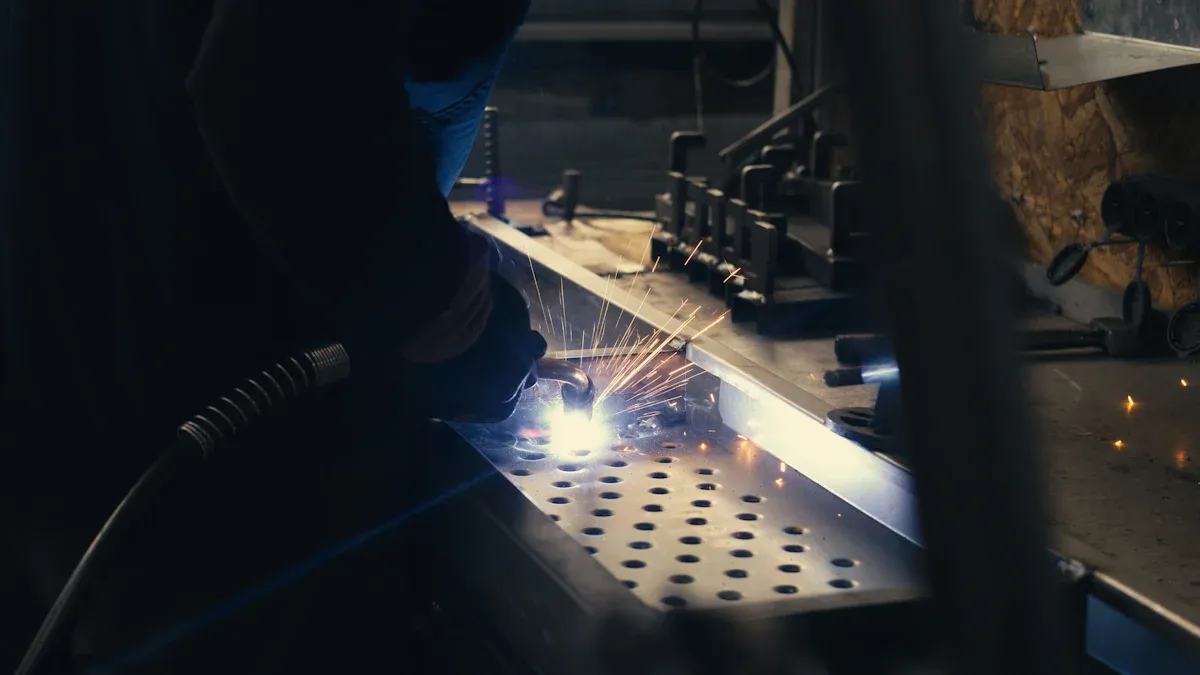

Sheet metal stamping is a way to shape flat metal sheets. It uses special tools and molds to make exact, useful shapes. This process is very important in making things today. It helps create detailed parts needed in many industries. New technology now allows for more complex designs with great accuracy. This improves how fast and well products are made.

The need for this process keeps increasing. For example:

The global metal stamping market was worth $242.08 billion in 2023.

It is expected to grow to $322.87 billion by 2030, with a steady growth rate of 4.2%.

Industries like cars, electronics, and airplanes depend on this method. Using a professional Sheet Metal Stamping Service ensures top-quality results made just for your needs.

Key Takeaways

Sheet metal stamping changes flat metal sheets into exact shapes. It uses special tools called dies to make parts for many industries.

The sheet metal stamping market is growing fast. By 2030, it may reach $322.87 billion, showing the need for better ways to make things.

New technology, like CAD software and machines, makes stamping faster and more accurate. This helps create better parts and lowers costs.

Picking the right materials, like steel, aluminum, or copper, is very important. Each material has special features that improve how products work.

Hiring expert sheet metal stamping services gives great results. These services save time, reduce mistakes, and meet industry rules.

What Is Sheet Metal Stamping?

Definition and Purpose

Sheet metal stamping changes flat metal sheets into exact shapes. It uses special tools called dies to do this. This process is key for making many parts quickly and accurately. Industries that need reliable and precise parts often use it.

Stamping is important for making metal parts in electronics. Items like phone frames and headphone parts are made this way. It helps create pieces with good electrical flow and exact sizes.

The goal of stamping is more than shaping metal. It helps make parts cheaply, especially in big amounts. Once the tools are ready, each part costs less to make. Machines work fast, making thousands of identical parts every minute.

