Sheet metal bending changes flat metal into useful, nice-looking parts. It makes sure shapes are accurate and the right size. Big industries like car-making and airplanes use bending for top-quality work. Studies say bending machines will grow from $2.10 billion in 2023 to $2.80 billion by 2028. This growth comes from needing exact and automatic tools. Bending helps make things stronger and better-looking. It solves problems with making designs strong, smart, and new.

Key Takeaways

Sheet metal bending changes flat metal into exact shapes for use. It is important in industries like car-making and airplanes.

Knowing ideas like K-factor and bend allowance helps make good bends. It also stops the metal from getting damaged.

New methods like CNC bending and multi-axis bending make work more accurate. They also help create tricky designs and save time.

Picking the right metals, like steel or aluminum, makes designs strong. It’s also good to think about helping the environment.

New tools, like AI and digital twins, will change metal bending. They will make it faster and help create cooler designs.

Understanding Sheet Metal Bending

Defining Sheet Metal Bending

Sheet metal bending changes flat metal into exact shapes. This process keeps the metal from breaking by using tools like press brakes. Engineers use ideas like the K-factor and bend allowance to measure sizes correctly.

K-factor: This shows how much the metal stretches when bent.

Bend allowance: This adds extra length for the stretching during bending.

When bending, the outside of the metal stretches, and the inside gets squeezed. The neutral axis moves, so I always check it for accuracy. Methods like V-bending, U-bending, and rotary bending help make sharp edges or smooth curves.

Following rules about hole placement and material properties ensures perfect bends. These steps help me create high-quality work every time.

Applications in Modern Design

Sheet metal bending is very important in today’s designs. I’ve seen it used in cars, planes, and buildings. In cars, it makes strong brackets and smooth panels. In planes, it creates light but strong parts for safety.

Designers use bending for both looks and function. For example, electronics need exact bends to fit parts well. Buildings use bent metal for beautiful walls and strong structures.

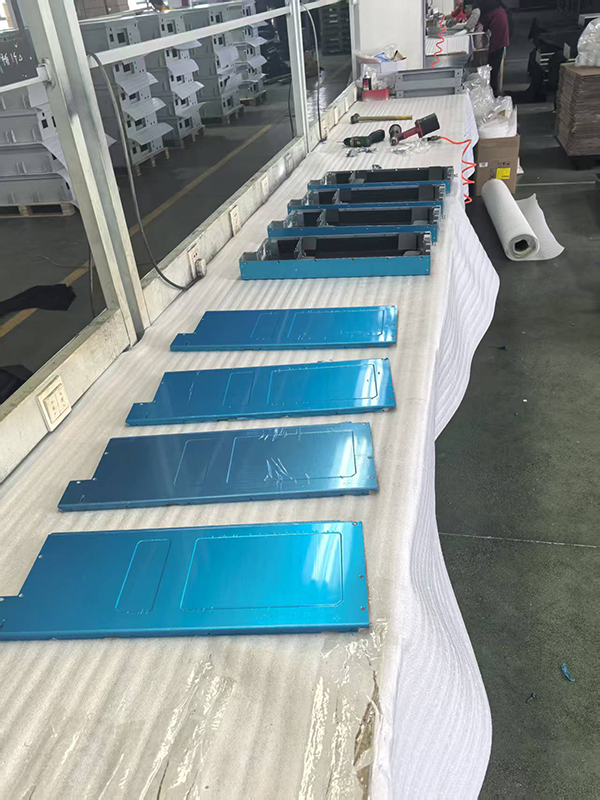

At Foxsen, we focus on bending to meet these needs. Our advanced machines shape metal perfectly, making every design just right.

Benefits in Sheet Metal Fabrication

Sheet metal bending has many advantages. I’ve noticed it saves material, keeps sizes correct, and speeds up production. Here’s a breakdown:

At Foxsen, we are proud to offer these benefits. Using top tools and materials, we make sure every project is strong and precise.

Advanced Techniques in Metal Bending

CNC Bending for Precision

Precision is key to bending metal correctly. CNC bending, which means Computer Numerical Control bending, makes this easier. These machines help control every part of the bending process. They can make detailed shapes that are accurate and repeatable.

Why CNC bending is special:

Modern machines keep bends accurate, even for tricky designs.

Software like 3D simulation lets me test bends before making them. This reduces mistakes and improves the process.

CNC bending handles hard shapes that older methods struggle with.

Using CNC bending ensures parts match exact designs. This method has changed how I work on projects needing high accuracy.

Comparing Air Bending and Bottom Bending

Air bending and bottom bending are two ways to bend metal. Each has its own benefits, and knowing the difference helps me pick the best one.

