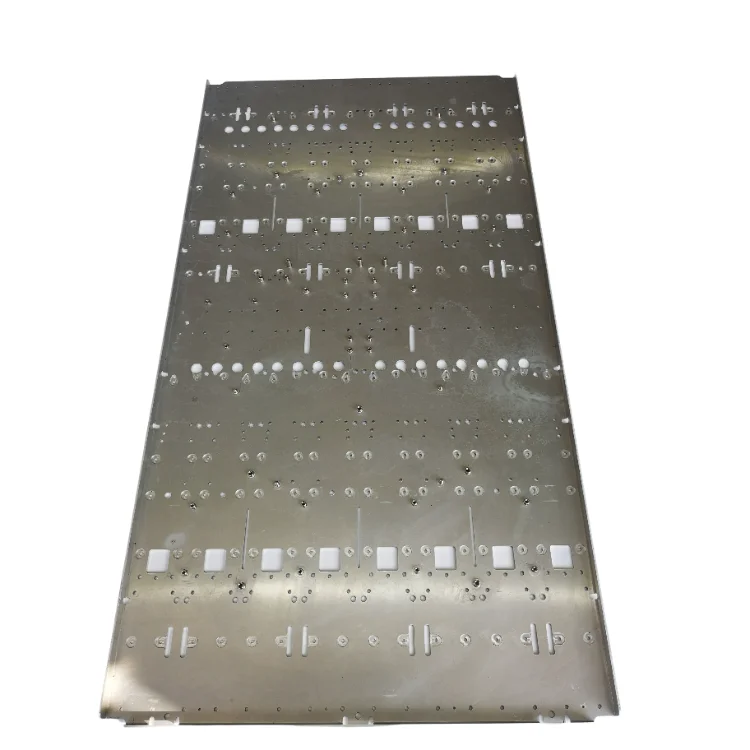

FOXSEN Sheet Metal CNC Punching Services

CNC sheet metal punching is a highly efficient and precise metalworking process that uses a computer-controlled punching machine to rapidly punch various shapes of holes and cuts in metal sheets. Compared to traditional manual punching, CNC punching has the advantages of high precision, high efficiency, and flexibility, and is widely used in electronics, electrical appliances, automotive, aerospace, and other industries.

Advantages of Sheet Metal Bending in FOXSEN

Complex Shapes, Easily Mastered:

Various Shapes of Holes: Round holes, square holes, oval holes, irregular holes, etc., to meet different product needs.

Cuts: Straight cuts, curved cuts, bending cuts, etc., to realize the processing of complex contours.

Forming: Punch forming various convex and concave shapes to improve product appearance.

Sheet Metal CNC Punching Application Fields:

Electronic Products: Chassis, panels, heat sinks, connectors, etc.

Automotive Industry: Body parts, dashboards, interior parts, etc.

Mechanical Equipment: Housings, protective covers, operating panels, etc.

Communication Equipment: Antenna covers, cabinets, etc.

Architectural Decoration: Curtain walls, doors, windows, metal roofs, etc.