Key Characteristics of the Process

Sheet metal stamping is great for making detailed shapes with accuracy. It works with different metals like steel, aluminum, and copper. This makes it useful for many industries.

Here are some main features of the process:

Material Preparation: Metal sheets are cut and cleaned before stamping.

Stamping Operations: Bending, cutting, and stretching shape the metal.

Finishing Techniques: Polishing makes parts look better and last longer.

Workers check quality during the process. They use tools to monitor and inspect parts to meet strict standards.

Special methods like progressive die stamping make many parts fast. Transfer die stamping is used for bigger, detailed pieces. These techniques help meet different production needs.

How Does Sheet Metal Stamping Work?

Overview of the Process

Sheet metal stamping changes flat metal sheets into useful parts. It uses special tools like dies and presses to shape the metal. Each step is important to make sure the part is correct.

First, engineers design the die, which shapes the metal. Then, the metal sheet is prepared and placed into the stamping machine. The machine presses the sheet to form the needed shape. After stamping, finishing steps like polishing or heat treatment make the part stronger and better-looking.

Tip: Good die design and material prep are key for quality results.

Step-by-Step Explanation

Here’s how sheet metal stamping works, step by step:

Die Design: Engineers use software to create exact designs for the die.

Material Preparation: Metal sheets are chosen, cut, and cleaned for stamping.

Feeding: The sheet is placed into the machine, either by hand or automatically.

Stamping Operation: The machine presses the sheet into shape using the die. Techniques like bending or deep drawing may be used.

Finishing and Post-Processing: Extra steps like polishing or coating improve the part’s look and strength.

Each step helps ensure the part is accurate and high-quality. Following these steps lets manufacturers meet strict industry rules.

Common Techniques Used

Different methods are used in sheet metal stamping for various needs. Knowing these methods helps pick the best one for your project:

Deep Drawing: Makes hollow shapes and works well for big production runs.

Stretch Forming: Uses less force and saves material but can’t make sharp edges.

Hydroforming: Reduces waste and creates smooth surfaces with even pressure.

Each method has its own benefits. For example, deep drawing is great for making many parts, while hydroforming is good for detailed designs. Choosing the right method depends on the material, design, and number of parts needed.

Note: Metal stamping is fast, but making tools can cost a lot. Planning ahead can save money.

By learning about the process and methods, you can make smart choices for your project.

Materials and Tools Used in Sheet Metal Stamping

Common Materials (e.g., Steel, Aluminum, Copper)

Choosing the right material is very important in sheet metal stamping. Materials must match your project needs, like strength or recyclability. Common materials include steel, aluminum, and copper because of their special qualities.

Steel is strong and works well for tough jobs. Aluminum is light and easy to recycle, making it eco-friendly. Copper is excellent for carrying electricity and is used in electronics.

Steel: Strong and reliable for many uses.

Aluminum: Light and recyclable, good for green projects.

Copper: Best for electrical parts and special alloys.

These materials help make stamped parts that are affordable and meet industry rules.

Essential Tools and Equipment (e.g., Dies, Presses)

Special tools shape metal sheets into exact forms. Dies and presses are the main tools used. Dies are molds that shape the metal, while presses apply force to form the parts.

There are different types of presses:

Mechanical presses are fast and good for simple tasks.

Hydraulic presses are slower but better for detailed designs.

Other tools include:

Blanking Dies: Cut sheets into shapes.

Forming Dies: Bend or stretch sheets into curves.

Progressive Dies: Do many steps at once to save time.

These tools make sure parts are accurate and consistent, turning flat sheets into useful items.

Role of Precision and Technology

New technology has improved sheet metal stamping a lot. Tools like CAD software help design 3D models with exact sizes. Simulation software finds problems before production starts, saving time and money.

Modern factories use robots and automation to make parts more consistent. AI helps spot defects and improve quality checks. Sensors track the process in real-time to keep everything running smoothly.

These advancements allow for creating complex designs with high accuracy. Flat sheets can now become detailed parts for industries like cars and airplanes.

Tip: Using advanced tools and technology can make your projects faster and better.

Applications of Sheet Metal Stamping

Industries Using Sheet Metal Stamping

Sheet metal stamping is important in many industries. It makes parts that are light, strong, and exact. This process is widely used in making cars, airplanes, and electronics. For example, over 75% of car parts and more than half of airplane parts are made with stamped metal. These include big frames and small connectors.

