a fast, affordable way to get durable, high-quality results. It’s perfect for industries needing precise and lasting designs at a good price.

Applications of UV Printing on Sheet Metal

Automotive Industry

UV printing is important in making car parts look good. It helps create strong and exact designs on metal parts. For example, car logos, labels, and decorations are printed using UV technology. These prints stay clear and don’t wear out, even in tough conditions like heat or friction.

UV systems also protect metal parts from heat damage. This keeps the parts strong and in good shape. Small UV machines, like those from Foxsen, fit easily into factories. This means companies can use UV printing without big changes to their work process.

Signage and Advertising

UV printing makes signs and ads bright and long-lasting. It’s great for outdoor signs, billboards, and displays. The ink doesn’t fade in sunlight or wash away in rain. This makes it perfect for outdoor advertising.

Foxsen’s UV printers can print tiny details like small letters or fancy logos. This helps businesses stand out with clear and sharp designs. UV printing also offers many color choices, so you can make creative and bold ads.

Manufacturing and Industrial Uses

In factories, UV printing is useful for marking and branding. It can print things like barcodes, serial numbers, or safety notes directly on metal parts. These prints are tough and last in hard-working environments.

UV printing also speeds up production. The ink dries instantly, saving time and helping meet deadlines. Foxsen’s UV machines use less energy, cutting costs while keeping quality high. This makes UV printing a smart and affordable choice for industries needing strong and precise designs.

Custom Merchandise and Nameplates

UV printing on sheet metal lets you make cool custom items. You can create unique designs that look great and last long. Whether it's gifts, business products, or industrial labels, UV printing gives strong and accurate results.

Why Pick UV Printing for Custom Items?

UV printing has many benefits for making custom designs:

Versatility: It works on materials like metal, plastic, and wood.

Durability: Prints resist fading, scratches, and bad weather.

Flexibility: It’s useful for nameplates, tags, and promo items.

These features make UV printing a smart choice for anyone wanting lasting designs.

Common Uses

Custom items and nameplates are helpful in many industries. Here’s how they’re used:

For example, UV printing can make branded nameplates for offices or tough tags for tools. Bright colors and clear details make these items useful and attractive.

Advantages for Your Projects

UV printing lets you try creative ideas with bold colors and cool designs. The ink dries fast, so projects finish quickly. Prints last longer, meaning fewer replacements are needed.

Using UV printing for custom items gives professional results. Whether for personal use or business branding, this method offers great quality and flexibility.

UV printing on sheet metal is strong, accurate, and creative. It makes bright, lasting designs useful in industries like cars, ads, and factories.

Tip: Need nameplates, tags, or signs? UV printing gives durable, professional results.

As more people use this technology, it’s a great time to try it. Use UV printing for your next project and see its amazing quality yourself.

FAQ

What is UV digital printing?

UV digital printing uses special light to dry ink right away. This makes bright, strong prints on many surfaces like sheet metal. It’s great for projects needing clear and lasting designs.

How does UV printing achieve high accuracy printing?

UV printers have advanced nozzles to place ink exactly where needed. The quick drying stops smudges and keeps details sharp. This is perfect for custom designs and detailed graphics.

Can UV printing be used for direct-to-object printing?

Yes, UV printing works directly on objects like metal, glass, or plastic. It’s flexible and great for creative projects with unique designs.

Why choose UV printing for custom printed graphics?

UV printing gives bright colors, clear details, and strong prints. It’s affordable and fast, making it ideal for custom graphics that look great and last long.

Is UV printing environmentally friendly?

UV printing uses safe inks and energy-saving LED lights. It releases fewer harmful chemicals, making it a better choice for the environment.