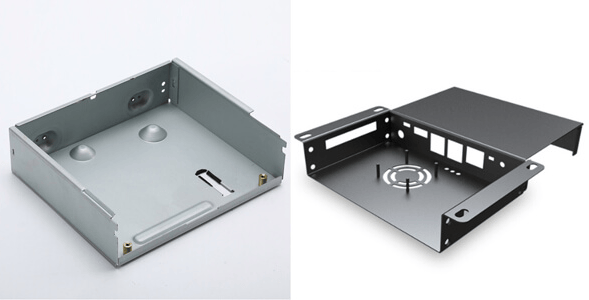

FOXSEN Sheet Metal CNC Bending Services

Sheet metal CNC bending is an advanced metalworking process that uses a computer-controlled bending machine to precisely bend metal sheets. It can transform flat sheet metal parts into V-shaped, U-shaped, or groove shaped shapes.Compared to traditional manual bending, CNC bending has the advantages of high precision, high efficiency, and a high degree of automation

FOXSEN Sheet Metal CNC Bending processing technology

our Sheet Metal CNC Bending are used in a wide range of materials and applications.

Wide Range of Materials:

Stainless Steel: SUS304, SUS316, etc., widely used in electronics, food, and medical industries.

Aluminum Alloy: 6061, 5052, etc., lightweight and high strength, suitable for aerospace and automotive industries.

Carbon Steel: Q235, SPCC, etc., high strength, low cost, and widely used.

Copper, Brass: Good conductivity, corrosion resistance, often used in electronics and electrical industries.

Complex Shapes, Easily Mastered:

Various Angle Bending: From small angles to right angles, precise control to meet different design requirements.

R-Angle Bending: Achieve arc transitions, improving product appearance and strength.

V-Groove, U-Groove: Process various profiles to meet different functional needs.

Custom-made Special-shaped Parts: According to drawings or samples, custom-made various complex-shaped sheet metal parts.