New tools like simulations help improve this process. They test if complex parts can be made before production starts. This ensures parts are reliable and saves time. Industries like cars and airplanes use these tools to make better products and extend their lifespan.

Examples of Products Made

Sheet metal stamping can create many different products. In cars, it makes body panels, brackets, and engine parts. Electronics companies use it for terminals, springs, and heat sinks. Even home appliances use stamped parts like casings and inner mechanisms.

These examples show how flexible sheet metal stamping is. Whether you need small connectors or strong casings, this process delivers accurate and efficient results.

Importance in Manufacturing

Sheet metal stamping is a key part of modern manufacturing. It’s fast and very precise, making it essential for industries like cars, airplanes, and electronics. The process also works well for custom designs, meeting specific needs.

New technology has made stamping even better. Robots and AI now watch the process in real-time, catching mistakes early. This improves quality and reduces waste. Green practices have also made stamping more eco-friendly and efficient.

Tip: Use advanced stamping methods to save money and reduce waste while getting top-quality results.

Advantages and Limitations of Sheet Metal Stamping

Benefits (e.g., cost-effectiveness, efficiency)

Sheet metal stamping has many benefits for making products. It saves money, especially for making lots of parts. The process works without heating, which lowers energy costs. Unlike forging, it uses cold-working methods to shape metal. Stamping combines steps into one, making production faster and cheaper.

For smaller batches, new tools like AM polymer composite tooling cut costs. Regular metal tools last longer but cost more upfront. AM tooling is cheaper and works well for custom designs and sizes.

Stamping is also very efficient. Machines can make thousands of identical parts quickly. This ensures the parts are accurate and consistent. Industries like car-making and electronics rely on this process for high-quality parts.

Challenges and Limitations

Sheet metal stamping has some problems to solve. Keeping quality high in mass production needs careful checks. Making complex shapes, like deep or uneven designs, can be tricky. Sometimes, the metal bends back after stamping, causing size errors.

Waste and energy use can hurt the environment. Factories must find ways to use less energy and recycle materials. Small companies may struggle to afford new technologies.

Other issues include cracks during rolling because of uneven heat or material problems. Stress in the metal can make shaping harder, especially with stainless steel.

How to Overcome Challenges

You can fix these problems with smart tools and methods. Simulation software predicts issues like bending back or cracking before production starts. This helps design better tools and pick the right materials.

Using eco-friendly methods, like hybrid forming, saves energy and reduces waste. Learning how stress affects parts improves designs. AI-powered tools catch mistakes early, even when making lots of parts.

AM tooling is great for custom designs and small batches. It costs less and still makes precise parts. By using these ideas, factories can save money, work faster, and help the environment.

Sheet metal stamping changes flat metal sheets into exact parts. This process uses cutting, bending, and shaping to make high-quality items. It is widely used in industries like cars, airplanes, and electronics. Its ability to handle both simple and complex designs makes it a popular choice.

Using professional sheet metal stamping services ensures accurate and reliable results. These services use advanced tools and machines to improve quality. Studies show the market for these services will grow from USD 15 billion in 2023 to USD 25 billion by 2032. This growth is due to the need for eco-friendly methods and better technology.

Choosing a professional service reduces mistakes and boosts efficiency. This helps your projects meet industry rules while staying affordable.

Tip: Working with a trusted sheet metal stamping service improves your products’ quality and durability.

FAQ

What are perforated sheets, and how are they used?

Perforated sheets are metal sheets with holes or patterns. They are used to make strong, lightweight parts. These sheets work well for ventilation, filtering, or decoration.

Can perforated sheets be made for special projects?

Yes, perforated sheets can be made to fit your needs. Manufacturers can change hole sizes, patterns, or thicknesses. This ensures the sheets match your design and purpose.

What industries use perforated sheets?

Many industries use perforated sheets, like cars, planes, and electronics. They help with soundproofing, filtering, and adding strength. These sheets are useful for both looks and function.

How does technology help make perforated sheets?

New tools like CAD software and machines improve production. They make designs more detailed and parts more accurate. This saves time and reduces waste.

Are perforated sheets good for the environment?

Yes, perforated sheets are eco-friendly. They are often made from recyclable metals like steel or aluminum. Their light weight also saves energy during shipping.