We believe that a superior Energy Storage Cabinet Enclosure starts with superior materials. There's no shortcut to long-term reliability, which is why we're meticulous about the sheet metal we use:

Tailored for the Elements – Smart Material Selection: Your Energy Storage Cabinet Enclosure needs to withstand its specific environment. That's why we don't take a one-size-fits-all approach.

Facing corrosive salt spray in coastal areas or extreme humidity? We’ll often specify hot-dip galvanized steel with a substantial protective coating of , or even high-grade stainless steel. These aren't just claims; when combined with advanced finishes like fluorocarbon sprays, these sheet metal solutions can endure grueling salt spray tests for over 1500 hours, giving you genuine peace of mind.

For environments demanding robust EMI shielding, such as in control sections, we utilize materials like cold-rolled steel, often thick, to ensure your sensitive equipment is protected from interference.

A Finish That Fights Back – Advanced Surface Treatments: The bare sheet metal is just the beginning. Our Energy Storage Cabinet Enclosure units receive cutting-edge surface treatments for maximum endurance.

Our electrostatic powder coating, applied to a consistent thickness of , isn't just for looks. It provides a resilient barrier that’s been tested to withstand the equivalent of over 5000 hours of harsh weather conditions. To put that in perspective, that’s a lifespan up to 3 times longer than you might get from conventional paint finishes. This robust shield on the sheet metal is your first line of defense against whatever nature throws at it.

This rigorous approach to sheet metal selection and treatment is fundamental. It’s how we build an Energy Storage Cabinet Enclosure designed not just to last, but to protect your investment reliably for years to come.

A pile of high-quality sheet metal is one thing; transforming it into an intelligent Energy Storage Cabinet Enclosure is another. It's the precision in our sheet metal fabrication – every laser cut, every CNC bend, every meticulously laid weld – that truly unlocks lasting performance and security.

Rock-Solid Structural Integrity: These enclosures house significant weight – from battery arrays to hefty inverters. Our sheet metal designs are engineered for this. Precision laser cutting ensures components fit flawlessly, while CNC bending creates exact angles for maximum rigidity. Our welding, a blend of robotic consistency and expert human oversight, results in an Energy Storage Cabinet Enclosure that can handle the stresses of transport and the demands of long-term operation without flinching. We design for real-world forces, ensuring your equipment remains secure.

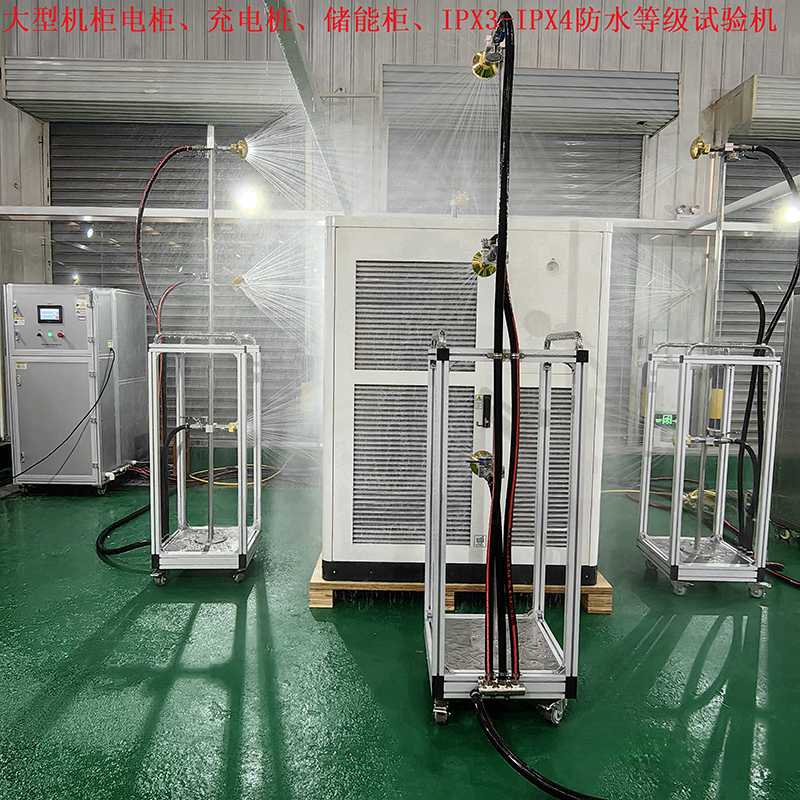

A Fortress Against the Elements: Keeping dust, moisture, and contaminants out is non-negotiable. Our Energy Storage Cabinet Enclosure designs regularly achieve high Ingress Protection ratings, such as IP65 (meaning they're completely dust-tight and can withstand water jets) and, for particularly demanding applications, even IP67 (allowing for temporary immersion in water). This superior sealing is a direct result of:

Precision sheet metal forming, including "bending and full welding" techniques.

Durable, high-grade silicone rubber seals.

Secure, corrosion-resistant stainless steel locking mechanisms. What does this mean for you? It means the sensitive electronics inside are shielded, and internal humidity can be actively managed, often kept below a crucial threshold, drastically reducing the risk of short circuits and component corrosion.

Cool Under Pressure – Optimized Thermal Management: Batteries generate heat, and managing that heat is critical for their lifespan and safety. An intelligent Energy Storage Cabinet Enclosure plays a vital role here.

We incorporate strategically designed ventilation, often using precisely stamped sheet metal "louver-style" vents. These aren't just random holes; their opening rate is carefully calculated, typically between , to ensure optimal airflow without compromising protection.

Combined with internal sheet metal baffles, this system works to maintain a stable thermal environment, aiming to keep temperature variations across your battery modules within a tight range. This careful thermal control isn't just a nice-to-have; it's been shown in projects to help reduce annual battery degradation rates, for example, from a typical 3% down to as low as 1.8%.

Safety as a Standard, Not an Add-On: The structural integrity of the sheet metal in an Energy Storage Cabinet Enclosure is also a critical safety feature. While we embrace innovation like lightweighting, it's never at the expense of safety. We achieve this balance through smart sheet metal design – optimizing profiles for strength – and by selecting advanced high-strength, low-density materials when the application calls for it. This ensures your Energy Storage Cabinet Enclosure offers a robust barrier against physical impacts and can help contain issues should an internal component fault occur.

Designed for Today and Tomorrow – Modularity & Maintainability: We understand that operational efficiency extends to maintenance. Our sheet metal designs often incorporate features for easier access and component replacement. For instance, internal sheet metal frameworks can feature "U-shaped guide rails + buckle" systems, potentially allowing for electrical component swaps in under 10 minutes – that's up to 5 times faster than traditional screwed fixings. Some Energy Storage Cabinet Enclosure designs even utilize "upper and lower split" sheet metal structures, which can improve the efficiency of replacing battery modules by as much as 60%.

We've thought a lot about what matters when you're investing in an Energy Storage Cabinet Enclosure. Here are some common questions, with answers rooted in our design philosophy and real-world data:

Q1: Our sites can be pretty rough – coastal salt, desert heat, heavy rain. How will this Energy Storage Cabinet Enclosure cope?

A1: We design for exactly these challenges. For instance, using hot-dip galvanized steel with an coating or stainless steel, often paired with a fluorocarbon spray finish that withstands over 1500 hours of salt spray testing, tackles corrosive environments head-on. Our standard powder coating offers 5000+ hours of weather resistance. Plus, with IP65 or higher ratings and thoughtful details like drainage holes to prevent condensation, our sheet metal enclosures are built to protect.

Q2: These battery racks are seriously heavy. Can the sheet metal structure really take the strain long-term?

A2: Absolutely. This is a core design requirement for any Energy Storage Cabinet Enclosure. We use appropriately gauged sheet metal, engineer reinforced internal frameworks, and employ robust welding techniques. The entire structure is designed to safely support the considerable weight of battery systems and power conversion units for its full operational life.

Q3: Battery temperature is a big concern for us. How effectively does your Energy Storage Cabinet Enclosure manage heat?

A3: Very effectively. It’s a critical design parameter. Our Energy Storage Cabinet Enclosure units feature engineered ventilation – like sheet metal louvers with a opening rate – and often internal air-guiding baffles. The target is to keep temperature differences across battery modules within , which is vital for maximizing battery lifespan and performance.

Q4: What about electromagnetic interference (EMI) for our sensitive control gear inside the Energy Storage Cabinet Enclosure?

A4: We can certainly address that. For applications requiring EMI shielding, the Energy Storage Cabinet Enclosure can be constructed using cold-rolled steel ( thick for key areas), with sheet metal design features like continuous folded edges to create a 360° shielded environment. Combined with conductive gaskets, these designs aim for an impressive EMI leakage reduction of in the 1GHz frequency band.

Q5: We hear a lot about lightweighting. How do you make an Energy Storage Cabinet Enclosure lighter without it becoming flimsy or unsafe?

A5: That's a great question, and it’s all about smart engineering. Safety and structural integrity are never compromised. We achieve weight optimization in an Energy Storage Cabinet Enclosure by using advanced high-strength, low-density sheet metal alloys where suitable, and by intelligently designing the sheet metal profiles (e.g., using 'I-beam' or 'Omega' shapes in internal supports) to maximize strength while minimizing material. For example, in related applications like PV mounting, aluminum structures can be 60% lighter than steel but still meet stringent 14-level typhoon standards – the same principles of smart material use and design apply here.

Q6: How precise is the sheet metal fabrication? If we have tight tolerances for equipment fitting, is that an issue?

A6: Precision is paramount in our sheet metal work. For critical interface dimensions within the Energy Storage Cabinet Enclosure, such as mounting hole patterns, we typically adhere to tolerances of . This ensures that your equipment integrates smoothly and that assembly is straightforward. We often use CMM (Coordinate Measuring Machines) for first-article inspection to guarantee this precision.

An Energy Storage Cabinet Enclosure is a critical, long-term investment. It's the unsung hero that ensures your broader energy storage system can perform reliably and safely, year after year. By focusing on best-in-class sheet metal materials, precision engineering driven by real-world data, and a deep understanding of the challenges you face, we deliver an Energy Storage Cabinet Enclosure that offers more than just protection—it offers lasting peace of mind.

Choose an Energy Storage Cabinet Enclosure that’s built with insight, integrity, and a commitment to safeguarding your energy future. Let's build that secure foundation together.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness