A sheet metal switchgear enclosure is a strong box that protects electrical parts from harm. These enclosures are important for keeping out dust, water, and accidental touches. They are built tough to keep electrical systems safe and working well.

More companies are using these enclosures worldwide. For example:

The market for electrical enclosures may grow from $7.7 billion in 2024 to $13.6 billion by 2033.

Asia Pacific owns 36% of the market because of fast industrial growth.

The U.S. holds 82.6% of North America's market, thanks to automation and green energy.

Because they are so dependable, sheet metal switchgear enclosures help keep things safe and running smoothly.

Key Takeaways

Sheet metal enclosures keep electrical systems safe from dust, water, and accidental contact.

Using materials like stainless steel or aluminum makes them stronger and last longer.

Customizing enclosures for size and features helps them work better in different places.

Good ventilation and cooling stop overheating, saving money on repairs.

Meeting industry rules ensures enclosures are safe for people and equipment.

What Is a Sheet Metal Switchgear Enclosure?

Definition and Purpose

A sheet metal switchgear enclosure is a strong box that protects electrical parts. It acts like a shield to block dust, water, and accidental touches. These enclosures are made from tough materials like aluminum or stainless steel. They can handle rough conditions and stay sturdy over time.

The main job of these enclosures is to keep equipment and people safe. They stop electrical shocks, short circuits, and equipment breakdowns. They also help organize electrical systems, making repairs and checks easier.

Did You Know?

Sheet metal switchgear enclosures follow strict rules like IEC 62208 and IEC 61439. These rules make sure they resist rust and stay strong in tough situations.

Here are some examples showing how useful these enclosures are:

A lab used custom enclosures for its special power needs.

An airport used tailored enclosures for better safety and efficiency.

A movie studio saved money and improved safety with these enclosures.

These examples show how sheet metal enclosures can fit different needs while staying safe and reliable.

