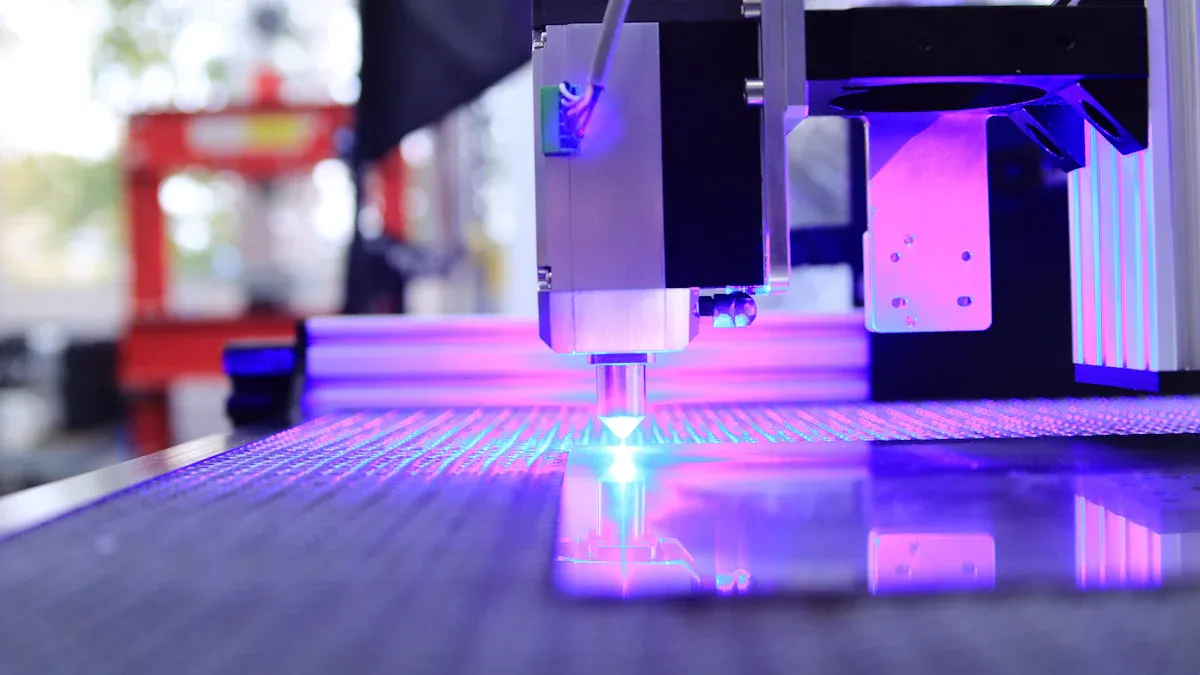

Sheet metal laser cutting has changed manufacturing by being precise and fast. It is used in industries that need high-quality parts. For example:

The demand for these machines is growing because they are accurate and help with smart manufacturing.

Industries like cars, planes, and buildings use this technology to work better and faster.

New tech, like CNC machines, has improved the process, making it popular with manufacturers.

This method is very precise, with accuracy up to ±0.0005 inches and cuts as thin as 0.2 mm. It wastes little material and makes high-quality parts, making it very important in modern manufacturing.

Key Takeaways

Sheet metal laser cutting is very accurate, with tiny errors of ±0.1 mm. This helps parts fit well and reduces mistakes.

It works quickly and saves time, cutting production times and labor costs. This makes it great for big projects.

Laser cutting can handle many metals like aluminum and stainless steel. It allows for detailed designs in different industries.

It creates clean cuts, reducing waste and saving money. Less finishing work is needed, and materials are used efficiently.

Learning to use laser cutters is important for safety. Training also helps prevent expensive errors while cutting.

What is Sheet Metal Laser Cutting?

Sheet metal laser cutting is a modern way to cut metal sheets. It uses advanced tools to make detailed designs and smooth edges. This method is very important in making metal parts. Industries like cars, planes, and buildings use it for high-quality work.

How a Metal Laser Cutter Works

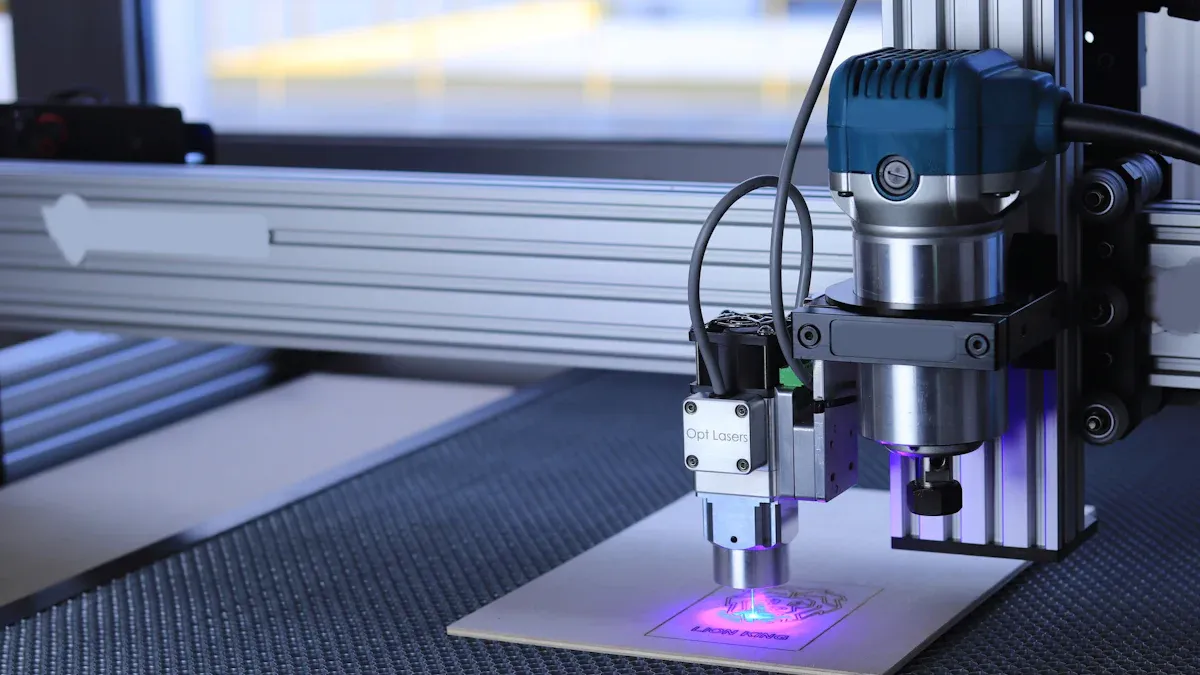

A metal laser cutter uses a strong laser beam to cut metal. First, a G-code file is made using special software. This file gives instructions for the cutting job. The laser beam is created through a process called stimulated emission. Its power is increased to make it strong enough for cutting.

The laser beam is aimed at the metal and focused. It melts or turns the metal into gas, creating clean cuts. A gas like nitrogen or oxygen helps remove melted metal for a smooth finish. This process doesn’t touch the metal directly, so it avoids bending or damage. CNC systems control the machine, making it accurate and fast.

G-code File Creation: Instructions are made using CAM software.

Laser Beam Creation: The laser is formed in the resonator.

Beam Strengthening: The laser’s power is increased for cutting.

Beam Aiming: The laser is aimed and focused on the metal.

Cutting Process: The laser melts or vaporizes metal with gas help.

This step-by-step process ensures clean and exact cuts, making it a key tool in metalwork.

Materials Used in Sheet Metal Laser Cutting

Sheet metal laser cutting works with many types of metals. Common ones include aluminum, stainless steel, and mild steel. Each metal reacts differently to the laser based on its properties, like how much light it reflects or absorbs.

For example, aluminum reflects 95.2% of light, making it harder to cut. But new laser tech can handle reflective metals well. Stainless steel absorbs more light, so it’s easier to cut. These metals are popular in industries like planes, electronics, and construction because they are strong and flexible.

Knowing these details helps you pick the best metal for your project. This ensures great results in metal cutting.

Key Features of the Laser Cutting Process

Laser cutting has many features that make it a top choice for cutting metal. One big advantage is its accuracy. It can cut with tolerances as small as ±0.1mm. This is great for jobs needing detailed designs and exact sizes, like in plane or medical industries.

Another benefit is its speed. Laser cutters work fast, especially with thin or medium-thick metals. This saves time and boosts production, making it cost-effective for big projects. The process is also automated, needing little human help. CNC systems run the machine, ensuring steady and error-free results.

These features make laser cutting a dependable and efficient way to cut metal. Whether for simple or complex shapes, this method delivers top-quality results every time.

Applications of Sheet Metal Laser Cutting

Sheet metal laser cutting has changed how things are made. It is very accurate and works quickly. Many industries depend on it for their needs. Below are examples of how it helps different fields.

Automotive and Transportation

Laser cutting is important for making car and vehicle parts. It is used for things like frames, exhausts, and detailed interiors. The accuracy ensures parts fit well, improving safety and performance.

