Key Takeaways

Pick a reliable sheet metal supplier for good materials and fewer delays.

Find suppliers with certifications like ISO 9001:2015 for quality products.

Choose suppliers that care about the environment and new ideas to make your project greener.

Work with suppliers long-term for steady help and better results.

Check a supplier's reviews and tools to see if they fit your project needs.

The Sheet Metal Industry in 2025

Importance of Sheet Metal in Industrial and Construction Applications

Sheet metal is a big part of our daily lives. It’s used in buildings, cars, and many other things. In construction, it’s important for roofs, walls, and strong structures. In factories, it helps make tough parts for machines to work well.

The need for sheet metal is growing quickly. Why? Cities are expanding, and new buildings need more materials. Green building is also becoming popular. People now prefer energy-saving materials like insulated sheet metal for eco-friendly projects.

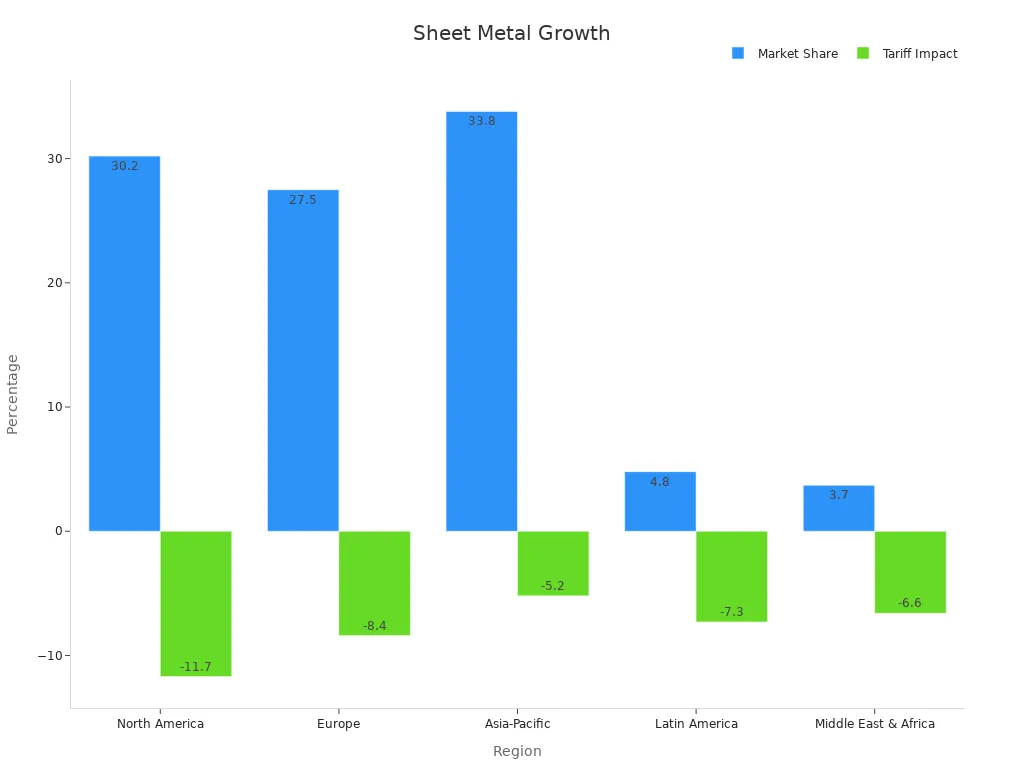

Trends Driving Growth in the Sheet Metal Industry

The sheet metal market is growing fast, and numbers show it. By 2032, it could reach $490.65 billion, growing 4.7% each year. This is due to more buildings, cars, and better technology.

Here’s what’s driving the growth:

More local production because of tariffs.

Over 31% of factories went digital since 2022.

The U.S. might make 22.5 million metric tons of sheet metal in 2025.

Asia-Pacific is leading because of fast industrial and building growth. In the U.S., contract manufacturing may grow by 21.3% from 2025 to 2027. These trends show how important the sheet metal industry is becoming.

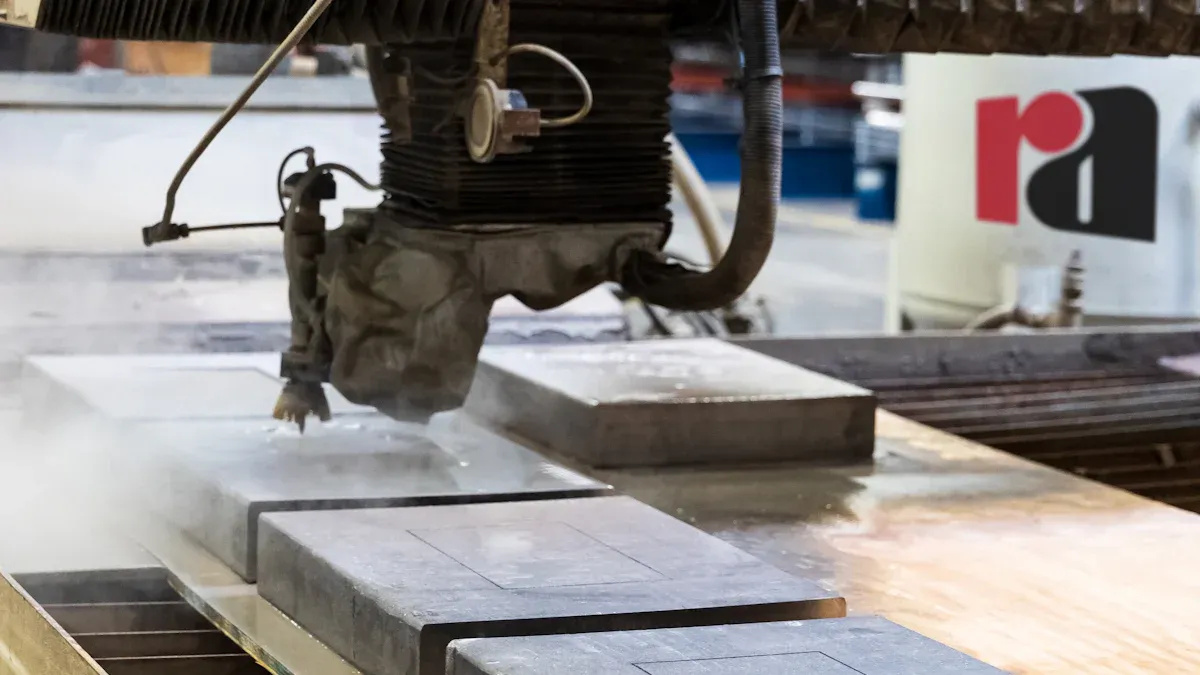

Technological Advancements in Sheet Metal Fabrication

Technology is changing how sheet metal is made. You might know about 3D printing. Now, it’s used to make tricky sheet metal designs faster and easier.

Other new technologies include:

Laser Cutting: Faster and cheaper with fiber lasers.

Advanced CNC Machinery: Cuts and shapes metal with high accuracy.

IoT Monitoring Systems: Tracks work to avoid mistakes.

Sustainability is also pushing new ideas. Recycling and energy-saving methods are now common. These changes make the industry better and help protect the environment.

Leading Sheet Metal Suppliers for Industrial and Construction Needs

Global Leaders in the Sheet Metal Industry

Finding a trusted sheet metal supplier is important. Top companies lead with quality, new ideas, and great service. They stand out because they produce a lot, sell well, and meet many needs.

These companies always provide top products to keep projects running smoothly. For example, many leaders deliver 99.88% on time, with an average of 10 days. They also follow ISO 9001:2015 rules, so you can trust their materials.

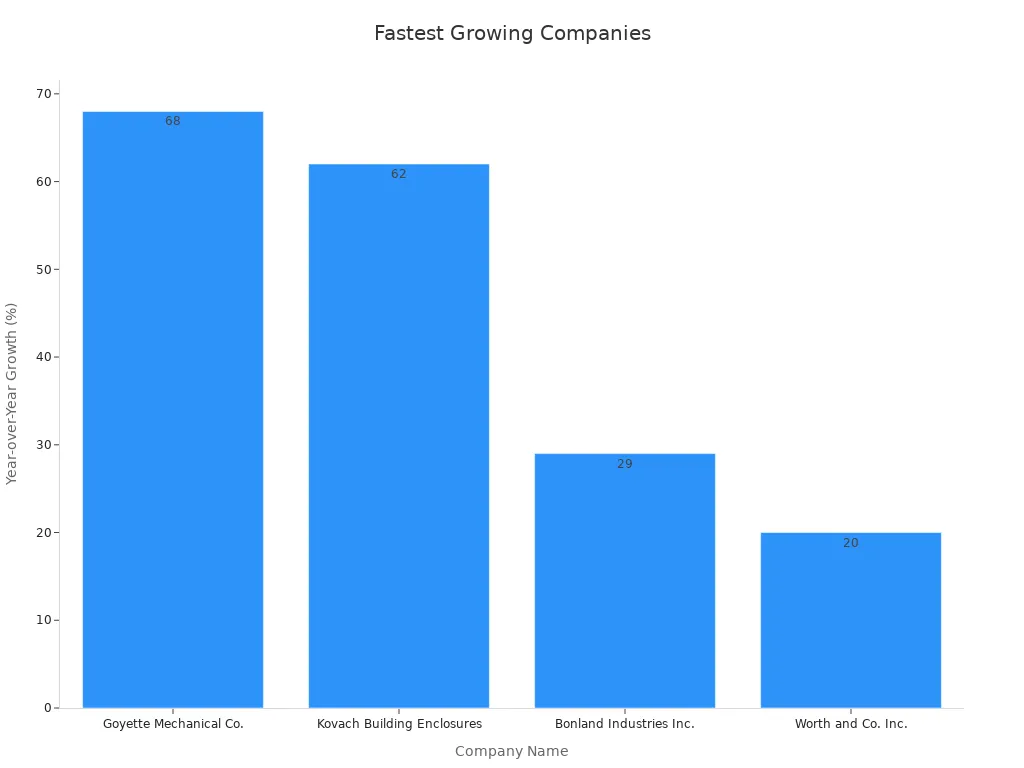

Fastest-Growing Sheet Metal Companies

The sheet metal industry is changing fast, and some companies are growing quickly. They are expanding, using new technology, and meeting the need for precise sheet metal work.

These companies are not just growing—they’re improving. They focus on custom and precise sheet metal work to meet special needs. Whether it’s HVAC systems or custom jobs, they offer solutions for contractors and industries.

Companies Specializing in Sheet Metal Fabrication Services

If you need custom designs or precise metal fabrication, work with experts in this field. These companies make high-quality parts that match your needs.

The global market for precise sheet metal services is growing fast. Trends like eco-friendly methods, custom designs, and new tech drive this growth.

Big companies use advanced tools like laser cutting and CNC machines to save time and reduce waste.

North America and Asia-Pacific are key areas for growth, especially in aerospace and electronics.

These companies know how to deliver great products on time. They team up with certified sheet metal makers to ensure every part is perfect. Whether you need industrial parts or custom jobs, these experts can handle it all.

Tip: Pick a sheet metal supplier that offers both making and installing services. This saves time and makes the process easier for you.

Suppliers Focused on Sustainability and Innovation

The future of sheet metal companies depends on being green and smart. These suppliers do more than make products—they help build a better world. By using eco-friendly methods and new technologies, they cut waste, save energy, and improve designs.

Many suppliers now work to protect the environment. They use recycled materials and energy-saving methods. Advanced tools help them make smarter choices. For instance, some follow ISO 50001 rules to manage energy well. This lowers costs and helps the planet.

Innovation is also changing the game. Tools like laser cutters and IoT systems make work faster and better. These tools help companies create high-quality products with less waste and fewer delays.

Here’s how they measure their efforts:

These steps show how suppliers mix eco-friendly ideas with smart production. Choosing these companies means getting great products and helping the planet.

How can you find these suppliers? Look for ones using renewable energy and recyclable materials. They should also invest in new tech and offer lifecycle reports to meet your green goals.

Tip: Picking eco-friendly and innovative suppliers can improve your project’s image and success. It’s good for both your business and the Earth.

By teaming up with these suppliers, you’ll get better materials, smarter solutions, and a trusted partner for your needs.

How to Choose the Right Sheet Metal Supplier

Checking Product Quality and Standards

When picking a sheet metal supplier, start by checking product quality. Good materials make sure your projects are safe and last longer. Look for suppliers with certifications like ISO 9001:2015. These show they follow strict rules for quality during production.

You can ask for samples or visit their factory. This lets you see the quality yourself. Check things like thickness, finish, and strength. For industrial or construction projects, these details are very important. A good supplier will always give you reliable materials that meet your needs.

Tip: Ask about their testing process. Suppliers who test often are more likely to provide dependable products.

Looking at Supplier Reputation and Experience

A supplier’s reputation shows how trustworthy they are. Read reviews and feedback from other contractors. Positive reviews mean good service and on-time deliveries. Also, check if they have experience in your industry, like construction or custom fabrication.

Experienced suppliers know the challenges of your projects. They can give advice on materials and planning. For big projects, they help with bulk orders and avoid delays.

Here’s a simple checklist to check a supplier’s reputation:

Do contractors in your field give them good reviews?

How many years have they been in the business?

Do they specialize in your type of project, like construction or industrial work?

Note: A supplier with a good history is more likely to be a trusted long-term partner.

Why Technology Matters in Sheet Metal Fabrication

Technology is key in today’s sheet metal work. Suppliers with advanced tools can make precise and accurate parts. Tools like CNC machines and laser cutters help create detailed designs with fewer mistakes. This leads to better results for your project.

Here’s how technology helps:

Faster Work: Magnetic die tools speed up project changes, saving time.

Less Waste: Smart nesting methods use materials efficiently, cutting costs.

Better Accuracy: CNC machines ensure every part is made perfectly.

Automation also keeps work consistent. Real-time monitoring systems fix issues quickly during production. Data tools help suppliers improve over time, making their work even better.

Tip: Ask about the supplier’s technology. Advanced tools mean they can handle tricky designs and deliver great results.

By focusing on quality, reputation, and technology, you can find a sheet metal supplier who fits your needs and helps your projects succeed.

Customer Support and Service Reliability

Picking a sheet metal supplier with good customer support is important. They should listen, reply fast, and fix problems quickly. Reliable service keeps your projects running smoothly, even if issues come up.

Top suppliers build trust by offering steady quality and help. Look for these signs:

Strong focus on quality checks. This shows they care about giving you reliable products.

Few complaints or returned items. Happy customers mean fewer project delays.

Following rules like ISO 9001. This ensures safety and better work processes.

Suppliers who care about customer happiness often get repeat clients. They know your success helps their business grow. Whether you’re working on big construction jobs or smaller industrial tasks, dependable service saves time and reduces stress.

Tip: Ask how quickly they respond to problems and handle complaints. A supplier who acts fast will always support you.

Balancing Pricing and Delivery Efficiency

Finding the right balance between cost and delivery speed is tricky but necessary. You need high-quality materials delivered on time without spending too much money.

Here’s how great suppliers manage this balance:

Suppliers using these methods offer fair prices and reliable service. For contractors, this means fewer delays and steady costs. For example, suppliers with good inventory systems always have materials ready when needed. This avoids downtime and keeps projects moving.

Note: Don’t just pick the cheapest option. Check if the supplier delivers on time and handles big orders well. Paying a bit more might be worth it for better reliability.

By focusing on customer care and smart pricing, you can find a supplier who fits your needs and helps your projects succeed.

Benefits of Partnering with Trusted Sheet Metal Companies

Making Projects Faster and More Affordable

Working with trusted sheet metal companies helps projects go smoothly. They provide high-quality metal parts that match your needs exactly. This reduces mistakes and saves time. When materials arrive on time, you avoid expensive delays. Reliable suppliers also help you plan better with clear timelines and cost estimates.

You can also save money over time. Trusted suppliers use advanced tools to make accurate parts, reducing waste. Many offer discounts for large orders, making big projects cheaper. Picking the right supplier means getting great service and materials within your budget.

Tip: Ask about their delivery history. A supplier with on-time deliveries can prevent delays.

Getting Custom Sheet Metal for Special Projects

Every project is different, and standard materials don’t always work. That’s when custom sheet metal products are needed. Trusted companies make parts designed just for your project. Whether you need detailed designs or special shapes, they can help.

These companies use advanced tools like CNC machines and laser cutters. This ensures the parts fit perfectly in your project. They also guide you in picking the best materials for strength and durability.

Note: Custom services are great for unique projects. Look for suppliers who offer advice to meet your needs.

Building Strong Partnerships for Reliable Supplies

Having a good relationship with your supplier makes a big difference. Long-term partnerships mean you’ll always have a steady source for metal parts. Trusted suppliers focus on your needs, delivering quality and on-time service.

These partnerships make sourcing easier. You won’t need to find new suppliers for every job. Instead, you’ll work with a team that knows your goals and challenges. Over time, this leads to better teamwork and project success.

Tip: Pick a supplier who values long-term partnerships. They’ll support your goals and become a key part of your team.

Picking the right sheet metal supplier is very important. Good suppliers give you strong materials and helpful solutions. This is key because buyers can ask for better deals. Reliable suppliers also create new ideas to meet special needs. They make lightweight and custom parts for modern projects. By choosing wisely, you can work with suppliers for a long time. This helps your projects stay on budget, run smoothly, and stay ahead of others.

FAQ

What industries use sheet metal?

Sheet metal is used in many industries. It’s common in construction, car-making, and airplane parts. Factories, HVAC systems, electronics, and furniture also use it. Its flexibility makes it useful for many things.

How do I check if a supplier meets quality standards?

Check for certifications like ISO 9001:2015. These prove they follow strict rules for quality. You can also ask for samples or visit their factory. Good suppliers are open about how they work.

What’s the difference between standard and custom sheet metal?

Standard sheet metal comes in fixed sizes and shapes. Custom sheet metal is made to fit your project’s needs. If you need special sizes or designs, choose custom options.

Are there eco-friendly sheet metal choices?

Yes, there are! Some suppliers offer recycled or energy-saving sheet metal. Look for companies using ISO 50001 or green methods. Picking eco-friendly materials helps the environment.

How do I decide between cost and delivery speed?

You need to find a balance. Paying a bit more might be worth it if the supplier delivers on time and offers good quality. Compare suppliers to find one that fits your budget and schedule.

Tip: Ask about their delivery record to avoid late shipments.