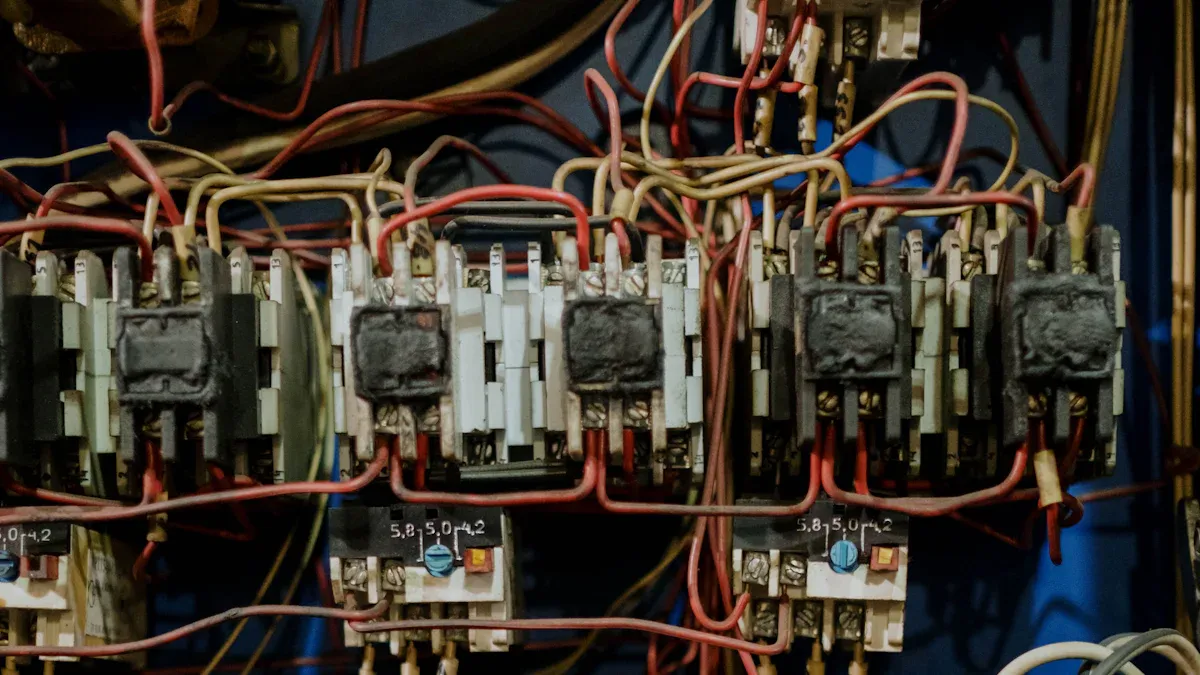

Applications in Industrial and Commercial Settings

Sheet metal switchgear enclosures are important in factories and businesses. They protect and organize electrical systems in places where conditions are tough. Their strong design keeps them working well for a long time.

Here are some common uses:

Factories: They protect systems that run machines, keeping production smooth.

Power Plants: They shield parts from heat and moisture.

Solar and Wind Energy: They guard electrical systems in renewable energy setups.

Buildings: Offices and malls use them to manage electrical systems safely.

Tests like the salt spray test check how well enclosures resist rust. This test shows how they handle years of wear in just days. It proves they are safe and strong for industrial use.

Tip for Buyers: Pick an enclosure based on your needs. Think about size, material, and the environment to get the best performance and durability.

Key Features of a Sheet Metal Switchgear Enclosure

Durability and Environmental Protection

A sheet metal switchgear enclosure is built to handle tough conditions. It is strong and lasts a long time. These enclosures resist damage from impacts, rust, and extreme heat or cold. They keep electrical systems safe in places with dust, water, or chemicals.

They also protect against weather like rain, snow, and sunlight. Makers use materials like stainless steel or aluminum to make them stronger. Stainless steel stops rust, while aluminum is light but sturdy. Both materials help the enclosure last longer, saving money over time.

Tip: Pick an enclosure rated IP65 or higher for outdoor use.

Heat Dissipation and Thermal Management

Electrical systems get hot when they work, so cooling is important. A good sheet metal enclosure has vents or fans to cool it down. These features stop overheating, which can break parts or cause problems.

Some enclosures use special designs like heat sinks or materials that move heat away. This keeps equipment working well, even in very hot places.

Did You Know? Cooling properly helps equipment last longer and saves energy.

Electromagnetic Shielding

Electromagnetic shielding is key for sheet metal switchgear enclosures. It blocks outside electromagnetic waves and stops the system from sending out waves that might disturb other devices. This keeps systems working well in places with lots of electromagnetic activity, like factories.

The metal in the enclosure absorbs and redirects these waves. This is especially useful for sensitive tools like communication or medical devices.

Note: Check the enclosure’s EMI shielding to match your needs.

Customizability for Specific Needs

Each electrical setup is different. Your needs depend on the environment, tools, or goals. Sheet metal switchgear enclosures can be customized to match your exact needs. This makes them very useful for many situations.

You can pick the size, shape, and design you want. For small spaces, manufacturers can make smaller enclosures that still work well. Bigger setups may need enclosures with sections to keep parts organized.

Customization includes features like doors, panels, and cable openings. You can add extra doors, removable panels, or special locks for safety. If your system gets hot, you can choose enclosures with cooling tools like fans or heat exchangers.

The outside finish can also be customized. Outdoor enclosures may need coatings to stop rust. Commercial spaces might prefer powder-coated finishes for a clean look. Food factories often use stainless steel enclosures for cleanliness.

Tip: Write down your needs before ordering. Include details like the environment, equipment layout, and safety needs. This helps manufacturers create the best enclosure for you.

Custom designs protect your systems and improve how they work. By choosing the right design, you get a solution that works well and saves money.

Material Choices for Sheet Metal Enclosures

Common Materials (e.g., Aluminum, Stainless Steel, CRCA)

The material of a sheet metal enclosure affects how well it works and lasts. Popular materials include aluminum, stainless steel, and CRCA (Cold Rolled Close Annealed steel). Each has special features for different uses and environments.

Aluminum: This material is light and doesn’t rust easily. It’s great for places where weight matters. Alloys like 5052 bend well, while 6061 is easier to shape. Adding an anodized layer makes it stronger, perfect for outdoor use.

Stainless Steel: This metal resists rust very well because it has chromium and nickel. It’s strong and works well in tough conditions or where impacts happen often.

CRCA: CRCA is stiff and strong, making it a cheaper option for indoor use. But it needs a coating to stop rust since it doesn’t resist corrosion naturally.

Performance and Longevity Considerations

How long a sheet metal enclosure lasts depends on its material and where it’s used. Aluminum doesn’t rust and works well in wet or coastal areas. Stainless steel is very strong and lasts longer in outdoor or industrial places. CRCA is strong but needs coatings to avoid rust, so it doesn’t last as long in harsh areas.

To make enclosures last longer, think about what they’ll face, like water, chemicals, or heat. For example, stainless steel is great for chemical plants, while aluminum suits renewable energy setups. CRCA works best indoors where conditions are controlled.

Cost Implications of Material Selection

The price of a sheet metal enclosure depends on the material. Aluminum costs a medium amount and balances price with good performance. Stainless steel costs more but is very durable and rust-resistant, making it worth the money over time. CRCA is the cheapest but needs extra coatings and care to stop rust, which adds to its cost.

Think about how you’ll use the enclosure when looking at costs. Aluminum enclosures are light and easy to hang, saving on labor. Stainless steel ones are heavier but strong for tough jobs. CRCA enclosures are good for tight budgets but should avoid harsh conditions.

Tip: Pick a material that fits your budget and lasts long for the best value.

Design Tips for Sheet Metal Enclosures

Picking the Right Size and Layout

The size and setup of an enclosure are very important. Think about the space you have and the parts inside. A good layout makes it simple to install and fix equipment. It also ensures everything fits without wasting room.

Plan for the future when designing the enclosure. If you might add parts later, leave extra space. Place doors or panels where they make repairs easier. This helps save time when upgrading or fixing things.

Key points to remember:

Pick a size that fits your parts and allows airflow.

Arrange parts to make setup and repairs simple.

Leave space for future upgrades to avoid buying a new box.

A smart design saves money and effort over time.

Keeping Things Cool with Ventilation

Cooling is key to keeping the enclosure safe. Electrical parts get hot, and without airflow, they can break. Add vents, fans, or other cooling tools to stop overheating.

Place these tools near the hottest parts for better airflow. Fans help move air around, keeping the temperature steady.

Why cooling matters:

It stops overheating and helps parts last longer.

It keeps sensitive parts at a safe temperature.

It lowers the chance of breakdowns caused by heat.

Good ventilation protects your equipment and keeps it working well.

Making Maintenance Easy

Easy access to the inside makes repairs quicker and safer. Use removable panels, wide doors, or other features to reach parts easily.

The layout also matters for access. Place parts where they’re easy to check or replace. Avoid putting things in hard-to-reach spots. Mounting brackets shouldn’t block important parts.

Tips for better access:

Use doors or panels that open wide for easy entry.

Arrange parts to avoid taking things apart during repairs.

Make sure mounts don’t block access to key parts.

Good access cuts downtime and makes repairs faster.

Following Industry Standards

Industry standards are important for keeping sheet metal switchgear enclosures safe and reliable. These rules guide how enclosures are designed, built, and tested. By following them, you make sure your enclosure is high-quality and safe to use.

Why Standards Are Important

Standards keep people and equipment safe. They make sure enclosures can handle things like water, dust, and heat. They also stop electrical dangers like shocks or short circuits.

Tip: Check if the enclosure meets rules like IEC 62208 or IEC 61439. These rules ensure it is strong and safe.

Common Standards for Enclosures

Here are some well-known standards:

IEC 62208: Checks if enclosures are strong and durable.

IEC 61439: Makes sure they are safe for electrical use.

NEMA Ratings: Shows how well they protect against water and dust.

UL Certification: Proves they meet U.S. safety rules.

Why Standards Help You

Following standards gives you confidence in your enclosure. It works well even in tough conditions. It also saves money by avoiding repairs or replacements caused by poor designs.

Note: Certified enclosures lower risks and save money over time.

By choosing enclosures that meet standards, you keep your systems safe and running smoothly.

Benefits of Sheet Metal Switchgear Enclosures

Better Safety and Protection

A sheet metal switchgear enclosure keeps electrical systems safe. Its strong build protects parts from dust, water, and accidental touches. This keeps both equipment and people safe. The metal also blocks electromagnetic waves, stopping interference. This is helpful in places like factories or power plants with lots of electromagnetic activity.

Another big benefit is rust resistance. Materials like stainless steel and aluminum don’t rust easily, even in tough conditions. This strength keeps systems safe for a long time and lowers the chance of failures caused by the environment.

Tip: Use enclosures with good grounding for better shielding and safety.

Affordable and Long-Lasting

Metal enclosures are strong and cost less than plastic or glass ones. They handle impacts, extreme weather, and wear, making them a smart choice for long-term use.

Metal enclosures also cool down systems well. This stops overheating and helps parts last longer, saving on repairs. For example, aluminum is light but strong, offering good value and performance.

This mix of strength and usefulness makes metal enclosures a great choice for many uses.

Useful for Many Purposes

Metal enclosures work well in many settings. You can customize them for factories, offices, or solar farms. Factories use them to protect machines, while solar farms use them to guard systems from weather.

You can change their size, layout, and features to fit your needs. Add vents, panels, or special coatings for better performance. This flexibility makes them reliable and useful in different places.

Note: Think about the environment and setup when picking an enclosure for the best results.

Stylish and Practical Design Choices

You can have both style and function with sheet metal switchgear enclosures. Modern designs look neat and work well. This mix of looks and usefulness makes them great for factories, offices, and stores.

Why Looks Are Important

A good-looking enclosure makes your workspace appear professional. Smooth finishes and clean designs give a polished feel. This is helpful in places like offices or stores where people see the equipment.

Tip: Powder-coated finishes not only look nice but also stop rust and scratches.

Features That Make Them Useful

Smart designs make enclosures easy to use and efficient. Some helpful features include:

Easy-to-Use Handles: These make opening and closing simple.

Panels You Can Remove: These help you reach parts quickly for repairs.

Wire Organizers: These keep cables neat and tidy.

Custom Options for Special Needs

You can change enclosures to fit your needs. For example:

Pick a Color: Match your brand or blend with the space.

Choose a Size: Use small ones for tight spots or big ones for complex setups.

Add Coatings: Use anti-graffiti coatings for public areas or food-safe finishes for clean spaces.

By mixing style and function, these enclosures protect your equipment and improve your workspace.

Note: Think about where and how you’ll use the enclosure. This helps you pick features that work best and look great.

Sheet metal switchgear enclosures are important for keeping electrical systems safe. They protect parts from damage, improve safety, and help equipment last longer. Made from strong materials, they can be customized and meet safety rules, making them useful in many places.

Picking the right enclosure boosts safety, lowers repair costs, and fits your needs. These enclosures work well in factories or offices, offering a mix of usefulness and good design.

FAQ

What does a sheet metal switchgear enclosure do?

It keeps electrical parts safe from dust, water, and accidental touch. It helps organize systems and stops damage from the environment.

How do you pick the best material for an enclosure?

Think about where it will be used. Stainless steel is great for tough outdoor areas. Aluminum is good for lightweight needs. CRCA works well indoors in controlled spaces.

Can a sheet metal switchgear enclosure be customized?

Yes, it can! You can choose the size, design, cooling tools, and finish. Custom options make sure it fits your needs and space perfectly.

Why is airflow important in enclosures?

Airflow stops overheating by letting air move around. It keeps parts safe, makes them last longer, and avoids problems caused by too much heat.

Do sheet metal enclosures follow safety rules?

Yes, they do! Many meet rules like IEC 62208, IEC 61439, and NEMA ratings. These rules make sure they are strong, safe, and protect against the environment.