At its heart, Galvanized Steel Sheet is straightforward: it's steel with a zinc coat. But the way that zinc is applied and the quality of both the steel and the process? That's where the game is won or lost. This isn't just some rust-proofing paint; it's a scientifically proven method, so crucial that about half the world's zinc production goes into it. Why? Because it’s one of the most reliable and cost-effective ways to protect steel from the corrosion that can eat away at your investment. Think of it as the first line of defense, extending the life of everything from massive structural beams to the casing of your washing machine. This isn't just a commodity; it’s a critical component, which is why you’ll often see Galvanized Steel Sheet holding a strong position in export markets and generally offering better profitability than standard hot or cold rolled coils.

We've learned a thing or two over the years about what makes Galvanized Steel Sheet truly dependable. It starts with the base metal and carries right through to the final coating.

The Right Coat for the Right Battle – Hot-Dip vs. Electro-Galvanized:

Hot-Dip Galvanizing (HDG): When you need serious, long-haul protection, especially outdoors or in tough environments, this is your workhorse. The steel is literally dipped into a bath of molten zinc. This creates a thicker, tougher, metallurgically bonded coating. We're talking about a zinc layer that can be dozens of times thicker than electro-galvanizing. What does that mean in the real world? In a fairly standard suburban setting, a quality hot-dip coating can last upwards of 50 years without needing repairs. Even in harsher coastal or industrial zones, you can realistically expect 20 years or more. It’s the go-to for things like highway barriers, large fasteners, or agricultural equipment – the "rougher" jobs that need to last.

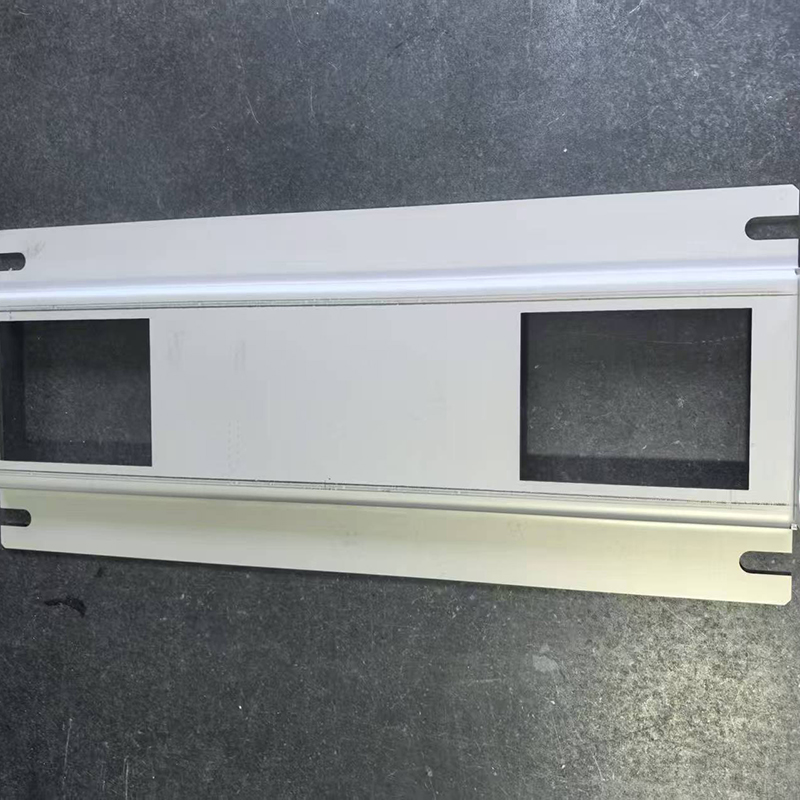

Electro-Galvanizing (EG): This is a more refined process, using electrolysis. You get a much thinner zinc layer, typically just 10 to 50 grams per square meter (g/m²), which translates to a coating thickness often in the 5 to 30 micron range. Now, while it won't match HDG for raw corrosion resistance in extreme conditions, it gives a super smooth, uniform, and bright finish. It's excellent for parts that need a high-quality paint finish, like appliance panels, computer casings, or smaller indoor fasteners. You can even get EG sheet metal coated on just one side, or with different thicknesses on each side (differential coating), which can be a real cost and performance advantage in specific applications. Hot-dip, on the other hand, is an all-or-nothing, full-coverage process.

