Modern factories use sheet metal processing to make strong, exact parts. This method is key to manufacturing, helping create detailed designs quickly and easily.

Look at the facts. In 2024, the global sheet metal market was worth $3.5 billion. By 2033, it is expected to grow to $5.8 billion, increasing by 6.1% each year. This shows how important it is in industries like cars, airplanes, and buildings. For instance, making lightweight electric cars needs advanced sheet metal to create strong but light pieces. Also, more cities mean more need for good building materials, like roofs and frames.

Sheet metal processing helps meet these needs while staying accurate and high-quality. It is a must-have in today’s fast-changing manufacturing world.

Key Takeaways

Sheet metal work is important for making strong, exact parts. It helps industries like cars, planes, and buildings.

Main methods include cutting, shaping, joining, and finishing. Each method improves speed and product quality.

Machines and smart tools make work faster and more accurate. This saves money and helps the environment.

Finishing steps like polishing, painting, and coating make parts last longer. They also make parts look better and meet high standards.

Eco-friendly practices like recycling and saving energy reduce waste. These help make manufacturing better for the planet.

Key Techniques in Sheet Metal Processing

Sheet metal processing uses many methods to turn flat sheets into useful parts. These techniques help make manufacturing precise, fast, and flexible. Let’s look at the main methods.

Cutting Methods (Laser Cutting, Plasma Cutting, Waterjet Cutting)

Cutting is the first step in working with sheet metal. It breaks large sheets into smaller, usable pieces. Laser cutting is very accurate and quick. It uses a focused laser beam to cut materials with little waste. This method is great for detailed designs and patterns. Plasma cutting uses a hot plasma arc to cut thicker materials. It’s faster than laser cutting but less exact. Waterjet cutting uses high-pressure water mixed with abrasives. It avoids heat damage, making it good for heat-sensitive materials.

Key Advantages:

Laser cutting is precise, fast, and reduces waste.

Plasma cutting works well for thick materials and is affordable.

Waterjet cutting avoids heat damage and handles many materials.

New technology has made these methods better and more accurate. For example, laser cutting is now the most popular choice because of its advanced features.

Forming Processes (Bending, Hydroforming, Stamping)

Forming shapes sheet metal without removing any material. Bending is simple and uses a press brake to bend sheets at angles. Stamping presses sheets into shapes using a die. It’s fast and consistent, making it great for mass production.

Hydroforming is a more advanced forming method. It uses high-pressure fluid to create complex shapes. This process makes lightweight but strong parts. For instance, hydroforming is used in cars to make parts like A-pillars and beams. These parts are lighter and stronger, improving car performance.

Hydroforming works well with CNC machines for better precision. This makes it a top choice for industries needing strong, lightweight parts.

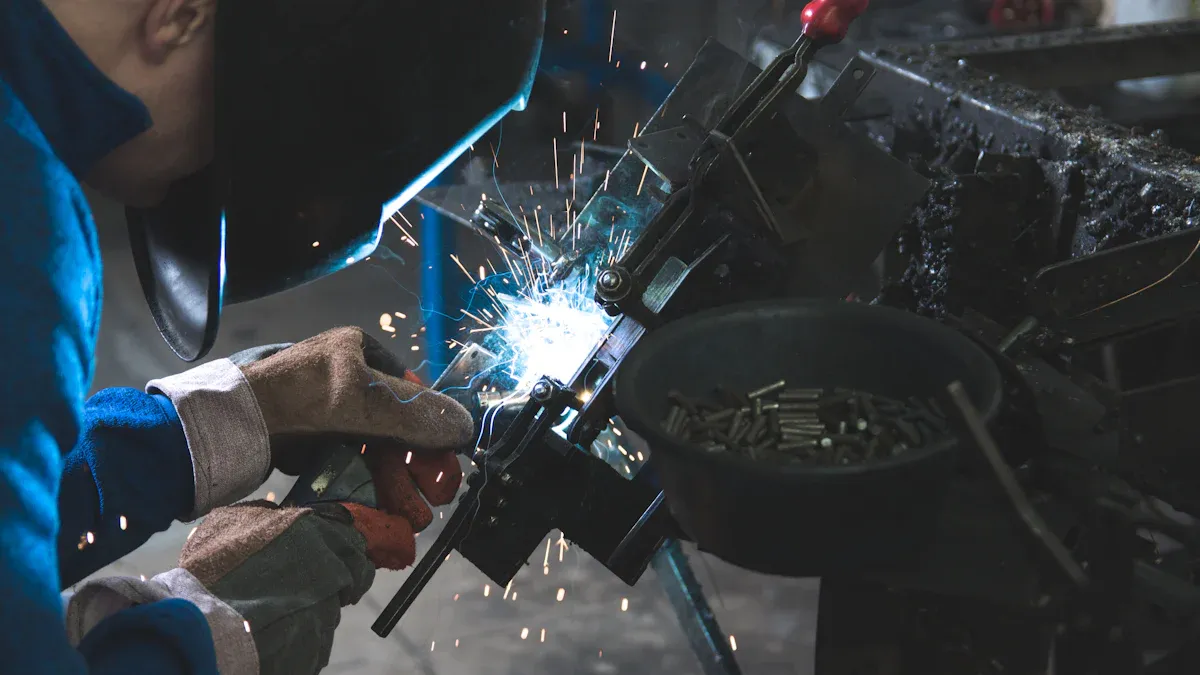

Joining Techniques (Welding, Riveting, Adhesive Bonding)

After cutting and forming, joining methods connect sheet metal parts. Welding is common and uses heat to join metals, creating strong bonds. Riveting uses fasteners to connect parts where welding isn’t possible. Adhesive bonding uses glue to join materials. It’s good for lightweight parts and materials that can’t handle heat.

Key Benefits:

Welding creates strong and lasting joints.

Riveting works for materials that can’t be welded.

Adhesive bonding is great for lightweight, heat-sensitive parts.

Automation has improved these methods. Robots and machines make joining more precise and efficient. This saves money and boosts production, making these techniques essential in modern manufacturing.

Finishing Processes (Polishing, Coating, Anodizing)

Finishing processes are important for making sheet metal parts better. These methods improve how parts look and protect them from damage. Three common finishing methods are polishing, coating, and anodizing.

Polishing

Polishing makes metal surfaces smooth and shiny. It removes scratches, rough spots, and flaws. This process helps parts look nice and stay clean. Polished surfaces are great for things like electronics or decorations.

Polishing also makes parts stronger. Smooth surfaces stop dirt and water from causing rust. After stamping, polishing ensures the product is high-quality and durable.

Coating

Coating adds a protective layer to metal surfaces. This layer can be paint, powder, or other materials. Coatings stop rust, protect against chemicals, and make parts look better. For example, car parts are coated to handle bad weather.

The type of coating depends on the job. Some coatings handle heat, while others add color or shine. Coating is great for stamped parts, keeping them strong and good-looking.

Anodizing

Anodizing is a special process for aluminum. It creates a strong, protective layer on the surface. This layer stops rust and makes the metal harder. Industries like aerospace and electronics use anodizing for lightweight, tough parts.

Anodized parts last longer and resist damage better. This process is perfect for making products last. For example, anodized aluminum in phones is strong and stylish.

Tip: Pick the right finishing process for your project. Polishing is best for looks, coating protects well, and anodizing is great for aluminum.

Benefits of Finishing Processes

Finishing methods like polishing, coating, and anodizing have many benefits:

They make metal parts last longer by stopping rust.

They make parts harder and less likely to wear out.

They fix and protect old parts, helping them last longer.

Anodizing gives aluminum extra strength and protection.

Using these finishing methods ensures your sheet metal projects are strong and long-lasting.

Applications of Sheet Metal in Manufacturing

Sheet metal is crucial for making parts in many industries. Its strength and flexibility make it perfect for high-quality components. Let’s see how it helps three major fields.

Automotive Components (Body Panels, Chassis Parts)

Sheet metal is key for car body panels and chassis parts. These parts need to be strong and fit perfectly for safety. CNC machines help create accurate designs for these components. This ensures every piece fits well in the car's structure.

To keep quality high, companies follow strict rules like ISO 9001:2015. They also check for problems using tests like ultrasonic and dye penetrant testing. Trusted suppliers, like Foxsen, provide good materials to make safe and durable car parts.

Sheet metal improves cars in many ways:

Lighter parts save fuel and extend electric car ranges.

Faster production keeps up with new car designs.

These improvements show how sheet metal helps car manufacturing grow.

Aerospace Structures (Aircraft Skins, Engine Components)

The aerospace field uses sheet metal for strong, lightweight parts. Aircraft skins and engine parts must handle tough conditions but stay light. Hydroforming and stamping make complex shapes with great accuracy, meeting strict standards.

Anodizing makes aluminum parts stronger and stops rust. This process helps parts last longer, like in airplane bodies, reducing repairs and boosting performance.

Being eco-friendly is also important. Sheet metal production cuts waste and saves energy. This supports green goals, like making fuel-saving engines. It helps the aerospace industry reduce its carbon footprint.

Construction Materials (Roofing, HVAC Systems)

In construction, sheet metal is used for strong, useful materials. Roofing panels and HVAC systems are common examples. These products must handle bad weather and last a long time. Coatings, like powder coating, protect metal from rust and improve its look.

Growing construction in places like North America and Asia-Pacific increases sheet metal demand. Big projects need this material for its strength and flexibility. Companies like Foxsen provide top-quality sheet metal for modern buildings.

Sheet metal also makes HVAC systems more efficient. Lightweight ducts and panels lower building weight and improve airflow. This saves energy and supports eco-friendly building designs.

Did You Know? Asia-Pacific is growing fast in sheet metal use due to industrial growth and government projects in countries like China and India.

Consumer Electronics (Enclosures, Frames)

Sheet metal is important in making consumer electronics. It is used for enclosures and frames that protect delicate parts. These enclosures keep devices like computers, phones, and appliances safe. They also make sure the devices work well and last long.

Sheet metal is strong but lightweight, which is great for portable devices. Laptops and tablets can have slim designs without losing durability. Manufacturers can also customize sheet metal to create unique looks for their products. This makes electronics both stylish and sturdy.

Sheet metal is also used in factories and industrial machines. For example, it protects electronics in production lines and robotic arms. These enclosures keep parts safe from dust, heat, and damage. They also help machines work smoothly in tough conditions. Below are some uses and benefits:

Sheet metal enclosures also help manage heat in electronics. Gaming consoles and desktop computers get hot when used. Sheet metal frames can include heat sinks and vents to cool them down. This keeps devices working well and lasting longer.

Tip: Choose materials that resist heat, prevent rust, and allow flexible designs. These features make electronics reliable and attractive.

Technology is improving how sheet metal is used in electronics. New designs include better heat control and modular features. These changes make products more useful and eco-friendly, meeting modern needs.

Benefits of Sheet Metal Processing in Modern Manufacturing

Precision and Customization

Sheet metal processing helps make parts with great accuracy. Methods like hydroforming and stamping create exact shapes every time. This reduces mistakes and cuts down on wasted materials.

Factories using precise tools save up to 40% in costs. Better material use and faster work lower expenses while keeping quality high. Fixing quality issues, which can take 15-20% of sales, becomes less costly with these methods.

Another big benefit is customization. You can change designs to fit special needs. This works well for cars, airplanes, or electronics. Custom parts help your products stand out in busy markets.

Cost-Effectiveness and Material Efficiency

Modern sheet metal methods save money and materials. Using thinner sheets keeps products strong but costs less. "Think thin" ideas cut material use by 20% and energy by 70%.

These eco-friendly ways also boost profits. For example, hydroforming makes light but strong parts. This reduces waste and saves energy. These methods help both the planet and your budget.

Integration of Automation and Smart Technologies

Automation and smart tools make sheet metal work faster and better. Machines track their own performance to stay efficient. Automated systems adjust settings for perfect results during forming.

Smart tools predict when machines need fixing, avoiding breakdowns. IoT lets machines change based on real-time needs, saving resources. Tracking tools like OEE measure how well machines work, helping improve processes.

Better systems mean fewer delays and smarter choices. Automation speeds up production, meeting deadlines without losing quality. These tools make sheet metal processing a key part of modern manufacturing progress.

Sustainability and Eco-Friendly Practices

Sustainability is very important in manufacturing today. Sheet metal processing helps create greener solutions for the planet. Using eco-friendly methods reduces waste, saves energy, and protects nature.

Reducing Material Waste

Advanced methods like laser cutting and hydroforming cut down waste. These techniques use every piece of metal efficiently. For example, laser cutting makes exact shapes with little leftover scrap. This saves materials and lowers costs.

Did You Know? Smart material use can cut waste by 30%, making manufacturing greener.

Energy Efficiency

Modern machines use less energy during sheet metal processing. CNC technology helps machines work only when needed. This saves power and reduces pollution. Lightweight metal parts, like those in electric cars, also improve energy use.

Recycling and Reusability

Sheet metal can be recycled easily. Old or unused parts are melted and reused without losing quality. Recycling cuts the need for new materials and reduces mining pollution.

Supporting Green Goals

Using sustainable sheet metal practices supports global climate efforts. Many companies earn eco-friendly certifications like ISO 14001. These show care for the environment and attract green-minded customers.

Tip: Start by recycling scrap metal and using energy-saving machines. Small steps lead to big changes.

Eco-friendly sheet metal processing helps both the planet and businesses. It’s a smart way to succeed while protecting the Earth.

Challenges and Future Trends in Sheet Metal Processing

Overcoming Material Limitations

Working with sheet metal can be tricky due to material issues. If you ignore how metals behave, parts may crack or tear. Picking the wrong metal can make parts weak or unsuitable for certain uses.

Tiny flaws in sheet metal are another problem. These defects are hard to see with regular tools but can weaken the structure. For example, large sheets need many cameras to check for flaws. Shiny surfaces cause glare, making it harder to spot problems. Fast production lines also make manual checks difficult, leading to more mistakes.

Different metal thicknesses bring their own challenges. Thin sheets under 1 mm can bend or warp easily. Very thin sheets cost more to process. Sheets between 1-6 mm are harder to work with and cost more too. Solving these problems needs better inspection tools and flexible solutions.

Tip: Always check the metal's thickness and properties before starting. This saves materials and improves results.

Adapting to Technological Advancements

The sheet metal industry is changing fast with new technology. Methods like hydroforming, laser cutting, and 3D printing make work faster and more accurate. These tools help create complex shapes and save time without needing special molds.

Customers now want unique designs and smaller orders. Using flexible manufacturing methods helps meet these demands while keeping quality high. Being eco-friendly is also important. Machines that use less energy and recyclable materials help protect the environment and meet industry rules.

Automation and AI are making sheet metal work smarter. Machines with IoT can adjust settings instantly for better results. These tools improve tasks like stamping and hydroforming, making them easier and more reliable.

Workforce Training and Skill Development

New technology means workers need better skills to use modern machines. Training programs help employees learn the latest tools and methods. Hands-on lessons from experts improve teamwork and problem-solving skills.

Groups like SMART spend millions each year on worker training. Programs under the National Apprenticeship Act give workers a clear path to learn new skills. These programs not only teach technical knowledge but also offer long-term career growth.

Did You Know? Over half of fabrication mistakes happen because of poor material choices. Teaching workers to pick the right materials can lower these errors.

Investing in training helps workers handle new tools like hydroforming and stamping. This boosts efficiency and prepares your business for future challenges.

New Trends in AI and Robotics

AI and robots are changing how sheet metal is made. These tools make work smarter, quicker, and more efficient. Factories can now produce better parts with less effort.

Important Trends in AI and Robotics

AI for Quality Checks

AI systems find flaws in sheet metal instantly. Cameras and sensors spot tiny defects people might miss. This ensures all parts are high-quality. AI also warns about problems early, saving money and time.Robots for Cutting and Forming

Robots do tasks like bending, stamping, and cutting. They are faster and more accurate than humans. For example, robotic arms with lasers can cut detailed shapes easily. This speeds up production and keeps results consistent.AI for Machine Maintenance

AI tools watch machines and predict when repairs are needed. This stops sudden breakdowns and keeps work on track. Fixing issues early saves both time and money.

Did You Know? AI can cut machine downtime by 30%, making factories more efficient.

How AI and Robotics Help Sheet Metal Work

AI and robots also allow custom designs. Machines can be programmed to make special parts for different projects. This helps meet customer needs and stay competitive.

Tip: Start small by using AI for quality checks or robots for simple jobs. Add more as you see success.

Using these tools keeps you ahead in today’s fast-paced manufacturing world. AI and robots make sheet metal work smarter, faster, and more dependable.

Sheet metal work is very important in today's manufacturing. It helps make accurate, fast, and creative parts for cars and planes. New trends show the sheet metal tools market is growing quickly. This is because of better machines and the need for lighter, energy-saving materials. Developing countries are using more sheet metal as they build factories. As technology improves, sheet metal will keep changing how things are made. It will meet the needs of a world that is always moving forward.

FAQ

What is sheet metal processing?

Sheet metal processing changes flat metal sheets into useful items. It uses methods like cutting, shaping, joining, and finishing. These steps make strong, exact parts for cars, planes, and buildings.

How is laser cutting different from plasma cutting?

Laser cutting uses a laser beam for neat, detailed cuts. It wastes less material and works well for fine designs. Plasma cutting uses hot plasma to cut thick metal fast but less precisely. Each method fits different tasks.

Why is hydroforming used in manufacturing?

Hydroforming makes strong, light parts with high-pressure fluid. It shapes complex designs and saves materials. This method is common in car and airplane making because it’s precise and efficient.

Can sheet metal be reused?

Yes, sheet metal can be recycled easily. Old parts are melted and made new without losing quality. Recycling helps save resources, cuts waste, and supports green manufacturing.

Which industries use sheet metal processing the most?

Car, airplane, building, and electronics industries depend on sheet metal. It makes strong, light, and custom parts needed for modern products.