When it comes to making things today, sheet metal stamping is special. It’s not just about shaping metal; it’s about doing it fast, precise, and eco-friendly. Did you know machines can repeat tasks perfectly, saving time? Also, CNC technology helps make every part exactly right. This is why car and airplane industries trust it.

Plus, using materials has improved a lot. Methods like Transversal Compression Drawing (TCD) make work 4.5% better and stop thinning, which happens with old ways. This means less waste and stronger parts. Whether for light pieces or tricky designs, sheet metal stamping is super useful and hard to beat.

Key Takeaways

Sheet metal stamping is fast, accurate, and eco-friendly. It works well for industries like cars and airplanes.

Modern tools like CNC and CAD help make parts precise. They ensure tiny measurements for perfect fits.

Smart methods cut down waste and use materials better. This saves money and helps the environment.

Machines speed up production, making many parts quickly and consistently.

Sheet metal stamping can make tricky shapes and fit different needs. It’s used for cars, gadgets, and more.

Precision in the Metal Stamping Process

Precision is the key to metal stamping. At Foxsen, we focus on every detail. Small changes can make a big impact. We create top-quality parts for cars, planes, and electronics. Precision is what makes us stand out.

Achieving Micro-Tolerances

Micro-tolerances are a big deal in stamping. They help parts fit perfectly every time. For example, we make car suspension brackets with ±0.05mm accuracy. In aerospace, we handle large aluminum panels with ±0.1mm precision. These numbers show how much we care about accuracy.

How do we do it? We use advanced tools like lasers and precision benders. Every part is tested to match exact designs. We ensure each batch is as perfect as the last one.

High-Strength Material Compatibility

Shaping strong materials like stainless steel is tough. But we’ve learned how to do it well. These materials are great for making light but strong parts. They’re important for cars and planes. At Foxsen, we use special tools to shape these materials without damaging them.

Why does this matter?

Strong materials make safer, better-performing products.

They help create lighter parts, saving fuel in vehicles and planes.

Our skills ensure even hard-to-shape materials are stamped precisely.

By mixing material knowledge with modern tools, we make high-quality stamped parts.

Advanced Die and Lubrication Technology

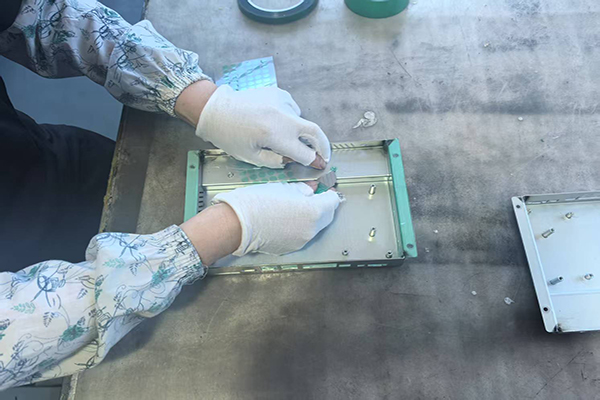

Dies and lubricants may seem boring, but they’re vital. At Foxsen, we use advanced dies and smart lubrication methods. This ensures every part we make is perfect.

We use digital tools to test lubricants during hot stamping. By studying heat and pressure, we improve lubricant performance and part quality.

Our dies are built to last and work well under stress. We harden their surfaces to make them stronger. Our lubricants handle high heat, cutting down friction and wear. This improves part quality and speeds up production.

In short, our dies and lubricants focus on precision and dependability. It’s another way we meet Foxsen’s high standards.

Efficiency and Benefits of Sheet Metal Stamping

Making metal parts needs to be fast and reliable. Whether making thousands or millions, the process must save time and money. That’s why sheet metal stamping is so useful. It’s not just quick; it also makes accurate, high-quality parts every time. Let’s see how this process works so well.

Fast Production for Large Quantities

Sheet metal stamping is great for making many parts quickly. Once the tools are ready, machines work non-stop. They can make thousands of parts in one day. This is why industries like cars and planes use it. The best part? Every piece looks and works the same, no matter how many are made.

Here’s why this method is so effective:

This process ensures every part meets high standards, even at fast speeds. That’s why it’s trusted for making large quantities.

Affordable Manufacturing

Sheet metal stamping saves money in the long run. Setting up tools may cost a lot at first, but it pays off. Once running, the cost per part becomes much lower. This makes it one of the cheapest ways to make many parts.

Here’s why it’s so cost-friendly:

It makes parts quickly and with great accuracy.

