Custom sheet metal enclosures help protect parts in many industries. These include electronics and industrial machines. They are more than just covers. They help parts work well in different conditions. Their quality depends on accurate bending and welding of the metal. This is why careful metal work is so important. It makes the enclosures strong, long-lasting, and exactly the right size.

Making these enclosures takes several steps. Each step ensures they are strong, precise, and fit their purpose. By following these steps, I can make enclosures that work well and last a long time.

Key Takeaways

Custom sheet metal enclosures keep parts safe in many industries.

Knowing what is needed helps design enclosures for specific uses.

CAD software makes designing faster and creates exact digital models.

Picking the right materials ensures strength, lightness, and durability.

Testing and inspections make sure enclosures meet standards and work well.

Design and Specification for Custom Metal Enclosures

Understanding Application Requirements

When making custom sheet metal enclosures, I first learn what they’re for. Each enclosure has a job, so its design must match where and how it’s used. For example, I once worked on enclosures for green tech. They had to fit inside fiberglass housings and handle heavy use at fuel stations. The design needed tight fits, and rivets were used instead of welding for strength. These needs affected everything, like the materials and how it was built.

Creating CAD Designs for Sheet Metal Enclosure

After knowing the needs, I create designs using CAD software. CAD helps me see the enclosure and check if it’s right. I use exact measurements to make a digital model. This model shows details like holes for wires and spots to attach parts. At Foxsen, CAD makes designing custom enclosures faster and easier. This step ensures the enclosure works well and looks good too.

Prototyping and Design Validation

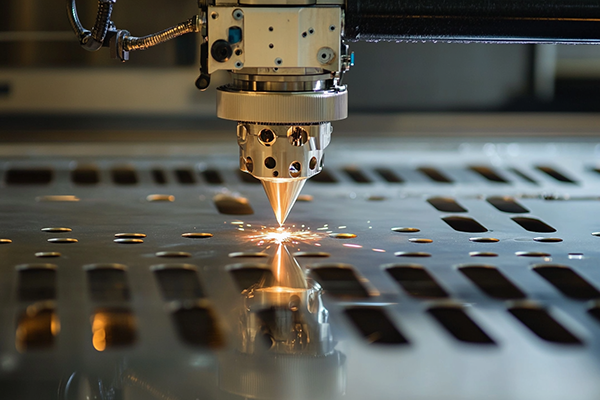

Prototyping is key when designing custom enclosures. It lets me test the design before making many. Fast methods like laser cutting and bending help me make prototypes quickly. These tests show problems early, so I can fix them fast. For example:

Quick prototyping saves time in development.

Advanced tools make prototypes faster.

Finding problems early speeds up the process.

At Foxsen, I use prototypes to ensure every enclosure is top quality. This step saves time and ensures the final product works perfectly.

Material Selection for Custom Sheet Metal Enclosures

Factors Influencing Material Choice

Picking the right material is very important in metal work. I think about things like strength, weight, and price. For example, outdoor enclosures need materials that don’t rust. Indoor ones might focus more on looks or saving money. The environment matters too. Heat or moisture can change how materials perform.

Studies show how industries choose materials. For example:

These studies help me see how industries pick materials for their needs.

Common Materials in Precision Metal Fabrication

I often use materials like stainless steel, aluminum, and copper. Each has special benefits. Stainless steel doesn’t rust and is great for medical tools. Aluminum is light and works well in planes and telecom. Copper carries electricity well, so it’s good for electrical parts.

Here’s a simple comparison:

This table helps me quickly match materials to their uses.

Matching Material Properties to Application Needs

Matching materials to their job takes careful thought. I check things like strength, rust resistance, and conductivity. For example, some materials are made for special uses, like heat sinks or lightweight covers.

I use numbers to measure how materials perform. This makes sure the enclosure does its job well. For example:

Strong materials are good for factories.

Light materials save on shipping costs.

Rust-proof materials last longer outside.

By choosing the right material for the job, I make sure every enclosure works its best.

Cutting and Shaping in Precision Metal Fabrication

Cutting and shaping are key steps in making custom sheet metal enclosures. These steps decide the size, fit, and quality of the enclosure. I use advanced tools to make sure the work is accurate and fast.

Cutting Techniques (Laser Cutting, CNC Punching, Waterjet Cutting)

Cutting is the first step in shaping metal sheets. I use three main methods: laser cutting, CNC punching, and waterjet cutting. Each method has its own benefits, and I pick the best one for the job.

Laser Cutting: A strong laser beam cuts metal with high accuracy. It’s great for detailed designs and small holes. I use it for patterns or tight spaces in enclosures.

CNC Punching: This uses a computer-guided machine to punch shapes or holes. It’s best for repeating patterns or when speed is needed.

Waterjet Cutting: A high-pressure water stream with grit cuts metal without heat. It’s ideal for metals that can’t handle heat.

These methods create smooth edges and exact sizes, which are important for quality fabrication.

Bending and Forming Methods for Custom Metal Enclosures

After cutting, I shape the metal into its final design by bending and forming. This step turns flat sheets into usable enclosures.

I use machines like press brakes to bend the metal at the right angles. Planning is important to adjust for material thickness and bending needs. For example:

Small changes in thickness can affect bending accuracy. A tiny change of ±0.006 inches can cause angle errors of ±4 degrees.

Bend allowance helps get the right angles by adding extra length for bending.

The type of metal also matters. Some metals need more force to bend, while others are easier to shape. By adjusting for each material, I make sure the enclosure is made correctly.

Ensuring Accuracy During Shaping

Accuracy is very important when shaping metal. Even tiny mistakes can ruin the fit or function of the enclosure. I follow strict rules to keep everything precise. For example:

These rules help me make sure every part fits perfectly. I also check each piece after shaping to confirm it matches the design. This careful work ensures the custom sheet metal enclosures are high-quality and reliable.

Assembly of Custom Electronic Enclosures

The assembly step is where all the parts are joined to make a working custom electronic enclosure. This process ensures the enclosure is strong and fits its purpose. I use methods like welding, riveting, and other techniques to connect the pieces. Each method helps make the enclosure tough and reliable.

Welding Techniques for Sheet Metal Enclosure Assembly

Welding is a trusted way to join metal parts. It creates a strong bond that lasts and handles tough conditions. For custom electronic enclosures, I follow rules from SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association). These rules ensure the welding meets industry standards and produces good results.

I use TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. TIG welding is precise and works well for thin metal. MIG welding is faster and better for thicker sheets. Both methods create clean, strong welds that make the enclosure sturdy.

Tip: Cleaning the metal before welding is very important. Dirt or grease can ruin the weld.

SMACNA’s guidelines are approved by ANSI (American National Standards Institute). This means the welding methods I use are trusted worldwide.

Riveting and Other Joining Methods

Sometimes, welding isn’t the best choice. Riveting is useful when heat could harm delicate parts. Rivets join pieces without using heat. For example, I’ve used impact riveting in packaging projects. This method cuts material waste from 22% to 2%.

Another method I use is orbital forming. It uses less force and makes parts fit better. This is great for jobs needing precision and less stress on materials.

Here’s a simple comparison of these methods:

These methods let me choose the best way to assemble each enclosure.

Ensuring Structural Integrity in Custom Metal Enclosures

Making sure the enclosure is strong is very important. I do tests to check if it can handle tough conditions. These tests find weak spots and make sure the enclosure meets standards.

Some tests I use are vibration, thermal shock, and salt spray corrosion tests. These tests show how the enclosure performs in different environments.

Here are examples of tests I do:

Sand and Dust Test

Thermal Shock Test

Humidity Test

Vibration Test

Salt Spray Corrosion Test

I also follow strict rules during assembly to keep everything accurate. For example, I check the position and angle of parts to avoid errors.

By following these steps, I make sure every custom electronic enclosure is strong, dependable, and ready for its job.

Surface Finishing for Sheet Metal Enclosures

Surface finishing is important for making metal enclosures better. It helps them last longer, stops rust, and makes them look nice. I pick the right finish based on where and how it will be used.

Types of Finishes (Powder Coating, Plating, etc.)

