Precision Copper Parts | Copper sheet metal fabrication | Copper extrusion | Copper machined part | High-precision customization

Precision Copper Parts | Copper sheet metal fabrication | Copper extrusion | Copper machined part | High-precision customization

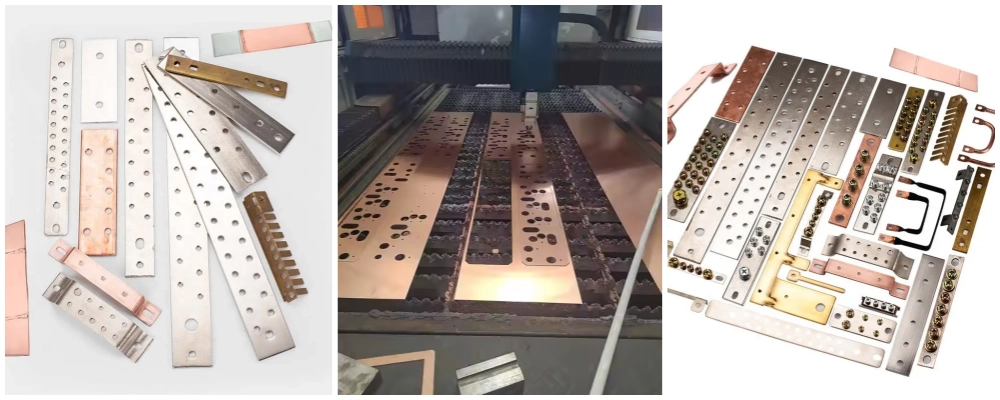

Our precision copper parts factory is dedicated to providing customers with a variety of high-precision, high-quality copper products. Whether it's copper sheet metal fabrication, copper extrusion, or copper machined part, we can provide precise processing and customization services according to your drawings or samples.

Need components that can take on tough tasks without missing a beat? Precision Copper Parts from Foxsen are here to deliver. These aren’t your run-of-the-mill parts—they’re custom-crafted from high-grade copper, shaped with sheet metal know-how to match your exact specs. Whether you’re piecing together machinery, wiring up an electrical system, or tackling a unique project, these parts bring the reliability and punch you need.

At their core, Precision Copper Parts are custom components made from pure copper, machined down to the tiniest detail for a perfect fit. Think connectors, brackets, or whatever else your setup calls for—we use advanced sheet metal techniques to make each one just right. They’re designed to carry current, resist wear, and keep things running smooth as can be.

Here’s what makes our Precision Copper Parts shine, starting with the material we stand by:

Top-Grade Copper:

We use copper with a resistivity of just 0.0185 Ω·mm²/m—that’s about as conductive as it gets, letting electricity zip through with hardly any loss. With a density of 8.9g/cm³, it’s solid and tough, built to hold up under pressure.

Pinpoint Accuracy:

Our sheet metal skills mean every part is spot-on. Complex shape or simple piece, you get a fit so tight there’s no room for error—no tweaks needed.

Long-Lasting Grit:

Copper’s got a knack for fighting corrosion and handling heat like a pro. These Precision Copper Parts won’t rust, warp, or give out, even in rough conditions.

Power Efficiency:

With 100% conductivity, they keep your system humming without wasting energy as heat. That’s better performance and a lighter hit to your wallet over time.

Wondering if these parts are up to snuff? Here’s what you might ask, with quick answers grounded in real data:

Are they strong enough for heavy use?

You bet. Copper’s 8.9g/cm³ density and solid tensile strength mean these Precision Copper Parts can take a beating without bending or breaking.

Will they rust or wear out?

Nope. That natural oxide layer on copper keeps corrosion at bay, so they stay reliable even in humid or dusty spots.

How do they stack up against aluminum?

Copper’s 100% conductivity blows aluminum’s 60% out of the water. Smaller size, more power—perfect when space is tight.

Are they a pain to install?

Not at all. Our sheet metal precision ensures every edge and hole lines up, making setup a breeze.

Is the price worth it?

Totally. Copper costs more upfront, but with 0.0185 Ω·mm²/m resistivity and long-term durability, you’re dodging replacements and inefficiencies.

At Foxsen, we’re not just slapping parts together—we’re building solutions. Our Precision Copper Parts come from the finest copper, shaped with expert sheet metal craftsmanship to tackle whatever you throw their way. With 100% conductivity, a rugged 8.9g/cm³ build, and a fit you can trust, they’re a no-brainer for any project that matters.

Here’s the gist:

High Performance: Power flows fast and clean.

Rock-Solid: Built to outlast the toughest jobs.

Perfect Fit: Precision that saves you time.

Ready to level up with Precision Copper Parts? Get in touch with Foxsen today and let’s get your project rolling!

Precision Copper Parts Manufacturing Capabilities

Precision Copper Parts Manufacturing Capabilities

Our copper sheet metal fabrication are crafted with precision using advanced production techniques. From custom designs to unique shapes, our skilled craftsmen ensure that every piece meets your copper sheet fabrication exact specifications.

process flow:

Raw material procurement: Purchasing high-quality copper materials.Covers brass, copper, bronze and other copper alloys.

Blanking: according to customer drawings or samples.

Processing: Processing by laser cutting, water cutting, CNC machining, stamping, bending, etc.

Surface treatment: Surface treatment according to customer needs.

Inspection: strong QC team to ensure 100% inspection before shipment.

Custom copper sheet metal Applications

Custom copper sheet metal Applications

FOXSEN's copper precision parts stand out in the product field Our copper machined parts are widely used in the medical ,electronics, automotive and telecommunications industries,etc.

Copper extrusion Packaging&Shipping

Copper extrusion Packaging&Shipping

FAQ

FAQ

Q: Are you a trading company or manufacturer?

A: We are the manufacturer.Our advanced equipment ensures that every cut is accurate and consistent.

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or the sample of your product. Details below should be included,

A. Materials B. Surface Finish C. Tolerance D. Quantity

Q: How does the payment process work?

A: Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance before shipment.

Q: How do I know about the delivery?

A: Tracking number will be provided to you once we get it from shippi

Our copper busbars are manufactured using high-quality electrolytic tough pitch (ETP) copper, known for its excellent conductivity and mechanical properties. We also offer options for other alloys and finishes to meet specific requirements.

Contact us today to discuss your copper machined part needs and receive a customized quote.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness