CNC sheet metal bending machines are revolutionizing metalwork methods. These machines provide exceptional accuracy, making it easy to create detailed designs. Many manufacturers utilize sheet metal CNC bending to save materials and increase efficiency. A survey revealed that 72% of companies consider CNC and robotic bending crucial for enhanced precision. Additionally, these machines incorporate AI tools that anticipate issues, which 64% of users report helps prevent delays. Whether producing simple components or complex designs, sheet metal CNC bending ensures consistent, high-quality results every time.

Key Takeaways

CNC bending machines shape metal automatically. They are very accurate and make fewer mistakes. This improves the quality of metalwork.

CNC technology helps save money by lowering labor costs and reducing wasted materials. It is a smart choice for manufacturers.

Automation in CNC machines makes work faster and reduces delays. This allows production to keep going without stopping.

AI in CNC machines can find and fix problems during bending. This makes the process better and cuts down on errors.

CNC machines can work with tricky designs. They are important for industries that need exact shapes and custom designs.

Basics of Sheet Metal CNC Bending

What Are CNC Sheet Metal Bending Machines?

CNC sheet metal bending machines are tools that shape flat metal. They use CNC technology to automate bending and ensure accuracy. These machines read CAD files to calculate angles and dimensions. This removes guesswork and reduces mistakes, making them great for quality work.

Important parts include precise guides, hydraulic systems, and easy controls. These features improve accuracy, reliability, and ease of use. For example, hydraulic systems make bending faster and more reliable. Easy controls let users program and operate the machine simply.

How Do CNC Machines Perform Sheet Metal Bending?

CNC machines bend flat sheets into shapes using controlled force. They push the metal past its limit to change its shape permanently. First, the metal bends slightly, then locks into the new shape.

The process starts with the machine reading CAD files for angles and sizes. A punch and die system applies force to create shapes like V or U. Techniques like V-bending or U-bending are used based on the design. After bending, tools like 3D scanners check the product for quality, with tiny error margins of ±0.001mm.

To get the best results, follow these tips:

Bend smaller parts before larger ones.

Use custom dies to avoid interference.

Plan for springback, where metal slightly unbends after bending.

Types of CNC Machines for Sheet Metal Bending

Different CNC machines handle various bending tasks. The most common are CNC press brakes and CNC panel benders.

CNC press brakes are good for detailed designs and flexible projects. They work with many materials and shapes. CNC panel benders are better for large-scale jobs, needing less manual work. Pick the right machine based on your project needs.

Key Capabilities of CNC Sheet Metal Bending Machines

Precision and Accuracy in Sheet Metal Bending

CNC sheet metal bending machines are known for their great precision. They use advanced CNC technology to make sure every bend is exact. Things like material type, machine quality, and process planning affect accuracy. For example, using strong materials and precise tools improves the product's quality.

New calibration methods make machines even more accurate. Regular checks, like laser alignment, keep the machine working properly. Systems that adjust for temperature changes help during long jobs. Automated tools also reduce human mistakes, giving consistent results.

Tip: Always check your machine and fine-tune settings for better results.

Efficiency in High-Volume Sheet Metal Production

CNC machines are built for speed and efficiency. They are perfect for making large amounts of sheet metal parts. These machines work nonstop, cutting downtime and boosting production. Automated systems plan tool movements to save material and time. For instance, you can save bending patterns in the machine, which reduces setup time.

Automated bending saves time compared to manual methods. These machines work fast, handling large amounts of material quickly. Industries like construction and car manufacturing rely on them for high-speed production.

Note: Using CNC machines can help you save money and increase productivity.

Flexibility for Complex Sheet Metal Designs

CNC sheet metal bending machines are very flexible. They can create detailed designs easily. Hydraulic systems give steady pressure, ensuring accuracy for tricky shapes. These machines work with different materials and thicknesses, making them useful for many jobs.

Fully automatic models have advanced controls for programming complex bends. This reduces mistakes and improves performance. New technologies like STEP-NC allow quick design changes to meet market needs.

With CNC machines, you can make complex designs while keeping quality high. This makes them essential for industries needing custom or detailed sheet metal work.

Callout: CNC machines help you create innovative designs that look great and work well.

Technological Advancements in CNC Machines

AI Integration in CNC Sheet Metal Bending

AI is changing how CNC machines bend sheet metal. It helps improve accuracy and speed. AI can predict problems and fix them during bending. For example, AI adjusts for springback, making bends more precise. This leads to fewer mistakes and better quality.

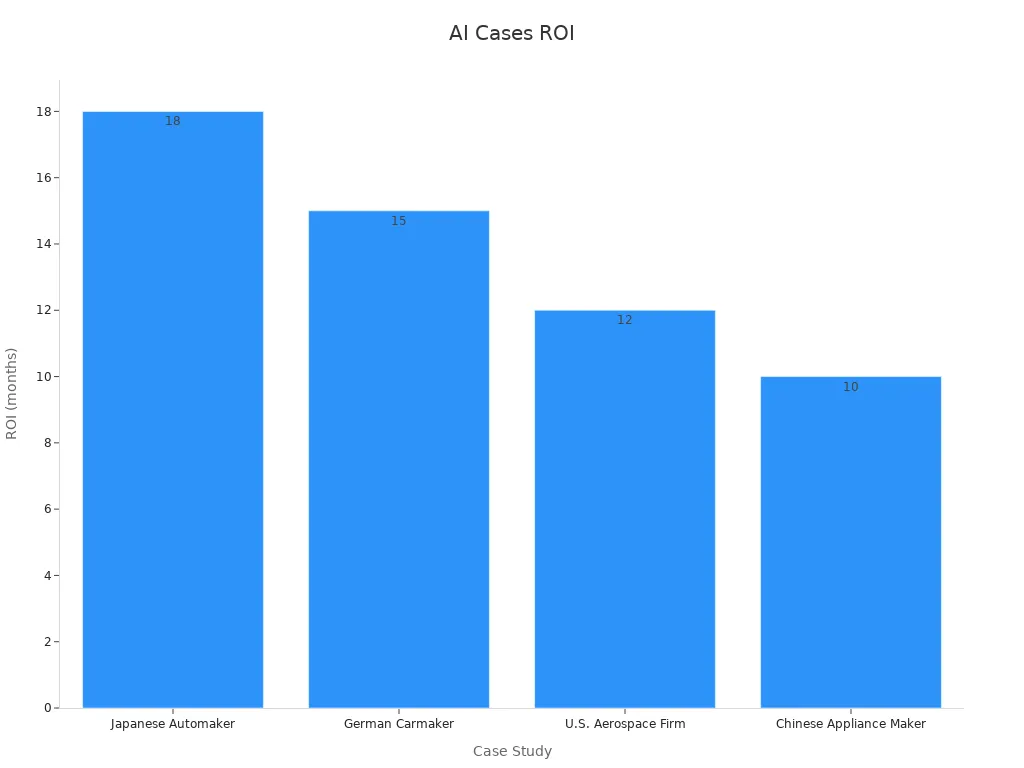

Real-world examples show AI's benefits. A Japanese car company used AI to make hoods, cutting energy use by 18%. They also saved 50 tons of CO2 each year. A German automaker reduced aluminum waste from 6% to 1%, saving €1 million annually. These cases prove AI increases productivity and lowers costs.

Automation Features for Enhanced Productivity

Automation makes CNC machines faster and more efficient. Robotic arms and sensors help with bending tasks. Industry 4.0 tools allow real-time tracking and adjustments. These features save time and reduce waste.

Manufacturers gain many benefits from automation:

Faster cycles mean quicker production.

Smart systems use less material.

Setup times are shorter with advanced controls.

Automation ensures consistent quality and reduces human mistakes. It’s perfect for making large amounts of sheet metal parts quickly.

Advanced Software for Customization and Control

Modern CNC machines use smart software for better control. These programs let you design and adjust bending settings easily. For example, 3D modeling software shows designs before production starts. This saves time and money.

New software includes AI and IoT features. AI predicts errors and fixes them automatically. IoT tracks machine performance and schedules maintenance. These tools reduce downtime and improve efficiency. Energy-saving software also supports eco-friendly goals.

Popular software trends include:

Industry 4.0 tools for smoother operations.

IoT for tracking and maintenance.

AI for smarter error fixes.

3D modeling for testing designs.

These software tools make CNC machines flexible and reliable. They help create complex designs while keeping quality high.

Practical Benefits of CNC Sheet Metal Bending

Lower Labor Costs and Less Material Waste

CNC sheet metal bending machines help save on labor costs. They automate tasks, so workers don’t need to do everything manually. You can program the machine to handle tough jobs on its own. This reduces the need for workers by about 30%. With fewer workers needed, they can focus on other important tasks, boosting productivity.

These machines also cut down on material waste. They plan tool movements carefully to make accurate cuts and bends. This accuracy means fewer mistakes and less wasted material. For example, industries using CNC machines report using fewer resources than older methods. This makes CNC machines both eco-friendly and cost-saving.

Tip: Keep your CNC machine’s software updated to save more materials and work faster.

Reliable and Repeatable Results in Metal Work

CNC sheet metal bending machines are great at making consistent parts. They use advanced tools to ensure every piece is the same. This is important for keeping quality high in metal projects. Whether you need one part or thousands, CNC machines make sure they all match.

Tools like Cpk and Gage R&R measure how consistent the machine is. High consistency means fewer mistakes, which is vital for industries like cars and airplanes. These industries need CNC machines to make exact parts over and over again, meeting strict quality rules.

Ways to Measure Consistency:

Cpk (Process capability index)

Gage R&R

Testing and analyzing results

With reliable results, you waste less and improve quality checks. This makes CNC machines a must-have for precise metal bending jobs.

Saving Money and Speeding Up Production

CNC sheet metal bending machines are very cost-effective. They lower labor costs, reduce wasted materials, and work faster. Many companies recover their investment in just 1-3 years. By using CNC machines, you can produce more while spending less.

These machines also speed up production. Features like automatic tool changes and quick adjustments make work faster. This is helpful for meeting tight deadlines and making large orders. Industries like construction and electronics rely on CNC machines to stay competitive by working quickly.

Callout: CNC machines keep quality high even when working fast, so you don’t have to choose between speed and precision.

By using CNC sheet metal bending machines, you can work faster, save money, and improve productivity. These benefits make them essential for modern metalworking.

CNC sheet metal bending machines help you work with precision and speed. They make creating complex designs easier and keep quality consistent. Features like automation and AI meet today’s manufacturing needs. Using CNC technology helps you stay ahead in a fast-moving industry. Whether making many parts or detailed designs, CNC machines give dependable results.

Tip: Try CNC machines to improve your work and save money.

FAQ

What materials can CNC sheet metal bending machines handle?

CNC machines can bend steel, aluminum, copper, and brass. They also work with metals of different thicknesses. Check your machine's manual to confirm it fits your material.

How do you maintain a CNC sheet metal bending machine?

Keep the machine clean and lubricate its moving parts. Inspect hydraulic systems and replace worn tools regularly. Update the software to keep it running smoothly. Follow the maintenance schedule from the manufacturer for best results.

Can CNC machines create custom designs?

Yes, CNC machines are great for custom designs. Upload CAD files to program shapes and angles. This makes them perfect for unique or detailed projects.

Are CNC machines suitable for small-scale production?

Yes, CNC machines work well for small and large jobs. For small batches, they save setup time and ensure quality. This makes them cost-effective even for smaller projects.

What safety measures should you follow when using a CNC machine?

Wear gloves and goggles to protect yourself. Keep the area clean and clear of clutter. Follow all safety rules and use emergency stops when needed.

Tip: Train operators often to improve safety and avoid accidents.