You’ve probably heard terms like Aluzinc or Galvalume – SUPER GALUM is right in that top tier. It’s a steel sheet metal at its core, but the real story is its protective coating. It all comes down to a precise, proven formula: 55% aluminum, 43.4% zinc, and a crucial 1.6% silicon. This isn't just a mix; it's an alloy that’s hot-dipped onto the steel in a continuous process and then solidified at a high temperature, around 600°C.

Why does this matter? Because this process forms an incredibly dense, intermetallic layer – a quaternary crystal structure of Al-Fe-Si-Zn, to be exact. Think of it as a microscopic, highly organized shield. This unique structure is the engine behind SUPER GALUM’s exceptional performance, creating a barrier against corrosion that leaves traditional galvanized coatings far behind. The 1.6% silicon, by the way, plays a vital role in controlling the reaction between the molten alloy and the steel, ensuring optimal coating adhesion and long-term performance.

We know that not all coated sheet metal is created equal. The final quality of SUPER GALUM depends on getting every step right, from the raw materials to the finished coil. Here’s what makes the difference:

The Power of the 55% Aluminum Alloy: That specific 55% aluminum in the coating is key. It forms a highly stable and passive barrier layer – an aluminum oxide – that’s incredibly resistant to breakdown. Alongside it, the 43.4% zinc component provides what we call sacrificial protection. If the sheet metal gets a deep scratch or if you have a cut edge, the zinc preferentially corrodes, effectively "sacrificing" itself to protect the steel beneath. This dual-action – barrier plus sacrificial – is what gives SUPER GALUM its robust, long-lasting defense.

Quality In, Quality Out – Our Production Process: You can't get premium SUPER GALUM without a meticulous manufacturing process. We ensure our sheet metal starts right.

Pre-treatment: It begins with the cold-rolled coil. First, it’s uncoiled and passes through a thorough degreasing section. Then, it enters a reduction furnace. This step is critical: it cleans the steel surface perfectly and reduces any oxides, making the steel ideally receptive for the coating.

The Coating Heart: This is where the magic happens. The prepared steel strip travels through the "zinc pot" – which in this case holds our molten 55% Al-Zn-Si alloy. As it emerges, it carries that transformative protective layer.

Finishing Touches: It’s not over yet. The coated sheet metal immediately goes into a cooling tower to carefully solidify and set the coating structure. After that, it undergoes crucial post-treatment steps: skin passing for surface texture and flatness, tension leveling (拉矫) to ensure excellent shape, and passivation for added surface protection, especially during storage and transport. Only then is it coiled as the final, high-quality SUPER GALUM product.

Corrosion Resistance You Can Count On (The Proof is in the Numbers): We’re talking 2 to 6 times the corrosion resistance of conventional hot-dip galvanized steel of the same thickness when exposed to the same environment. This isn't just a lab finding; it's backed by extensive real-world performance. For instance, studies by organizations like Bethlehem Steel have shown SUPER GALUM (specifically 55% Al-Zn) to be 2 to 4 times more durable than G90 galvanized steel, based on the coating's much lower dissolution rate in various atmospheres. And what about those cut edges, a common worry? You can set those aside. Over 15 years of practical application in diverse environments have clearly demonstrated that the cut-edge protection of SUPER GALUM is excellent. This effectively dispels any old concerns about edge performance.

More Than Just Tough – It Looks Good Too: Our SUPER GALUM sheet metal comes with a characteristically smooth, flat surface and a bright, silver-white base color. It often features an attractive "star flower" (spangle) pattern, making it perfectly suitable for applications where aesthetics are important, even if you choose not to paint it.

While its fight against rust is legendary, SUPER GALUM brings a lot more to your project:

Takes the Heat: If your application involves elevated temperatures, SUPER GALUM is a solid choice. It offers excellent heat resistance, performing reliably in environments up to 315°C (599°F). Standard galvanized steel simply can't match that.

Reflects Heat, Potentially Saves Energy: Here’s a neat benefit: SUPER GALUM sheet metal has a heat reflectivity almost twice that of galvanized steel. Think about what that means for roofing or wall panels – it acts as an effective heat barrier, which can contribute to noticeable energy savings by reducing cooling loads, especially in sunny climates, even when unpainted.

Ready for Paint (But Only If You Want To): The surface of SUPER GALUM is inherently excellent for paint adhesion. Unlike galvanized steel, which often requires weathering or special chemical pre-treatments before painting, you can typically apply paint directly to SUPER GALUM. That’s a real saving in time and preparation costs.

Smarter Material, Thicker Protection: The Al-Zn alloy coating actually has a lower density than a traditional zinc coating. What does this mean for you? For the same weight of coating applied, you effectively get a thicker protective layer with SUPER GALUM. More barrier for your buck.

