The name "hot rolled" tells you a lot. We start with a hefty slab of steel, often a product of continuous casting. This slab is then heated in what’s typically a walking beam furnace until it's glowing hot – think well above its recrystallization temperature, making it pliable. Before it heads to the rollers, high-pressure water jets blast off any surface scale (iron oxides) that formed during heating. Getting rid of that scale is key for a cleaner product down the line.

Then comes the muscle: the heated slab passes through a series of massive rolling mills. First, the roughing mills make big reductions in thickness, and then the finishing mills bring it down to the precise thickness needed. This isn't just brute force; it's a computer-controlled process to ensure consistency. That computer control is vital for managing things like the cooling rate as it exits the last mill. The strip then moves onto a laminar cooling system – basically, precisely controlled water sprays cool the steel at a specific rate. This step is crucial because that cooling rate helps determine the final grain structure and, therefore, the steel's mechanical properties. Finally, this long strip of hot rolled plate is coiled up.

Now, these initial coils, what are sometimes called "straight hair coils" in the industry, aren't always the final product you see. They might have some unevenness at the ends (we call them "tongue" or "fish-tail" shapes) and the width and thickness might not be perfectly uniform yet. That’s why, to become the reliable hot rolled plate you need for your job, these coils usually go through further "finishing." This means processes like cutting off those irregular ends, trimming the sides for a consistent width, and then levelling and straightening it. After that, it can be cut into specific plate lengths or re-coiled as flat, ready-to-use hot rolled plate or slit into narrower bands. It’s quite a journey from a raw, hot slab to a dependable sheet metal, typically available in a thickness range of 1.2mm up to 25.4mm, and sometimes even thicker.

We know that the hot rolled plate you use is fundamental to your project's success. It’s not just about ticking a box on a spec sheet; it’s about providing a sheet metal that genuinely performs:

Good Bones from the Start: You can't make top-notch hot rolled plate from subpar materials or a poorly controlled process. We believe that meticulous control over the initial heating and the entire rolling schedule is where quality begins. This isn't just about hitting dimensions; it’s about creating that sound internal grain structure that gives the steel its desirable properties.

Precision That Carries Through: Our attention to detail continues right through the finishing lines. When we talk about levelling, straightening, or cutting your hot rolled plate, our goal is to deliver a product that’s consistently flat and true to size. This means fewer headaches for you when it comes to fabrication, minimizing those frustrating waves or buckles that can plague lesser-quality material.

Delivering on Steel's Natural Strengths: The hot rolling process itself is what gives this steel its fantastic inherent characteristics: we’re talking high strength, good toughness, an excellent ability to be processed and formed, and very good weldability. Our job is to make sure our processes enhance and preserve these core benefits, so the hot rolled plate you get truly lives up to its reputation.

That straightforward combination of strength, workability, and cost-effectiveness makes hot rolled plate an absolutely essential sheet metal across a huge range of critical applications:

The Real Foundation of Construction: Look around any major construction site. The structural beams holding up floors, the sturdy columns, the intricate trusses spanning wide gaps – there’s a very good chance they started life as hot rolled plate. It’s frequently formed into the industry-standard H-beams and I-beams that are quite literally the skeleton of high-rise buildings, expansive factories, and long-span bridges. As our cities grow and infrastructure expands, the need for this fundamental sheet metal only increases.

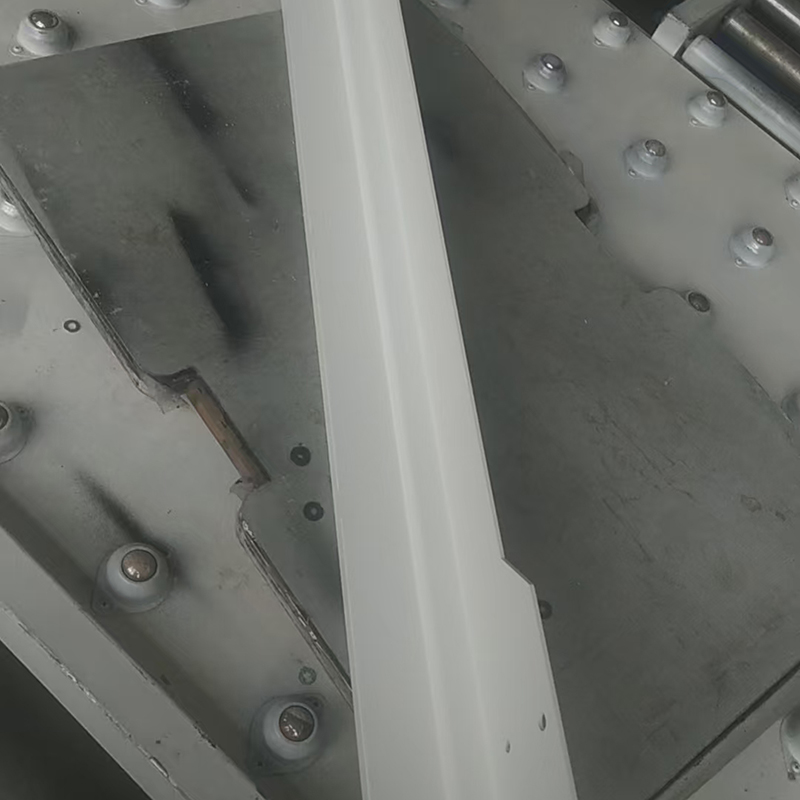

The Guts of Heavy Machinery: If you're building machinery that’s going to be put through its paces, you need a frame and components that won’t quit. Hot rolled plate provides that robust structural integrity for heavy equipment casings, unyielding frames, and countless internal parts. Its inherent toughness means it can provide lasting support, ensuring machinery operates dependably even under high stress and vibration.

Keeping the Wheels of Automotive Turning: The automotive world, especially for trucks and heavier vehicles, relies significantly on hot rolled plate. It's shaped into critical safety components like vehicle chassis, structural frames, and the main load-bearing beams. These parts need to handle all the dynamic stresses of being on the road. The high strength and good formability of hot rolled plate allow engineers to design complex shapes that are both strong and effective at absorbing energy, directly contributing to vehicle safety and longevity.

A Starting Point for Everyday Appliances: While you might not see raw hot rolled plate on the outside of your kitchen appliances, it often serves as the initial material for their casings and internal structures, especially for larger units. Its formability makes it suitable for being stamped and shaped, and once it's properly cleaned (pickled) and painted, it provides a durable and cost-effective solution.

An Unseen Role in Reaching New Heights: Now, you won't find standard off-the-shelf hot rolled plate in a jet engine or a spacecraft's skin. However, the journey for some very specialized high-strength steel alloys used in aerospace can indeed begin with a hot rolling process. This initial forming creates the basic shape and refines the grain structure before the steel undergoes much more complex and proprietary alloying, heat treatments, and finishing processes to meet those extreme demands.

This sheet metal isn't just a product; it’s a fundamental enabler, quietly supporting grand architectural designs and making the precision of modern manufacturing possible.

We’ve been talking about hot rolled plate for a long time, with everyone from structural engineers to workshop foremen. Here are some of the things people often ask, and our straightforward take on them:

Q: "Alright, lay it on me – what’s the actual, practical difference between hot rolled and cold rolled sheet metal if I’m trying to decide?"

A: "Fair question! Think of it like this: Hot rolled plate gets its main shaping done while it’s literally glowing hot – well above 900°C (around 1700°F). This makes it really easy to form into thicker sections, generally from 1.2mm to 25.4mm, and it’s usually more cost-effective. The surface will have a bit of a rougher, dark 'mill scale' on it unless you specify it to be 'pickled' – which is an acid cleaning process. Cold rolled steel, on the other hand, starts as a hot rolled coil that then gets pickled clean and rolled again at room temperature. This second rolling gives it a smoother, brighter finish and much tighter thickness tolerances, usually for thinner material, say 0.3mm to 3.5mm. But, that cold working makes the steel harder and less bendy until it’s annealed (softened by heating). So, if you need thicker sheet metal, ultimate surface smoothness isn't your top priority, and good 'as-is' formability matters, hot rolled plate is very often the smarter call."

Q: "When I get a delivery of hot rolled plate, what are the key mechanical properties I can really count on?"

A: "You're getting a solid package for most general fabrication and structural work. Expect high strength combined with really good toughness – meaning it can take a knock and resist fracture. What people in the shop really appreciate is its ease of processing and forming. It’s generally not a fussy material. And critically for so many jobs, it offers good weldability. That means less hassle and more reliable joints when you're putting things together."

Q: "What’s the typical surface of hot rolled plate actually like? Do I need to do a lot to it before I can use it?"

A: "Standard hot rolled plate is going to have what we call 'mill scale.' It’s a dark bluish-grey, slightly rough oxide layer that forms on the surface because it was rolled at such high temperatures. For many industrial applications, this is perfectly fine. But if you need to paint it and want really good adhesion, or if you just don’t want that scale flaking off, you’d ask for 'hot rolled pickled and oiled' (HRPO) sheet metal. The pickling process uses acid to strip off that mill scale, leaving you with clean, bare steel."

Q: "I'm looking at different options for a project needing some thicker material. What kind of thickness range are we really talking for hot rolled plate?"

A: "This is where hot rolled plate really comes into its own. You’re generally looking at a thickness range from about 1.2mm on the thinner end, right up to 25.4mm, and for certain plate products, it can go significantly thicker than that. It’s a stark contrast to cold rolled steel, which is typically made in much thinner gauges, usually between 0.3mm and 3.5mm. So, if your design calls for substantial sheet metal, hot rolled is almost certainly the category you'll be in."

Q: "My application is purely structural, and the strength is absolutely critical. Is hot rolled plate up to that kind of job?"

A: "Absolutely, without a shadow of a doubt. That's the bread and butter for hot rolled plate. Its inherent high strength and good toughness make it the default sheet metal for load-bearing structural members, heavy equipment bases, and any application where the steel needs to reliably carry significant weight or withstand serious forces. There's a very good reason why the construction and heavy manufacturing industries have built so much of their world on it."

When it comes down to it, if your project needs a sheet metal that offers an honest, no-frills combination of real strength, reliable toughness, good workability, and solid value, then hot rolled plate has proven its mettle for decades. It’s not always the flashiest material, but it's the dependable foundation of countless successful projects and robust products across nearly every industry.

We’re here to talk through your specific needs and help you figure out if hot rolled plate is the right workhorse sheet metal to bring its foundational strength to your next build. Let’s make sure you get exactly what you need.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness