When I first learned about sheet metal fabrication, I realized how vital it is in modern manufacturing. The process involves transforming flat sheets of metal into specific shapes and structures through cutting, forming, and joining techniques. These methods allow industries to create everything from car bodies to architectural designs.

The demand for sheet metal processes continues to grow. For example:

The automotive segment is projected to register a revenue CAGR of 7.03% over the next few years.

The building and construction sector, holding 54.9% of the volume share, is expected to expand rapidly.

This growth highlights how essential these processes are to industries that rely on precision and durability.

Key Takeaways

Sheet metal work changes flat metal sheets into useful parts. It uses cutting, shaping, and joining methods. This is important for industries like cars and buildings.

Picking the right metal is very important. Think about cost, strength, and how long it lasts. This helps the material fit the project and work better.

Modern cutting methods, like laser and plasma cutting, are very accurate. They also waste less material. Using these tools can make production faster.

Finishing the surface is key for strength and looks. Methods like powder coating stop rust and make products last longer.

Learning about sheet metal work can lead to new ideas in making things. Study this area to make better designs and work faster.

What Is Sheet Metal Fabrication?

Definition and Purpose

When I first encountered sheet metal fabrication, I realized it’s more than just shaping metal. It’s a process that transforms thin, flat sheets of metal into functional parts or structures. This involves techniques like cutting, bending, punching, and welding. The versatility of this process allows it to work with various metals, including steel, aluminum, copper, and even titanium.

One fascinating aspect is how the thickness of sheet metal is measured. It’s indicated by a gauge system, where lower numbers mean thicker sheets. For example, 30-gauge metal is very thin, while 8-gauge is much thicker. This precision makes sheet metal fabrication ideal for creating components with specific dimensions and shapes.

Importance in Manufacturing

Sheet metal fabrication plays a critical role in manufacturing. It enables industries to produce durable and precise components efficiently. For instance, I’ve seen how HVAC systems rely on sheet metal to create ductwork and ventilation systems. Similarly, construction projects use it for roofing, beams, and architectural panels.

The process also enhances manufacturing efficiency. A case study from Dalsin Industries showed how redesigning a 9-piece assembly into a single sheet metal component reduced costs by 22% and cycle time by 57%. Another example involved automated CNC panel bending, which cut cycle time by 60% and reduced material usage by 17%. These examples highlight how precision sheet metal fabrication improves both cost-effectiveness and productivity.

Common Applications

Sheet metal fabrication is everywhere. In construction, it’s used for roof gutters, downspouts, and safety guards. Aerospace relies on it for fuselage panels and wing skins. Automotive industries use it for body panels and chassis components. Even electronics benefit from sheet metal enclosures and casings.

Here’s a quick look at its applications across industries:

From construction to healthcare, sheet metal fabricators contribute to countless industries. Their expertise ensures that sheet metal components meet the demands of modern manufacturing.

Types of Metals Used in Sheet Metal Fabrication

Common Materials (Steel, Aluminum, Copper)

When I first started learning about sheet metal fabrication, I was amazed by the variety of metals used. Each metal offers unique properties that make it suitable for specific applications. Among the most common materials are steel, aluminum, and copper.

Steel stands out for its strength and durability. It’s a go-to choice for industrial and construction projects. I’ve seen it used in everything from building frameworks to heavy machinery. Stainless steel, in particular, is prized for its corrosion resistance and thermal stability. These qualities make it ideal for high-temperature environments.

Aluminum is another popular option. It’s lightweight yet strong, which is why it dominates transportation industries. In fact, 65% of aluminum sheet metal products are used in automotive and aerospace applications. I’ve noticed how its relative strength and resistance to rust make it perfect for creating fuel-efficient vehicles.

Copper, though less common, plays a vital role in electrical and plumbing systems. Its excellent conductivity and malleability make it indispensable for wiring and piping. While it’s not as strong as steel or aluminum, its unique properties fill a niche that other metals can’t.

Here’s a quick comparison of these metals:

Factors Influencing Material Choice

Choosing the right metal for a project isn’t always straightforward. Several factors come into play, and I’ve learned that balancing these considerations is key to successful fabrication.

Cost is often the first factor. For example, switching from steel to aluminum in automotive design reduces weight by 65%, improving fuel efficiency by 6-8% for every 10% weight reduction. However, aluminum can be more expensive than steel, so the decision depends on the project’s budget.

Strength-to-weight ratio matters for performance. Lightweight metals like aluminum excel in applications where reducing weight is critical.

Durability is another consideration. Stainless steel’s corrosion resistance makes it ideal for outdoor or high-moisture environments.

Machinability and weldability affect ease of manufacturing. Some metals are easier to cut, bend, or weld, which can save time and labor costs.

Design complexity also plays a role. Intricate designs may require metals that are more malleable, like copper.

Here’s a breakdown of additional factors:

Ultimately, the choice of material depends on the project’s specific needs. I’ve found that understanding these factors helps ensure the best results in sheet metal fabrication.

Key Processes in the Sheet Metal Fabrication Process

When I first explored the sheet metal fabrication process, I realized how critical the key processes are to achieving precision and efficiency. These processes—cutting, forming, and joining—are the backbone of sheet metal work. Each step plays a unique role in transforming raw metal sheets into functional components.

Cutting Techniques

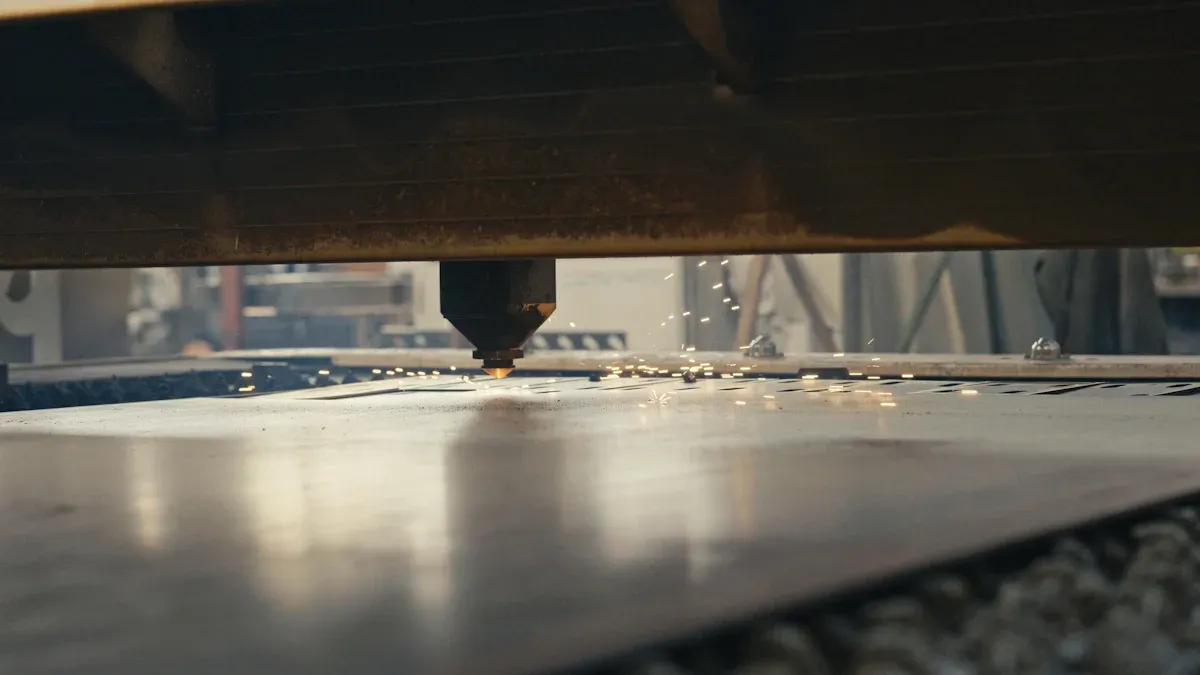

Cutting is the first step in the sheet metal fabrication process. It involves separating a sheet metal workpiece into smaller sections or specific shapes. I’ve seen how advanced cutting techniques improve production efficiency and reduce waste. Some common methods include laser cutting, plasma cutting, and waterjet cutting.

Laser cutting stands out for its precision. It uses a focused beam of light to slice through metal, achieving dimensional accuracy and smooth edges. Plasma cutting, on the other hand, uses ionized gas to cut through thicker materials like steel. Waterjet cutting is ideal for heat-sensitive applications since it uses high-pressure water mixed with abrasives to cut without generating heat.

Here’s a table highlighting the importance of cutting techniques in production efficiency:

At Foxsen, we’ve adopted cutting-edge CNC cutting systems to enhance precision and productivity. These systems integrate automation and AI, enabling adaptive cutting speeds and defect prediction. This innovation has transformed how sheet metal cutting techniques are applied in modern manufacturing.

Forming Techniques

Forming techniques shape the sheet metal workpiece into the desired geometry. This step involves bending, rolling, and stamping. I’ve noticed how forming techniques allow for complex designs while maintaining the structural integrity of the metal.

Bending is one of the most common methods. It uses press brakes to fold the metal into specific angles. Rolling is another technique that creates cylindrical or curved shapes by passing the sheet metal through rollers. Stamping involves pressing the metal into molds to create intricate patterns or shapes.

Technological advancements have revolutionized forming techniques. For example, automated CNC panel bending systems have reduced cycle times by up to 60%. These systems also minimize material usage, making the process more cost-effective. At Foxsen, we’ve embraced these innovations to deliver high-quality sheet metal workpieces efficiently.

Joining Techniques

Joining techniques bring individual sheet metal components together to form a complete assembly. I’ve found this step to be crucial for ensuring the durability and functionality of the final product. Common methods include welding, adhesive bonding, mechanical fastening, and brazing.

Welding is the most widely used joining method. It fuses metals together using heat, creating strong and permanent bonds. Adhesive bonding, however, offers unique advantages like uniform stress distribution and the ability to join dissimilar materials. Mechanical fasteners, such as screws and rivets, provide easy disassembly, making them ideal for applications requiring maintenance. Brazing and soldering use filler metals to join components, offering good sealing properties and fatigue resistance.

Here’s a table comparing different joining methods:

I’ve seen how adhesive bonding has gained popularity for lightweight construction and vibration damping. It also enhances aesthetics by eliminating visible fasteners or weld marks. At Foxsen, we prioritize joining techniques that align with our clients’ needs, ensuring optimal performance and design flexibility.

Sheet Metal Fabrication Process Steps

Designing and Blueprint Generation

When I first learned about the importance of designing in the sheet metal fabrication process, I realized how crucial it is to get this step right. The design phase sets the foundation for the entire fabrication process. It involves creating detailed blueprints that guide every subsequent step, ensuring precision and efficiency.

I always emphasize the significance of Design for Manufacturing (DFM) strategies during this phase. These strategies help optimize designs to reduce errors and improve manufacturability. For instance, incorporating manufacturing tolerances ensures consistency and quality in the final product. Technical drawings serve as the blueprint, detailing essential information like dimensions, material specifications, and finishing requirements.

Accurate dimensioning is vital. I’ve seen how using Geometric Dimensioning and Tolerancing (GD&T) maintains precision by clearly defining tolerances and originating dimensions from a single reference point. This approach minimizes tolerance stack-up, which can lead to misaligned components.

Tip: Always prioritize clarity in technical drawings. Clearly defined dimensions and tolerances eliminate ambiguity, saving time and reducing errors during fabrication.

Material Selection

Material selection is another critical step in the sheet metal fabrication process. I’ve learned that choosing the right material can make or break a project. This decision impacts not only the cost but also the performance and durability of the final product.

Several criteria influence material selection. Economic aspects play a significant role, as the choice of material affects design and fabrication costs. Operational aspects, such as mechanical strength and surface finish, determine how well the material performs in its intended application. Performance properties, like corrosion resistance and dimensional stability, are essential for products exposed to harsh environments.

Here’s a table summarizing these criteria:

When selecting materials, I often weigh these factors against the project’s requirements. For example, steel is ideal for applications requiring strength and durability, while aluminum excels in lightweight designs. Copper is perfect for electrical systems due to its conductivity.

Cutting and Shaping

Cutting and shaping are where the magic happens in the sheet metal fabrication process. This step transforms raw metal sheets into the desired shapes and sizes. I’ve seen how advanced techniques like laser cutting, plasma cutting, and waterjet cutting revolutionize this phase.

Laser cutting is my favorite for achieving precision. It uses a focused beam of light to slice through metal, creating smooth edges and accurate dimensions. Plasma cutting is better suited for thicker materials like steel, while waterjet cutting is ideal for heat-sensitive applications.

Shaping involves techniques like bending, rolling, and stamping. Bending uses press brakes to fold metal into specific angles. Rolling creates cylindrical or curved shapes by passing the sheet through rollers. Stamping presses the metal into molds, forming intricate patterns or designs.

Here’s a step-by-step breakdown of the cutting and shaping process:

I always stress the importance of precision in parameter settings. Small batch testing bridges theoretical settings with real-world production, ensuring consistent quality. Continuous monitoring during production helps maintain accuracy and reduces waste.

Note: Cutting and shaping are interrelated steps. Proper setup and testing during cutting ensure smooth shaping, while continuous monitoring guarantees quality throughout the process.

Assembly and Joining

When I first explored the assembly stage of the sheet metal fabrication process, I realized how crucial it is for creating durable and functional products. This step involves combining individual components into a complete structure. The choice of joining methods depends on the material, design, and application requirements.

One of the most common techniques I’ve encountered is welding. It uses heat to fuse metal parts together, forming strong and permanent bonds. For example, in automotive manufacturing, welding ensures the structural integrity of car bodies. Another method I’ve seen is adhesive bonding, which distributes stress evenly and works well for joining dissimilar materials. Mechanical fasteners, like screws and rivets, are ideal for applications requiring easy disassembly.

Here’s a table summarizing some advanced joining methods and their applications:

I’ve noticed that these methods offer unique advantages. For instance, flow-drill-screwing eliminates the need for pre-drilled holes, saving time and reducing material waste. Adaptive joining elements create robust interlocks, making them perfect for load-bearing applications.

Tip: Always choose a joining method that aligns with the material properties and design requirements. This ensures optimal performance and longevity of the final product.

Surface Finishing and Quality Control

Surface finishing is the final step in the sheet metal fabrication process. It enhances the appearance, durability, and functionality of the product. I’ve learned that finishing processes, such as painting, powder coating, and anodizing, play a vital role in protecting the metal from corrosion and wear.

One of the most fascinating aspects of finishing is its impact on product longevity. For example, smoother surfaces reduce friction, leading to less energy loss and wear. Improved finishes also minimize surface irregularities, which helps prevent corrosion. I’ve seen how this extends the lifespan of products, especially in harsh environments.

Here’s a table illustrating the benefits of surface finishing:

Quality control is equally important in this stage. I’ve observed how manufacturers use inspection methods like visual checks, thickness measurements, and adhesion tests to ensure the finishing meets industry standards. Detailed documentation throughout the process helps maintain traceability and ensures consistent quality.

Note: Investing in high-quality finishing processes not only improves product performance but also reduces maintenance costs over time.

Applications of Sheet Metal Fabrication

Automotive and Aerospace

When I first learned about the role of sheet metal in automotive and aerospace industries, I was amazed by its versatility. Sheet metal fabricators create components that are essential for vehicle and aircraft performance. In automotive manufacturing, sheet metal is used for body panels, chassis, and structural parts. These components must be lightweight yet durable to improve fuel efficiency and safety.

I’ve seen how advanced processes like laser cutting and stamping enhance precision in automotive applications. For example, an electromagnetic-acoustic transducer system was employed to assess the formability of sheet steel. This system achieved frequency measurements up to 7.5 MHz, establishing a correlation between the dimensionless frequency ratio and the steel’s formability. This research is crucial for optimizing sheet metal in automotive manufacturing.

In aerospace, sheet metal fabrication plays a key role in creating fuselage panels, wing skins, and internal structures. These parts must withstand extreme conditions while maintaining lightweight properties. The process ensures that aircraft components meet strict safety and performance standards.

Construction and Architecture

Sheet metal fabrication has transformed the construction and architecture industries. I’ve noticed how sheet metal is used to create roofing, gutters, ventilation systems, and decorative panels. Its durability and adaptability make it ideal for both structural and aesthetic applications.

One of the most fascinating aspects is how sheet metal fabricators contribute to modern architectural designs. They use forming techniques to create intricate patterns and shapes that enhance building aesthetics. For example, curved metal panels are often used in contemporary designs to achieve a sleek and modern look.

Sheet metal also improves efficiency in construction. Prefabricated components reduce installation time and labor costs. I’ve seen how this approach speeds up projects while maintaining high-quality standards.

Consumer Goods and Appliances

Sheet metal fabrication is everywhere in consumer goods and appliances. I’ve observed how it’s used to create parts that require high strength and precision. These include chassis, brackets, frames, panels, enclosures, and structural components in products ranging from refrigerators to electronic devices.

The process ensures that these components meet the demands of modern manufacturing. For example, finite element methods (FEM) were used to analyze the eigenfrequencies of a soundboard. This study revealed that frequencies increase with the material’s density and elasticity. This research highlights how sheet metal fabrication optimizes sound quality in musical instruments like pianos.

Sheet metal fabricators also prioritize durability and aesthetics in consumer goods. I’ve seen how surface finishing techniques, such as powder coating, enhance the appearance and longevity of products. These methods ensure that appliances and electronics remain functional and visually appealing for years.

When I reflect on the sheet metal fabrication process, I see how it forms the backbone of modern manufacturing. Its ability to transform raw metal into precise, durable components makes it indispensable across industries. From automotive to aerospace, the versatility of sheet metal ensures it meets diverse needs.

Advancements like machine learning have further enhanced its efficiency. For instance, early detection of tool wear now improves workpiece quality while reducing failures. Inline wear quantification achieves deviations as low as 0.83% in blanking and 2.21% in roll forming. These innovations ensure consistent results and minimize waste.

I encourage anyone interested in manufacturing to explore this field. Whether you’re designing a product or optimizing a process, understanding sheet metal fabrication can unlock new possibilities.

FAQ

What is the difference between sheet metal and plate metal?

Sheet metal is thinner than plate metal. I’ve learned that sheet metal typically measures less than 6mm in thickness, while plate metal is thicker. This distinction makes sheet metal ideal for lightweight applications, such as automotive panels, while plate metal suits heavy-duty uses like shipbuilding.

How do I choose the right sheet metal for my project?

I always consider factors like strength, weight, and corrosion resistance. For example, aluminum works well for lightweight designs, while stainless steel resists rust in outdoor environments. Matching the material to the project’s needs ensures durability and performance.

Can sheet metal be recycled?

Yes, sheet metal is highly recyclable. I’ve seen how industries reuse metals like aluminum and steel to reduce waste and conserve resources. Recycling also lowers production costs, making it an eco-friendly and economical choice.

What tools are used to cut sheet metal?

Common tools include laser cutters, plasma cutters, and waterjet machines. I’ve noticed that laser cutters excel in precision, while plasma cutters handle thicker materials. Waterjet machines are perfect for heat-sensitive projects since they don’t generate heat during cutting.

Is sheet metal fabrication expensive?

The cost depends on factors like material type, design complexity, and production volume. I’ve found that bulk orders and efficient designs can lower costs. For example, using automated processes like CNC cutting reduces labor expenses and material waste.