Display enclosure sheet metal plays a vital role in safeguarding and improving the performance of modern displays. It serves as a protective barrier against environmental challenges like dust, moisture, and temperature variations. This makes it indispensable for industries such as consumer electronics, where sensitive components require robust protection.

The importance of display enclosure sheet metal extends beyond protection. Its use spans industries with significant economic impact. For example:

The global sheet metal market reached $188.31 billion in 2023 and is projected to grow at a 7.0% CAGR until 2030.

The display enclosure market alone is poised to hit $435.6 billion by 2032, growing at 4.00% annually from 2024.

With such growth, this material proves essential for creating durable, efficient, and visually appealing enclosures that meet diverse industrial needs.

Key Takeaways

Display enclosure sheet metal keeps parts safe from dust, water, and heat changes. This helps it work well.

Picking the right material is very important. Think about rust-proof materials for outside use and cheaper ones for inside.

Good airflow and heat control are key. Add slots or cooling parts to stop it from getting too hot.

Nice designs make people like it more. Add colors and logos to make enclosures look good and unique.

Material Types and Their Properties

Common Materials for Display Enclosure Sheet Metal

When selecting materials for display enclosure sheet metal, I always consider the specific needs of the application. Each material offers unique advantages and limitations. Here’s a quick comparison of the most commonly used materials:

Aluminum stands out for its lightweight nature and corrosion resistance, making it ideal for portable or outdoor displays. CRCA (Cold Rolled Close Annealed) steel is a budget-friendly option for indoor enclosures. Stainless steel, though more expensive, provides unmatched strength and durability for demanding environments. Galvanneal is perfect for wet conditions, while copper excels in conductivity but lacks structural strength.

Physical and Chemical Properties

Understanding the physical and chemical properties of these materials helps me make informed decisions. For example, aluminum’s low density makes it lightweight, while its oxide layer provides natural corrosion resistance. Stainless steel, on the other hand, owes its strength and rust resistance to its chromium content. CRCA steel is durable but requires additional coatings to prevent rust. Galvanneal combines the strength of steel with a zinc coating for corrosion resistance, and copper’s high electrical conductivity makes it a favorite for specialized applications.

These properties directly impact the performance of display enclosure sheet metal. A material’s thermal conductivity, for instance, determines how well it dissipates heat, which is crucial for electronics. Similarly, corrosion resistance ensures longevity, especially in harsh environments.

Criteria for Material Selection

Choosing the right material for display enclosure sheet metal involves balancing several factors. I always start by considering the environment where the enclosure will be used. For outdoor applications, corrosion resistance becomes a top priority. In contrast, indoor displays may focus more on cost-effectiveness and aesthetics.

Mechanical properties like strength and stiffness also play a role. For heavy-duty industrial displays, stainless steel might be the best choice. For lightweight consumer electronics, aluminum often works better. Additionally, I evaluate the ease of manufacturing. Materials like aluminum and CRCA steel are easier to cut, shape, and weld, which can reduce production costs.

Finally, I think about the visual appeal. A polished stainless steel finish can enhance a product’s premium look, while powder-coated CRCA steel offers a variety of color options. By carefully weighing these criteria, I can ensure the enclosure meets both functional and aesthetic requirements.

Structural and Functional Characteristics

Strength and Durability

When I evaluate display enclosure sheet metal, strength and durability are two of the most critical factors. These properties ensure the enclosure can withstand physical stress and maintain its integrity over time. Strength refers to the material's ability to resist deformation or breaking under force, while durability measures its capacity to endure wear and tear.

Here’s a quick breakdown of key strength and durability metrics for common materials:

For heavy-duty applications, I often recommend materials like stainless steel due to their high ultimate and fatigue strength. For lightweight designs, aluminum offers a good balance of strength and portability.

Thermal and Electrical Conductivity

Thermal and electrical conductivity play a vital role in the performance of display enclosure sheet metal, especially for electronic displays. High thermal conductivity ensures efficient heat dissipation, which prevents overheating and extends the lifespan of sensitive components. Aluminum, for instance, is an excellent conductor of heat, making it ideal for enclosures with built-in cooling systems.

Electrical conductivity is equally important for grounding and shielding purposes. Copper is the best choice for applications requiring high electrical conductivity, but its softness limits its structural use. Aluminum also performs well in this area, offering a cost-effective alternative for many designs.

Resistance to Corrosion and Environmental Factors

Corrosion resistance is essential for enclosures exposed to harsh environments. I always prioritize materials that can withstand moisture, chemicals, and temperature fluctuations. Stainless steel and galvanneal are excellent choices for wet or corrosive conditions due to their protective coatings and natural resistance.

Experimental data highlights the effectiveness of coatings in enhancing corrosion resistance. For example:

By selecting the right material and finish, I can ensure the enclosure remains durable and functional, even in challenging environments.

Key Design Considerations

Dimensional Precision and Tolerances

Dimensional precision is critical when designing display enclosure sheet metal. Precise measurements ensure the enclosure fits perfectly with the display components, avoiding gaps or misalignments that could compromise functionality. I always prioritize tight tolerances during manufacturing to achieve optimal performance.

Here’s a table summarizing recommended tolerances for different materials and processes:

For aluminum and steel, tolerances as tight as ±0.005 mm ensure seamless assembly and high durability. Processes like grinding offer even finer tolerances, making them ideal for applications requiring extreme precision. By adhering to these standards, I can guarantee that the enclosure performs reliably under various conditions.

Ventilation and Heat Management

Effective ventilation and heat management are essential for maintaining the performance of electronic displays housed within sheet metal enclosures. Heat buildup can damage sensitive components, reducing their lifespan. I always incorporate features like ventilation slots, perforations, or integrated cooling systems to address this issue.

Aluminum is my preferred material for enclosures requiring heat dissipation. Its high thermal conductivity allows it to transfer heat efficiently, preventing overheating. For designs with limited space, I recommend using compact heat sinks or fans to enhance airflow.

When designing ventilation systems, I also consider the placement of components. Strategic positioning ensures that heat-generating parts, such as power supplies, receive adequate cooling. This approach minimizes thermal stress and keeps the display functioning optimally.

Aesthetic and Branding Elements

Aesthetic design plays a significant role in consumer perception of display enclosures. I’ve seen how visually appealing designs can elevate the perceived value of a product. Research highlights that attractive aesthetics evoke positive emotional responses, which are crucial for marketing strategies.

To achieve this, I focus on finishes and branding elements that align with the client’s vision. Polished stainless steel offers a premium look, while powder-coated CRCA steel provides vibrant color options. I also integrate branding elements like embossed logos or custom textures to enhance the enclosure’s visual appeal.

Design aesthetics aren’t just about looks; they also influence functionality. For example, rounded edges improve safety, while textured surfaces reduce glare. By combining form and function, I create enclosures that not only protect displays but also leave a lasting impression on consumers.

Manufacturing Techniques for Display Enclosure Sheet Metal

Cutting and Shaping Methods

Cutting and shaping are the first steps in manufacturing display enclosure sheet metal. I rely on various methods depending on the material and design requirements. For instance, laser cutting is my go-to for intricate designs. It produces clean, precise cuts, making it ideal for detailed enclosures. When working with thicker sheets, I often use plasma cutting. Its speed and ability to handle dense materials make it highly efficient.

For mass production, I prefer punching and blanking. Punching creates consistent holes or slots, while blanking produces flat, uniform parts with tight tolerances. Shearing is another method I use for straight-line cuts, especially when simplicity and speed are priorities. In cases where heat-sensitive materials are involved, water jet cutting becomes invaluable. It delivers high precision without causing thermal distortion.

Here’s a quick comparison of these methods:

Joining and Assembly Techniques

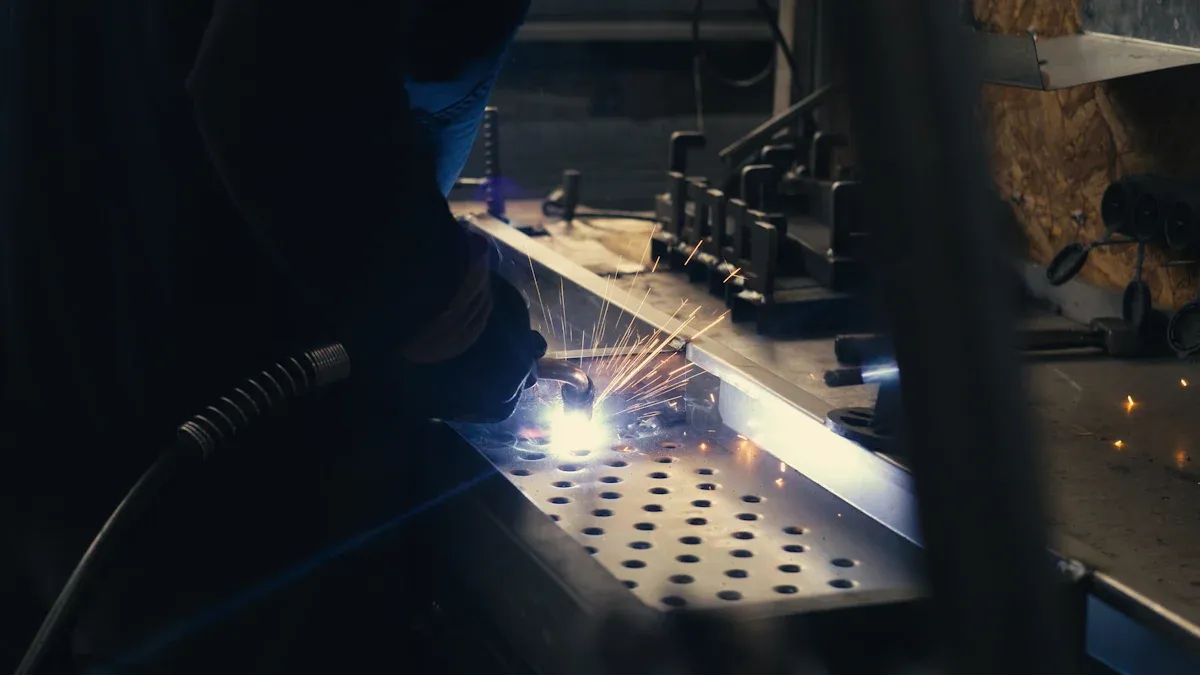

Joining and assembly are critical for creating durable and functional enclosures. I focus on optimizing fixture design to ensure precision and efficiency. A well-designed fixture minimizes dimensional inaccuracies, which improves the overall quality of the final product. For example, welding is a common technique I use for its strength and permanence. However, I always consider the material and application before choosing a method.

For lightweight or portable enclosures, I often use riveting or adhesive bonding. These methods are less intrusive and maintain the material's integrity. When working with modular designs, I prefer mechanical fasteners like screws or bolts. They allow for easy disassembly and maintenance. By carefully selecting the right joining technique, I can enhance both the structural integrity and functionality of the enclosure.

Surface Finishing and Coating Options

Surface finishing and coating are the final steps in manufacturing display enclosure sheet metal. These processes not only improve aesthetics but also enhance durability. I often use powder coating for its versatility and vibrant color options. It provides a smooth, uniform finish that resists scratches and corrosion.

For premium enclosures, I recommend anodizing. This process creates a protective oxide layer on aluminum, enhancing its corrosion resistance and appearance. Galvanization is another option I use for steel enclosures. It involves applying a zinc coating to prevent rust. In some cases, I opt for electroplating to achieve a polished, metallic finish.

Each finishing method serves a specific purpose. By choosing the right one, I can ensure the enclosure meets both functional and aesthetic requirements.

Real-World Applications

Industrial and Commercial Uses

Display enclosure sheet metal plays a pivotal role in industrial and commercial settings. I often see it used in factories, where it protects sensitive electronics from dust, liquids, and mechanical impacts. For example, industrial control systems rely on robust enclosures to maintain functionality in harsh environments. In retail spaces, these enclosures house interactive kiosks and digital signage, ensuring durability while maintaining a sleek appearance.

In commercial kitchens, enclosures withstand frequent cleaning and exposure to moisture. Food and beverage processing facilities benefit from materials like stainless steel, which resists corrosion and handles rigorous sanitation protocols. Additionally, I’ve noticed their use in telecommunications, where outdoor enclosures shield equipment from weather extremes. These applications highlight the versatility and reliability of sheet metal in demanding environments.

Consumer Electronics and Interactive Displays

In consumer electronics, display enclosure sheet metal enhances both protection and aesthetics. I’ve worked on projects where aluminum enclosures provided lightweight yet sturdy housing for tablets and laptops. These materials not only safeguard internal components but also contribute to a premium look and feel.

Interactive displays, such as those in retail or educational settings, also benefit from these enclosures. They protect screens from accidental damage while offering ventilation to prevent overheating. For outdoor displays, materials like galvanneal ensure resistance to moisture and corrosion. This combination of functionality and design makes sheet metal enclosures indispensable in the consumer electronics market.

Specialized Applications in Challenging Environments

Certain environments demand enclosures with exceptional performance. I’ve seen them excel in protecting marine electronics from saltwater exposure and safeguarding outdoor security cameras from rain and humidity. In renewable energy, they shield inverters and controllers in solar and wind installations.

Other specialized uses include ruggedized enclosures for military and aerospace electronics, which endure extreme temperatures and vibrations. In transportation, they protect vehicle electronics from moisture and temperature fluctuations. Even scientific research equipment benefits from these enclosures, especially in fieldwork or environmental monitoring.

These examples demonstrate how display enclosure sheet metal adapts to unique challenges, ensuring reliability across diverse industries.

Display enclosure sheet metal combines strength, durability, and precision to protect and enhance modern displays. I always focus on selecting the right material, designing for functionality and aesthetics, and using advanced manufacturing techniques. These steps ensure enclosures meet industry demands and perform reliably. By prioritizing these factors, you can create enclosures that last longer, look better, and function effectively in any environment.

FAQ

What is the primary purpose of display enclosure sheet metal?

Display enclosure sheet metal protects sensitive components from environmental factors like dust, moisture, and temperature changes. It also enhances the durability and aesthetics of displays, ensuring they perform reliably in various settings.

How do I choose the right material for my enclosure?

I recommend considering the environment, mechanical requirements, and aesthetics. For outdoor use, prioritize corrosion resistance. For lightweight designs, aluminum works best. Stainless steel suits heavy-duty applications.

Why is ventilation important in display enclosures?

Ventilation prevents heat buildup, which can damage electronic components. I always design enclosures with slots, perforations, or cooling systems to ensure proper airflow and maintain optimal performance.

Can display enclosures be customized for branding?

Absolutely! I often incorporate custom finishes, embossed logos, or unique textures to align with a brand’s identity. These elements enhance the enclosure’s visual appeal while maintaining its functionality.

Are sheet metal enclosures suitable for harsh environments?

Yes! Materials like stainless steel and galvanneal excel in challenging conditions. They resist corrosion, moisture, and extreme temperatures, making them ideal for marine, industrial, and outdoor applications.