In the world of modern manufacturing, efficiency, precision, and scalability are paramount. Among the various processes that bring these qualities to life, Metal Stamping stands out as a cornerstone technology. We are a leading provider of precision manufacturing solutions, and we are proud to highlight our advanced Metal Stamping Service. This process is fundamental to producing high-volume, complex, and cost-effective parts used across countless industries. Our expertise in Metal Stamping, combined with our capabilities in CNC machining and enclosure fabrication, allows us to offer a comprehensive suite of services to our global clientele. This article explores the critical role of Metal Stamping, our technical process, and the unique value we bring as your manufacturing partner.

1. Understanding Metal Stamping and Its Pervasive Applications

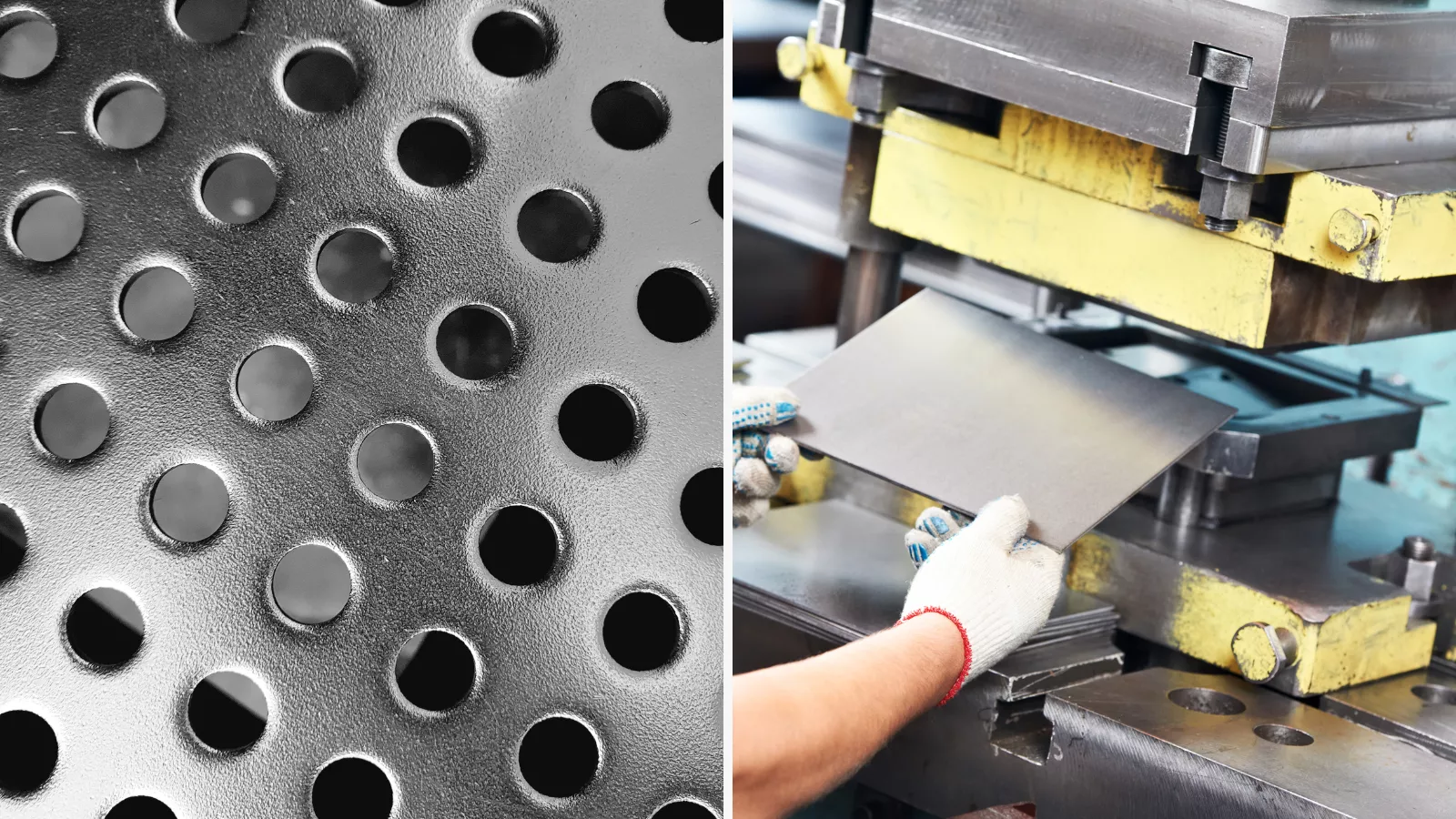

Metal Stamping is a cold-forming manufacturing process that uses specialized presses and tooling—namely dies and stamps—to transform flat sheet metal (Sheet Metal) into specific, often complex shapes. The process can involve a variety of techniques such as punching, blanking, bending, and coining, all performed in a rapid, sequential manner. The versatility of Metal Stamping makes it indispensable. Components produced through our Metal Stamping Service are vital in the automotive sector (brackets, connectors), electronics industry (shielding cases, contacts), appliance manufacturing (chassis, hinges), and even in the production of our own Electronic Enclosures and Battery Enclosures. When a project requires the high-volume production of durable, identical parts with tight tolerances, Metal Stamping is often the most efficient and economical solution available.

2. Our Metal Stamping Service: A Synergy of Technology and Expertise

Our Metal Stamping Service is built on a foundation of advanced technology, skilled engineering, and an unwavering commitment to quality. We operate a range of high-speed stamping presses, from compact to large-tonnage machines, capable of handling various part sizes and material types, including the stainless steel used in our Stainless Steel Enclosures.

Precision Tool and Die Making: The heart of any successful Metal Stamping operation is the die. Our in-house tool and die shop designs and manufactures precision dies using our CNC Machining Parts capability. This vertical integration ensures our dies meet the exacting standards required for producing millions of consistent, high-quality parts.

High-Speed Production and Automation: Once the die is perfected, our automated stamping presses take over. They can perform hundreds of strokes per minute, dramatically reducing per-part cost and lead times for large-volume orders. This efficiency is a key reason why clients choose our Metal Stamping Service for their high-demand components.

Secondary Operations and Integration: A stamped part is often just the beginning. We provide a full range of value-added services to create a finished product. This can include tapping, welding, deburring, and various surface treatments. Furthermore, we seamlessly integrate our stamped components with other services, such as assembling them into a complete Electronic Enclosure or machining critical features using our CNC Machining Parts service for added precision.

3. Key Advantages of Choosing Our Metal Stamping Service

Partnering with us for your Metal Stamping needs delivers distinct competitive advantages that go beyond simply pressing metal.

Cost-Effectiveness at High Volumes: The initial investment in tooling is quickly amortized over large production runs, making Metal Stamping exceptionally cost-effective for mass production.

Exceptional Repeatability and Consistency: Our automated presses and precision dies guarantee that every single part produced in a run is virtually identical, ensuring consistent quality and performance in your final assembly line.

High Production Speed and Scalability: The rapid cycle times of the Metal Stamping process enable us to fulfill large orders quickly and scale production to meet fluctuating market demands.

Material Versatility and Strength: The Metal Stamping process work-hardens the material, which can enhance the strength and durability of the final part compared to other fabrication methods.

Comprehensive Solution Provider: By offering Metal Stamping alongside CNC Machining Parts and custom enclosure fabrication, we act as a one-stop shop. This simplifies your supply chain, reduces logistical overhead, and ensures compatibility across all components of your product.

In conclusion, Metal Stamping remains a vital, dynamic, and highly efficient manufacturing process that forms the backbone of modern industrial production. Our deep investment in technology, tooling, and expertise in Metal Stamping ensures that we can deliver components that meet the highest standards of precision, durability, and value. We invite you to leverage our Metal Stamping Service to optimize your production, reduce costs, and bring your most ambitious projects to life with reliability and speed.