Safety and speed are very important in sheet metal work. Sharp edges, heavy items, and heat can cause injuries or waste. Studies show less contact with sharp edges lowers accidents. Faster work, like cutting time by 47%, boosts output. Foxsen helps with both safety and speed. Their smart tools and safety gear let you work safely and efficiently.

Key Takeaways

Always wear safety gear like gloves, goggles, and boots. This helps prevent injuries when working with sheet metal.

Lift heavy things the right way to protect your back. Use your legs, keep items close, and ask for help if needed.

Keep your workspace clean and tidy to avoid accidents. Clean spills quickly and put tools away properly for safety.

Use the correct tools for each task. Special tools make work faster and more accurate, reducing mistakes and waste.

Use Foxsen's guides and videos to learn safe and efficient sheet metal work tips.

Risks in Handling Sheet Metals

Cuts and Lacerations

Working with sheet metals can lead to cuts easily. Sharp edges are dangerous if not handled carefully. Injuries often happen when cutting or moving sheet metals. Even small mistakes can cause deep wounds needing medical care. Studies show cuts are a common danger in this work. To stay safe, wear gloves made for handling sheet metals. Be careful of sharp edges or poorly stored sheets in your area.

Burns and Heat Hazards

Sheet metals heat up fast, which can cause burns. Using hot tools or welding increases the chance of burns. Cold sheet metals in winter can also harm your skin. Wearing the right safety gear is very important. Use heat-resistant gloves and check tools are cool before touching them.

Respiratory Risks in Sheet Metal Workshop

Breathing in metal dust can harm your lungs over time. Cutting or grinding sheet metals creates dust that is dangerous. A study found cobalt and chromium dust reduced workers' lung health. Only 35.8% of workers wore masks all the time. This shows the need for better safety habits. Dust can cause asthma, lead poisoning, or brain problems. Always wear a mask and keep your workspace well-ventilated to stay safe.

Strain from Improper Lifting

Lifting sheet metal the wrong way can hurt you badly. You could injure your back, shoulders, or arms without proper methods. Sheet metal is heavy and hard to carry, making injuries more likely. Doing this wrong often can lead to lasting pain or damage.

To stay safe, follow these lifting tips:

Check the weight: See if the sheet metal is too heavy for you.

Lift with your legs: Bend your knees and keep your back straight. This helps protect your spine.

Get help: If it’s too big or heavy, ask someone or use tools.

Keep it close: Hold the sheet metal near your body to stay balanced.

Tip: Use tools like carts or hoists when you can. They help prevent injuries.

Good posture is very important. Don’t twist your body while carrying metal. Turn your whole body by moving your feet instead. This keeps your back and joints safe.

If you feel pain after lifting, don’t ignore it. Rest and put ice on the sore area. If the pain doesn’t go away, see a doctor. Using safe lifting habits keeps you healthy and helps you work better. Always remember, your health matters most.

Safely Handling Sheet Metal

Importance of PPE

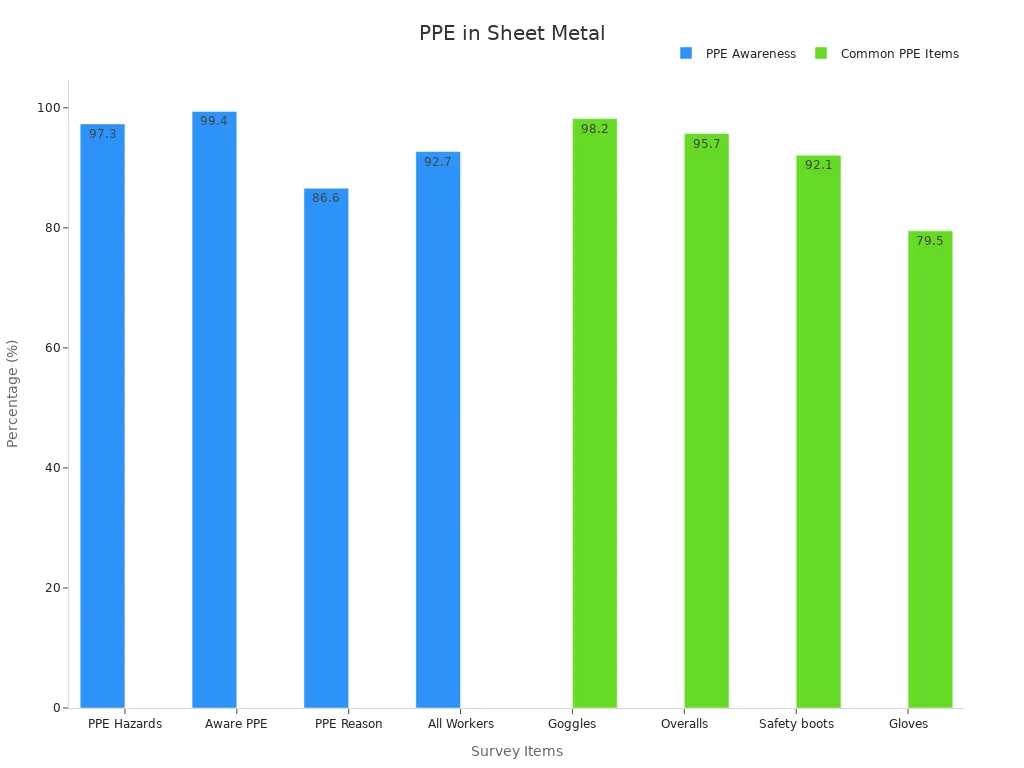

Personal protective equipment (PPE) is key to staying safe with sheet metal. Wearing the right gear helps prevent cuts, burns, and breathing problems. Gloves keep your hands safe from sharp edges. Goggles protect your eyes from flying bits during cutting. Safety boots stop injuries from falling metal. Overalls cover your body to keep you safe.

Tip: The International Labor Organization (ILO) says workers should be protected from sickness and injuries at work. Always wear PPE to stay safe.

Tool Inspection and Maintenance

Checking and fixing tools often is important for safety. Broken tools can cause accidents, injuries, or slow down your work. Before starting, look for damage on your tools. Make sure blades are sharp and handles are tight. Check that electrical tools work properly.

Safety measures: Check tools regularly to find and fix problems.

Maintenance logs: Write down issues to fix them quickly and track repairs.

Safety checklists: Use the right tools to lower risks at work.

Note: Regular checks make tools safer and last longer, saving money over time.

Clean and Organized Workspace

Keeping your workspace clean and tidy is very important. Messy areas can cause trips, falls, or injuries from misplaced tools. A neat space helps you find tools faster and work better.

Clean up spills and trash right away to avoid slips.

Put tools and sheet metals in their proper places.

Teach workers to keep the area clean every day.

Important Safety Tips: Both bosses and workers must keep the workspace clean. A tidy area lowers accidents and helps everyone work faster.

Proper Lifting Techniques

Lifting sheet metals the wrong way can cause bad injuries. You should use safe lifting methods to protect your body. These methods lower muscle strain and prevent long-term harm.

Steps for Safe Lifting

Check the Load

Look at the weight and size before lifting. If it’s too heavy, use carts or hoists. Don’t lift more than you can handle.Stand Correctly

Stand close to the metal with feet apart. Keep your back straight and bend your knees. This lets your legs do the work, not your spine.Use Your Legs

Push with your legs to lift the metal. Don’t bend your back or twist your body. Hold the metal close to your chest for balance.Move Slowly

Walk carefully and avoid quick movements. Turn by moving your feet, not twisting your torso. This protects your back and shoulders.Get Help

For big or heavy sheets, ask someone to help or use tools. Working together prevents accidents and keeps you safe.

Tip: Safety training teaches workers how to lift correctly. Training helps avoid injuries like sprains and strains.

Why Proper Lifting Helps

Safe lifting keeps you healthy and improves your work. You’ll have fewer injuries and can focus better on tasks. Studies show trained workers get hurt less often. Rigging safety training also explains how to avoid accidents and lift safely.

Tools That Help with Lifting

Modern tools make lifting easier and safer. Try using:

Carts and Dollies: Good for moving heavy sheets around.

Hoists and Cranes: Great for lifting big or heavy metals.

Magnetic Lifters: Useful for holding and moving metal sheets.

Using these tools lowers strain and makes work faster.

By using safe lifting methods, you’ll stay healthy and work better. These techniques are important for anyone working with sheet metals.

Efficiency in Sheet Metal Workshop

Being efficient in a sheet metal workshop means making smart choices. Use the right tools, keep your workspace neat, and care for your equipment. These steps save time, cut waste, and help you work better.

Picking the Best Tools

Using proper tools makes your work faster and easier. Special tools for certain tasks give better results with less effort. For example, plasma cutters cut thick metal quickly and neatly. Advanced CAM software helps set cutting rules for speed and accuracy.

Choosing the right blade also avoids ruining materials. This saves both time and money. Studies show good tools can boost work speed by 15-40% and cut mistakes by up to 90%.

Tip: Match your tools to the job. This keeps your tools in good shape and improves results.

Organizing Your Workspace

A tidy workshop helps you work faster and stay safe. When tools are in the right place, you don’t waste time looking for them. Using systems like 5S can make your workspace much better.

Sort: Get rid of things you don’t need.

Set in Order: Put tools where they’re easy to find.

Shine: Clean your workspace often.

Standardize: Make rules to keep things organized.

Sustain: Check and improve your system regularly.

A study found that using 5S raised productivity by 23% and cut mistakes by 47%. Value stream mapping also reduced lead times by 50-80%.

Note: A clean and organized workshop not only helps you work better but also keeps everyone safer.

Caring for Your Tools

Taking care of tools keeps them working well and lasting longer. Predictive and preventive maintenance are great ways to avoid problems.

Predictive maintenance uses data to spot problems early. This lowers downtime by 15% and defects by 87%. Preventive maintenance means checking and fixing tools regularly to keep them in good shape.

Tip: Make a schedule to check and fix your tools. This keeps them reliable and avoids sudden breakdowns.

By caring for your tools, you save money and time. Well-kept tools break less and last longer, so you can focus on your work without delays.

Planning to Reduce Waste

Cutting waste in sheet metal work saves money and helps nature. Careful planning lets you use materials better and create less scrap. Try these five simple ways to lower waste:

Use Lean Manufacturing Ideas

Make your work steps simpler to cut waste. Lean manufacturing removes extra steps and improves how work flows. Check your process for slow spots or repeated tasks. Fixing these saves time and materials.Tip: Draw a map of your workflow to find areas to improve.

Get Modern Tools

Tools like CNC machines make exact cuts and reduce waste. These machines follow programmed steps for perfect results. They can cut tricky shapes with little leftover material.Note: CNC machines cost more at first but save money by reducing waste and working faster.

Plan Material Use Well

Arrange parts on metal sheets to use space wisely. This is called nesting, and it lowers leftover scraps. Special software can help you plan layouts to use every bit of material.Example: Good nesting can cut waste by 30%, saving money and resources.

Recycle and Reuse More

Recycling leftover metal is a great way to cut waste. Set up a system to collect and reuse scraps. Smaller pieces can be used for other projects, lowering the need for new materials.Tip: Work with local recyclers to make sure your scraps are reused properly.

Make Processes Better

Check your work methods often to find wasteful steps. Some tools or techniques might cause too much waste. Fixing these problems makes your work smoother and saves materials.Actionable Advice: Review your processes every month to spot and fix wasteful habits.

By using these tips, you’ll waste less and work smarter. Careful planning helps you use materials wisely, saving money and protecting the planet.

Foxsen’s Role in Sheet Metal Safety and Efficiency

Reliable Safety Gear

Foxsen makes safety gear to keep you safe while working. Their gloves protect hands from sharp edges and burns. Goggles shield your eyes from flying bits during cutting or grinding. Safety boots guard your feet from falling objects. Every product is tested to meet strict safety rules.

Tip: Pick safety gear that fits well. Loose gear can be less safe and uncomfortable.

Using Foxsen’s safety gear helps you focus on work without fear of injuries.

High-Quality Sheet Metal Tools

Foxsen’s tools help you work faster and more accurately. Their plasma cutters make clean cuts on thick metal. Hand tools, like snips and shears, are easy to use and reduce strain. Foxsen’s CNC machines cut automatically, saving time and reducing waste.

Good tools improve your work and lower accident risks. Foxsen’s tools are strong, reliable, and simple to care for, lasting a long time.

Solutions for Workspace Organization

A tidy workspace makes work safer and quicker. Foxsen offers racks and cabinets to store tools neatly. Their workbenches are sturdy and can be adjusted for different tasks. Magnetic holders keep small metal parts organized and out of the way.

Note: A clean workspace saves time and prevents accidents caused by misplaced tools.

Foxsen’s storage solutions help you keep your area neat and ready for work.

Expert Resources for Best Practices

Foxsen offers more than just tools and safety gear. They provide expert resources to help you improve your skills and stay safe while working with sheet metal.

1. Easy-to-Follow Guides and Tutorials

Foxsen shares clear guides and simple tutorials. These explain important topics like using tools correctly, keeping your workspace tidy, and advanced cutting tips. Whether you're new or experienced, these materials help you learn better ways to work and follow industry rules.

Tip: Get Foxsen's free e-books to discover new trends in sheet metal work.

2. Training Videos

Watching videos can make hard tasks easier to learn. Foxsen has helpful training videos that show safe ways to handle sheet metals. You’ll see how to use tools properly, lift heavy sheets safely, and reduce waste while working.

3. Live Webinars with Experts

Foxsen organizes live webinars with skilled professionals. You can ask questions and learn directly from experts. Topics include staying safe, working faster, and trying new techniques for sheet metal tasks.

4. Help and Advice from Experts

Foxsen’s team is ready to help you anytime. You can ask for advice on picking tools, setting up your workspace, or improving safety. Their support helps you use your tools better and keep your workshop safe.

Note: Reach out to Foxsen’s team for free advice on making your workshop better.

Using Foxsen’s expert resources gives you the knowledge to work safely and efficiently. These tools help you get better results and lower risks in your workshop.

Staying safe and working efficiently with sheet metal is very important. It helps protect your body and makes your work better. Using tools and methods that reduce strain can lower risks like muscle pain and bad posture. Foxsen offers great safety gear and expert advice to keep you safe and help you work smarter.

Simple steps like lifting correctly and keeping your workspace tidy can make a big difference. Foxsen’s products and tips can turn your workshop into a safer and faster place to work.

Tip: Try one safety idea today. Small changes can lead to big results over time.

FAQ

What makes Foxsen’s safety gear special?

Foxsen creates safety gear that is strong and comfy. Every item follows strict safety rules and gives great protection. The gear fits well, making it safer and easier to wear for long hours.

How can I waste less in my sheet metal workshop?

Plan how you use materials wisely. Use nesting software to fit parts better and make less scrap. Recycle leftover metal and buy accurate tools like CNC machines. These steps save money and reduce waste.

Why does workspace organization matter for efficiency?

A tidy workspace prevents accidents and saves time. You can find tools quickly and avoid tripping. Using systems like 5S helps make your workspace neat and boosts how well you work.

How often should tools be checked?

Check tools before using them every time. Regular checks stop accidents and help tools last longer. Make a schedule to track fixes and keep your tools in good shape.

Does Foxsen help beginners learn?

Yes! Foxsen offers guides, videos, and tutorials for new learners. You’ll learn safe ways to handle tools, work smarter, and stay safe. Live webinars with experts also teach useful tips to improve your skills.