Key Takeaways

Sheet metal stamping shapes flat metal sheets into exact parts using tools and machines, ensuring they are accurate and the same every time.

This method is important for industries like car-making and airplanes, creating parts that are strong, light, and save money.

Picking the right metal, like steel or aluminum, makes the parts work better and last longer, fitting the project’s needs.

New stamping methods make work faster, waste less, and allow special designs, giving manufacturers more options.

Using sheet metal stamping saves money and speeds up production, helping many types of businesses.

What Is Sheet Metal Stamping?

Definition and Overview

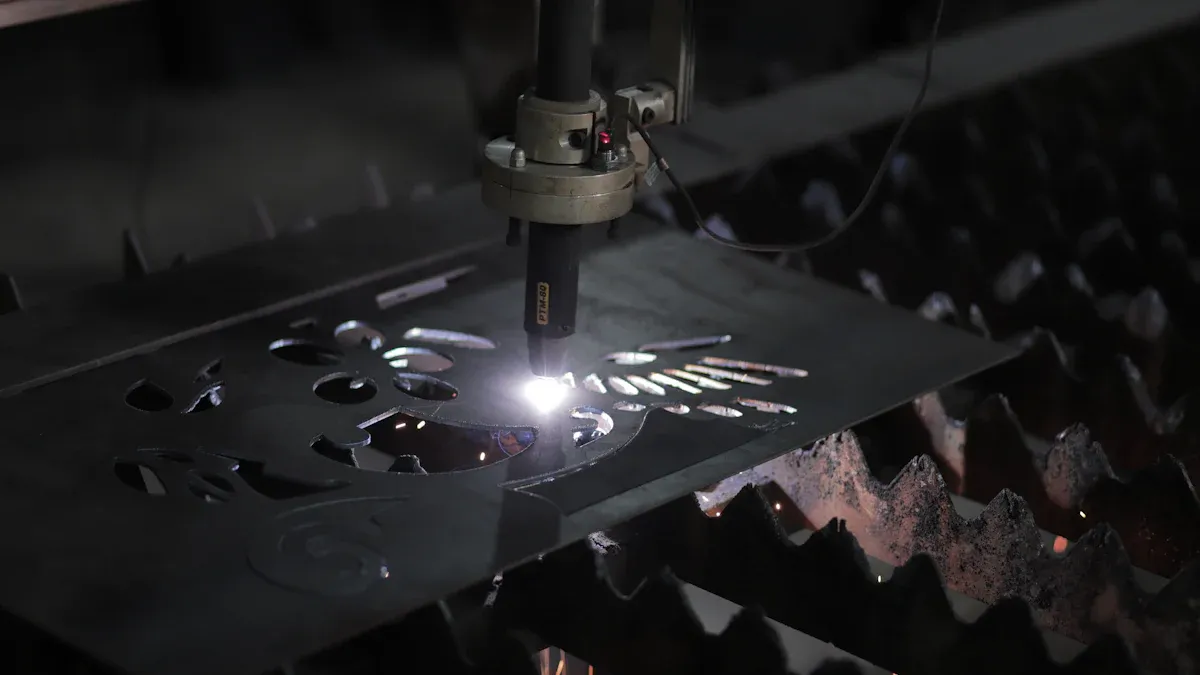

Sheet metal stamping changes flat metal sheets into specific shapes. It uses tools called dies and presses. This process is important for making accurate and identical parts. Industries like cars, planes, and electronics use it to make detailed pieces.

The process starts with a flat metal sheet, like steel or aluminum. The sheet is placed between a die and a punch. The punch pushes the metal into the die's shape. Simple parts need one step, but complex ones need more steps.

Main methods in metal stamping include blanking, punching, bending, and piercing. These help make parts with exact sizes and tricky designs. For example:

Blanking cuts out a piece of metal into a shape.

Bending folds the metal into angles or curves.

Piercing makes holes in the metal for looks or function.

Sheet metal stamping is very useful in modern manufacturing. New methods like progressive stamping and deep drawing improve it. These updates help meet the need for custom and fast production.

Purpose and Importance in Manufacturing

The main goal of sheet metal stamping is to make many detailed metal parts quickly. It is very important for industries like cars and electronics that need lots of parts. For example, it makes car panels, brackets, and appliance parts.

One big benefit of sheet metal stamping is its accuracy. It keeps parts the same size and quality, even in large batches. This reduces mistakes, which is crucial for industries where small errors can cause big problems.

Sheet metal stamping is not just about accuracy. It also helps create new ideas in manufacturing. Techniques like tailor-welded blanks save material and money by using different thicknesses. Hydroforming also uses materials better, making the process more efficient.

New technology has made sheet metal stamping even better. Tools like visual scanning and computer checks find problems early. These improvements help manufacturers make high-quality parts while wasting less and working faster.

How Does Sheet Metal Stamping Work?

The Stamping Process Explained

Sheet metal stamping changes flat metal into exact shapes. It follows several steps to get the right design. First, the right metal is picked based on cost and strength. After choosing, the metal is prepared and placed in the machine. A die and punch press the metal to form the shape needed.

Computer programs help predict problems before starting the process. These programs use data to check how the metal will behave. During production, pressure, speed, and settings are checked often. This ensures the parts are made correctly every time.

Manufacturers test small batches to check for issues. These tests show how the metal reacts and how well the tools work. Testing also helps fix problems and confirm the process works before making more parts.

Types of Stamping Techniques

There are different ways to stamp metal, each with a purpose:

Blanking: Cuts metal into a specific shape.

Embossing: Makes raised or lowered designs for looks or function.

Bending: Folds metal into curves or angles.

Piercing: Creates holes in metal for design or assembly.

Drawing: Pulls metal into hollow shapes like cups.

Trimming: Cuts off extra metal for a clean finish.

These methods make custom designs possible and very accurate.

Key Features of Stamping Equipment

Stamping machines must be precise and reliable for good results. They ensure parts fit and work as needed. Machines also check the metal's strength to make sure it can handle weight. Surface checks look for smoothness and any flaws to keep parts functional and nice-looking.

Performance is tracked using key measures like speed and errors. For example:

By learning the stamping process and using good machines, manufacturers can make quality parts faster and better.

Materials Used in Sheet Metal Stamping

Commonly Used Metals

The type of metal used in sheet metal stamping is very important. Some popular metals include:

Steel: Strong and long-lasting, great for cars and machines.

Aluminum: Light and rust-proof, often used in planes and gadgets.

Copper: Conducts electricity well, perfect for electrical parts.

Brass: Looks nice and resists tarnishing, ideal for decorations.

Each metal has special features for different jobs. For example, steel is super strong, while aluminum is light for fast-moving designs.

Criteria for Material Selection

Picking the right metal involves checking several key factors. These checks make sure the metal works well and looks good for its purpose.

Following these rules helps pick the best material for your project.

Benefits of Using Specific Materials

Using the right metal has many advantages. For example:

Strong steel makes car parts last longer.

Aluminum alloys stop rust and make planes lighter.

Copper and brass add style and work well in electronics.

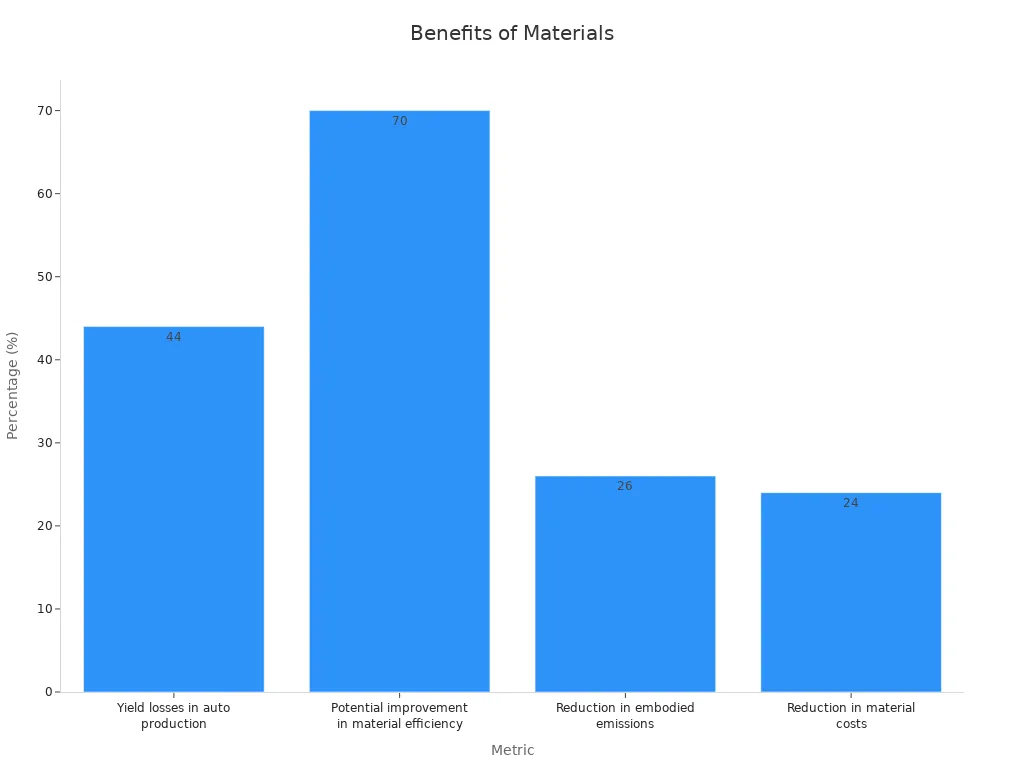

A study on car production showed these benefits:

44% less wasted material.

70% better material use.

26% lower emissions.

24% cheaper material costs.

These benefits improve product quality, save money, and help the environment.

Choosing the right metal ensures strong, precise, and efficient results in your projects.

Applications of Metal Stamping Across Industries

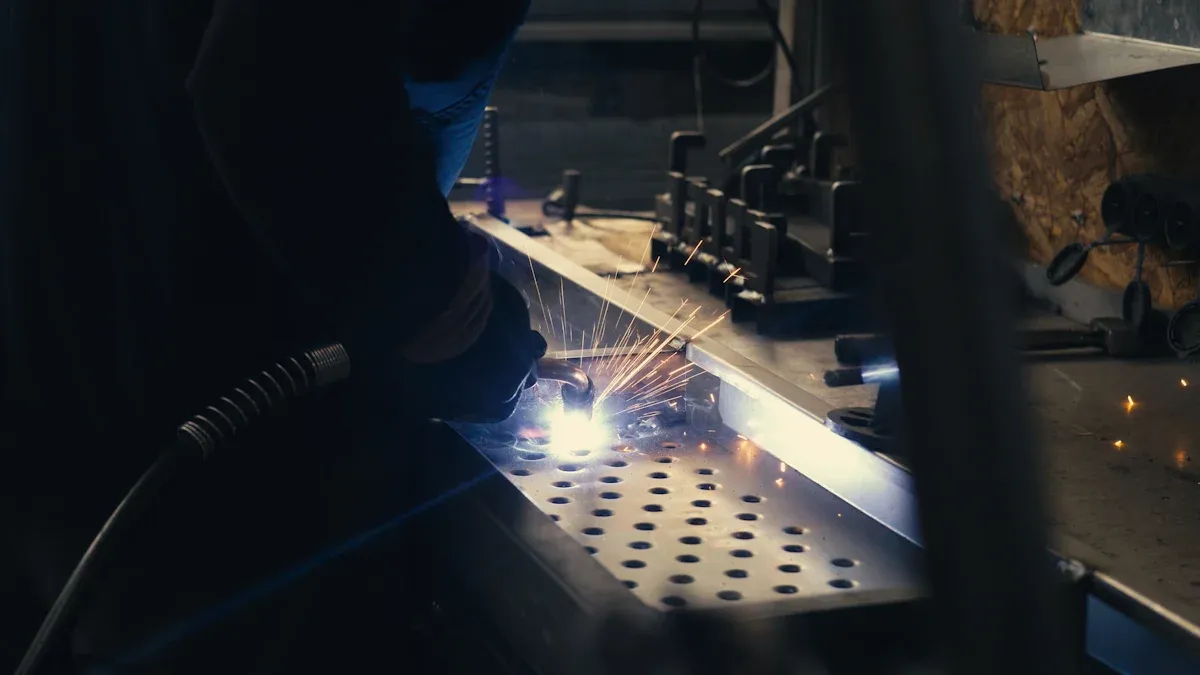

Metal stamping is crucial in many industries. It helps make custom parts quickly and accurately. Its flexibility allows companies to produce large amounts while keeping quality high. Below are examples of how different industries use metal stamping.

Automotive Industry Applications

The car industry depends on metal stamping for key parts. These include body panels, brackets, and fuel injectors. These parts must be strong and precise to keep cars safe and working well.

The need for metal stamping in cars is growing. This is because more cars, especially electric ones, are being made. In 2023, over 14 million new electric cars were registered worldwide. Lightweight materials like aluminum are popular because they make cars lighter and more efficient.

In 2022, the car industry made up 30.5% of the metal stamping market. New designs and better stamping tools help make custom parts faster. As a manufacturer, you can use these improvements to meet the demand for large orders.

Aerospace and Defense Applications

In aerospace and defense, parts must be exact and reliable. Metal stamping makes complex items like airplane frames and engine parts. These parts must handle tough conditions without breaking.

In 2024, aerospace and defense will make up 30.3% of the sheet metal services market. More money is being spent on airplanes and defense, increasing the need for stamped parts. For example, North America is expected to lead the market with USD 3.1 billion in 2024, growing by 4.2% yearly until 2034.

The U.S. defense budget for 2023-24, about USD 72.38 billion, shows big opportunities for metal stamping. Manufacturers can meet this demand by making precise parts for these industries.

Electronics and Consumer Goods Applications

Metal stamping is also important for electronics and everyday products. It helps make small, detailed parts like circuit boards, cases, and connectors. These parts need to be exact to work properly and last long.

Copper and brass are common materials here. Copper is great for electrical parts, while brass looks nice for decorative items. Metal stamping allows for custom designs to fit different needs.

As more people buy electronics and smart devices, the need for stamped parts grows. Manufacturers can benefit by offering creative solutions for these industries.

Construction and Industrial Applications (e.g., industrial walkways, support structures)

Metal stamping is very important in construction and industry. It helps make strong, precise, and long-lasting parts. Examples include industrial walkways, support beams, and safety barriers. These parts must meet strict rules to ensure safety and reliability.

How Metal Stamping Helps in Construction

In construction, metal stamping creates custom parts for buildings and bridges. Stamped steel panels are used for roofs and walls because they are light but strong. Support beams and brackets made this way keep large structures stable. Stamped metal is also found in stairs, railings, and walkways, where safety matters most.

Stamped parts are both strong and accurate. This accuracy makes sure every piece fits perfectly during assembly. It saves time and effort on construction sites. Using stamped metal ensures consistent quality, which is key for safe and efficient projects.

Industrial Uses of Metal Stamping

In factories, metal stamping makes parts for machines and storage. For example, stamped shelves in warehouses hold heavy items without bending. Frames for conveyor belts and scaffolding are also made with this process. These parts handle tough use and harsh conditions well.

Stamped metal is also used for safety gear. It makes guardrails, barriers, and grates to prevent accidents. These parts are strong and last a long time, making them ideal for factories and construction sites.

Why Metal Stamping Is Useful in Construction and Industry

Metal stamping has many benefits for these fields. It allows for making many parts quickly and with the same quality. This speeds up big projects and lowers costs. The process also allows custom designs to meet specific needs. Stamped parts are tough and resist wear, perfect for hard-working environments.

Choosing metal stamping means getting strong, reliable parts. Whether building tall buildings or running a factory, stamped metal provides the strength and performance needed.

Advantages of Sheet Metal Stamping

Cost-Effectiveness and Efficiency

Sheet metal stamping is a budget-friendly way to make parts. It uses materials wisely, cutting down on waste and costs. Fast production speeds help meet big orders without losing quality. This makes it perfect for industries needing many parts quickly.

These features show why metal stamping is a top choice for saving money and time.

Precision and Consistency

Metal stamping is known for making exact and reliable parts. It keeps tight measurements, which is important for cars and planes. This process ensures every part is made the same, even for hard designs.

Precision is key, focusing on exact measurements for each design.

Stamping creates parts that are accurate and consistent for many industries.

This accuracy lowers mistakes and ensures parts meet all requirements. By staying consistent, metal stamping helps make strong and dependable products.

Scalability for Mass Production

Sheet metal stamping is great for making lots of parts. It works well for both small and large projects, helping businesses grow. For example, the car stamping market may grow from USD 125.33 billion in 2024 to USD 187.87 billion by 2032. This is due to the need for lighter car parts.

New tools like AI and robots make production faster and easier.

Robots improve accuracy, especially for electric car parts.

Virtual tools test designs before production, saving time and materials.

These updates make metal stamping flexible and eco-friendly for big projects. Whether you need a few parts or millions, it delivers reliable results.

Versatility in Design and Functionality

Sheet metal stamping is very flexible for making custom designs. It easily creates detailed shapes and useful features. This makes it perfect for industries needing new ideas and accuracy. Whether you need simple parts or complex ones, this process can deliver.

A big benefit of sheet metal stamping is combining many parts into one. For example, Dalsin Industries changed a door panel from five pieces to one. This cut production time by 60% and used 17% less steel. Another redesign turned nine parts into one, removing 18 welds and improving efficiency by 57%. These examples show how stamping simplifies work while keeping quality high.

Sheet metal stamping also adds useful features like embossing for strength or holes for airflow. This makes designs both attractive and functional.

With advanced tools, manufacturers can test designs before making them. This lowers mistakes and ensures the product is just right. Whether for cars, planes, or electronics, sheet metal stamping gives the flexibility needed to stay competitive.

Tip: Combining parts into fewer pieces saves time and materials, making projects more eco-friendly.

Sheet metal stamping is key in today's manufacturing world. It turns flat metal sheets into precise, high-quality parts. Industries like cars, planes, and electronics rely on it for reliable solutions. This process makes complex designs while keeping parts consistent and reducing mistakes.

The need for strong, lightweight parts is rising, especially in cars. New stamping methods help by using materials better and working faster. For example:

Using sheet metal stamping saves money, scales easily, and helps the environment. It creates exact, high-quality parts that meet top standards.

Note: Advanced stamping methods boost efficiency and cut waste, supporting eco-friendly practices.

FAQ

What industries use sheet metal stamping the most?

Industries like cars, planes, electronics, and construction use it a lot. It’s also important for making medical tools because it’s precise and reliable.

How is sheet metal stamping different from other methods?

Sheet metal stamping is faster, cheaper, and more accurate. It’s better than casting or machining for making many parts quickly.

Can custom designs be made with sheet metal stamping?

Yes, it can make special shapes and designs. This helps meet specific needs for how parts look and work.

What materials are best for sheet metal stamping?

Steel, aluminum, copper, and brass are common choices. The material depends on what your project needs, like strength or rust resistance.

Is sheet metal stamping good for the environment?

Yes, it wastes less material and uses less energy. New methods like progressive stamping cut waste even more, making it eco-friendly.

Sheet Metal Stamping Service shapes flat metal sheets using dies and presses. This process produces detailed parts with high accuracy and consistency. Many industries utilize Sheet Metal Stamping Service to create components like brackets and supports. It is essential for modern manufacturing because it generates custom metal pieces. Custom designs provided by Sheet Metal Stamping Service help make production flexible and save money on large projects.

Sheet Metal Stamping Service shapes flat metal sheets using dies and presses. This process produces detailed parts with high accuracy and consistency. Many industries utilize Sheet Metal Stamping Service to create components like brackets and supports. It is essential for modern manufacturing because it generates custom metal pieces. Custom designs provided by Sheet Metal Stamping Service help make production flexible and save money on large projects.