In air bending, the metal doesn’t touch the die completely. This lets me make different angles with fewer tools. It’s fast and good for less precise jobs. Bottom bending presses the metal fully into the die. This gives better accuracy and works well for tight designs.

Quick comparison:

Air Bending:

Needs less force and fewer tools.

Allows easy angle changes.

Can cause springback, which I plan for.

Bottom Bending:

Gives more accurate and steady results.

Needs more force and special tools.

Best for exact angles and less springback.

Knowing these methods helps me choose the right one. For example, air bending works better with aluminum because it needs less force.

Multi-Axis Bending Innovations

Multi-axis bending lets me bend metal in many directions. This creates shapes that were hard to make before.

One study showed how multi-axis bending helps in medical device making. Researchers used special tools to measure how surgical devices bend. This helped improve designs and inspired new bending ideas.

I’ve found multi-axis bending great for complex designs. It’s useful in industries like aerospace and cars, where parts need tricky shapes. This method makes parts that work well and look good.

Multi-axis bending is the future of metal bending. It mixes creativity and accuracy, letting me create amazing designs and strong parts.

Material Selection for Sheet Metal Bending

Picking Metals for Bending

Choosing the right metal is very important for good results. I often use steel, aluminum, and titanium because they are strong and useful. Steel is tough, aluminum is light, and titanium is super strong.

When bending, I check the K-factor. This shows how much the metal stretches. Most metals have a K-factor between 0.3 and 0.5 mm. The average is about 0.4468 mm. This helps me make accurate bends without ruining the metal. I also make sure the bend radius is as big as or bigger than the metal’s thickness. This keeps the metal strong.

Studies on the sheet metal market show how important these steps are. They explain how metal properties and bending methods affect the final product. By knowing this, I can make better designs that fit perfectly.

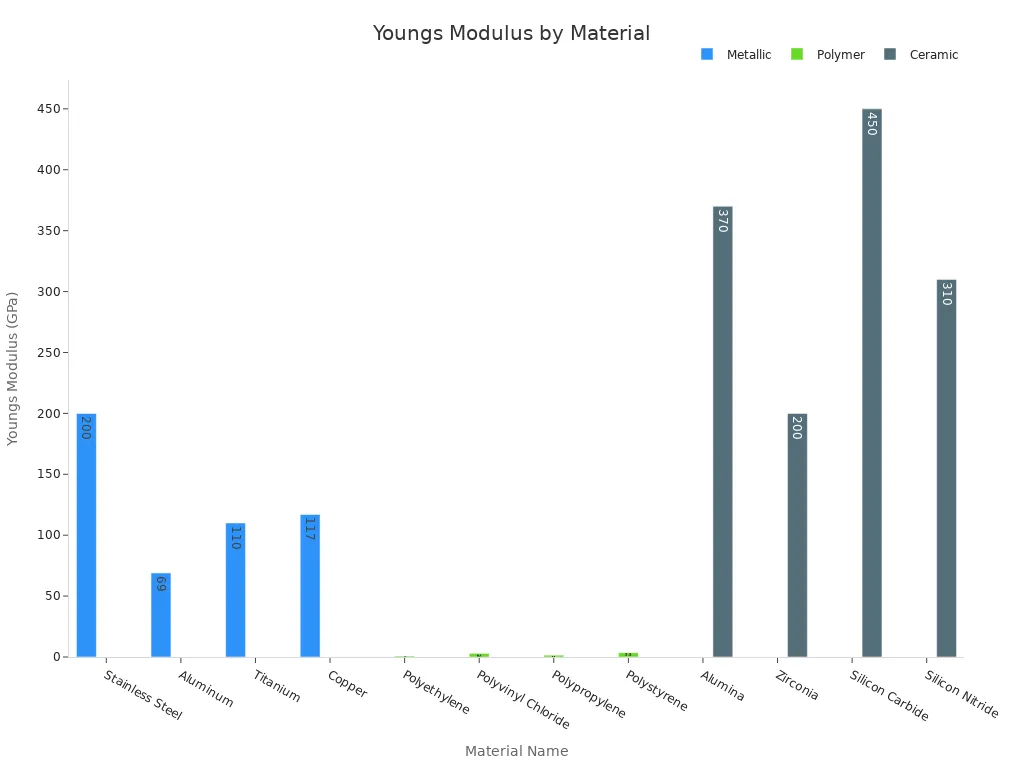

How Material Properties Affect Design

The type of metal changes how well bending works. Metals like stainless steel, aluminum, and copper have special traits. Stainless steel is strong and stretches well, so it’s great for tough designs. Aluminum bends easily but needs care to avoid cracks.

These details help me pick the best metal for each job. If I need something flexible, I might use copper because it stretches a lot. For strong designs, titanium is a great choice.

Making Sheet Metal Work Sustainable

Being eco-friendly is now very important in metal work. I try to use metals that can be recycled and save energy. Aluminum is easy to recycle, and steel lasts a long time, which cuts down waste.

Using green methods also makes work faster and cheaper. For example, using less energy with metals like Invar and aluminum alloys saves resources. This helps the planet and lowers costs for customers.

By focusing on eco-friendly choices, I make sure my work is good for the environment. This way, I can create great products and help protect the Earth.

Technology’s Role in Sheet Metal Bending

Laser Cutting Integration

Laser cutting has changed how I work with metal. It helps me make exact cuts for better bending. Fiber lasers are very useful. I use them for custom items and small projects. They let me meet special design needs without losing quality.

New laser forming methods have also helped a lot. These methods make complex parts more accurate. This is important for perfect designs. Using computer simulations, I can see how metal acts during forming. This helps me improve designs and make sure every bend is just right.

Software for Design Optimization

Modern software tools are very helpful in my work. They let me see and test designs before bending metal. 3D modeling programs show how bending will work and find problems early. This saves time and materials.

One great feature is design optimization. The software checks things like metal thickness and bend angles. It suggests changes to make the product better. This way, the parts I make are strong and work well.

Case Studies in Technological Applications

I’ve seen how technology improves metal work. In one project, I used lasers and software to make a light but strong aerospace part. The laser cuts made pieces fit perfectly. The software helped me design for strength and less weight.

In another project, I used multi-axis bending and simulations for medical devices. These tools helped me meet exact needs for the job. This shows how technology makes amazing metal designs possible.

Challenges and Future of Metal Bending

Addressing Common Bending Challenges

Bending metal often comes with problems that need fixing. I’ve faced issues that slow work and hurt quality. Here are some common ones:

Technical Inflexibility: Stiff methods block creativity and waste time.

Welding and Cutting Errors: Bad practices cause weak spots and broken parts.

Equipment Maintenance Issues: Skipping tune-ups leads to more mistakes and dangers.

Quality Control Oversights: Missing checks causes big errors and delays.

Improper Material Selection: Picking the wrong metal causes most bending problems.

To solve these, I follow rules like ASTM E290 and ISO 7438. These give clear steps to test and improve bending. Keeping tools in good shape and planning ahead also helps me avoid mistakes.

Emerging Trends in Sheet Metal Fabrication

The metal industry is changing fast, and I see new trends. Hybrid methods mix different processes to make work faster and better. Robots help speed up tasks and keep workers safe, especially when there aren’t enough people.

Cloud tools now let me check project data anytime. This makes managing work easier and quicker. Machines with comfy controls also help workers stay less tired, making advanced tools easier to use.

The market for automatic bending machines is growing. It’s expected to rise from $1.9 billion in 2019 to $2.4 billion by 2024. This growth is due to the need for precise and automated tools in industries like cars and planes.

Future Innovations in Metal Bending

The future of bending looks exciting with new ideas changing the field. Companies like Amada Holdings and Trumpf Group are adding robots and smart systems to their work. Digital twin technology, used by Bystronic and MetalLogic, helps make designs more accurate and reduces mistakes.

Machine learning is also a big deal. Salvagnini’s BendAI software uses smart tools to plan bending steps better. Cobots, or helper robots, are becoming popular too. Prima Power and HanRobo teamed up to make safer and faster solutions.

These new tools not only improve bending but also allow for cooler, more detailed designs. I’m eager to see how these technologies will keep improving the industry.

Sheet metal bending is important for making modern designs and products. It changes flat metal into strong, exact, and nice-looking parts. Methods like CNC bending and multi-axis bending help make accurate shapes. Picking the right materials also makes parts stronger and eco-friendly.

I’m excited about the future of metal bending. New tools like AI and digital twins will make work faster and smarter.

Using skill and new technology, we can create designs that solve today’s problems and fit future needs.

FAQ

What is sheet metal bending?

Sheet metal bending changes flat metal into shapes or angles. Tools like press brakes help make bends accurate. This process turns raw metal into useful parts for cars and planes.

How do you pick the right bending tools?

Choose tools based on the metal type, thickness, and bend needed. Press brakes work well for most metals. Using the right tools keeps bends accurate and avoids damage.

Why does precision matter in bending?

Precision makes sure the product matches the design exactly. Accurate bends make parts stronger and work better. This is very important for buildings and electronics where mistakes cause problems.

Can bending be good for the environment?

Yes, it can be eco-friendly. Using recyclable metals like aluminum and steel cuts waste. Efficient methods also save energy. These steps help make designs better for the planet.

Which industries use sheet metal bending the most?

Car-making, airplane-building, and construction use bending a lot. It makes strong, light, and nice-looking parts. Electronics and medical tools also need exact bending for their designs.