Speed and Efficiency: Laser cutting works on both thin and thick metals. For example:

Low-power lasers cut thin sheets quickly and easily.

High-power lasers (12 kW to 40 kW) handle thick metals like carbon steel without losing quality.

Market Growth: The sheet metal equipment market was worth USD 33.68 billion in 2024. By 2032, it may grow to USD 61.78 billion, with an 8.2% yearly increase. This shows more demand for laser cutting in making cars.

Laser cutting helps make strong but light parts. These are good for saving fuel and being eco-friendly. It also helps create complex designs for electric cars, which are becoming more popular.

Aerospace and Defense

The aerospace and defense fields need exact and reliable parts. Laser cutting is perfect for this. It is used for turbine blades, plane panels, and supports. It handles tricky shapes while meeting strict rules.

In aerospace, safety is very important. Laser cutting makes sure every part is made perfectly. It also reduces waste, which helps the environment. Whether for planes or defense tools, laser cutting is a trusted method.

Medical Equipment and Devices

The medical industry uses laser cutting for making small, detailed parts. It is used for tools and devices that go inside the body. This method ensures high-quality and safe products.

Precision and Hygiene: Laser cutting makes smooth edges with no rough spots. This is important for clean and safe medical tools. The process doesn’t touch the material, so it stays sterile.

Versatility: It works with many materials like stainless steel and titanium. These are common in medical devices. It also helps make advanced tools for surgeries.

Growing Demand: As healthcare grows, more medical tools are needed. Laser cutting provides fast and accurate solutions to meet this demand.

Laser cutting helps create devices that save lives and improve health. Its role in medicine shows how important it is for making advanced tools.

Electronics and Consumer Products

Sheet metal laser cutting is key in making electronics and home items. It helps create small, detailed parts for things like phones, laptops, and appliances. This method works well with delicate materials, ensuring top-quality results.

Cutting Speed Improvements: Laser machines cut faster, especially metals like zinc and aluminum. This speeds up production, helping meet the rising demand for products.

Precision and Quality: Smooth edges and perfect finishes mean no extra work is needed. This improves product quality and lowers costs for manufacturers.

Efficiency Gains: Laser cutting makes production quicker and smoother. More items can be made in less time without losing quality.

Laser cutting is also great for making jewelry. It helps create detailed designs in gold, silver, or platinum. Every piece looks the same, making it good for both custom and mass production. From earrings to necklaces, this technology ensures beautiful results.

This method also helps improve electronics. It makes strong and light parts that work better in devices. Whether it’s a phone case or laptop parts, laser cutting ensures every detail is just right.

Construction and Architectural Design

In construction and design, laser cutting helps turn creative ideas into reality. Its accuracy and flexibility make it perfect for unique and useful building features.

Laser cutting lets you design detailed building facades that mix beauty and function. You can make decorative items like railings and screens to improve spaces. For signs and branding, it creates clear and eye-catching designs.

Inside buildings, laser cutting helps make custom lights and dividers with fancy patterns. These features add style and usefulness to rooms. It’s also great for staircases and railings, blending artistic looks with practical use.

Outdoor spaces benefit too. Laser cutting makes garden features with unique designs that stand out. For building parts, it ensures accuracy and strength, improving construction quality.

Whether for jewelry or buildings, laser cutting helps create amazing designs. Its precision and flexibility make it a key tool in modern manufacturing and design.

Advantages of Sheet Metal Laser Cutting

Precision and Accuracy in Manufacturing

Laser cutting is very precise and accurate for making metal parts. It can create detailed designs with tolerances as small as ±0.1 mm. This ensures parts fit perfectly, reducing mistakes during assembly. Advanced software and tools help match the final product to the design.

This method also saves material. Smaller cuts use more of the metal sheet, lowering waste. Unlike older cutting methods, laser cutting makes smooth edges that don’t need extra finishing. Machines work automatically, ensuring consistent results for big projects.

Speed and Efficiency in Production

Laser cutting works fast, helping finish jobs quickly. It cuts thin and medium-thick metals without losing quality. Machines work automatically, reducing labor costs and human mistakes.

This technology handles different materials without needing tool changes. Metals like aluminum, stainless steel, and mild steel are cut easily. This makes laser cutting useful for projects needing speed and flexibility.

The laser doesn’t touch the metal directly, so it avoids bending or damage. This saves time and skips extra steps, making the process faster and smoother.

Versatility Across Materials and Designs

Laser cutting works with many types of metals, like aluminum and stainless steel. It’s flexible, so you can use it for different projects.

It creates detailed designs that older methods can’t do. Industries like aerospace, medicine, and construction use it for complex shapes. Whether for building decorations or machine parts, laser cutting fits many needs.

Switching between materials and designs is easy without changing tools. This saves time and keeps the quality high for different industries.

Minimal Waste and Cost-Effectiveness

Sheet metal laser cutting is a smart and eco-friendly way to make things. It uses advanced tools to save materials and lower costs.

One big benefit is its precision. The laser makes clean and thin cuts, removing less metal. This lets you fit many parts on one sheet, using it fully. For example, if your project has detailed designs, laser cutting keeps waste small and saves materials.

Tip: Use nesting software to arrange parts better and waste less.

Laser cutting skips extra finishing steps. Old methods leave rough edges that need polishing. Laser cutting makes smooth edges, saving time and work.

Laser cutting doesn’t need physical tools that wear out. This lowers maintenance costs and keeps quality steady. Choosing laser cutting saves money and helps the planet. 🌱

Challenges and Limits of Using a Metal Laser Cutter

High Starting Costs

Metal laser cutters are expensive to buy. Advanced machines can cost a lot, making it hard for small businesses to afford them. These high prices often stop companies from using this technology, even though it saves money later. Besides the buying cost, running the machine also costs money. You need to pay for maintenance, spare parts, and electricity. Planning your budget is very important.

Note: Even though it costs a lot at first, laser cutting’s accuracy and speed can save money over time.

Limits with Materials and Thickness

Laser cutting works best with certain materials and thicknesses. Some metals, like aluminum, reflect the laser, making cutting harder. Very thick materials may need stronger lasers or more time to cut. Studies show that larger plasma cutting setups (PCC) create more waste when cutting wide materials. Smaller pieces reduce waste but only up to a point.

Knowing these limits helps you pick the right materials and improve your cutting process.

Energy Use and Maintenance

Running a metal laser cutter uses a lot of electricity. High-powered lasers need more energy, which raises costs. Keeping the machine in good shape is also important. You need to clean lenses, replace old parts, and adjust the laser. If you don’t take care of it, the machine might break and cost more to fix.

Tip: Use predictive maintenance to find problems early and avoid delays.

By solving these issues, you can get the most out of laser cutting while reducing its downsides.

Operator Skills and Training Needs

Using a sheet metal laser cutter takes special skills. You must know how the machine works, use its software, and follow safety rules. Without training, mistakes can happen, wasting materials or breaking the machine.

Why Learning is Important

Laser cutters use advanced tools like CNC systems and G-code files. Operators must learn to write clear instructions for the machine. Errors in programming can cause bad cuts or slow down work. Training helps you fix problems and keep the machine running well.

Tip: Read the user manual and join workshops to get better at using the machine.

Skills to Focus On

To use a laser cutter well, you need both technical and hands-on skills. Here are the main areas to learn:

Software Skills: Practice using CAM software to design cutting patterns.

Metal Knowledge: Learn how lasers affect different types of metals.

Safety Practices: Always follow safety rules to avoid injuries.

Machine Care: Know how to clean and fix parts when needed.

Ways to Learn

Many companies offer training for their machines. These lessons teach you how to use the tools and get the best results. You can also take online classes or earn certificates to learn advanced skills.

Spending time on training helps you become skilled at using the machine. With the right knowledge, you can create top-quality work and make the most of laser cutting technology.

Sheet metal laser cutting has changed how things are made. It speeds up production, cutting time by over half. Efficiency improves by about 30%, reducing mistakes and making better products. This method also saves money and uses less energy, helping local factories work smarter. It’s flexible and useful for industries like cars, planes, and medical tools. Even though there are some challenges, the advantages are much bigger. Laser cutting is now a key part of modern manufacturing.

FAQ

What projects are best for sheet metal laser cutting?

Projects needing accuracy, speed, and detailed designs are ideal. Industries like cars, planes, and construction use it for precise parts. It’s also great for custom items like jewelry, gadgets, and building decorations.

Can laser cutting cut all metal thicknesses?

Laser cutting works well on thin to medium-thick metals. For thicker metals, stronger lasers are needed. Knowing your material helps avoid problems and improves cutting results.

Is laser cutting good for the environment?

Yes, laser cutting reduces waste by using materials wisely. It also uses less energy than older methods. Clean cuts and no extra finishing steps make it eco-friendly.

Do I need training to use a laser cutter?

Yes, training is needed to use a laser cutter safely. You’ll learn software, machine care, and safety rules. Many companies offer classes or online lessons to teach these skills.

How is laser cutting better than older cutting methods?

Laser cutting is more accurate, faster, and wastes less material. It doesn’t touch the metal, so there’s less chance of damage. It’s also flexible, making it easy to create complex designs.