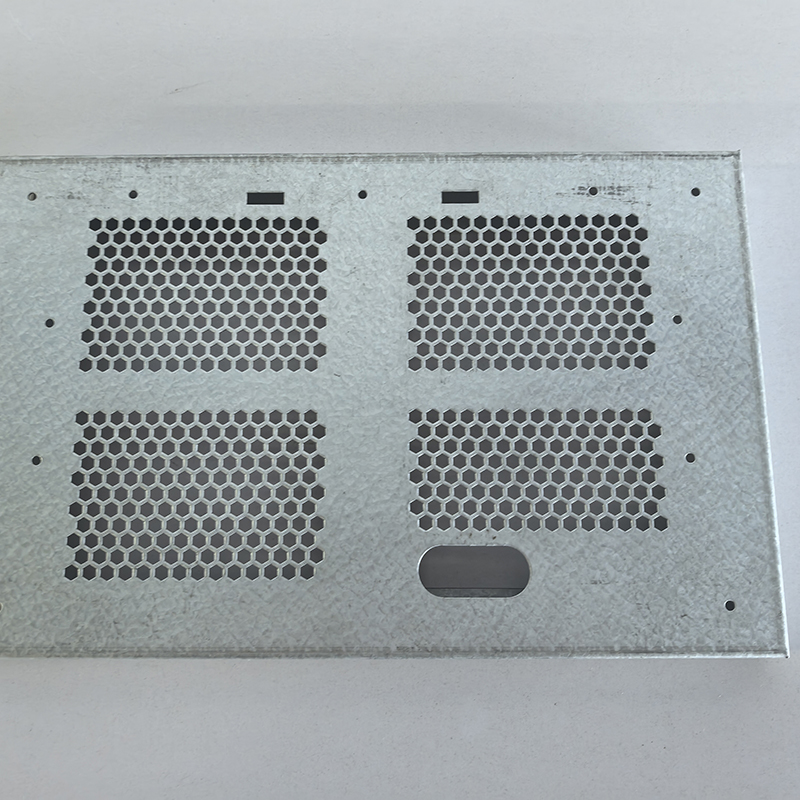

Works With You (Excellent Processability): Despite its inherent toughness and protective qualities, SUPER GALUM is designed for manufacturing. It can be readily stamped, cut, roll-formed, and welded, making it a truly versatile sheet metal for a vast range of fabrication processes.

Good Surface Conductivity: This is a more specialized benefit, but its good surface conductivity can be an advantage in certain electrical or grounding applications.

When you’re specifying a material, you need clear, practical answers. Here’s what we typically discuss with engineers and designers about SUPER GALUM:

Q: "Realistically, how long can I expect this SUPER GALUM sheet metal to last in a typical outdoor application?"

A: "That’s the million-dollar question, right? Under normal atmospheric exposure conditions, you can confidently design for a service life of up to 25 years with SUPER GALUM. That superior lifespan is a direct result of its unique 55% aluminum alloy coating and the way it protects the underlying steel."

Q: "You keep saying it's better than galvanized steel. Can you quantify that for me?"

A: "Absolutely. In terms of sheer corrosion resistance, SUPER GALUM with its 55% Al-Zn coating typically outlasts standard G90 galvanized steel by 2 to 6 times in similar environments – some long-term tests show even 2 to 4 times greater longevity. Its heat reflectivity is nearly double, which can matter for energy efficiency. Plus, it generally doesn't need the pre-treatment for painting that galvanized steel often requires. And as we mentioned, the dissolution rate of the SUPER GALUM coating is significantly lower."

Q: "My application involves some pretty high temperatures. How does SUPER GALUM sheet metal hold up?"

A: "It holds up very well. You can comfortably use SUPER GALUM in environments reaching up to 315°C (599°F) without significant degradation of the coating. That’s a clear advantage over traditional galvanized products if heat is a factor."

Q: "I'm always concerned about cut edges on coated steels. Is that still an issue with SUPER GALUM?"

A: "That's a fair question, and it's one that the industry took seriously. The good news is that more than 15 years of real-world use have shown that the cut-edge corrosion resistance of SUPER GALUM – thanks to that precise 55% Al, 43.4% Zn, 1.6% Si formulation – is excellent. The zinc provides sacrificial protection right where it's needed, while the aluminum forms stable oxides that help seal the area."

Q: "What does the surface of SUPER GALUM actually look like? Is it distinct?"

A: "It is. SUPER GALUM sheet metal has a very characteristic surface. It's smooth, flat, and has a bright, silver-white appearance. You'll often see a 'star flower' or spangle pattern, which many find aesthetically pleasing. It’s definitely suitable for applications where the sheet metal will be visible."

Q: "How does SUPER GALUM handle forming and welding operations in our plant?"

A: "It’s designed for good processability. You’ll find that SUPER GALUM can be readily stamped, sheared, roll-formed, and welded using the appropriate techniques and considerations for coated steels. It’s a material that works with your manufacturing processes."

Q: "I've seen terms like 'G550' and 'S550' associated with Aluzinc or SUPER GALUM. What's the practical difference for me?"

G550 SUPER GALUM: This often emphasizes the coating itself – that high-performance 55% Aluminum, 43.4% Zinc, 1.6% Silicon alloy – on a steel base. The "G" often refers to the coating, and "550" typically indicates a high yield strength for the base steel (around 550 MPa). So, you're getting a strong sheet metal with top-tier corrosion resistance, ideal for demanding environments.

S550 SUPER GALUM: Here, 'S550' usually refers to a specific high-strength structural steel grade (with a minimum yield strength of 550 MPa) that is then protected with the SUPER GALUM Al-Zn coating. Think of applications like light steel framing, purlins, or other structural components where you need both the high mechanical strength of S550 steel and the exceptional corrosion protection of the SUPER GALUM coating. Essentially, both give you the SUPER GALUM advantage; the designation just helps pinpoint whether the primary focus is on the coating's general application (G550) or its use on a specific high-strength structural steel (S550)."

A: "That's a good point of clarification. Both terms refer to SUPER GALUM products, but they can give you a hint about the base steel's properties:

When your projects, your products, and your reputation depend on materials that last, SUPER GALUM is a choice you can make with confidence. It’s not just a sheet metal; it’s a carefully engineered solution that delivers measurable benefits in longevity, performance, and even appearance. That unique 55% Al, 43.4% Zn, 1.6% Si coating, applied through a quality-controlled process, makes SUPER GALUM the go-to material for everything from demanding construction applications (like roofing and wall panels) to appliances, automotive components, and countless other uses where beating corrosion and standing up to the elements are non-negotiable.

Let's talk about your specific needs. We're confident that our SUPER GALUM sheet metal can help you build better, stronger, and for longer.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness