Laser cutting is now a key part of modern manufacturing, especially when it comes to sheet metal laser cut processes. It offers great accuracy and speed for cutting sheet metal. A strong laser, controlled by advanced CNC systems, makes detailed designs possible. For example, fiber lasers can cut with accuracy as small as 0.1 mm, making them perfect for projects needing fine details. Laser cutting also reduces waste by up to 50% using smart nesting methods, which saves both materials and money. It works up to five times faster than older methods, making it quicker and more precise.

By mixing CNC programming with sheet metal laser cut techniques, work becomes easier and faster. This teamwork allows for quick and accurate cuts while maintaining high quality. Whether making prototypes or producing many parts, laser cutting provides excellent results every time.

Key Takeaways

Laser cutting is very accurate, cutting as small as 0.1 mm. This makes it great for detailed designs.

Smart nesting methods can cut material waste by half. This saves money and resources.

Fiber lasers use less energy and need little upkeep. They are a good choice for cutting thin to medium metals.

Taking care of laser machines, like cleaning parts and checking coolers, keeps them working well for a long time.

Laser cutting can work with many materials and tricky shapes. This helps industries make things faster and better.

Overview of Laser Cutting Technology

How laser beams work in the laser cutting process

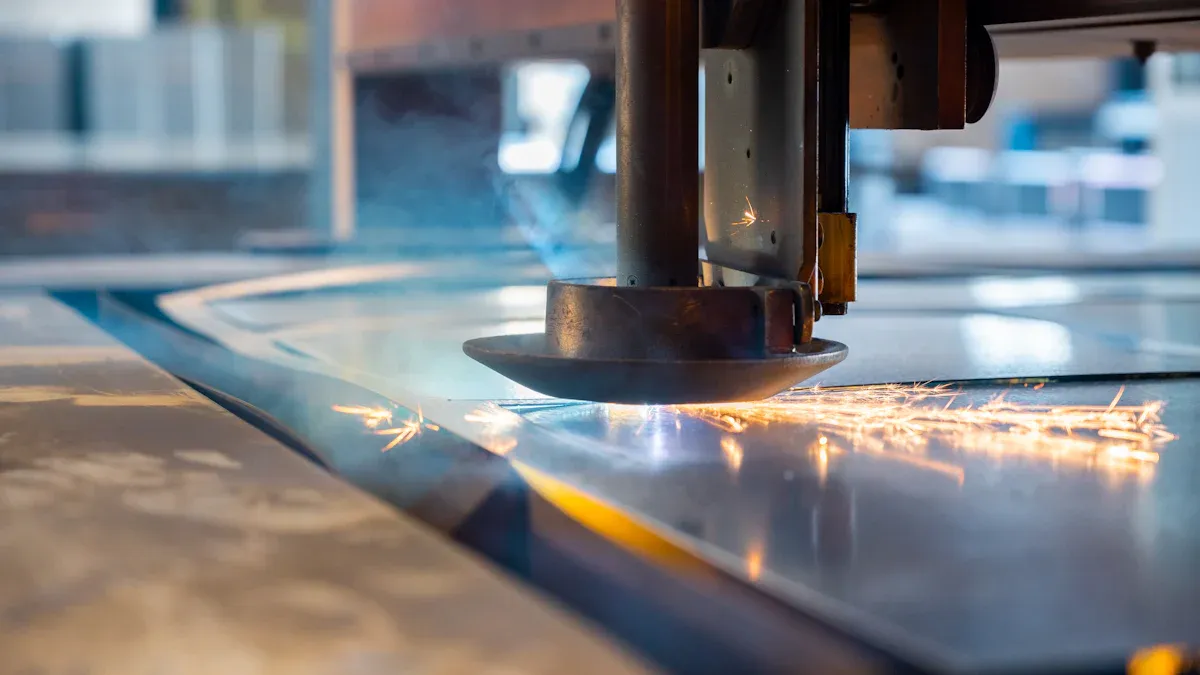

Laser beams are important for cutting sheet metal. They focus energy on the metal to heat it quickly. This heat makes the metal melt, burn, or turn into gas. The way the laser works depends on the metal's properties, like how shiny it is or how well it conducts heat. Metals like steel and aluminum absorb laser energy well, making cutting easier. When laser light hits the metal, it heats up fast and forms a melted pool. This melted metal is pushed away, leaving clean cuts behind.

Choosing the right laser type is key for good results. Fiber lasers work well for cutting metal because they deliver strong energy. Their light matches how metals absorb energy, cutting efficiently without overheating nearby areas. This lets you make detailed designs while keeping the metal strong.

Key components of a laser cutting machine: laser source, optics, and CNC control

Laser cutting machines have three main parts: the laser source, optics, and CNC control. The laser source creates the powerful beam needed for cutting. Fiber lasers are popular because they use energy efficiently, saving power and cutting better.

The optics system, like lenses and nozzles, focuses the laser beam on the metal. These parts keep the cuts accurate and protect the machine from dirt. The CNC control system reads design files and moves the laser head. This makes cutting easy and consistent, even for tricky shapes. Together, these parts help the machine cut metal with great precision and quality.

Role of assist gases in sheet metal laser cut operations

Assist gases help make laser cutting faster and cleaner. Gases like oxygen, nitrogen, and air are used during cutting. Oxygen helps cut thick metals by reacting with the melted material to speed up cutting. Nitrogen is good for clean edges because it stops rust and stains.

Compressed air is cheaper and works well for thin metals. It cools the cutting area and removes dirt, keeping the process smooth. The type of gas used depends on the metal and the finish you want. Using the right gas makes cutting quicker, edges cleaner, and reduces extra work later. Assist gases are important for keeping laser cutting machines efficient and accurate.

Step-by-Step Laser Cutting Process

Getting the sheet metal and design file ready

Getting the sheet metal and design file ready is very important. First, pick the right material and thickness for your project. Most projects use sheet metal between 1 mm and 10 mm thick. This range balances cost and cutting quality.

For the design file, use vector formats like SVG, AI, EPS, or DXF. These formats work well with laser machines and ensure precise cuts. Avoid raster formats like PNG or JPG because they lack detail. Turn text into outlines and separate cutting lines from engraving lines. Make sure all shapes are closed to get clean cuts.

To save material, arrange pieces smartly using nesting techniques. Leave enough space between shapes to avoid problems during cutting. Before starting, simulate the cuts to check the design and adjust settings for the material and thickness.

Cutting process: focusing the laser and working with metal

The cutting starts by focusing the laser beam on the metal. The machine uses lenses to make the beam very strong in one spot. This melts, burns, or turns the metal into gas.

Several things affect how well the laser cuts:

Beam Divergence: A focused beam makes cleaner cuts.

Beam Waist: A smaller waist means sharper and more detailed cuts.

Rayleigh Range: A longer range keeps the beam focused over more distance.

Power Density: More power makes cutting faster and easier.

Beam Quality (M²): Better quality helps cut tricky shapes with precision.

When the laser hits the metal, it heats up fast and melts. Gases like oxygen or nitrogen blow away the melted metal, leaving smooth edges. This makes the cuts neat and reduces extra work later.

Post-processing: cleaning and finishing the edges

After cutting, the edges need cleaning to meet quality standards. Cleaning removes leftover bits that could affect the product's look or use.

Polished edges improve how the metal performs. Research shows polished edges can expand holes by 62%-75%, compared to 21.8% for unpolished ones. This happens because polishing changes the edge structure, making it stronger and more flexible.

Check the edges for sharpness and smoothness to ensure safety. Use polishing tools or chemicals to make the edges even better. By spending time on post-processing, you create high-quality parts ready for use.

Types of Lasers Used in Laser Cutting Machines

CO2 lasers: strengths and common applications in sheet metal fabrication

CO2 lasers are great for cutting thick materials. They work well with metals and non-metals like wood and acrylic. These lasers use a 10.6μm wavelength, which helps them cut smoothly. They are fast when cutting materials thicker than 8 mm. This makes them useful in construction and heavy machinery industries.

But, CO2 lasers cost more to run because they use a lot of electricity and need laser gases. Even so, they are the best choice for cutting thick plates. For example, a 4900-watt CO2 laser can cut 8 mm metal at 1900 mm/s. This shows how strong and efficient they are for tough materials.

Fiber lasers: advantages and uses in modern laser cutting machines

Fiber lasers are very precise and efficient. They use a 1.06μm wavelength, which metals absorb well. This makes them perfect for cutting thin to medium-thick plates. They save energy with a 30% photoelectric conversion rate, lowering costs.

Fiber lasers are faster for materials thinner than 4 mm. For instance, a 500-watt fiber laser can cut 1 mm metal at 90 mm/s. This is faster than CO2 lasers for thin materials. They also need less maintenance and no laser gases, making them cheaper to use. Industries like aerospace and electronics benefit from these features.

Nd:YAG lasers and diode lasers: specialized applications in laser cutting

Nd:YAG and diode lasers are used for special tasks like cutting, welding, and marking. Nd:YAG lasers, with a 1.06μm wavelength, are good for thin plates and marking metals. Diode lasers are cheaper and more powerful now, making them popular.

Diode lasers are great for welding tricky shapes and mixed materials. Nd:YAG lasers may not work as well for these tasks. Both types are used in industries needing high precision, like medical tools and decorative metalwork. They are flexible and create detailed designs with smooth finishes.

Diode lasers are now affordable and powerful, competing with Nd:YAG lasers.

Both types are good for cutting and marking nonmetals, offering many uses.

Diode lasers are best for welding complex shapes and mixed materials.

Advantages of Laser Cutting for Sheet Metal Fabrication

High precision and minimal material waste in sheet metal laser cut processes

Laser cutting is very accurate, making it great for detailed work. It creates clean cuts while wasting less material. Special computer models predict heat and material removal to improve cutting. Research shows laser machines make smoother surfaces and smaller heat-affected zones (HAZ). This ensures parts meet strict quality rules.

Foxsen’s laser cutting service provides precise cuts for your projects. By using less material, you save money and help the environment.

Faster cutting speeds compared to traditional methods

Laser cutting is much faster than older cutting methods. For example, it can cut low carbon steel at 15,000 px/min and polypropylene resin at 30,000 px/min. Waterjet cutting is slower, working at only 1–20 inches per minute.

Laser cutting speeds range from 20 to 1000 inches per minute.

Waterjet cutting is slower, with speeds of 1 to 20 inches per minute.

Foxsen’s laser cutting technology speeds up production, helping you meet deadlines. Whether for prototypes or large orders, our service is quick and reliable.

Versatility in cutting complex shapes and a variety of materials

Laser cutting works well with many materials and detailed designs. It can make parts with tolerances as small as 0.0005 inches. This makes it perfect for industries needing precise patterns. It cuts materials like copper, aluminum, stainless steel, and titanium.

Laser cutting creates detailed designs with smooth edges and little waste.

It works with many materials, including metals like stainless steel and titanium.

The process leaves clean edges with no rough spots, ensuring high quality.

Foxsen’s machines handle complex projects with ease. Whether you need precise cuts or custom designs, we deliver safe and efficient results.

Common Challenges and Solutions in Laser Cutting

Fixing dross and burr issues during laser cutting

Dross and burrs can lower the quality of cuts. These flaws happen when melted metal hardens on the edges or bottom. To fix this, adjust laser settings like focus, speed, and gas pressure. For example, slowing down the cut or raising gas pressure can reduce dross.

There are different types of burrs that may appear:

Cut-Off Burr: Happens when material drops during cutting.

Poisson Burr: Forms from downward pulling on the metal.

Rollover Burr: Appears when the tool lifts off the metal.

Tear Burr: Occurs when the sheet bends during cutting.

Thermal Burr: Forms when melted metal hardens on the surface.

A report shows how adjusting settings can improve edge quality:

By tweaking your laser settings, you can get cleaner cuts and save time on finishing.

Avoiding warping in thin sheet metals

Thin metals can warp if too much heat builds up. To stop this, use smart nesting software to arrange parts better. This reduces torch movement and spreads heat evenly.

Changing the cutting order also helps. Start cutting inside shapes first to lower stress on the metal. Use supports like slats or vacuum tables to keep the material steady and cool. These steps improve cut quality and prevent accidents caused by shifting metal.

Keeping laser cutting machines in good shape

Regular care keeps laser machines working well. Clean lenses and mirrors to keep the beam steady and accurate. Check the cooling system to avoid overheating. Lubricate moving parts to reduce wear and keep the machine running smoothly.

Studies show how maintenance improves performance:

By following a maintenance routine, you can boost efficiency and ensure your machine produces top-quality cuts.

Practical Uses of Laser Cutting in Different Industries

Making Cars and Airplanes

Laser cutting is very important for making cars and airplanes. It helps create car parts like body panels, interiors, and frames. For airplanes, it works well with light materials and detailed shapes needed for modern designs.

This technology makes strong and neat parts for both looks and strength. It uses less energy, which saves power and is better for the environment. Also, it works fast to meet the high demand for car and airplane parts.

High accuracy improves product quality.

Less wasted material saves money.

Handles tricky designs, making it very useful.

Electronics and Everyday Products

Laser cutting has changed how electronics and daily items are made. It can cut many materials like metal, plastic, and fabric. For example, it makes phone parts and circuit boards with great detail. This reduces waste and skips the need for hard tools.

More companies are using laser cutting for electronics and goods. Experts say this industry will grow quickly from 2024 to 2030. The reason is that laser cutting saves time and money while being very flexible.

The value of laser cutting machines is rising. In 2022, sales were about USD 5,280 million. By 2032, they may reach USD 59,426 million, growing at 8.7% yearly. This shows how much companies trust this advanced technology.

Building and Architecture

In building and design, laser cutting helps make detailed and exact cuts. It works on materials like metal, glass, and wood. This is great for making fancy panels, strong parts, and custom decorations.

Laser cutting lets architects create complex designs easily. It also works fast, keeping projects on time. For example, it can make detailed building fronts or special indoor designs. Plus, it wastes less material, which is good for eco-friendly building.

Foxsen’s laser cutting services support these industries with top-quality solutions. Whether you need airplane parts or creative building designs, Foxsen delivers reliable and precise results.

Laser cutting has changed how sheet metal is made. It offers great accuracy, speed, and flexibility. Companies like Akışlar Metal now earn 50% more and finish jobs twice as fast using this method. It can cut materials up to 40mm thick, opening new possibilities. The metal fabrication market is growing by 9.54% each year. Industries like aerospace and automotive depend more on laser technology. Learning how it works can help you improve efficiency and handle different project needs.

FAQ

1. What materials can laser cutting machines cut?

Laser cutting works on metals like steel, aluminum, and titanium. It also cuts non-metals like wood, acrylic, and glass. The material depends on the laser type and project needs.

2. How is precision achieved in laser cutting?

Precision comes from CNC programming, focused lasers, and assist gases. Adjusting beam quality and power ensures clean cuts and fine details.

3. Is laser cutting good for the environment?

Yes, laser cutting reduces waste with smart nesting techniques. It uses less energy than older methods, making it eco-friendly.

4. Can laser cutting create detailed designs?

Yes! Laser cutting makes complex patterns and shapes easily. It can achieve tolerances as small as 0.0005 inches, perfect for precise work.

5. How often should laser cutting machines be maintained?

Regular care is important. Clean optics weekly, check cooling monthly, and lubricate parts every three months. This keeps the machine working well and lasting longer.