When I think about workplace safety, I think of sheet metal Industrial Machine Enclosures. These strong covers made from sheet metal protect machines from damage and help them operate efficiently. They also enhance workplace safety by preventing accidents. Additionally, they reduce machine downtime and extend the lifespan of equipment.

More companies are adopting these sheet metal Industrial Machine Enclosures now. For instance, the global market for sheet metal equipment was valued at $2.5 billion in 2023. By 2032, it is projected to grow to $4.3 billion. This trend highlights how much industries prioritize safety and efficiency. These enclosures are versatile and can be utilized in various settings, making them essential for modern factories.

Key Takeaways

Sheet metal enclosures keep workers safe by blocking moving parts.

They also lower noise, making the workplace quieter and safer.

These enclosures protect machines from dust, water, and heat.

This helps machines last longer and need fewer repairs.

Using strong materials like steel or aluminum makes them durable.

They work well indoors and outdoors in many environments.

Custom designs can fit specific needs for better safety and use.

Good enclosures save time and boost productivity for industries.

What Are Sheet Metal Industrial Machine Enclosures?

Definition and Purpose

Sheet metal industrial machine enclosures are protective covers for equipment. They keep machines safe from damage and harsh environments. These enclosures also control conditions like temperature and humidity. This helps sensitive equipment work properly and last longer.

These covers protect workers by blocking access to moving parts. This lowers the chance of accidents in the workplace. They also reduce loud noises from machines, making the environment quieter and safer.

Key Functions of Equipment Enclosures:

Keep machines safe from harm.

Control temperature and humidity for better performance.

Prevent accidents by separating workers from machinery.

Reduce noise to improve the workspace.

Industries are using more of these enclosures because they are helpful. Reports show that businesses rely on them to protect machines and work efficiently.

Common Materials Used

The materials used for industrial machine enclosures affect how well they work. Manufacturers pick materials based on the needs of the equipment and its surroundings.

Common Materials for Industrial Enclosures:

Stainless Steel: Strong and resists rust, great for tough conditions.

Aluminum: Light and sturdy, good for portable enclosures.

Galvanized Steel: Protects against rust, perfect for outdoor use.

Cold-Rolled Steel: Smooth and affordable, ideal for indoor settings.

Each material works best for certain uses. For example, stainless steel is used in food factories because it doesn’t rust and is easy to clean. Aluminum is chosen when lightweight and durable covers are needed.

Importance in Industrial Settings

Factories need strong solutions to protect machines and keep them running. Industrial machine enclosures help with safety, efficiency, and making equipment last longer.

The market for these enclosures was worth $6.8 billion in 2023. Experts say it will grow to $11.5 billion by 2032. This shows how important safety and performance are to industries.

Why Industrial Enclosures Matter:

They protect machines from dirt, dust, and extreme weather.

They stop unauthorized access, keeping operations safe.

They make machines last longer by preventing damage.

These enclosures help factories work better by reducing machine downtime. They are a smart investment for any business that wants to stay productive.

Key Features of Sheet Metal Industrial Machine Enclosures

Durability and Strength

Durability is a major feature of machine enclosures. These covers handle tough use and harsh conditions. They are built to resist impacts, shaking, and wear over time. This keeps machines safe, even in rough environments.

New studies show improvements in durability. For example, special coatings now make metals stronger. These coatings help enclosures resist damage and last longer. Below is a table showing some recent research:

These findings show how engineering makes enclosures stronger and more reliable.

Corrosion Resistance

Corrosion resistance is another important feature of these enclosures. Moisture and chemicals can harm machines, but these covers stop that. They protect equipment from rust and keep it working well.

Stainless steel and galvanized steel are common materials for this purpose. Advanced coatings, like graphene-reinforced epoxy, add extra protection. A study in the Journal of Materials Research and Technology shows how these coatings fight corrosion in tough conditions.

This feature is especially helpful for outdoor machines. It keeps equipment running, no matter the weather. Businesses save money by avoiding frequent repairs or early replacements.

Thermal Management

Thermal management is key to keeping machines running smoothly. Overheating can cause breakdowns or permanent damage. Enclosures with cooling systems help control temperature and prevent problems.

Manufacturers use materials that spread heat quickly to avoid buildup. Some enclosures also have vents or cooling fans. These features are great for machines that produce a lot of heat.

Controlling heat doesn’t just protect machines; it also improves safety. By managing temperature, enclosures lower the risk of fires or accidents. This makes them a smart choice for any factory or industrial site.

Design Flexibility

One great feature of sheet metal enclosures is flexibility. These covers can be made to fit different needs. This makes them useful for many industries and purposes. Modern tools allow for easy changes in designs.

New technologies, like automation, help adjust sizes and thicknesses. This lets manufacturers create enclosures for special machines without losing quality. Parametric programming is also important. It allows quick design changes, saving time and keeping designs accurate. For example:

Automated tools change size and thickness to fit needs.

Parametric programming makes fast and precise design updates.

Designs adjust to material thickness while keeping proper bends.

Laser welding is another exciting improvement. It allows more detailed and complex designs than older methods. This opens up new ways to create unique shapes. Manufacturers can also change cut blanks to use materials better. This reduces waste and adds more design options. Key benefits include:

Laser welding creates detailed and complex designs.

Changing cut blanks saves materials and adds flexibility.

This customization helps enclosures meet different industry needs. Whether it’s a small design for tight spaces or a strong cover for outdoor machines, the options are endless. This flexibility makes sheet metal enclosures a smart choice for businesses needing custom solutions.

Benefits of Using Machine Enclosures

Enhanced Safety

Safety is the top reason to use industrial enclosures. These covers act as barriers, keeping workers away from dangerous machines. They stop accidental contact with moving parts, lowering injury risks. For instance, enclosures with lockable doors block untrained people from using machines. Only trained workers can access them safely.

Fire prevention is another safety advantage. Many enclosures use fire-resistant materials to stop sparks or overheating. This helps prevent fires from spreading in factories. By adding these enclosures, workplaces become much safer for everyone.

Tip: Pick enclosures with safety certifications to meet workplace rules.

Noise Reduction

Factories can be very loud, but machine enclosures help reduce noise. Acoustic enclosures lower sound levels, making work areas quieter. Studies show they can cut noise by 15dB(A) to over 50dB(A). This protects workers from hearing damage.

Main Noise Reduction Benefits:

Helps follow noise control laws.

Creates a quieter space, boosting worker focus.

For example, diesel engines and gas turbines use soundproof covers. Research shows these can lower noise by up to 50dB in certain ranges. This makes enclosures vital for healthier workplaces.

Environmental Protection

Machine enclosures also shield equipment from tough conditions. Weatherproof covers protect machines from rain, dust, and extreme heat. This keeps equipment working well and lasting longer.

Many enclosures have ratings like IP67 and NEMA 4X. These show how well they resist water, dust, and corrosion. For example:

These features make enclosures perfect for outdoor machines and transport systems. They cut repair costs and prevent damage, improving efficiency overall.

Extended Equipment Lifespan

Enclosures help machines last longer by keeping them safe. They block damage from dust, moisture, and extreme heat. This protection helps machines work better for more years.

Enclosures stop wear and tear by keeping dirt away. Dirt can make machines break faster. Covers act like shields to block harmful particles. This means fewer repairs and replacements. For example, conveyor belts in factories stay clean with enclosures. These belts work well for many years.

Tip: Clean and check enclosures often to keep them effective.

Temperature control is another way enclosures help. Overheating can harm machine parts, but cooling systems fix this. Some enclosures have fans or vents to keep air moving. This stops overheating and keeps machines running smoothly.

Benefits of Temperature Control:

Stops overheating and damage.

Protects machine parts from wear.

Lowers fire risks.

Rust protection is also important. Materials like stainless steel and galvanized steel fight rust. This is great for outdoor machines facing rain or wet air. Businesses using rust-proof enclosures spend less on repairs.

Buying good enclosures is a smart idea. They protect machines, cut downtime, and save money. A cared-for enclosure adds years to a machine’s life. This makes it a valuable tool for any industry.

Applications of Industrial Enclosures

Industrial enclosures are crucial for keeping machines safe and working well. Let’s explore how they are used in different industries.

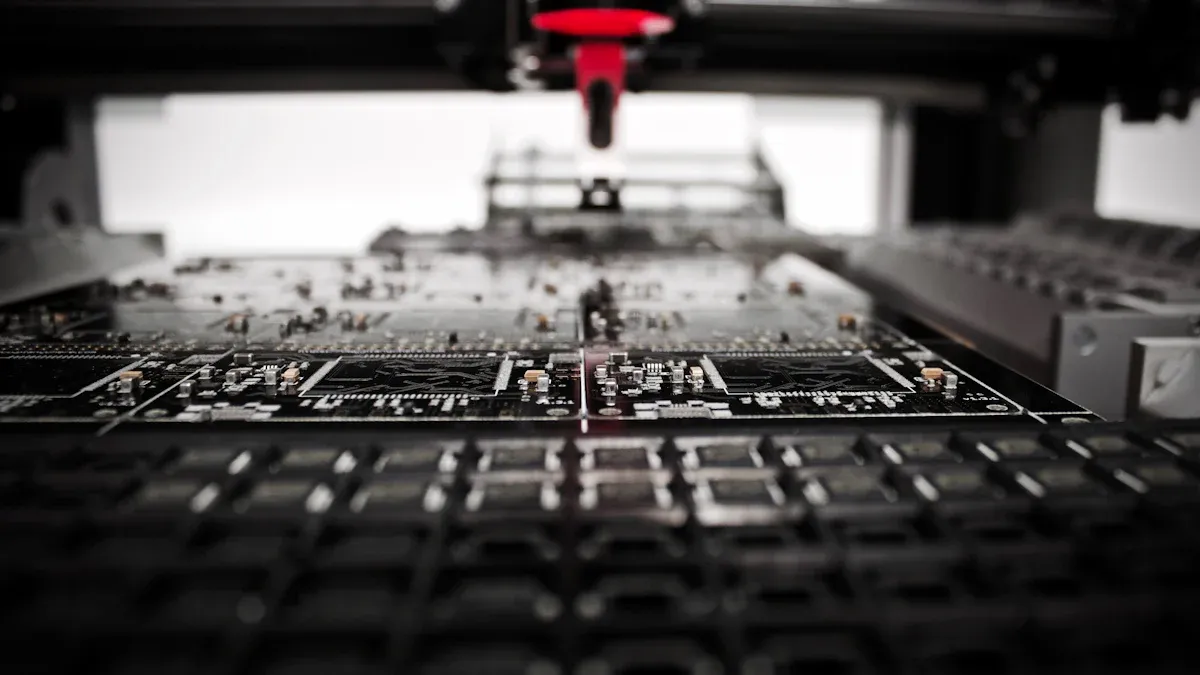

CNC Machines

CNC machines are key tools in modern factories. They cut, drill, and shape materials with great accuracy. But they create heat, noise, and debris while working. CNC machine enclosures help by protecting the machines from dirt and keeping the workspace clean. They also trap metal shavings and coolant splashes inside.

These enclosures make workshops safer. They cover moving parts, stopping accidental contact and reducing injuries. Some enclosures even have vents to cool machines and improve air quality.

Tip: Pick enclosures with good ventilation and noise control for CNC machines. This helps machines work better and keeps workers comfortable.

Laser Equipment

Laser machines, like cutters and engravers, need special protection. Lasers can cause eye injuries, burns, or fires if not handled safely. Laser room enclosures are made to block harmful laser beams and keep workers safe.

These enclosures also stop sparks and fumes from spreading. For example, CO2 and fiber lasers need strong covers to meet safety rules. Laser room enclosures follow Class 1 safety standards, protecting operators and the environment.

Safety Benefits of Laser Room Enclosures:

Block laser beams to avoid accidents.

Reduce fire risks and harmful fumes.

Meet industry safety rules.

More companies now use these enclosures to stay safe. Groups like FABTECH enforce strict safety rules, shutting down unsafe machines. This shows how important enclosures are for safe workplaces.

Electrical Control Rooms

Electrical control rooms hold equipment that powers factories. These rooms face risks like dust, moisture, and electrical sparks. Industrial enclosures protect this equipment and keep it running smoothly.

NEMA-rated enclosures are great for these rooms. They block dust and water, preventing damage. They also contain sparks or arcs during maintenance, stopping fires or accidents.

Benefits of Electrical Control Room Enclosures:

Stop electrocution and fire risks.

Follow safety codes and rules.

Help equipment last longer.

High-quality enclosures make control rooms safer and more efficient. They cut downtime and prevent costly accidents, saving businesses money.

Outdoor Machinery

Outdoor machines deal with tough conditions like rain, dust, and heat. These challenges can damage equipment quickly. That’s why industrial enclosures for outdoor use are so important. They protect machines from weather and help them last longer.

Choosing the right material is key for outdoor enclosures. Common materials include stainless steel, aluminum, fiberglass, and polycarbonate. Each has its own pros and cons:

For outdoor machines, enclosures should meet certain standards:

I.P. Rating: At least IP65 to block dust and water.

I.K. Rating: High ratings to resist impacts.

