You might wonder how factories make sheet metal copper busbars quickly. It begins with careful process control. Statistical Process Control (SPC) helps keep quality high and waste low. Workers watch production closely to find problems early. They fix issues before defects happen. Tools like capability indices and reducing variability improve efficiency. This ensures every sheet metal copper busbar works well and meets strict rules. These steps save time, cut costs, and make strong, conductive busbars.

Key Takeaways

Picking pure copper sheets is very important. Pure copper helps busbars work better and last longer.

CNC machines make production faster and easier. They cut precisely, wasting less material and making more parts.

Surface treatments like smoothing edges and adding tin make busbars safer and stronger. These steps stop rust and keep edges smooth.

Automated testing and smart computers improve quality checks. They find problems early to make sure busbars are made right.

Using eco-friendly methods reduces waste. Recycling copper and green practices help protect the environment.

Material Preparation for Sheet Metal Copper Busbars

Picking Pure Copper Sheets

The first step is choosing very pure copper. This type of copper is great for carrying electricity. Electrolytic Tough Pitch (ETP) copper has 99.90% purity. It helps move energy efficiently and works well in electrical projects.

Why pure copper is important:

It carries electricity better, saving energy.

It makes busbars stronger and more reliable.

It helps electrical systems work more efficiently.

Choosing the right copper sheets is key to making high-quality busbars.

Cleaning, Pre-Treatment, and Melting Steps

Copper sheets need cleaning before shaping into busbars. Cleaning removes dirt and prepares the copper for the next steps. Heat treatment improves the surface and electrical properties.

After cleaning, copper is melted to get the right texture for shaping. This step keeps the process efficient.

Annealing for Better Copper Properties

Annealing uses heat to make copper easier to work with. It softens the metal, making it simple to bend and shape. It also reduces stress inside the copper, improving its strength.

Annealing ensures copper sheets are ready for modern electrical systems and efficient production.

Cutting and Shaping Techniques

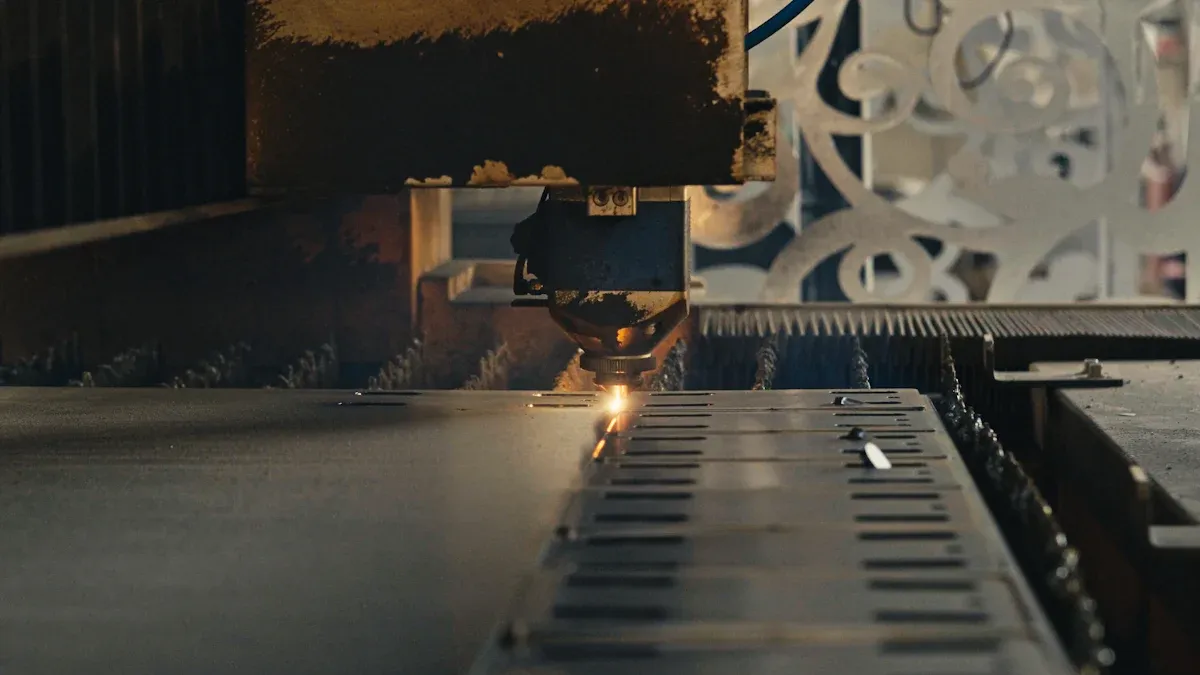

Precision Cutting with CNC Machines

CNC machines are important for cutting sheet metal copper busbars accurately. They use computers to control cutting, punching, and bending. This process reduces waste and increases speed.

Why CNC Machines Are Useful:

Cuts with high accuracy, as close as ±0.1mm.

Makes production consistent and lowers mistakes.

Uses materials efficiently, saving over 95% of copper.

CNC machines can cut up to 200 pieces every hour. This makes them perfect for making copper busbars for power systems.

Advanced Shaping and Bending Methods

Shaping and bending copper busbars need special tools for modern designs. CNC bending machines are great for this job. They make detailed shapes while keeping the busbars strong.

These methods help busbars fit into small systems like motor controls and battery setups. Using these tools saves time and reduces wasted materials.

Customization for Specific Applications

Custom designs are needed for busbars in different power systems. Manufacturers adjust busbars to match project needs for better performance.

Electric Cars: Manage power between batteries, motors, and controllers.

Charging Stations: Custom busbars for fast charging.

Motor Control Systems: Precisely shaped busbars for compact designs.

Battery Systems: Special busbars for connecting battery cells.

Trains and Transit: Strong busbars for electric transportation.

Companies like Storm Power use CNC machines and lasers to make custom busbars. These designs save energy, lower heat, and last longer. Custom busbars also help the environment by reducing waste and lasting a long time.

Surface Treatment and Coating

Making Edges Smooth with Deburring and Polishing

Deburring and polishing help prepare copper busbars for use. These steps remove rough edges, burrs, and small flaws. Smooth edges make busbars safer and work better.

Why deburring and polishing are important:

Remove sharp edges for safer handling.

Make parts fit together perfectly during assembly.

Strengthen busbars to last longer under stress.

Industries like car-making and airplanes use advanced deburring tools. These methods ensure busbars are strong and work well in tough conditions.

Tin Coating to Stop Rust

Tin coating protects copper busbars from rust and damage. A thin tin layer stops oxidation and makes busbars last longer. Tin also helps busbars carry electricity better.

Tin coating keeps busbars working even in bad environments. This step is very important for industries needing strong and reliable parts.

Adding Layers for Better Busbar Performance

Lamination improves how copper busbars work by saving energy and managing heat. Laminated busbars have layers that move electricity efficiently and block interference.

Why lamination is helpful:

Reduces energy loss and interference.

Spreads heat evenly to stop overheating.

Makes busbars more reliable in powerful systems.

The layered design of laminated busbars handles high currents well. This setup boosts performance and makes busbars last longer. Laminated busbars are great for modern electrical systems.

Assembly and Final Processing

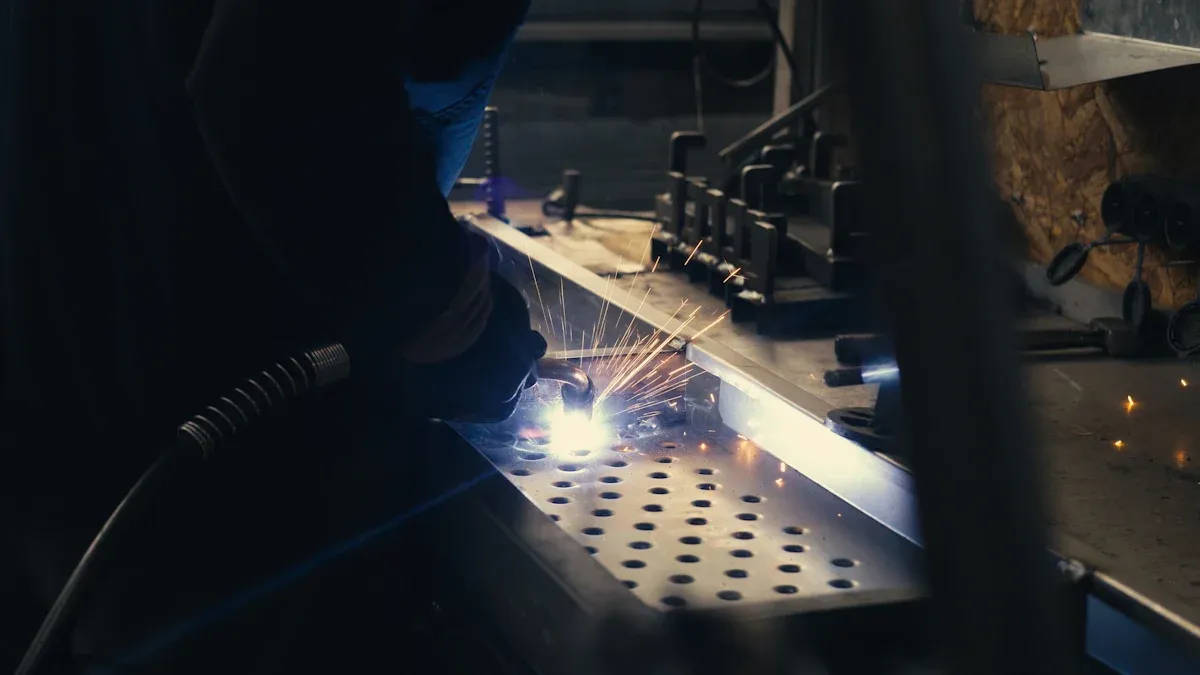

Joining Techniques and Proper Joint Design

Joining methods are key to making strong copper busbars. Techniques like hole hemming, clinching, and tube fit joining create solid connections. Each method works best for specific uses. For instance, tube fit joining uses pressure to make tough joints. This is great for high-stress systems like power supplies.

Good joint design helps busbars carry electricity better. Reducing resistance at joints improves conductivity and lowers heat. This is important for systems like motor controls and batteries, where reliability matters most.

Final Adjustments and Dimensional Inspections

Final adjustments make sure busbars are the right size and shape. Inspections check if they fit well in systems like power supplies. These checks use data to find errors and ensure accuracy.

Inspections help during testing, design, and production stages.

They lower the chance of unnoticed problems by about 3.5%.

Quality checks improve production and ensure high standards.

These inspections confirm the busbars work properly. They ensure the busbars meet strict rules for systems like electric cars and chargers.

Packaging for Safe Transportation

Packaging keeps copper busbars safe during shipping. Custom packaging stops damage from water, bumps, or rust.

Packaging often includes foam or shrink wrap for protection. These materials keep busbars safe from damage. This ensures they are ready to use in systems like power supplies.

Quality Control and Efficiency Innovations

Automated Testing for Electrical Conductivity

Automated tests check how well copper busbars carry electricity. These tests use sensors and software to find small problems. This helps make sure the busbars meet strict rules.

For example, tests can spot issues like impurities or defects. Fixing these early keeps the busbars working well. Companies like Foxsen use this to make reliable busbars for power systems.

Tests also check if busbars handle high currents without overheating. This helps improve energy use in electric cars and renewable energy systems.

Use of Robotics and AI in Manufacturing

Robots and AI have changed how copper busbars are made. Robots do tasks like cutting and shaping with great accuracy. This reduces waste and keeps quality high.

AI looks at production data to improve processes and find problems. For example, AI can suggest fixes for CNC machines to work better. This saves time and speeds up production.

Robots also help build busbars for complex systems like converters. Using robots and AI makes production faster and more efficient. It also reduces waste, helping the environment.

Sustainable Practices to Minimize Waste

Making copper busbars now focuses on being eco-friendly. Copper can be recycled many times without losing quality. Companies like Foxsen use green methods to cut pollution and save resources.

Recycled copper keeps its quality after reuse.

Eco-friendly methods lower waste and emissions.

Busbars last over 50 years, reducing replacements.

These steps help the environment and improve energy use. Long-lasting busbars save materials and work well in power systems.

By using sustainable methods, companies help the planet and meet demand for better busbars. This supports global goals for cleaner energy and less waste.

Making sheet metal copper busbars uses smart tools and careful checks. These steps make sure the busbars meet strict rules for electrical systems. The busbars are strong, work well, and help the environment. New ideas help manufacturers make designs that waste less and work better. This makes electrical systems more reliable and eco-friendly. These improvements also help save energy and support green practices. With these changes, busbars meet the need for better and efficient power solutions.

FAQ

What do copper busbars do in electrical systems?

Copper busbars move electricity between parts in a system. They handle high power levels and keep energy flowing smoothly. Their strength and ability to carry electricity make them important for things like switchgear, electric cars, and green energy setups.

How do makers stop copper busbars from rusting?

Manufacturers cover copper busbars with tin or special layers. These coatings protect them from rust and damage. This helps the busbars stay strong and carry electricity well over time.

Why is heating (annealing) needed when making copper busbars?

Annealing heats copper to make it softer and easier to shape. It also helps copper carry electricity better and removes stress inside. This makes sure the busbars can handle high power without breaking or getting too hot.

How do machines help make busbars better?

Machines like CNC tools and robots make busbars more accurate. They use less material and keep the quality the same every time. These machines also create designs that work well with modern electrical systems.

Can old copper busbars be reused?

Yes, copper busbars can be recycled easily. Copper stays just as good after being reused. Recycling helps cut waste and supports eco-friendly ways to make electrical systems.