Electro-galvanised steel revolutionises industrial applications by combining the strength of sheet metal with advanced corrosion resistance. Its unique coating process ensures durability even in harsh environments, making it indispensable across sectors such as automotive, construction, and manufacturing.

The global production of sheet metal Electro galvanised steel reached 140 million metric tonnes in 2022, highlighting its widespread adoption.

The construction industry alone accounts for over 36% of its consumption, driven by urbanisation and infrastructural growth.

Market projections estimate a compound annual growth rate of 5-7%, showcasing increasing demand for this versatile material.

With electro-galvanisation, steel components can last over 50 years without maintenance in moderate conditions, ensuring long-term reliability.

The sustainability of sheet metal Electro galvanised steel also appeals to eco-conscious industries. Its recyclability reduces waste, aligning with global efforts to minimise environmental impact.

Key Takeaways

Electro-galvanised steel is strong and resists rust, making it great for cars and buildings.

The coating process gives it a smooth look and neat finish, improving how products appear.

This steel can be recycled easily, helping the environment and cutting waste in industries.

It can last more than 50 years in mild conditions, saving money on repairs.

Electro-galvanised steel works well for many uses, like roofs and car parts, fitting different needs.

The Electro-Galvanisation Process

What is electro-galvanisation?

Electro-galvanisation is a precise method of coating steel with zinc using an electric current. This process transfers zinc ions onto the steel surface, creating a uniform and thin protective layer. Unlike hot-dip galvanisation, which involves immersing steel in molten zinc, electro-galvanisation offers better control over coating thickness. This makes it ideal for applications requiring smooth finishes, such as automotive body parts, electronics housings, and indoor sheet metal products.

The impact of electro-galvanisation on modern industries is significant. It enhances the durability of steel while maintaining its original mechanical properties. This combination of strength and corrosion resistance ensures that electro-galvanized steel meets the demands of various sectors, from construction to manufacturing.

Key steps in the process

The electro-galvanisation process involves several critical stages to ensure a high-quality zinc coating. Each step prepares the steel surface and applies the protective layer:

Maintaining consistent temperature and bath composition is crucial during these stages. The use of a zinc sulphate solution ensures optimal conductivity and even zinc deposition.

Differences between electro-galvanisation and hot-dip galvanisation

Electro-galvanisation and hot-dip galvanisation differ in their methods and outcomes. Electro-galvanisation produces thinner coatings, making it suitable for applications requiring precision and smooth finishes. In contrast, hot-dip galvanisation creates thicker coatings, offering superior corrosion resistance for outdoor and heavy-duty uses.

While hot-dip galvanisation offers better long-term protection, electro-galvanisation excels in applications where aesthetics and precision are priorities.

Benefits of Electro-Galvanised Steel

Corrosion resistance and durability

Electro-galvanised steel offers exceptional corrosion resistance, making it a reliable choice for industries requiring long-lasting materials. The zinc coating acts as a barrier, protecting the steel from environmental factors like moisture and oxygen. Studies show that zinc-rich coatings outperform normal epoxy coatings in salt spray tests, demonstrating superior corrosion protection. Additionally, the formation of zinc oxide (ZnO) on the surface enhances durability by creating a secondary layer of defence.

A comparison of materials highlights the advantages of electro-galvanised steel:

This durability ensures that you can rely on electro-galvanised steel for applications in harsh environments, reducing maintenance costs and extending service life.

Precision and surface finish

Electro-galvanisation provides unmatched precision and a smooth surface finish. The process occurs at room temperature, preserving the steel's mechanical properties. It also allows for precise control over coating thickness, ensuring uniformity. This makes it ideal for applications requiring high-quality finishes, such as automotive body panels and electronics.

The bright, uniform coating enhances the aesthetic appeal of products while maintaining functionality. This combination of precision and quality ensures that your projects meet the highest standards.

Versatility in industrial applications

Electro-galvanised steel adapts to a wide range of industrial needs. Its use spans sectors like automotive, construction, and electronics. For example, in the automotive industry, it is used for body panels due to its corrosion resistance and smooth finish. In construction, it strengthens structural components and roofing materials.

The electronics sector increasingly relies on electro-galvanised steel for consumer products, driven by advancements in technology.

Innovations in production processes further enhance its adaptability, ensuring its relevance across industries.

This versatility makes electro-galvanised steel a valuable material for diverse applications, helping you achieve both functionality and efficiency in your projects.

Sustainability and recyclability

Electro-galvanised steel stands out as a sustainable material, offering significant environmental benefits. Its recyclability ensures minimal waste, making it an eco-friendly choice for industries aiming to reduce their carbon footprint. You can rely on this material to support green initiatives without compromising performance.

The lifecycle of electro-galvanised steel demonstrates its commitment to sustainability. Manufacturers recycle more than 95% of structural steel in North America from previously used materials. This process reduces the need for raw material extraction, lowering the environmental impact. Additionally, 30% of all zinc used in galvanisation comes from recycled sources. This practice further enhances the eco-friendly nature of the material.

At the end of its useful life, electro-galvanised steel doesn’t go to waste. It can be recycled into new structural steel or repurposed for other applications. This cradle-to-cradle lifecycle ensures that the material remains in use, reducing landfill contributions.

♻️ Choosing electro-galvanised steel means contributing to a circular economy where resources are reused rather than discarded.

The recyclability of this material also aligns with global sustainability goals. By incorporating electro-galvanised steel into your projects, you actively participate in reducing industrial waste. This choice supports a cleaner environment while maintaining the durability and versatility required for demanding applications.

Electro-galvanised steel proves that sustainability and performance can coexist. Its ability to be recycled repeatedly without losing quality makes it a reliable and responsible option for modern industries.

Applications of Electro-Galvanised Steel

Electro-galvanised steel plays a pivotal role in various industrial applications, offering unmatched durability, corrosion resistance, and versatility. Its unique properties make it indispensable across sectors like construction, automotive, and agriculture. Below, we explore how this material transforms these industries.

Construction: Structural steel and roofing

In construction applications, electro-galvanised steel provides the strength and longevity needed for demanding environments. Its corrosion-resistant coating ensures that structural components and roofing materials can withstand exposure to moisture, pollutants, and temperature fluctuations. This makes it an ideal choice for urban infrastructure and buildings in regions with harsh weather conditions.

A study on the performance of electro-galvanised steel in construction highlights its advantages:

These properties ensure that electro-galvanised steel not only meets but exceeds the requirements of modern construction projects. Its recyclability further enhances its appeal, aligning with the industry's push towards sustainable materials.

Tip: Electro-galvanised steel is particularly effective for roofing systems, where its smooth surface and resistance to rust ensure long-term performance.

Automotive: Body panels and undercarriages

The automotive industry relies heavily on electro-galvanised steel for its precision and aesthetic appeal. This material is widely used in body panels, undercarriages, and other components where a smooth finish and corrosion resistance are critical. Its thin zinc coating provides excellent protection without adding unnecessary weight, making it ideal for modern vehicles prioritising fuel efficiency.

The global demand for galvanised steel in the automotive sector continues to rise due to its unique benefits:

The smooth surface of electro-galvanised steel ensures high-quality paint adhesion, enhancing the vehicle's appearance.

Its corrosion resistance extends the lifespan of critical components, reducing maintenance costs.

Lightweight yet durable, it supports the industry's shift towards more sustainable and energy-efficient designs.

By incorporating electro-galvanised steel into your automotive projects, you can achieve both functionality and style. Its adaptability ensures that it meets the evolving demands of the automotive industry.

Agriculture: Fencing and equipment

In agriculture and farming, electro-galvanised steel offers a reliable solution for fencing, equipment, and storage structures. Its corrosion-resistant properties make it suitable for outdoor use, where exposure to moisture, soil, and chemicals is common. Farmers and agricultural businesses value its durability and low maintenance requirements, which translate to long-term cost savings.

Electro-galvanised steel is particularly effective for:

Fencing: Provides a sturdy barrier that resists rust and wear, even in challenging environments.

Equipment: Ensures that tools and machinery remain functional despite exposure to harsh conditions.

Storage structures: Protects grain silos and sheds from corrosion, preserving their structural integrity.

The trend towards sustainable materials further boosts the adoption of galvanised steel in agriculture. Its recyclability and long lifespan make it an eco-friendly choice for modern farming practices.

🌾 Choosing electro-galvanised steel for your agricultural needs ensures that your investments stand the test of time, even in the toughest conditions.

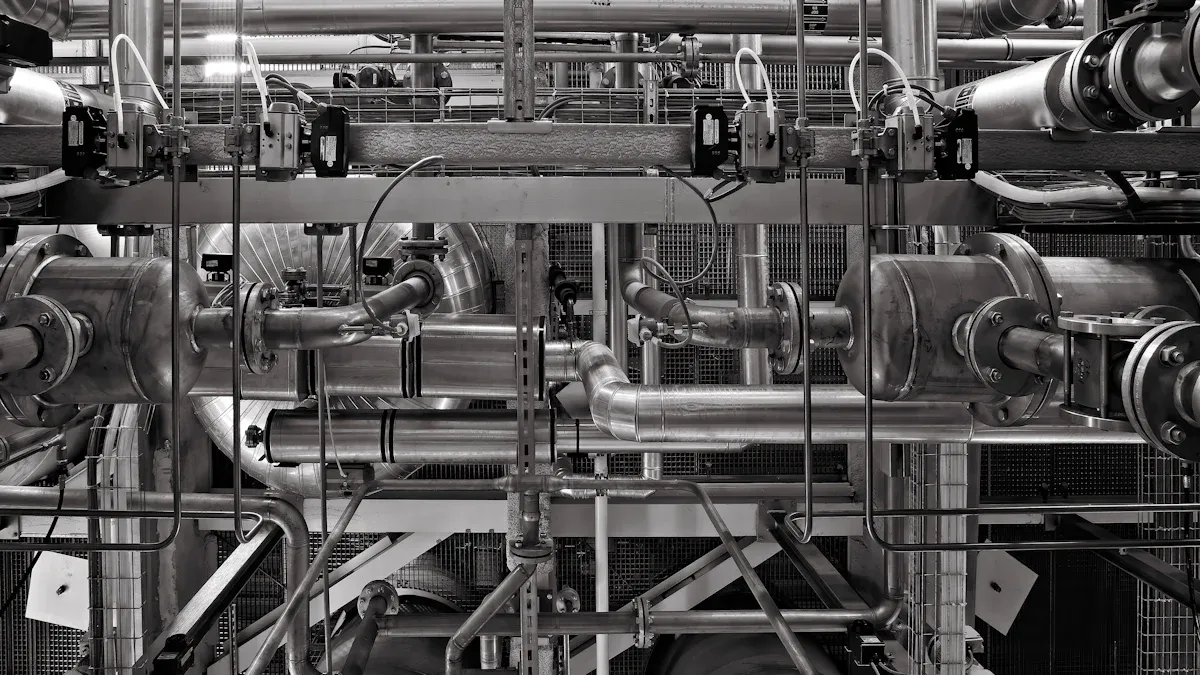

HVAC systems: Ductwork and enclosures

Electro-galvanised steel plays a vital role in HVAC systems, particularly in ductwork and enclosures. Its corrosion resistance ensures that ducts remain functional even in environments with high humidity or temperature fluctuations. This durability reduces the need for frequent replacements, saving you time and resources.

The smooth surface finish of electro-galvanised steel enhances airflow efficiency within ducts. A uniform coating prevents the accumulation of dust and debris, which can compromise air quality. This makes it an excellent choice for HVAC systems in residential, commercial, and industrial settings.

For enclosures, electro-galvanised steel offers both protection and aesthetic appeal. The material resists rust, ensuring that HVAC components remain shielded from external elements. Its bright, uniform finish also provides a professional appearance, which is particularly important for visible installations.

💡 Tip: Using electro-galvanised steel in HVAC systems ensures long-term performance and reduces maintenance costs.

Marine: Corrosion-resistant components

Marine environments pose significant challenges due to constant exposure to saltwater and humidity. Electro-galvanised steel excels in these conditions, offering reliable corrosion resistance for various marine applications. Its zinc coating acts as a sacrificial layer, protecting the underlying steel from rust and degradation.

Common marine applications include shipbuilding, offshore platforms, and dockside equipment. Electro-galvanised steel ensures that these components withstand harsh conditions, extending their service life. For example, it is often used in structural supports, ladders, and railings, where durability is critical.

Quantitative corrosion tests validate the effectiveness of electro-galvanised steel in marine environments:

These findings highlight the material's ability to perform under extreme conditions. By choosing electro-galvanised steel for marine applications, you ensure that your investments remain protected against the elements.

Electrical: Grounding devices and conductive parts

Electro-galvanised steel is a trusted material for electrical applications, particularly in grounding devices and conductive parts. Its zinc coating enhances conductivity while providing excellent corrosion resistance. This combination ensures that electrical systems remain safe and efficient over time.

Grounding devices rely on the material's ability to maintain a stable connection, even in challenging environments. Electro-galvanised steel resists oxidation, which can otherwise compromise electrical performance. Its durability also reduces the risk of system failures, ensuring reliable operation.

Performance metrics further validate its suitability for electrical applications:

These metrics demonstrate the superior performance of electro-galvanised steel in electrical systems. Its lower self-corrosion current ensures minimal energy loss, while the steeper passivation zone slope indicates better resistance to environmental factors.

⚡ Note: Electro-galvanised steel provides a cost-effective solution for electrical applications without compromising on safety or performance.

Manufacturing: Tubing, shelving, and rail cars

Electro-galvanized steel plays a crucial role in manufacturing, particularly in the production of tubing, shelving, and rail cars. Its unique properties, such as corrosion resistance, durability, and a smooth surface finish, make it an ideal material for these applications. You can rely on this material to meet the demanding requirements of modern manufacturing processes.

Tubing

Tubing made from electro-galvanized steel offers exceptional strength and longevity. The zinc coating protects the steel from rust, ensuring that the tubing remains functional even in harsh environments. This makes it suitable for industries like construction, plumbing, and automotive manufacturing.

Key benefits of using electro-galvanized steel for tubing include:

Corrosion resistance: The zinc layer acts as a barrier, preventing moisture and oxygen from reaching the steel.

Ease of fabrication: The material is easy to cut, bend, and weld, allowing you to create custom tubing designs.

Aesthetic appeal: The smooth, uniform coating enhances the appearance of the finished product.

For example, in plumbing systems, electro-galvanized steel tubing ensures reliable water flow without the risk of leaks caused by rust. Its durability reduces the need for frequent replacements, saving you time and money.

Shelving

Electro-galvanized steel is a popular choice for shelving in warehouses, retail stores, and homes. Its strength and corrosion resistance make it ideal for supporting heavy loads and withstanding exposure to moisture or chemicals.

Advantages of electro-galvanized steel shelving include:

High load capacity: The material can support significant weight without bending or breaking.

Low maintenance: The zinc coating prevents rust, reducing the need for cleaning or repairs.

Customisation options: You can easily modify the shelving to fit specific dimensions or designs.

In industrial settings, electro-galvanized steel shelving provides a reliable storage solution for tools, equipment, and inventory. Its recyclability also aligns with sustainable manufacturing practices, making it an eco-friendly choice.

Rail Cars

The manufacturing of rail cars demands materials that can withstand heavy loads, constant vibration, and exposure to the elements. Electro-galvanized steel meets these requirements, offering a combination of strength, durability, and corrosion resistance.

Rail car components made from electro-galvanized steel include:

Structural frames: Provide the necessary support for carrying cargo or passengers.

Exterior panels: Resist rust and maintain their appearance over time.

Interior fittings: Offer a smooth finish that enhances the comfort and safety of passengers.

The use of electro-galvanized steel in rail cars ensures long-term performance and reduces maintenance costs. Its lightweight nature also improves fuel efficiency, contributing to the sustainability of rail transport.

🚆 Tip: Electro-galvanized steel is an excellent choice for rail car manufacturing, as it combines durability with environmental benefits.

By incorporating electro-galvanized steel into tubing, shelving, and rail cars, you can achieve high-quality results that meet the demands of modern manufacturing. Its versatility and reliability make it a valuable material for a wide range of applications.

