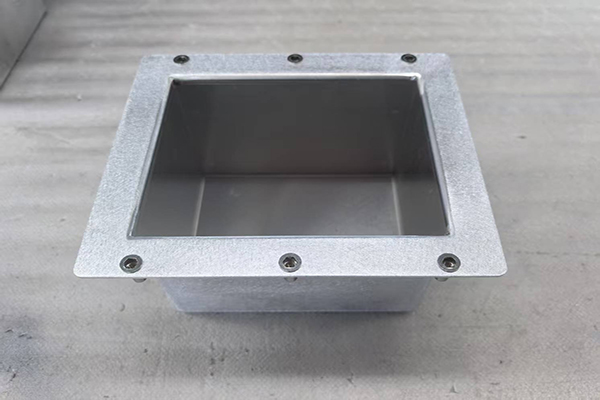

I’ve always believed that protecting LED displays is just as important as the technology itself. Sheet metal LED enclosures make this possible by shielding the displays from external harm. Their robust design ensures that LED lighting solutions remain functional and efficient for years. These enclosures help maintain the long lifespan of LED systems by preventing exposure to damaging elements. Whether used indoors or outdoors, they offer unmatched reliability in safeguarding lighting setups.

Key Takeaways

Sheet metal LED enclosures keep screens safe from water, dust, and heat changes. This helps them last longer.

Strong sheet metal enclosures stop damage and rust, making them great for tough conditions.

Businesses can customize these enclosures to fit their needs, improving how they work.

Sheet metal enclosures are stronger, handle heat better, and save money compared to plastic or aluminum.

Using sheet metal enclosures lowers repair costs and makes LED screens work better.

Protection from Environmental Factors

LED displays face constant challenges from environmental factors. I’ve seen firsthand how moisture, dust, and temperature fluctuations can degrade their performance. A well-designed sheet metal LED enclosure acts as a shield, ensuring that these elements don’t compromise the functionality or longevity of the display.

Shielding LED displays from moisture

Moisture is one of the most damaging elements for LED displays. It seeps into the delicate components, causing corrosion and reducing performance. I’ve noticed that without proper protection, moisture can lead to lumen degradation and even structural damage. Sheet metal LED enclosures provide a robust barrier against water ingress, especially in outdoor environments where rain and humidity are constant threats.

To illustrate, studies have shown how moisture affects LED displays:

This data highlights the importance of a reliable enclosure. By keeping moisture out, sheet metal LED enclosures ensure the display remains bright and functional, even in challenging conditions.

Preventing dust infiltration

Dust is another silent enemy of LED displays. It accumulates over time, blocking airflow and reducing visibility. I’ve seen how dust can settle on the surface of displays, diminishing their brightness and clarity. Worse, it can infiltrate the internal components, leading to overheating and eventual failure.

Sheet metal LED enclosures are designed to prevent dust infiltration. Their sealed construction ensures that no particles can enter, even in dusty environments like construction sites or busy urban areas. This not only protects the internal components but also maintains enhanced visibility for viewers. A clean, dust-free display always performs better and looks more professional.

Managing temperature fluctuations

Temperature fluctuations can wreak havoc on LED displays. Extreme heat can cause components to expand, while cold temperatures can make them brittle. I’ve observed how these changes can lead to cracks, warping, and reduced performance over time. Maintaining a stable temperature is crucial for high-performance LED lighting.

Sheet metal LED enclosures excel in managing thermal fluctuations. They are designed with features like ventilation systems and airflow mechanisms to regulate internal temperatures. For example:

These features ensure that the LED lighting solution operates efficiently, even in extreme weather. By preventing overheating, the enclosure safeguards the display’s brightness, color accuracy, and overall performance.

Durability of Sheet Metal LED Enclosures

Resistance to physical damage

I’ve always admired how sheet metal LED enclosures stand up to physical damage. Their heavy gauge steel body provides unmatched strength, making them ideal for environments where accidental impacts are common. Whether it’s a bustling retail space or an outdoor installation exposed to harsh conditions, these enclosures keep LED displays safe from harm.

The durability of these enclosures is evident in their ability to exceed IK10 ratings, which means they can withstand impacts of up to 20 joules. This level of protection ensures that even if someone accidentally bumps into the display or drops a heavy object nearby, the enclosure will maintain its integrity. I’ve seen how this feature prevents costly repairs and downtime, allowing businesses to focus on their operations without worrying about damaged displays.

Corrosion protection

Corrosion is a silent destroyer of metal components, especially in outdoor settings where humidity and salt exposure are prevalent. I’ve noticed that sheet metal LED enclosures excel in resisting corrosion, thanks to their use of marine-grade stainless steel. This material provides a protective barrier against rust, ensuring the enclosure remains functional and visually appealing for years.

In addition, many enclosures feature scratch-resistant surface treatments. These treatments not only enhance durability but also maintain the enclosure’s professional appearance. I’ve seen how this combination of features makes these enclosures ideal for coastal areas, where saltwater and high humidity pose significant challenges.

Long-term structural integrity

When it comes to long-term performance, sheet metal LED enclosures truly shine. Their UV-resistant construction prevents fading or yellowing, ensuring that illuminated elements remain vibrant and clear. I’ve observed how their sealed designs, rated up to IP68, protect LED displays from dust and water immersion, even in extreme conditions.

Premium models can operate within a temperature range of -40°C to +85°C, making them suitable for both freezing winters and scorching summers. Anti-vandal designs add another layer of security, with tamper-resistant mounting options that deter theft and unauthorized access.

Here’s a quick overview of their durability benchmarks:

These features ensure that sheet metal LED enclosures provide reliable protection and maintain their structural integrity over time. I’ve seen how this level of durability contributes to the consistent performance and visibility of LED displays, making them a worthwhile investment for any lighting setup.

Design Flexibility of Sheet Metal LED Enclosures

Customization for specific LED display needs

I’ve always appreciated how sheet metal LED enclosures can be tailored to meet unique requirements. Customization plays a vital role in ensuring that these enclosures align perfectly with the needs of different lighting setups. For instance, I’ve seen companies design enclosures with custom cutouts, mounting brackets, and ventilation systems. These features enhance functionality and ensure the enclosure supports the LED lighting system without compromise.

In the electronics industry, I’ve observed tailored enclosures designed for new product lines. These often include specific ventilation and access features, which improve both performance and cost efficiency. Similarly, in the telecom sector, modular designs adapt to unique site requirements, offering flexibility while controlling production costs.

This level of customization ensures that LED displays, including LED fabric light boxes, operate at peak quality and efficiency.

Compatibility with diverse installation setups

Sheet metal LED enclosures excel in adapting to various installation setups. I’ve seen how their versatility allows them to integrate seamlessly with different systems. Whether it’s a wall-mounted lightbox or a free-standing LED fabric light box, these enclosures fit perfectly into the design.

Their ability to adapt enhances the overall performance of the lighting system. For example, I’ve worked with setups where enclosures were customized to blend with existing structures. This not only improved compatibility but also ensured the lighting system operated without interruptions. The flexibility of these enclosures makes them a reliable choice for diverse environments, from retail spaces to outdoor advertising.

Aesthetic options for professional integration

Beyond functionality, I’ve noticed how sheet metal LED enclosures contribute to the visual appeal of lighting setups. Their sleek designs and polished finishes elevate the overall look of LED displays. This is especially important for applications like display graphics and advertisements, where aesthetics play a key role in attracting attention.

Many enclosures offer a variety of finishes, including powder-coated surfaces and custom colors. These options allow businesses to match the enclosure with their branding or surrounding décor. I’ve seen how this attention to detail enhances the quality of the display, making it more professional and visually appealing.

By combining durability with aesthetic flexibility, sheet metal LED enclosures ensure that lighting systems not only perform well but also look great in any setting.

Comparing Sheet Metal to Other Materials

Advantages over plastic enclosures

I’ve often noticed how plastic enclosures fall short when protecting LED displays. Sheet metal enclosures outperform plastic in several critical areas. Their strength and durability make them ideal for environments where displays face physical stress. Plastic enclosures, on the other hand, tend to deform or crack under pressure.

Thermal management is another area where sheet metal shines. It conducts heat efficiently, preventing overheating and ensuring consistent lighting performance. Plastic enclosures struggle with heat dissipation, which can lead to reduced brightness and shorter lifespans for LED systems.

Fire resistance is equally important. Sheet metal enclosures are non-combustible, offering better protection in case of fire hazards. Plastic enclosures, being combustible, pose a higher risk. Additionally, sheet metal provides natural shielding against electromagnetic interference (EMI), which plastic enclosures lack.

Here’s a quick comparison:

Superiority to aluminum in durability

I’ve worked with aluminum enclosures before, and while they’re lightweight, they don’t match the durability of sheet metal. Aluminum is prone to denting and warping under heavy impacts. Sheet metal enclosures, with their robust construction, resist physical damage and maintain their structural integrity over time.

Corrosion resistance is another area where sheet metal excels. Marine-grade stainless steel options ensure long-lasting protection against rust, even in humid or coastal environments. Aluminum enclosures, though resistant to corrosion, can develop surface pitting over time, which compromises their appearance and functionality.

Cost-effectiveness for long-term use

When considering a cost-effective solution for LED displays, sheet metal enclosures stand out. Their durability and resistance to environmental factors reduce maintenance costs significantly. I’ve seen how businesses save money by avoiding frequent repairs and replacements.

Sheet metal enclosures also enhance lighting performance by maintaining optimal operating conditions. This ensures LED systems last longer, providing a better return on investment. While the initial cost may be higher than plastic or aluminum options, the long-term savings make sheet metal the smarter choice.

I’ve seen how sheet metal LED enclosures transform the longevity of LED lighting systems. Their unmatched protection shields displays from environmental damage, while their durability ensures they withstand physical stress and corrosion. These enclosures also offer design flexibility, making them adaptable to various setups. Compared to plastic or aluminum, sheet metal stands out as the most reliable and cost-effective choice. By investing in these enclosures, businesses can enhance the performance of their LED lighting and ensure long-term efficiency.

FAQ

What makes sheet metal LED enclosures better for outdoor use?

I’ve found that sheet metal enclosures excel outdoors due to their durability and resistance to environmental factors. They protect displays from moisture, dust, and temperature changes, ensuring consistent performance even in harsh conditions.

Can sheet metal LED enclosures be customized for unique setups?

Yes, customization is a key advantage. I’ve seen businesses tailor enclosures with specific cutouts, mounting options, and ventilation systems to meet their unique needs. This flexibility ensures optimal functionality for any LED display setup.

How do sheet metal enclosures improve LED display performance?

Sheet metal enclosures regulate temperature and prevent dust infiltration. These features maintain the brightness and clarity of LED displays, ensuring they perform efficiently over time.

Are sheet metal enclosures cost-effective in the long run?

Absolutely. Their durability reduces repair and replacement costs. I’ve noticed that businesses save money by investing in these enclosures, as they ensure LED displays last longer and operate efficiently.

Do sheet metal enclosures offer aesthetic options?

Yes, they do. I’ve seen enclosures with polished finishes and custom colors that match branding or décor. This enhances the professional appearance of LED displays while maintaining their functionality.