Choosing the right custom sheet metal enclosures plays a pivotal role in ensuring the success of modern projects in 2025. Advanced technology now allows for high precision in fabrication, using tools like CAD and integrated machines for cutting and forming. This precision ensures that custom sheet metal enclosures meet calculated tolerances, enhancing both functionality and durability.

You’ll find that custom sheet metal enclosures offer several advantages:

They are tougher and more durable than plastics.

They support cost-efficient manufacturing, especially in high volumes.

Their versatility makes them suitable for various environmental conditions.

The development board enclosure market is projected to grow from USD 2.5 billion in 2024 to USD 4.1 billion by 2033, reflecting the increasing demand for custom sheet metal enclosure solutions. Proper selection not only ensures resilience but also long-term cost-effectiveness, making it a critical decision for any project.

Key Takeaways

Pick the right size so your enclosure fits well and works.

Choose materials based on where it will be used; aluminum is light and resists rust, while stainless steel is strong.

Add features like color and logos to make it look nice and stand out.

Make it last longer by using coatings and sealing it properly.

Work with trusted makers to get a well-made and accurate design.

Identifying Project Requirements

Size and Dimensions

When selecting custom sheet metal enclosures, size and dimensions play a critical role in ensuring a proper fit for your project. Accurate measurements prevent issues like overcrowding or misalignment, which can compromise safety and functionality. Before starting the design process, measure all components, including wiring, buttons, and connectors. This ensures the enclosure accommodates everything without unnecessary gaps or tight spaces.

Consider the tolerances of the manufacturing processes you plan to use. Precise feature sizes and placements directly impact the final fit and finish of your enclosure. For example, if the tolerances are too loose, parts may not align correctly, leading to operational inefficiencies. On the other hand, overly tight tolerances can increase production costs unnecessarily.

Tip: Always leave room for future expansion. A slightly larger enclosure can save you from costly redesigns if you need to add components later.

Environmental Conditions

The environment where your enclosure will operate significantly influences its design and material selection. Outdoor applications require enclosures that can withstand harsh weather conditions, including rain, UV exposure, and temperature fluctuations. For instance, weather-resistant enclosures are ideal for renewable energy grids, where they must endure prolonged exposure to the elements.

Indoor environments may have their own challenges, such as high humidity or exposure to chemicals. In such cases, corrosion-resistant materials like stainless steel are a better choice. By understanding the environmental conditions, you can select a custom enclosure that ensures durability and long-term performance.

Note: Manufacturers are increasingly developing enclosures with advanced coatings to combat UV degradation and other environmental stresses.

Functional Features

Functional features determine how well your enclosure meets the specific needs of your project. Start by identifying the essential functions your enclosure must perform. Does it need to provide thermal management for heat-sensitive components? Should it include ergonomic features for user interaction?

Testing plays a crucial role in validating these features. For example:

Design Validation: Ensures the enclosure meets your specifications.

Thermal Analysis: Evaluates heat transfer capabilities to prevent overheating.

Strength Tests: Verifies the structural integrity of the enclosure under stress.

Iterative improvement is another key aspect. Initial prototypes often reveal design flaws, which can be addressed through feedback and further testing. This process ensures your final product is both functional and reliable.

Tip: Don’t overlook user feedback during the design phase. It can help refine ergonomic aspects and improve overall usability.

Aesthetic Considerations

When designing custom sheet metal enclosures, aesthetics play a crucial role in creating a product that not only functions well but also appeals to users. A well-designed enclosure can elevate the overall perception of your project, making it more attractive and professional. By focusing on visual elements, you can ensure your enclosure aligns with user expectations and enhances the end-user experience.

Why Aesthetics Matter

Aesthetics influence how users perceive and interact with your product. A visually appealing enclosure can make your project stand out in competitive markets. For example, enclosures with sleek finishes and modern designs often convey a sense of quality and innovation. On the other hand, poorly designed enclosures may give the impression of low quality, even if the internal components are top-notch.

Tip: Think of your enclosure as the "face" of your project. A polished and professional appearance can leave a lasting impression on users and stakeholders.

Key Aesthetic Features to Consider

To create an enclosure that balances form and function, focus on the following aesthetic features:

Customization: Tailor the size, shape, and features of your enclosure to meet specific project needs. Customization not only enhances functionality but also improves visual appeal.

Color and Finish: Choose colors and finishes that align with your brand or project theme. Options like powder coating or brushed metal finishes can add a premium look.

Cutouts and Access Points: Incorporate unique cutouts and access points to optimize usability while maintaining a clean design.

Branding: Integrate logos, text, or patterns into the enclosure to reinforce your brand identity.

Design Insights from Studies

Research shows that aesthetic considerations significantly impact user preference for custom enclosures. The table below highlights key aspects that contribute to both functionality and visual appeal:

Practical Tips for Aesthetic Design

Start with a Theme: Decide on a design theme that reflects your project's purpose. Whether it's industrial, minimalist, or futuristic, consistency in design elements creates a cohesive look.

Use Prototyping Tools: Tools like CAD software allow you to visualize your design before production. This helps you refine details like color schemes and cutout placements.

Seek Feedback: Share your design with team members or potential users to gather input. Feedback can help you identify areas for improvement and ensure the design resonates with your audience.

Note: Aesthetic enhancements should never compromise functionality. Always prioritize the practical requirements of your enclosure while refining its appearance.

By paying attention to aesthetics, you can create a custom sheet metal enclosure that not only performs well but also leaves a lasting impression. A thoughtful design can transform your enclosure from a simple protective case into a visually striking component of your project.

Choosing the Right Material

Selecting the right metal for your custom sheet metal enclosures is crucial for ensuring durability, functionality, and cost-effectiveness. Each material offers unique advantages, making it essential to match the material to your project’s specific needs.

Steel vs. Aluminum vs. Stainless Steel

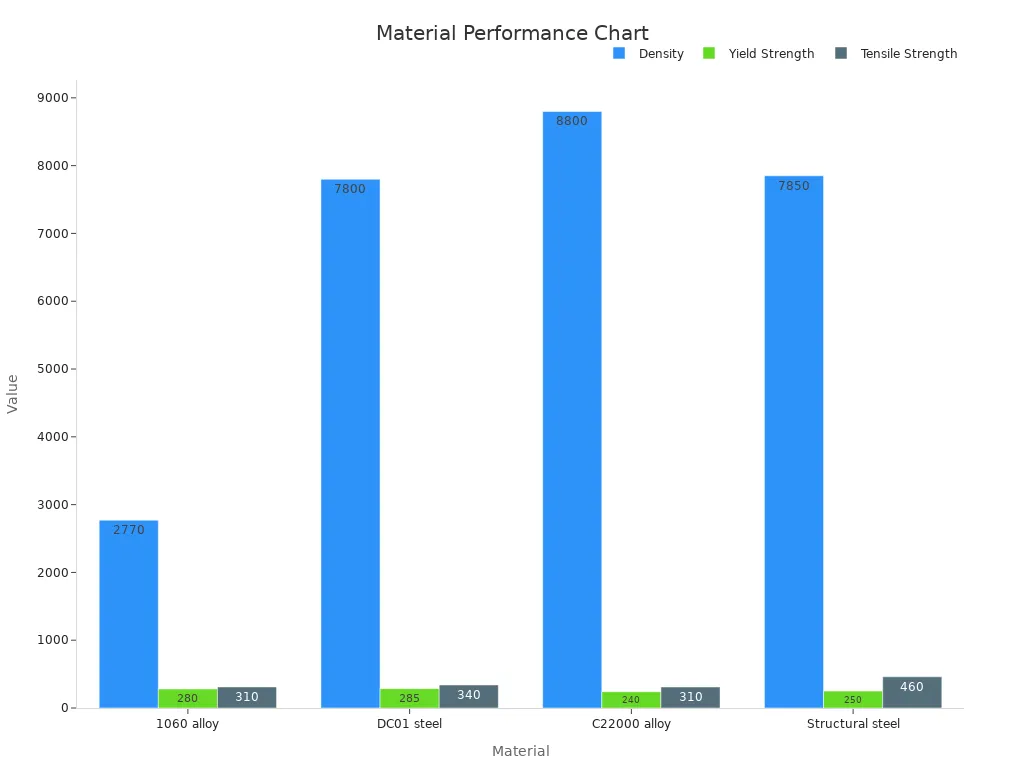

When choosing between steel, aluminum, and stainless steel, you must evaluate their properties based on your project requirements. Steel is known for its strength and affordability, making it ideal for heavy-duty applications. Aluminum, on the other hand, is lightweight and corrosion-resistant, making it perfect for portable or outdoor enclosures. Stainless steel combines the best of both worlds, offering exceptional corrosion resistance and a polished appearance, though it comes at a higher cost.

Tip: For projects requiring portability, aluminum is often the right metal due to its lower density and ease of handling.

Corrosion Resistance and Strength

Corrosion resistance is a critical factor, especially for outdoor enclosures exposed to moisture, chemicals, or UV radiation. Stainless steel excels in environments where corrosion resistance is paramount, such as marine or industrial applications. Aluminum also offers excellent corrosion resistance, particularly when anodized, making it suitable for outdoor use. Steel, while strong, requires protective coatings like galvanization to prevent rust.

Strength is equally important. Steel provides unmatched structural integrity, making it ideal for enclosures that must withstand heavy loads or impacts. Aluminum offers moderate strength but compensates with its lightweight nature. Stainless steel balances strength and corrosion resistance, making it a versatile choice for high-performance applications.

Note: Manufacturers often recommend advanced coatings to enhance corrosion resistance and extend the lifespan of sheet metal enclosures.

Cost and Weight Factors

Cost and weight play a significant role in material selection. Steel is the most cost-effective option for large-scale projects, especially when weight is not a concern. Aluminum, while more expensive, reduces transportation and handling costs due to its lightweight properties. Stainless steel, though the priciest, offers unmatched durability and aesthetic appeal, making it a worthwhile investment for premium projects.

Material options for custom enclosures:

Carbon steel

Galvanized or galvannealed steel

304 or 316 stainless steel

5052 or 6061 aluminum

To optimize costs, design parts with nesting efficiency to minimize scrap. Adjust dimensions to fit standard sheet sizes, reducing material waste. Consult with fabricators to achieve optimal material yields and ensure your enclosure meets both budget and performance goals.

Tip: For portable enclosures, prioritize lighter materials like aluminum to reduce strain during transportation and field use.

By carefully considering these factors, you can select the right metal for your custom enclosure, ensuring it meets your project’s functional, aesthetic, and budgetary requirements.

Design and Style Considerations

Enclosure Styles and Shapes

When designing a custom enclosure, selecting the right style and shape is critical for both functionality and aesthetics. Enclosure styles vary widely, from simple rectangular boxes to complex, multi-compartment designs. Each style serves a specific purpose, so you should align your choice with the needs of your project. For example, rounded edges can improve safety and reduce wear, while angular designs may better suit industrial applications.

User surveys and market studies highlight key considerations for enclosure styles. Proper sealing, achieved through rubber gaskets or washers, ensures protection for electronic components. Aluminum is often preferred for its corrosion resistance, especially in environments exposed to water. Additionally, minimizing seams in the design reduces potential leaks and ensures a better fit for internal components.

Practical applications also influence the choice of materials for different enclosure styles. Aluminum excels in lightweight designs requiring heat conductivity, while stainless steel offers durability for outdoor use. For specialized needs, materials like titanium or polycarbonate may provide unique advantages.

Metal Thickness and Tolerances

Metal thickness and tolerances play a vital role in ensuring the precision and durability of sheet metal enclosures. Variations in sheet stock thickness can complicate tolerancing, so understanding these factors is essential. For instance, a 16-gauge steel sheet may have an actual thickness of around 0.056 inches instead of the stated 0.057 inches. Such discrepancies can affect the final fit and performance of your enclosure.

Manufacturing processes impose specific tolerancing constraints. Precision in metal stamping ensures that parts match exact design specifications. Tight tolerances, often measured in thousandths of an inch or microns, are crucial for maintaining mechanical integrity and safety. Adhering to these tolerances ensures your enclosure performs reliably under stress.

Variations in sheet stock thickness can complicate tolerancing.

Manufacturing processes impose specific tolerancing constraints.

Precision in metal stamping ensures parts match exact design specifications.

Tight tolerances are crucial, often measured in thousandths of an inch or microns.

Actual thickness can vary from stated gauge thickness, affecting tolerances.

Tip: Collaborate with your manufacturer to determine the optimal thickness and tolerances for your design. This ensures your enclosure meets both functional and cost requirements.

Assembly Methods

The assembly method you choose impacts the structural integrity and ease of manufacturing for your enclosure design. Common methods include welding, riveting, and using fasteners. Each method has its advantages, so you should select one based on your project's requirements.

Welding creates a seamless and strong bond, making it ideal for heavy-duty applications. However, it may not be suitable for designs requiring frequent disassembly. Riveting offers a balance between strength and flexibility, while fasteners provide the most versatility for enclosures that need regular maintenance or upgrades.

Design Tip: Consider the end-use of your enclosure when selecting an assembly method. For example, if your enclosure will house sensitive electronics, opt for methods that minimize heat exposure during assembly, such as riveting or using fasteners.

By carefully evaluating enclosure styles, metal thickness, tolerances, and assembly methods, you can create a design that balances functionality, durability, and aesthetics. These considerations ensure your sheet metal enclosures meet the demands of modern applications.

Finishing and Customization Options

Powder Coating vs. Painting

When it comes to finishing sheet metal enclosures, powder coating and painting are two popular options. Each method offers unique benefits, and your choice depends on your project’s requirements. Powder coating provides a durable, scratch-resistant finish that holds up well in harsh environments. It also has a faster application process, making it ideal for large-scale production. In contrast, painting offers more flexibility in color matching and texture but requires more maintenance over time.

Tip: For outdoor enclosures or high-traffic areas, powder coating is often the better choice due to its superior durability and lower maintenance needs.

Protective Coatings for Durability

Protective coatings enhance the lifespan of your enclosure design by shielding it from environmental damage. These coatings prevent corrosion, resist UV radiation, and improve overall durability. For example, galvanized coatings protect steel enclosures from rust, while anodized finishes strengthen aluminum surfaces. Advanced coatings, such as fluoropolymer or epoxy-based options, offer additional resistance to chemicals and extreme temperatures.

Selecting the right protective coating depends on the operating environment. Outdoor enclosures benefit from weather-resistant coatings, while industrial settings may require chemical-resistant finishes. By choosing the appropriate coating, you ensure your enclosure remains functional and visually appealing for years to come.

Note: Manufacturers like Foxsen often recommend protective coatings tailored to specific enclosure styles, ensuring optimal performance in challenging conditions.

Branding and Aesthetic Customization

Branding and aesthetic customization transform your enclosure into a unique representation of your project or company. Features like custom logos, color schemes, and textured finishes enhance the visual appeal of your enclosure while reinforcing brand identity. Studies show that effective branding increases customer satisfaction by creating emotional connections and fostering loyalty.

When designing a custom enclosure, consider how branding elements can align with your project’s goals. For example, incorporating your company’s logo or using a signature color can make your enclosure stand out in competitive markets. Additionally, tactile finishes, such as brushed metal or textured coatings, create a premium feel that resonates with users.

Tip: Use prototyping tools to visualize branding elements before production. This ensures your design aligns with both functional and aesthetic goals.

By carefully selecting finishing and customization options, you can enhance both the performance and appearance of your sheet metal enclosures. These choices not only protect your enclosure but also elevate its overall impact.

Practical Tips for Selecting Custom Enclosures

Balancing Cost and Quality

Balancing cost and quality is essential when selecting custom enclosures. You should aim to maximize value without compromising functionality or durability. Start by identifying the critical features your project requires. For example, if your enclosure will face harsh environments, prioritize materials like stainless steel or aluminum, even if they cost more upfront. These materials often save money in the long run by reducing maintenance and replacement costs.

Consider production methods as well. Techniques like laser cutting and CNC machining offer precision and efficiency, which can lower production costs while maintaining high quality. Collaborating with your manufacturer to optimize material usage also helps reduce waste and expenses.

Tip: Design your enclosure to fit standard sheet sizes. This minimizes material waste and keeps costs under control.

Ensuring Long-Term Durability

Durability is a key factor in ensuring your enclosure performs well over time. Choose materials and finishes that match the operating environment. For outdoor applications, weather-resistant coatings like powder coating or anodized finishes protect against corrosion and UV damage. In industrial settings, chemical-resistant coatings can extend the lifespan of your enclosure.

Pay attention to enclosure styles that enhance durability. Rounded edges, for instance, reduce stress points and improve structural integrity. Proper sealing, achieved through gaskets or washers, prevents moisture and dust from compromising internal components.

Note: Regular maintenance, such as cleaning and inspecting seals, further extends the life of your custom enclosure.

Partnering with Reliable Manufacturers

Working with a reliable manufacturer ensures your custom sheet metal enclosures meet exact specifications. Experienced manufacturers bring expertise and precision to the table, helping you avoid costly errors. Look for partners with a proven track record of success.

A fast-growing electronics startup improved production efficiency and reduced costs by using custom enclosures, enabling them to scale operations.

An industrial equipment manufacturer enhanced durability in harsh environments, reducing equipment failures and improving efficiency.

Precision aluminum enclosures for a smart home company achieved a 30% weight reduction while maintaining strength.

Manufacturers like Washington Metal Fabricators emphasize quality and customer satisfaction. Their decades of expertise ensure precision and reliability across industries. Similarly, Robinson’s 40-year history highlights their commitment to fostering strong customer partnerships.

Tip: Always request prototypes before full production. This allows you to verify quality and make adjustments as needed.

By balancing cost and quality, ensuring durability, and partnering with trusted manufacturers, you can create custom enclosures that meet your project’s needs and stand the test of time.

Selecting the right custom sheet metal enclosures ensures your project aligns with its specific needs. Material choice, such as aluminum for lightweight designs or stainless steel for corrosion resistance, directly impacts performance. Design considerations, including size and shape, enhance functionality, while finishing options like powder coating improve durability and aesthetics.

Consulting experts ensures your enclosure meets both functional and aesthetic goals. Suppliers often provide insights tailored to your preferences, helping you make informed decisions. Staying updated with trends also ensures your design remains stylish and practical.

Tip: Partnering with experienced manufacturers guarantees precision and reliability, saving time and resources.

FAQ

What are the benefits of using custom sheet metal enclosures?

Custom enclosures provide a tailored fit for your project, ensuring optimal functionality and protection. They offer durability, design flexibility, and compatibility with various environmental conditions. Customization also allows you to incorporate branding and aesthetic features, enhancing the overall appeal of your product.

How do I choose the right material for my enclosure?

Evaluate your project’s needs. For lightweight designs, choose aluminum. For corrosion resistance, stainless steel works best. Steel offers strength at a lower cost. Consider environmental factors, weight, and budget to make the right choice. Consult your manufacturer for expert advice.

Can I modify my enclosure design after production starts?

Modifications after production begins can be costly and time-consuming. To avoid this, finalize your design during the prototyping phase. Use CAD tools to visualize and test your design before manufacturing. Early planning ensures fewer changes later.

What is the typical lead time for custom enclosures?

Lead times vary based on complexity, material availability, and manufacturer capacity. Simple designs may take 2-4 weeks, while intricate projects could require 6-8 weeks or more. Discuss timelines with your manufacturer to set realistic expectations.

How do I ensure my enclosure meets safety standards?

Work with manufacturers familiar with industry regulations. Use materials and finishes that comply with safety standards. Test your enclosure for durability, thermal management, and environmental resistance. Certification from recognized bodies ensures compliance and reliability.

Tip: Always request documentation from your manufacturer to verify compliance with relevant safety standards.