Starting Strong: The Base Metal Matters: You can't make great Galvanized Steel Sheet from substandard steel. We're meticulous about the chemical composition of our base material, keeping an eye on elements like carbon, manganese, phosphorus, sulfur, and silicon, because these affect the final strength, formability, and longevity. Our steel also benefits from carefully controlled annealing processes – whether it's continuous annealing (CAL) or batch annealing (BAF) – to achieve the precise mechanical properties needed before it even sees the zinc.

More Than Just Rust-Proof – It’s Tough: Our Galvanized Steel Sheet isn't just about fending off corrosion. It's built to take a knock. Whether it's for walling, where it might see some abuse, or for components that get handled a lot, it’s designed to resist dents and scratches. We aim to minimize common headaches like zinc layer peeling or flaking, which can be a real issue if the surface preparation of the steel isn't perfect or if the galvanizing process variables (like furnace atmosphere, line speed, or zinc bath aluminum content) aren't spot on.

Handling the Heat: Many materials will buckle or discolor when things get hot. Our Galvanized Steel Sheet is pretty resilient here. You can typically expect it to handle temperatures around 310°C for up to 120 hours without significant degradation or color change. That’s a practical plus for many industrial uses and appliances.

Formability is Key: What good is strong sheet metal if you can't shape it? We ensure our Galvanized Steel Sheet has the good plasticity needed for your stamping, roll-forming, or bending operations. We work with a range of steel grades to suit your needs, from general-purpose CQ (Commercial Quality), to formable DQ (Drawing Quality) and DDQ/EDDQ/SEDDQ (Deep Drawing/Extra Deep Drawing Quality), right through to HSLA (High Strength Low Alloy) for structural applications, and specialized grades like BH (Bake Hardenable), DP (Dual Phase), and TRIP (Transformation Induced Plasticity) steels. The goal is to give you material that works with your tooling, not against it, helping avoid processing defects caused by a mismatch between the material and the forming demands (like incorrect bend radii or worn tooling).

Saving You Time and Hassle: Good Galvanized Steel Sheet should make your life easier. Often, it's ready to use right after installation, no need for immediate on-site painting, which can really streamline a project schedule.

When you’re specifying Galvanized Steel Sheet, you’ve got practical things to consider. Let's tackle some common ones head-on:

Q: "Okay, those 'spangles' or 'zinc flowers' – what's the deal with them?"

A: "That crystalline pattern you see on some hot-dipped Galvanized Steel Sheet is called 'spangle.' You can get large spangle (the classic, more visible pattern), small/minimized spangle, or even no spangle (spangle-free), which gives a very smooth, uniform surface. The choice often comes down to aesthetics – if it's going to be painted, a no-spangle or minimized spangle is often preferred. Functionally, the spangle type doesn't drastically alter the corrosion protection for a given coating weight, but it can affect appearance and paint adhesion if not properly treated."

Q: "What about those nasty issues like white rust or black spots? How do I avoid that?"

A: "Ah, the dreaded white rust! It's usually a sign of moisture getting to the zinc surface before it's had a chance to form its own natural protective patina, or if the passivation isn't up to scratch. The main culprits are: (1) poor passivation – the chromate film isn't thick enough or uniform; (2) no oiling on surfaces that need it; (3) moisture trapped on the steel surface; (4) passivation not fully dried; (5) getting wet in transit or storage; (6) overly long storage times; or (7) contact with acidic or alkaline substances. Good handling, dry storage, and proper initial surface treatment (like our chromate passivation which uses both trivalent chromium for structure and self-healing hexavalent chromium) are key. Black spots can sometimes evolve from white rust, or be caused by friction if sheets rub together."

Q: "How long can I realistically store this Galvanized Steel Sheet?"

A: "Best practice? Aim to use your Galvanized Steel Sheet within about 3 months. If it's properly oiled and packaged, and stored in a dry, well-ventilated place, some product can definitely last over a year without issues. However, for un-oiled sheets, the clock is ticking faster. You really want to avoid prolonged storage that invites oxidation. Always check any specific storage advice that comes with your particular batch."

Q: "Let's talk tolerances. What can I expect for length?"

A: "Precision is important. For length, you shouldn't see any negative tolerance from us. We typically work to a maximum positive tolerance of +6mm. For width and thickness, there are also standard tolerances we adhere to, ensuring you get consistent sheet metal."

Q: "You mentioned different coating types beyond just zinc. Can you elaborate?"

A: "Absolutely. While standard zinc (galvanized) is common, the technology has evolved. With electro-galvanizing, you can also get electro-plated zinc-nickel, tin, or chromium for specialized needs. Hot-dip also has variations like zinc-iron alloy (galvanneal), which is excellent for painting, aluminum-zinc (like Galvalume® or Aluzinc®) which offers superior corrosion resistance in some environments, and even newer formulations like zinc-aluminum-magnesium alloys that provide enhanced protection, especially in very corrosive conditions or for cut-edge protection."

When you partner with Foxsen, you're not just buying Galvanized Steel Sheet. You're tapping into a deep understanding of how this critical sheet metal performs in the real world. We worry about the details – from preventing common hot-dip defects like thick edges, dross inclusions, or surface marks, to ensuring the zinc layer adhesion is tenacious – so you don't have to.

Whether your application is in automotive, construction, appliances, machinery, electronics, or light industry, we're confident we can provide Galvanized Steel Sheet that forms a reliable, long-lasting foundation for your work.

Got a specific challenge or a demanding application? Let’s talk. We're ready to put our experience with Galvanized Steel Sheet to work for you.

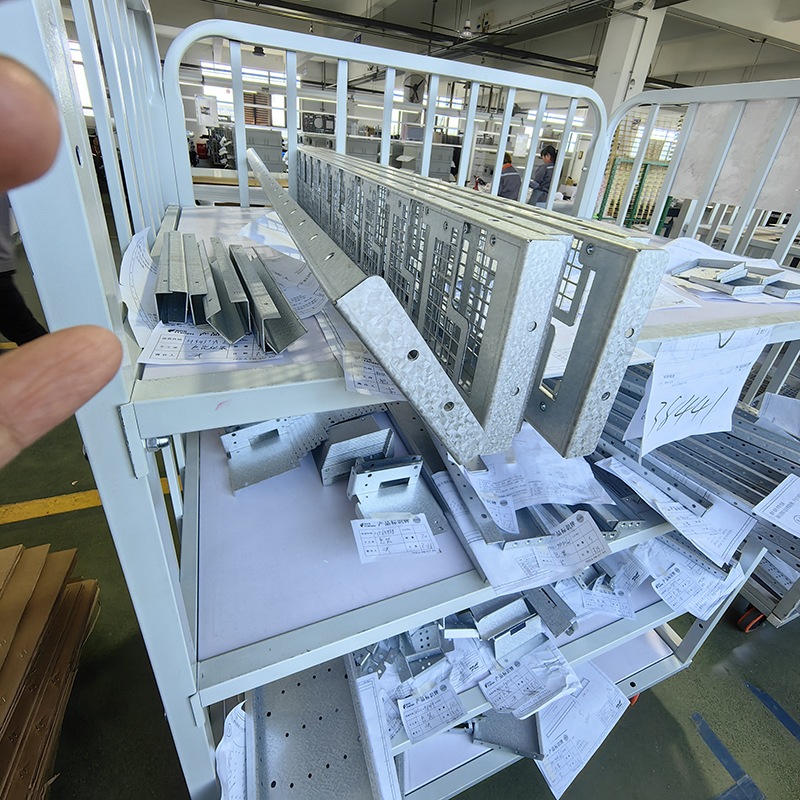

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness