Custom sheet metal services play a crucial role in modern manufacturing. These services transform raw metal sheets into precise, functional components tailored to meet specific needs. Industries increasingly rely on this expertise due to its precision and versatility. The global sheet metal fabrication market reflects this demand, with projections showing growth from USD 18.93 billion in 2024 to nearly USD 25.51 billion by 2032. Sectors like automotive, construction, and heavy machinery drive this expansion, fueled by industrial automation and infrastructure advancements. As you explore these services, you'll discover their value in delivering durable, customized solutions.

Key Takeaways

Custom sheet metal services shape raw metal into exact parts. This improves how products work and last longer.

Main steps are cutting, bending, welding, and finishing. Each step helps make the product better and more useful.

Picking the right material is very important for success. Aluminum is light, while stainless steel is strong and lasts long.

Custom designs create solutions that fit specific needs. This boosts efficiency and cuts down on waste.

Working with skilled fabricators gives great results. They also help keep communication clear during the project.

Overview of Custom Sheet Metal Services

What Are Custom Sheet Metal Services?

Custom sheet metal services involve transforming flat metal sheets into functional components through processes like cutting, bending, and assembling. These services cater to industries requiring precision and flexibility. The term "custom" highlights the ability to tailor designs, materials, and dimensions to meet specific needs. For example, bespoke metal fabrication services allow you to create unique parts for projects with specialized requirements.

The techniques used in custom metal fabrication include laser cutting, CNC machining, and sheet metal stamping. Each method ensures accuracy and efficiency, whether you're producing prototypes or large-scale components. A variety of metals, such as aluminum, stainless steel, and brass, can be shaped to suit your project. This adaptability makes custom sheet metal services a cornerstone of modern manufacturing.

Why Are Custom Sheet Metal Services Essential for Modern Industries?

Custom sheet metal services play a vital role in industries like automotive, aerospace, and construction. These services provide the precision needed to create components that meet exact specifications. For instance, in automotive manufacturing, custom metal fabrication produces unique body parts that enhance vehicle performance and aesthetics.

The global demand for these services continues to grow. The sheet metal fabrication market, valued at USD 150.0 billion in 2023, is projected to reach USD 230.0 billion by 2032. This growth reflects the increasing reliance on bespoke metal fabrication services for both prototypes and mass production.

By choosing custom sheet metal services, you gain access to tailored solutions that improve product performance and reduce waste. These services also offer cost-effective options for creating durable, high-quality components. Whether you're working on a small-scale project or a large production run, custom metal fabrication ensures your needs are met with precision and efficiency.

Key Processes in Sheet Metal Fabrication

Sheet metal fabrication involves several core processes that transform raw sheets into functional components. Each process plays a critical role in achieving precision, durability, and efficiency. Let’s explore the key processes: cutting, bending, and welding.

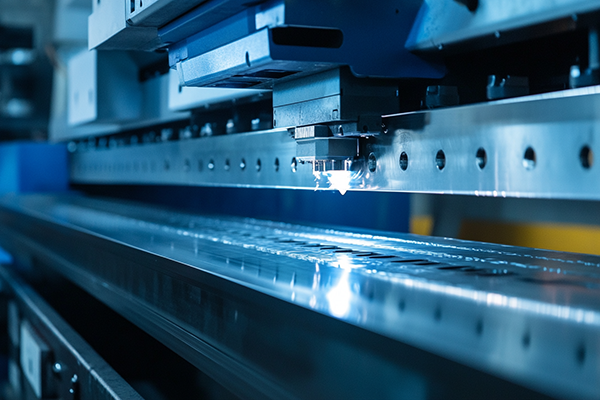

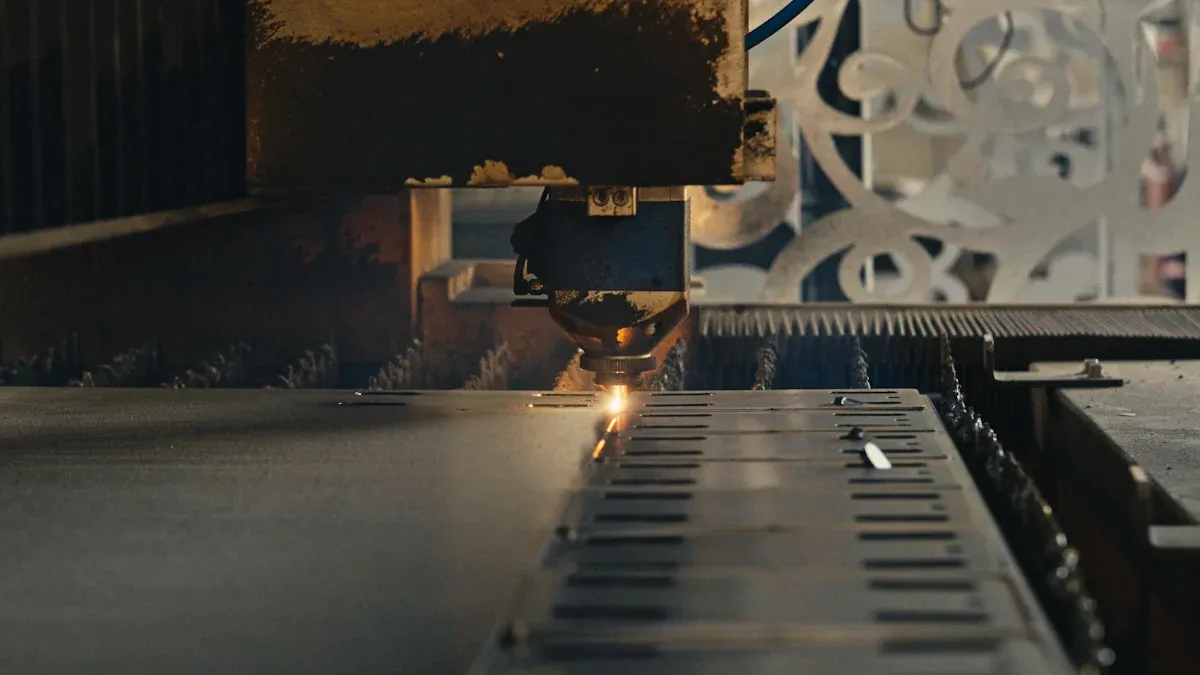

Cutting: Techniques like Laser Cutting, Plasma Cutting, and Punching

Cutting is the first step in sheet metal fabrication. It involves dividing a metal sheet into smaller, precise pieces. Techniques like laser cutting, plasma cutting, and punching are commonly used. Each method offers unique advantages depending on the material and design requirements.

Laser Cutting: This method uses a focused laser beam to achieve precision cutting. It is ideal for intricate designs and tight tolerances. Laser cutting is also energy-efficient, making it a cost-effective option for complex shapes.

Plasma Cutting: Plasma cutting employs a high-temperature jet of ionized gas to cut through thicker materials. It is faster than laser cutting but may produce a rake angle that requires additional finishing.

Punching: Punching involves using a die to create holes or shapes in the sheet. It is highly efficient for repetitive patterns and simpler designs. This method is often paired with metal stamping for mass production.

Key performance metrics for cutting include dimensional accuracy, tolerance specifications, and surface finish. These metrics ensure that the fabricated components meet design requirements and improve production efficiency.

Bending: Methods Including Press Brake Forming and Roll Forming

Bending transforms flat sheets into three-dimensional shapes. This process is essential for creating components with specific angles or curves. Two primary methods used in bending are press brake forming and roll forming.

Press Brake Forming: This method uses a press brake machine to bend the sheet along a straight axis. It offers precise control over angles and is suitable for smaller production runs.

Roll Forming: Roll forming involves passing the sheet through a series of rollers to achieve the desired shape. It is ideal for high-volume production but may introduce residual stresses in the material.

Residual stresses in roll-formed sections are typically larger than those in press-braked sections. This difference impacts the final product's strength and reliability. By selecting the appropriate bending method, you can ensure the component meets both functional and aesthetic requirements.

Welding: MIG, TIG, and Spot Welding for Metal Joining

Welding joins metal pieces to create a single, cohesive structure. It is a critical step in sheet metal fabrication, especially for assembling complex components. Common welding techniques include MIG, TIG, and spot welding.

MIG Welding: This method is fast and effective for joining thick materials. It achieves over 90% of the parent material's strength, making it reliable for heavy-duty applications.

TIG Welding: TIG welding provides precise control, resulting in a denser weld with nearly 95% of the parent material's strength. It is ideal for critical applications like medical devices or aerospace components.

Spot Welding: Spot welding uses heat and pressure to join thin sheets at specific points. It is best suited for lightweight materials and high-speed production.

The choice of welding technique depends on factors like material thickness, strength requirements, and application. For example, TIG welding is preferred for titanium alloys due to its superior precision, while MIG welding is more efficient for thicker plates.

By understanding these fabrication processes, you can select the most suitable methods for your project. Each process contributes to the overall quality and functionality of the final product.

Finishing: Powder Coating, Painting, and Other Enhancements

Finishing is the final step in sheet metal fabrication. It enhances the appearance, durability, and functionality of the fabricated components. This process ensures that the metal parts not only meet aesthetic standards but also withstand environmental and operational challenges. Among the most common finishing techniques are powder coating, painting, and other specialized treatments.

Powder Coating

Powder coating is a popular finishing method due to its durability and efficiency. This process involves applying a dry powder to the surface of the metal, which is then cured under heat. The result is a smooth, uniform finish that resists wear and tear. Powder coating is ideal for applications requiring long-lasting protection against corrosion and fading.

Compared to painting, powder coating offers several advantages. It achieves a uniform finish in a single coat, reducing material waste and application time. The table below highlights key differences between powder coating and painting:

If you need a finish that combines durability with cost efficiency, powder coating is an excellent choice.

Painting

Painting remains a widely used finishing technique in sheet metal fabrication. It involves applying liquid paint to the metal surface, either by spraying or brushing. While painting offers flexibility in terms of color and texture, it often requires multiple coats to achieve a uniform finish. This can increase both time and material costs.

Painted finishes are more prone to chipping and fading over time, especially in harsh environments. However, painting is still a viable option for projects with lower durability requirements or where specific colors and textures are essential.

Other Enhancements

Beyond powder coating and painting, other finishing techniques can further enhance the functionality and appearance of sheet metal components. These include:

Anodizing: This electrochemical process increases the corrosion resistance of aluminum parts while adding a decorative finish.

Electroplating: This method deposits a thin layer of metal, such as chrome or nickel, onto the surface to improve wear resistance and aesthetics.

Polishing: Polishing creates a smooth, reflective surface, often used for decorative purposes.

Each finishing method serves a specific purpose. By selecting the right technique, you can ensure that your sheet metal components meet both functional and aesthetic requirements.

Finishing plays a crucial role in the overall quality of sheet metal fabrication. Whether you choose powder coating, painting, or another enhancement, the right finish can significantly improve the performance and longevity of your components.

Materials Commonly Used in Custom Metal Fabrication

When selecting materials for custom metal fabrication, understanding their properties and applications ensures optimal performance and cost-efficiency. Each material offers unique advantages, making it suitable for specific industries and fabrication processes.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum stands out for its lightweight nature and exceptional corrosion resistance. Its versatility makes it a popular choice for industries like aerospace, automotive, and electronics. You can rely on aluminum for applications requiring strength without adding unnecessary weight.

Aluminum alloys also excel in machinability and weldability. CNC machining allows you to create intricate designs while maintaining strength and durability. Its lightweight property makes it ideal for bending applications, reducing waste and improving cost efficiency. Whether you're fabricating components for aircraft or consumer electronics, aluminum delivers high performance and reliability.

Tip: Aluminum's corrosion resistance eliminates the need for additional coatings, saving you time and reducing maintenance costs.

Stainless Steel: Durable and Versatile

Stainless steel offers unmatched durability and versatility. Its ability to resist corrosion and withstand physical impacts makes it indispensable for industries like construction, medical devices, and food processing. You can count on stainless steel for applications requiring strength and longevity.

Stainless steel remains strong under pressure and resists rust, ensuring reliability in harsh environments.

Its scratch-resistant surface makes it ideal for tools and equipment that endure frequent use.

The oxide layer formed by chromium protects stainless steel from environmental stress, enhancing its durability.

Compared to other metals, stainless steel requires minimal maintenance. Cleaning with soap and water suffices, reducing downtime and operational costs. While its initial cost may be higher, its long-term cost-effectiveness makes it a wise investment for projects demanding durability and low upkeep.

Note: Stainless steel's machinability allows you to shape it easily, making it suitable for custom designs in custom metal fabrication.

Carbon Steel: Cost-Effective and Strong

Carbon steel combines strength and affordability, making it a staple in construction, automotive, and energy sectors. Its high tensile strength ensures reliability in demanding applications, while its cost-effectiveness makes it accessible for large-scale projects.

Carbon steel's malleability allows you to shape and weld it with ease, providing flexibility in manufacturing processes. Its strength makes it suitable for frameworks, pipelines, and heavy machinery. By choosing carbon steel, you gain a material that balances performance with affordability, ensuring your project stays within budget without compromising quality.

Tip: Carbon steel's durability reduces the need for frequent replacements, saving you money in the long run.

Copper: Conductive and Aesthetic

Copper is a standout material in custom metal fabrication due to its exceptional conductivity and visual appeal. Its unique properties make it indispensable for industries requiring both functionality and aesthetics. Whether you're designing electrical components or decorative elements, copper offers unmatched versatility.

Copper's conductivity is one of its most significant advantages. It ranks as the second-best conductor of electricity, making it essential for applications like circuit boards, connectors, and electrical wiring. Its thermal conductivity is equally impressive, enabling efficient heat transfer in systems such as heat exchangers and HVAC units. These qualities ensure that copper performs reliably in demanding environments.

Beyond its functional benefits, copper's aesthetic qualities set it apart. Over time, it develops a natural patina, a protective layer that enhances its resistance to corrosion while adding a unique visual charm. This makes copper a popular choice for architectural elements, decorative fixtures, and even custom furniture. Its ability to combine beauty with durability ensures that your designs stand out while maintaining long-term reliability.

If you're looking for a material that balances performance with visual appeal, copper is an excellent choice. Its adaptability in custom metal fabrication allows you to create components that are both functional and striking.

Brass: Decorative and Corrosion-Resistant

Brass is another material that excels in custom metal fabrication, particularly for decorative and corrosion-resistant applications. Its golden luster and ability to accept various finishes make it a favorite for projects requiring a touch of elegance. Whether you're crafting lamp stands, lighting fixtures, or custom furniture hardware, brass delivers both beauty and functionality.

Brass offers a golden luster that enhances the aesthetic appeal of decorative fixtures.

It resists corrosion effectively, making it suitable for plumbing systems and marine environments.

Its natural antimicrobial properties make it ideal for public infrastructure and high-traffic areas.

The material's versatility allows it to be used in a wide range of applications, from custom furniture to industrial components.

Brass's corrosion resistance ensures durability in challenging environments. For example, it performs well in marine settings where exposure to moisture and salt is common. Its antimicrobial properties also make it a practical choice for public spaces, where hygiene is a priority. These qualities make brass a reliable material for both functional and decorative purposes.

When you choose brass for custom metal fabrication, you gain a material that combines elegance with resilience. Its ability to withstand environmental stress while maintaining its aesthetic appeal ensures that your projects achieve both form and function.

Applications Across Industries

Custom sheet metal services have revolutionized various industries by enabling the creation of precise, durable, and tailored components. Let’s explore how these services are applied in automotive, aerospace, and construction sectors.

Automotive: Custom Metal Parts for Vehicles

In the automotive industry, custom metal parts play a pivotal role in enhancing vehicle performance, safety, and aesthetics. These components are used in everything from body panels to engine mounts, ensuring vehicles meet stringent quality and durability standards.

Precision and Performance: Custom sheet metal fabrication allows you to create parts with exact specifications, improving engine efficiency and reducing weight.

Cost-Effective Manufacturing: Contract manufacturing services streamline production, making it easier to produce high volumes of parts without compromising quality.

Aesthetic Appeal: Custom metal parts, such as grilles and trim, add a polished look to vehicles, aligning with brand identity.

By leveraging these services, you can achieve a balance between functionality and design, ensuring your vehicles stand out in a competitive market.

Aerospace: Precision Components for Aircraft

The aerospace sector demands components that are lightweight, durable, and capable of withstanding extreme conditions. Custom metal parts meet these requirements, ensuring safety and efficiency in aircraft manufacturing.

Aircraft Engine Parts: Custom fabrication ensures precise tolerances, optimizing airflow and combustion for better fuel efficiency.

Structural Components: Lightweight yet durable materials like aerospace-grade aluminum and titanium enhance performance and safety.

Avionics and Electrical Systems: Custom parts with tight tolerances ensure reliable data transmission and control.

Tip: Using materials like titanium alloys and carbon-fiber-reinforced polymers (CFRP) reduces aircraft weight while maintaining structural integrity.

Custom metal parts in aerospace manufacturing not only improve performance but also contribute to safer and more efficient operations.

Construction: Structural and Decorative Metal Fabrication

In construction, custom sheet metal services provide solutions for both structural and decorative applications. These services enable the creation of components that are strong, lightweight, and adaptable to various designs.

Structural Applications: Custom metal parts are used in frameworks, roofing, and cladding, offering strength and durability.

Decorative Elements: Intricate designs for railings, facades, and fixtures enhance the aesthetic appeal of buildings.

Efficiency and Flexibility: Modern fabrication techniques support diverse geometries and quick modifications, reducing project timelines.

Key Benefits:

Cost-effective production for medium to high volumes.

Lightweight yet strong structures for versatile applications.

Fast turnaround times with modern automation.

By integrating custom metal parts into your construction projects, you can achieve a perfect blend of functionality and design, ensuring long-lasting and visually appealing results.

Electronics: Enclosures, Heat Sinks, and Custom Metal Parts

Custom sheet metal services play a vital role in the electronics industry. You rely on these services to create enclosures, heat sinks, and other custom metal parts that ensure the functionality and durability of electronic devices. These components protect sensitive electronics from environmental factors while improving performance.

Enclosures are essential for housing electronic circuits and components. They shield devices from dust, moisture, and electromagnetic interference. Custom metal parts allow you to design enclosures that fit specific dimensions and requirements. For example, you can create compact cases for smartphones or larger housings for industrial equipment. The precision of custom fabrication ensures that every enclosure meets your exact specifications.

Heat sinks are another critical application. These components dissipate heat generated by electronic devices, preventing overheating and ensuring optimal performance. Custom metal parts enable you to design heat sinks with intricate fins and channels that maximize heat dissipation. Materials like aluminum and copper are commonly used due to their excellent thermal conductivity.

Custom sheet metal services also support the production of brackets, connectors, and mounting hardware. These parts enhance the assembly and integration of electronic systems. By using custom metal parts, you can achieve a balance between functionality and aesthetics, ensuring your devices perform reliably while maintaining a sleek appearance.

Tip: Collaborate with experienced fabricators to design custom metal parts that meet both technical and aesthetic requirements.

Medical: Equipment and Devices Requiring Custom Metal Fabrication

The medical industry depends on custom sheet metal services for creating equipment and devices that meet strict standards. You benefit from these services when designing components for surgical tools, diagnostic machines, and hospital furniture. Custom metal parts ensure precision, hygiene, and durability in medical applications.

Surgical instruments require high levels of accuracy and reliability. Custom metal parts allow you to produce tools with precise dimensions and smooth finishes, ensuring they perform effectively during procedures. Stainless steel is a popular choice for its corrosion resistance and ease of sterilization.

Diagnostic equipment, such as MRI machines and X-ray systems, also relies on custom metal parts. These components provide structural support and protect sensitive electronics. Custom fabrication ensures that each part fits perfectly, enhancing the performance and longevity of the equipment.

Hospital furniture, including beds and carts, benefits from custom sheet metal services. You can design lightweight yet durable frames that withstand frequent use. Powder-coated finishes add an extra layer of protection, ensuring the furniture remains hygienic and easy to clean.

By using custom metal parts, you can meet the unique demands of the medical industry. These components combine precision with durability, ensuring the safety and effectiveness of medical devices and equipment.

Note: Always prioritize materials that meet medical-grade standards to ensure compliance and safety.

Advantages of Customization in Sheet Metal Fabrication

Tailored Solutions for Unique Requirements

Customization in sheet metal fabrication allows you to create components that meet specific needs. Whether you require intricate designs or unique dimensions, custom metal parts provide the flexibility to achieve your goals. For example, you can design parts for specialized machinery or create decorative elements for architectural projects. This adaptability ensures that every component fits perfectly into its intended application.

Custom solutions also enable you to select the most suitable materials for your project. You can choose lightweight aluminum for aerospace applications or durable stainless steel for medical devices. By tailoring the material and design, you ensure that the final product meets both functional and aesthetic requirements.

Enhanced Product Performance and Longevity

Custom metal parts improve the performance and lifespan of your products. Precision fabrication ensures that each component functions as intended, reducing the risk of failure. For instance, accurate cutting and forming techniques create parts with tight tolerances, enhancing their reliability in demanding environments.

Welding processes like TIG and MIG further contribute to durability. These methods produce strong joints that withstand stress and wear. When combined with finishing techniques such as powder coating, your components gain additional protection against corrosion and environmental damage. This attention to detail ensures that your products perform efficiently and last longer.

Cost Efficiency Through Precision and Waste Reduction

Precision in sheet metal fabrication minimizes waste and lowers costs. Advanced techniques like laser cutting and CNC machining reduce material wastage by achieving exact dimensions. This precision eliminates the need for rework, saving both time and resources.

For example, using a precision drilling jig can significantly cut costs. A jig costing only Pkr 3000 replaced the need for a Pkr 1000000 CNC machine. It achieved dimensional accuracy of 0.1mm, reducing setup time and eliminating marking and center punching. This demonstrates how precise fabrication processes lead to cost efficiency and streamlined production.

By investing in custom metal parts, you not only save money but also enhance the quality of your products. Precision and efficiency ensure that your components meet high standards while reducing unnecessary expenses.

Improved Aesthetics and Branding Opportunities

Custom sheet metal fabrication offers you the ability to enhance the visual appeal of your products while aligning them with your brand identity. A well-designed metal component not only performs its function but also leaves a lasting impression on your customers. By leveraging advanced fabrication techniques, you can create components that stand out in both form and function.

How Customization Enhances Aesthetics

Custom fabrication allows you to design metal parts with intricate patterns, unique shapes, and smooth finishes. Techniques like laser cutting and polishing ensure precision and a flawless appearance. For example, you can create decorative panels, stylish enclosures, or sleek automotive trims that elevate the overall look of your product.

Tip: Use finishing options like powder coating or anodizing to add vibrant colors and textures that match your brand's aesthetic.

Branding Opportunities with Custom Metal Parts

Custom sheet metal services also help you reinforce your brand identity. You can incorporate your logo, tagline, or signature design elements directly into the metal components. This creates a cohesive and professional look that strengthens brand recognition.

Logo Integration: Laser engraving or embossing your logo onto metal parts adds a premium touch.

Color Matching: Powder coating allows you to match the color of your components to your brand palette.

Unique Designs: Custom shapes and patterns make your products instantly recognizable.

By focusing on aesthetics and branding, you can create products that not only perform well but also leave a memorable impression. Custom sheet metal fabrication gives you the tools to achieve this balance, ensuring your products stand out in a competitive market.

Tips for Choosing the Right Custom Metal Fabricators

Assessing Experience and Expertise in Custom Metal Fabrication

When choosing custom metal fabricators, evaluating their experience and expertise ensures your project’s success. You should look for fabricators with a proven track record of delivering high-quality results across diverse projects. Their ability to handle various metals and fabrication techniques demonstrates versatility, which is crucial for meeting unique requirements.

A well-trained team is another indicator of expertise. Skilled professionals can execute complex designs with precision, ensuring your components meet exact specifications. Certifications and compliance with industry standards also reflect their commitment to quality and safety. Additionally, fabricators equipped with state-of-the-art facilities can manage projects of varying complexity, offering comprehensive services tailored to your needs.

Tip: Ask about their past projects to gauge their ability to handle challenges similar to yours. This helps you assess their reliability and adaptability.

Evaluating Equipment and Technology Used by Custom Metal Fabricators

The equipment and technology used by custom metal fabricators directly impact the quality and efficiency of your project. Advanced machinery ensures precise fabrication, reducing errors and waste. You should check if the fabricator adheres to internationally recognized standards, as this guarantees safety and quality benchmarks.

Fabricators who implement customized quality control protocols often deliver superior results. These protocols involve detailed inspections and testing processes tailored to different fabrication types. Continuous improvement practices, such as adopting the latest technology, also indicate their commitment to staying ahead of industry trends.

Look for fabricators who prioritize innovation and client feedback to refine their processes.

Ensure their employees receive regular training to stay updated on modern techniques.

Verify their ability to handle complex designs with precision and efficiency.

Note: Fabricators with cutting-edge equipment can optimize tooling and production processes, saving time and reducing costs.

Reviewing Past Projects and Client Testimonials

Reviewing past projects and client testimonials provides valuable insights into a fabricator’s reliability and performance. You should examine their portfolio to understand the scope and complexity of projects they have completed. This helps you determine if they can meet your specific requirements.

Client testimonials highlight the fabricator’s strengths, such as on-time delivery and defect-free products. Metrics like defect rates and non-conformance rates reveal their commitment to quality. Additionally, feedback on production volume and batch ordering efficiency indicates their ability to handle large-scale projects cost-effectively.

Tip: Prioritize fabricators with positive reviews and a history of successful collaborations. This ensures your project benefits from their expertise and professionalism.

Considering Turnaround Time and Cost Efficiency

Turnaround time and cost efficiency are critical factors when selecting a custom metal fabrication partner. You should evaluate how quickly a fabricator can deliver your project without compromising quality. Delays in production can disrupt your timelines and increase costs, especially for industries with tight schedules like automotive or electronics.

Fabricators with advanced equipment and streamlined processes often achieve faster turnaround times. For example, CNC machining and automated cutting systems reduce production time while maintaining precision. You should also inquire about their capacity to handle large orders or rush jobs. A fabricator with scalable operations can adapt to your needs, ensuring timely delivery.

Cost efficiency goes hand in hand with turnaround time. Efficient processes minimize material waste and labor costs, which helps you stay within budget. For instance, laser cutting offers precise results, reducing the need for rework and saving resources. You should request a detailed cost breakdown to understand how the fabricator allocates expenses. This transparency helps you identify areas where you can optimize costs without sacrificing quality.

Tip: Choose a fabricator who balances speed and cost-effectiveness. This ensures you receive high-quality components on time and within budget.

Importance of Communication and Collaboration with Custom Metal Fabricators

Effective communication and collaboration are essential for successful custom metal fabrication projects. You should establish clear expectations from the start, including design specifications, material preferences, and deadlines. A fabricator who listens to your needs and provides regular updates ensures your project stays on track.

Collaboration fosters innovation. When you share your goals and challenges, fabricators can suggest improvements or alternative solutions. For example, they might recommend a more cost-effective material or a design tweak that enhances functionality. This partnership approach leads to better outcomes and fewer revisions.

Regular communication also helps you address issues promptly. If a design change or production delay arises, staying in touch with your fabricator allows you to adjust plans quickly. Many fabricators offer project management tools or dedicated points of contact to streamline communication.

Note: Strong collaboration builds trust and ensures your custom metal fabrication project meets your expectations.

Custom sheet metal services transform raw materials into precise, tailored components for diverse industries. By understanding the core processes, materials, and applications, you can make informed decisions that enhance product quality and efficiency. For example, case studies show how automated systems like CNC plasma cutting and robotic assembly improve productivity while reducing risks.

Partnering with experienced fabricators like Foxsen ensures superior results. Their skilled professionals use advanced techniques such as CNC machining and laser cutting to deliver precision and durability. Close collaboration with experts allows for real-time adjustments, ensuring your project meets exact specifications.

Tip: Trusting a reliable partner like Foxsen guarantees high-quality outcomes and long-term benefits for your business.

FAQ

What industries benefit the most from custom sheet metal services?

Industries like automotive, aerospace, construction, electronics, and medical rely heavily on custom sheet metal services. These sectors demand precision, durability, and tailored solutions for components such as vehicle parts, aircraft structures, building frameworks, electronic enclosures, and medical devices.

How do I choose the right material for my project?

You should consider factors like strength, weight, corrosion resistance, and cost. For lightweight needs, aluminum works well. Stainless steel suits durable applications. Copper excels in conductivity, while brass offers decorative appeal. Discuss your requirements with your fabricator for expert guidance.

Are custom sheet metal services cost-effective?

Yes, they are. Precision techniques like laser cutting and CNC machining reduce material waste and rework. Customization ensures components fit perfectly, minimizing errors and long-term costs. While initial expenses may seem higher, the durability and efficiency of custom parts save money over time.

Can custom sheet metal fabrication handle complex designs?

Absolutely! Advanced technologies like CNC machining and laser cutting allow fabricators to create intricate shapes and patterns with high accuracy. Whether you need detailed decorative elements or complex functional components, custom fabrication can meet your design requirements.

How long does it take to complete a custom sheet metal project?

Turnaround time depends on the project's complexity, material availability, and the fabricator's capacity. Simple designs may take a few days, while intricate projects could require weeks. Communicate your deadlines clearly to ensure timely delivery.