Certifications: NEMA-rated for safety and protection.

These features lower repair costs and protect machines. For example, an IP67 enclosure keeps out rain and dust, stopping rust and electrical problems. This is great for pumps, generators, and HVAC systems.

Heat control is also important. Outdoor machines in sunlight can overheat. Aluminum enclosures or those with vents help cool machines. This keeps them working well, even in hot weather.

The right enclosure makes a big difference. It protects outdoor machines, helps them last longer, and keeps them running smoothly. Whether for farms, construction, or factories, these enclosures are a must-have for protecting valuable equipment.

Why Pick Foxsen for Sheet Metal Machine Covers?

Skilled in Making Covers

Foxsen is great at making strong machine covers. Their team builds covers that meet industry rules and last a long time. They use careful methods to make sure every cover is high quality.

Foxsen has earned awards and certifications for their work. For example:

Dalsin Industries, a partner, won the '2020 Manufacturer of the Year' award from FMA.

KDM, another partner, has ISO certifications showing their high standards.

KDM has over 10 years of experience and many finished projects.

These achievements show Foxsen’s skill and focus on quality. Their covers work well even in tough conditions.

Custom Designs

Foxsen knows businesses need covers made just for them. They offer many ways to customize machine covers. Their team works with clients to design covers that fit their needs.

Foxsen uses advanced tools to make custom designs easy. For example, parametric programming helps change designs quickly and accurately. Laser welding allows detailed designs that work better for machines.

Foxsen’s ability to create custom covers makes them special. Whether for CNC machines, lasers, or outdoor equipment, they can make covers that fit perfectly.

High-Quality Standards

Foxsen cares about making the best machine covers. They check every step, from picking materials to testing the final product. This ensures their covers are strong and reliable.

Foxsen uses top materials like stainless steel and aluminum. These materials resist rust and handle heavy use. Their team tests covers to make sure they are safe and durable.

Choosing Foxsen means getting covers that last a long time. Their focus on quality gives you confidence that your machines are protected by the best.

Proven Industry Experience

Foxsen is a trusted expert in making machine enclosures. Their many years of work show their skill and focus on quality. They’ve built a strong reputation for creating reliable and innovative solutions.

Foxsen has helped businesses in many fields, like manufacturing and energy. This wide experience helps them understand different industry needs. For instance, they design CNC machine enclosures differently from outdoor equipment covers. Each design shows their deep understanding of what each machine requires.

Did you know? Foxsen has finished over 5,000 projects worldwide, proving their reliability and precision.

Foxsen’s team doesn’t just make covers—they solve tough problems. They handle challenging projects that others might avoid. For example, they’ve created rust-proof covers for coastal factories and noise-blocking covers for loud machines. Their solutions are practical and effective.

Here’s why Foxsen stands out:

Decades of Experience: Over 20 years of expertise.

Global Reach: Clients in more than 15 countries.

Diverse Portfolio: Skilled in industries like aerospace, automotive, and electronics.

With their experience, you can trust Foxsen for important projects. Their ability to adapt and create custom designs makes them a great choice for durable enclosures.

Sheet metal machine enclosures are important for keeping machines safe. They improve how machines work and make workplaces safer. These covers also lower noise and protect equipment from weather or damage. Industries use them to make machines last longer and work better.

The need for strong enclosures is growing fast. The market size shows this increase:

Foxsen makes high-quality enclosures that fit your needs. Their designs are strong and built to last. Picking Foxsen means better safety, longer machine life, and smarter protection for your equipment.

FAQ

What are CMM enclosures, and why are they useful?

CMM enclosures keep measuring machines safe from dust and vibrations. They also protect against temperature changes for accurate results. These covers improve safety by keeping workers away from moving parts.

How do EDM enclosures make machines safer?

EDM enclosures protect discharge machines from dust and moisture. They also block access to high-voltage parts, stopping accidents. This keeps workers safe and ensures smooth machine operation.

Where are equipment enclosures commonly used?

Equipment enclosures are used for CNC machines, laser cutters, and robots. They shield machines from damage, lower noise, and improve safety. Industries like manufacturing and aerospace rely on them.

Can I get a custom enclosure for my machine?

Yes, custom enclosures can be made for special machines. Manufacturers design them to fit perfectly and work well. This makes them great for unique equipment or tough conditions.

Why do automated machinery need enclosures?

Automated machinery enclosures protect machines from dust and heat. They also keep moving parts away from workers for safety. These covers help machines last longer and work better.