Precision sheet metal chassis are strong and solve many engineering problems. These structures are very tough and made with great accuracy. Their smart design helps them work well and adjust to different needs. Using modern materials and new methods, these chassis are dependable for your projects. They are great for fixing structural issues or improving how things work. They give a custom solution for what you need.

Tip: Picking the right sheet metal chassis can improve how well your products work and last longer.

Key Takeaways

Pick the best materials for your chassis. Aluminum is light and strong, while stainless steel doesn’t rust. Choose based on what your project needs.

Add support features like ribs and gussets. These parts spread weight evenly and make the chassis stronger and steadier.

Improve airflow to manage heat better. Use vents and fans to stop overheating so your chassis works well in tough conditions.

Use modular designs for more flexibility. This makes it easy to change or upgrade your chassis for different uses.

Try advanced manufacturing methods. Tools like CNC machines and 3D printers make parts more precise and speed up production for better results.

Making Stronger Designs for Long-Lasting Chassis

Precision sheet metal chassis help make products last longer. A good design makes them strong, reliable, and durable. Picking the right materials, adding support, and stopping rust are key.

Picking Materials for Strength

The material you choose decides how strong the chassis is. Different materials solve different problems. For example, aluminum 5052-H32 is light and strong. Stainless steel 304 resists rust very well. Here's a table comparing common materials:

Think about what your project needs. For cars, aluminum is great because it’s light. For wet places, stainless steel works best since it doesn’t rust.

Adding Support for Heavy Loads

A strong design helps the chassis hold heavy weights safely. Features like ribbing, gussets, and reinforced corners spread weight evenly. This stops parts from breaking under pressure. Cross-bracing can also keep the chassis stable.

For example, industrial machines need strong joints to handle vibrations. Adding these features makes the chassis safer and stronger.

Protecting Against Rust

Rust can weaken a chassis over time. To stop this, use rust-resistant materials or protective coatings. Stainless steel naturally resists rust. Galvanized steel or powder coatings also protect against moisture and chemicals.

Good drainage and airflow in the design help too. They stop water and dirt from building up, which causes rust. These steps keep the chassis strong and lasting longer.

Thermal Management Challenges and Solutions

Managing heat is important for your sheet metal chassis. If heat builds up, it can harm parts or make them work poorly. Fixing airflow, heat removal, and cooling systems helps control these problems.

Ventilation and Airflow Optimization

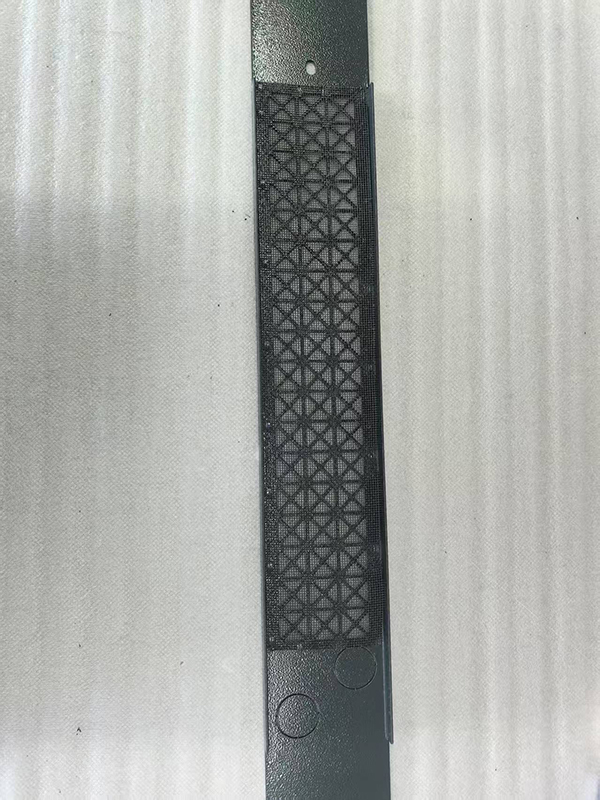

Good airflow removes heat from inside the chassis. Add vents or holes in smart spots to let air move. This stops heat from staying in one place.

Place hot parts near vents for better cooling. For example, in telecom devices, line up vents with hot parts. Fans or blowers can also push air through the chassis to cool it.

Tip: Use computer tools to see how air moves. This helps find better vent spots.

Heat Dissipation Techniques

Heat dissipation moves heat away from parts to keep them cool. Materials like aluminum are great because they spread heat well. Aluminum is strong and helps keep parts safe.

New methods, like tiny cooling channels, can improve heat removal. For example:

The Cool-3D system tests different cooling setups, like vertical channels.

Heat maps show hot spots and areas using lots of power. Better cooling designs lower these temperatures.

Mixing old and new ways can make your chassis handle heat better.

Integration of Cooling Systems

Adding cooling systems helps manage heat in powerful devices. Liquid cooling works well for data centers and electronics. It handles very hot processors and keeps working even with warm water supplies.

Plan your chassis layout to fit cooling parts like pumps and radiators. Modular designs make adding cooling systems easier for different uses.

Note: Adding cooling systems not only keeps parts cool but also makes them last longer.

By fixing airflow, heat removal, and cooling systems, your chassis will handle heat better. These steps make it work well, even in tough conditions.

Weight Optimization in Sheet Metal Chassis

Making a sheet metal chassis lighter helps it work better. By using light materials, smart designs, and new methods, you can build a strong and efficient structure.

Choosing Lightweight Materials

Light materials like aluminum and magnesium make chassis lighter. These materials lower weight and improve how well the chassis works.

Aluminum alloys, like AA 7075-T6, are 61.46% lighter than steel.

Magnesium alloys save even more weight, great for tight weight limits.

New ways to make these materials easier to use help create strong, light chassis.

Lighter materials also help vehicles use less fuel or energy. A lighter chassis needs less power to move, saving energy and improving efficiency.

Balancing Weight and Strength

A light chassis must still be strong and work well. Materials like AA 7075-T6 and T300 Composite are both light and strong.

T300 Composite is 82.4% lighter than Steel 304L but stays strong.

At 60 km/h, these materials use 58.76% less power than steel.

Lighter materials can bend more under pressure. To fix this, add strong joints or cross-bracing. This keeps the chassis stable without adding too much weight.

Using Advanced Manufacturing Methods

New ways to make chassis have changed production. Flexible systems, like Modular Flex Framing, let you make many designs on one line. This saves money and time.

Automated tools, like Automated Body in White Fixture Control, ensure accurate production. They check for mistakes in real-time, keeping quality high. These methods help make light, strong chassis that fit your needs.

By mixing light materials, smart designs, and modern methods, you can make a chassis that’s both strong and efficient. This ensures it works well for today’s needs.

Manufacturability and Scalability in Design

Precision Fabrication Processes

Precision fabrication helps make sheet metal chassis exactly as needed. Machines like CNC punchers and laser cutters create detailed designs. These tools ensure every part is accurate and fits perfectly. For example, CNC punching makes complex hole patterns for industries like telecom and aerospace.

Automation is very important in modern fabrication. Machines like the Salvagnini P4 Panel Bender bend panels with great accuracy. This reduces mistakes and keeps parts the same, even in big production runs. Using these methods saves time, cuts waste, and delivers high-quality results.

Simplified Assembly Techniques

Simplified assembly makes building and scaling designs easier. Using modular parts and standard designs saves time and boosts efficiency. Companies like Tesla and Toyota use Design for Assembly (DFA) to improve production. Tesla uses small battery modules for easy assembly. Toyota uses lean methods to cut waste and improve quality.

These methods save time and make chassis designs flexible. Modular designs let you adjust chassis for different uses, like cars or machines.

High-Volume Production Capabilities

High-volume production helps meet demand without losing quality. Machines like the Salvagnini P4 Panel Bender handle large orders with precision. They cut production time by 50%, making delivery faster.

Other companies, like Sinoway, use automated systems to keep production consistent. These systems make complex designs quickly and efficiently. Lean manufacturing also helps scale production while keeping quality high.

By using these methods, you can meet market needs and deliver reliable products. Whether for cars or planes, these processes make your chassis a strong choice.

Customization and Adaptability as a Solution

Precision sheet metal chassis are very flexible. They let you design structures for specific industries. Whether it's cars, planes, or telecom, customization makes sure the chassis fits your needs. It also keeps them strong and efficient.

Designs Made for Industry Needs

Special designs solve problems for industries needing unique engineering. Tools like finite element analysis (FEA) help test different ideas to find the best one. Companies like Mubea use AI to check designs for strength and fix mistakes.

For example, car chassis designs improve how vehicles work. They balance weight and make cars last longer. Custom designs make sure the chassis fits the job perfectly.

Modular Configurations

Modular designs make parts easy to change and adapt. You can swap components to fit different uses. This saves time and money while staying flexible.

For example, telecom companies often change equipment layouts. Modular chassis let them adjust without starting over. These designs also add features like cooling systems or brackets easily.

Fast Prototyping for Custom Designs

Rapid prototyping speeds up making custom chassis. Tools like CAD and 3D printing test designs quickly. This helps fix problems before making the final product.

For example, car companies use CAD to cut prototyping time from months to weeks. Farm equipment makers like Amazone use 3D printing to improve chassis designs. These methods save time and ensure the product works well.

By using special designs, modular setups, and fast prototyping, you can make chassis that fit your needs. This flexibility keeps your products strong and ready for changing industries.

Precision sheet metal chassis solve many design problems effectively. Their strong build makes them safe and long-lasting. These chassis can handle wind, heat, and tough conditions while working well. A good design plan helps your products look good and work properly. This way, they stay useful for a long time and adjust to future needs.

FAQ

What is the best material for a precision sheet metal chassis?

The best material depends on what you need. Aluminum is great for light designs. Stainless steel doesn’t rust and works in tough places. SPCC steel is strong and affordable. Pick based on weight, strength, and where it will be used.

How can you improve the durability of a sheet metal chassis?

To make it last longer, use strong materials. Add supports like ribs or gussets to spread weight. Use coatings to stop rust. These steps keep it strong and safe from damage.

Why is thermal management important in sheet metal chassis?

Thermal management stops parts from getting too hot. Overheating can break parts or slow them down. Good airflow, heat-spreading materials, and cooling systems keep it working well.

Can sheet metal chassis be customized for specific industries?

Yes, you can design them for different jobs. Modular designs and fast prototyping help make custom solutions. These work for cars, planes, telecom, and more.

How does weight optimization benefit your design?

Making it lighter saves energy and works better. Materials like aluminum or magnesium lower weight but stay strong. This helps vehicles and portable devices perform well.