Innovations and Future Trends

Advances in coating technologies

The evolution of coating technologies has significantly enhanced the performance of galvanized steel. Modern advancements focus on improving durability and corrosion resistance, making this material more reliable in harsh environments. For instance, industries like automotive and construction increasingly demand corrosion-resistant materials to ensure the longevity of their components.

Recent innovations in coating processes have also prioritised sustainability. Energy-efficient methods now dominate production, reducing the environmental impact of manufacturing. These advancements not only improve the quality of galvanized steel but also make it a preferred choice for eco-conscious industries.

Major companies, including ArcelorMittal and Nippon Steel, are investing heavily in research to refine these technologies. Their efforts aim to meet the growing demand for lightweight, corrosion-resistant materials across various sectors. As a result, you can expect galvanized steel to remain a cornerstone of industrial applications for years to come.

Smart manufacturing integration

The integration of smart manufacturing technologies is revolutionising how galvanized steel is produced. Automation and artificial intelligence (AI) now play a pivotal role in optimising production processes. For example, AI-driven systems can precisely control coating thickness, ensuring consistent quality across batches.

Smart factories also enhance efficiency by reducing waste and energy consumption. These facilities use real-time data to monitor production, allowing manufacturers to identify and address issues immediately. This level of precision not only improves the quality of galvanized steel but also reduces production costs.

As a consumer, you benefit from these advancements through access to high-quality materials at competitive prices. The adoption of smart manufacturing ensures that galvanized steel continues to meet the evolving needs of modern industries.

Sustainability-driven innovations

Sustainability remains a key focus in the production of galvanized steel. Innovations like trivalent chromium passivation have replaced toxic chemicals with safer alternatives, reducing the environmental impact of coating processes. Recycling practices have also improved, with companies like Umicore recovering up to 95% of zinc from scrap materials.

Water management innovations further enhance sustainability. Zero-Liquid Discharge (ZLD) systems recycle 100% of water used in production, conserving resources and minimising waste. Additionally, AI-optimised coating technologies reduce zinc usage by 20%, lowering material consumption and waste generation.

These advancements align with global efforts to reduce carbon emissions and promote sustainable practices. By choosing galvanized steel, you contribute to a circular economy where resources are reused efficiently.

🌍 Sustainability-driven innovations ensure that galvanized steel remains an environmentally responsible choice for industrial applications.

Electro-galvanised steel has transformed industries with its durability, precision, and sustainability. Its thin zinc layer protects steel from corrosion, ensuring long-lasting performance in moisture-prone environments. The automotive sector benefits from its uniform coating, which enhances paint adhesion and reduces manufacturing costs. Construction projects rely on its strength and recyclability, while agriculture and marine applications value its resistance to harsh conditions.

Foxsen remains committed to delivering premium sheet metal electro galvanised steel solutions. By prioritising quality and innovation, Foxsen ensures that your projects achieve superior results while supporting sustainable practices.

🌟 Electro-galvanised steel continues to shape industrial advancements, offering unmatched reliability and versatility for modern applications.

FAQ

What makes electro-galvanised steel different from regular steel?

Electro-galvanised steel has a zinc coating applied through an electric current. This coating protects the steel from corrosion and enhances its durability. Regular steel lacks this protective layer, making it more prone to rust and wear in harsh environments.

Can electro-galvanised steel be recycled?

Yes, you can recycle electro-galvanised steel multiple times without losing its quality. Its zinc coating and steel core are both recyclable, making it an eco-friendly choice for industries aiming to reduce waste and support sustainability initiatives.

Is electro-galvanised steel suitable for outdoor use?

Electro-galvanised steel works well in mild outdoor conditions. However, for extreme environments like marine or industrial areas, you may need additional coatings or treatments to enhance its corrosion resistance and longevity.

How does electro-galvanised steel benefit the automotive industry?

Electro-galvanised steel provides a smooth surface for paint adhesion, ensuring a high-quality finish. Its lightweight yet durable nature improves fuel efficiency. Additionally, its corrosion resistance extends the lifespan of body panels and undercarriages, reducing maintenance costs.

Does electro-galvanised steel require special maintenance?

Electro-galvanised steel requires minimal maintenance. Its zinc coating protects against rust and wear. For prolonged performance, you should clean it periodically and avoid exposing it to highly corrosive substances without additional protective measures.