Different finishes are used for different jobs. Powder coating is my favorite. It makes a strong, smooth layer that stops scratches and rust. Electroplating adds a thin metal layer to improve conductivity or stop rust.

For tough conditions, I use anodizing. This strengthens aluminum and adds a protective layer. Brushed finishes give a modern and stylish look. Each finish has a purpose, and I choose the best one for the job.

Making Enclosures Stronger and Rust-Proof

Enclosures need to be strong and resist damage. I use finishes that protect against water, chemicals, and heat. Powder coating works well outside because it blocks UV rays and rust. Galvanizing coats steel with zinc to stop rust.

I test finishes to make sure they work in tough conditions. Salt spray tests check how well they resist rust. These tests ensure the enclosure stays strong for years.

Making Enclosures Look Good

How an enclosure looks is also important. I use finishes that make them look clean and professional. Matte finishes give a simple look, while glossy ones add shine.

Colors matter too. Powder coating offers many color choices for branding or design. I work with clients to pick finishes that match their ideas. This makes sure the enclosure looks great and works well.

Quality Assurance in Precision Metal Fabrication

Inspection and Testing Methods

Quality checks start with careful inspections and tests. I check raw materials to ensure they meet needs. During production, I watch for mistakes early. After making the product, I test it to confirm it works well.

I use these methods to check quality:

Stress tests see if the enclosure can handle pressure.

Microscopes find tiny flaws not seen by the eye.

Vibration tests show how it works in real-life situations.

ISO 9001:2015 helps me follow global rules. It focuses on improving and meeting high standards. This system helps me adjust to changes and make reliable products.

Tip: Checking during production lowers mistakes and saves time.

Ensuring Compliance with Industry Standards

Following industry rules is very important for custom sheet metal enclosures. I use standards like ISO 2768 for size limits and ASME Y14.5 for precise shapes. These rules help make sure the product is accurate and consistent.

Different markets have different rules. For example, Europe needs products to meet EU safety and quality laws. Staying updated with these rules ensures my enclosures work everywhere.

Some key standards I follow are:

DIN 6930: Covers stamped metal parts.

ANSI Guidelines: Ensures safety and good quality.

ISO Benchmarks: Sets global rules for reliability.

Final Quality Checks Before Delivery

Before sending the product, I do final checks to ensure quality. I look at size, finish, and assembly to match the design. I also test for strength and rust resistance to ensure durability.

The certification process includes these steps:

Checking current methods and training workers.

Setting up systems that follow the rules.

Passing audits by certified groups.

Improving and renewing certifications regularly.

These steps make sure every enclosure is top quality. By focusing on quality, I deliver products that last and work well.

Making custom metal enclosures takes many careful steps. These include designing, picking materials, cutting, shaping, putting parts together, and finishing. Each step makes sure the enclosure works as needed. Being precise and making high-quality products are very important. This ensures the enclosures last long and work well for industries like airplanes, electronics, and green energy.

The worldwide sheet metal market shows how important this is. In 2024, it was worth $18.93 billion. By 2032, it might grow to $25.51 billion. This growth shows how useful these enclosures are in many fields. By focusing on detail and quality, I make products that solve problems and last a long time.

FAQ

What industries use custom sheet metal enclosures?

These enclosures are used in many fields like electronics, aerospace, medical tools, and green energy. They keep parts safe and last in tough conditions. Their flexibility makes them important for different industries.

How do you ensure precision during fabrication?

I use advanced machines like laser cutters and CNC tools. These machines help me make exact sizes and shapes. I also check every piece to make sure it matches the design.

What materials work best for outdoor enclosures?

For outdoor use, stainless steel and galvanized steel are great choices. They don’t rust and can handle bad weather. Adding powder coating gives even more protection and makes them last longer.

Can custom enclosures be made quickly?

Yes, I use fast methods like laser cutting and bending. These steps make the process quicker without losing quality. Testing early helps me fix problems fast and finish on time.

Are custom finishes expensive?

Not always. Powder coating is strong and affordable. Electroplating costs more but improves conductivity. I help clients pick finishes that match their budget and needs.