Less material is wasted, saving money on raw materials.

Over time, faster production and less waste save even more.

For example, car makers often waste 44% of sheet metal they buy. But smart stamping methods reduce waste, using materials better and cutting costs. That’s why companies love how affordable and efficient this process is.

Faster Results with Automation

Automation has changed how metal stamping works. Using advanced machines and programs, we can make parts faster. Automation doesn’t just speed things up; it also makes fewer mistakes. This means less fixing and better results.

Here’s how automation helps:

It makes the process faster, so more parts are made.

Programs ensure accuracy, reducing errors and rework.

Better planning keeps materials ready when needed.

By mixing automation with precise stamping, we make parts faster and better. This is key for industries needing quick and reliable production.

Material Use and Sustainability in Metal Stamping

When making things, I ask, "How can this be smarter?" That’s why using materials wisely and being eco-friendly is important. Metal stamping isn’t just about making parts; it’s about doing it responsibly. Let me explain how we make every piece matter.

Cutting Waste with Smart Stamping

Waste hurts both the planet and business. That’s why we use smart stamping methods to cut waste. By planning better, we use materials wisely and save money. For example, advanced tools help us plan cuts to leave less scrap.

Here’s why this works well:

It saves money by using materials better.

Workers join in to reduce waste, helping the environment.

Smart tools make better cuts, leaving less leftover material.

Every stamped part isn’t just useful—it also helps the planet.

Green Practices in Manufacturing

Being eco-friendly isn’t just a trend; it’s a promise. Manufacturing should care for the Earth. That’s why we use green methods in metal stamping. From recycling to saving energy, every step counts.

For example, we use machines that need less power but still work well. Leftover metal gets recycled into new products. These steps help the planet and save money too.

Green manufacturing means making great products while caring for the Earth.

Choosing metal stamping means picking a process that values both quality and the planet.

Using Materials Smartly for Lightweight Parts

Light parts are the future, especially for cars and planes. It’s exciting to see how new ideas make this happen. Methods like deep draw and hydroforming create strong but light parts.

Here’s how we use materials smartly:

CAD tools help design parts with extra strength.

Friction stir welding joins light materials without weakening them.

Carbon fiber is super strong and light, great for planes and cars.

By mixing smart designs with flexible materials, we make parts that are light, strong, and efficient. It’s amazing how these ideas change manufacturing for the better.

Versatility and Uses of Sheet Metal Stamping

Sheet metal stamping is amazing because it can do so much. It’s not just for flat parts; it makes detailed designs too. It works for many industries and adjusts to big or small jobs. Let me explain why this process is so flexible.

Making Complex Shapes

Making tricky shapes is hard, but stamping makes it easier. We use methods like bending, coining, and embossing to shape metal perfectly. For example, coining uses high pressure to make smooth, exact shapes. Drawing stops wrinkles when making big parts. Here’s a quick look at some methods:

What’s even cooler? Smart robots with AI adjust the process as they work. These robots learn and improve with every step. This makes it easier to create tricky designs. That’s why custom stamping is great for special projects.

Uses in Cars, Planes, and Gadgets

Sheet metal stamping is used in many industries. It’s perfect for cars, planes, and electronics. Here’s how it helps:

Car parts like panels and brackets are made quickly.

Planes need light, strong parts, and stamping delivers.

Electronics use it for tiny, detailed pieces.

This makes sheet metal stamping super important. From cars to planes to gadgets, stamped parts are everywhere.

Adapts to Big or Small Jobs

One great thing about stamping is how it fits any job size. Need a few parts? It focuses on detail and custom work. Need millions? Automation keeps it fast and consistent.

This is why industries like construction and medical tools trust it. Need a light part for a plane? Or a strong piece for a building? Stamping can do it all. It grows with what you need.

Advancements in the Metal Stamping Process

Using CAD and Simulation Tools

Technology makes manufacturing easier and smarter. CAD (Computer-Aided Design) and simulation tools have changed metal stamping. These tools help design and test parts before production starts. It’s like seeing the future of manufacturing!

CAD creates detailed 3D models of parts. Simulation tools predict how metal will act during stamping. Will it crack or wrinkle? These tools answer those questions. This saves time and materials by fixing problems early. Every part ends up meeting exact requirements.

These tools also help with lightweight designs. For example, car parts can be strong and fuel-saving. Technology lets us achieve amazing results.

Smarter Machines and Tools

Machines and tools are key to stamping. Over time, they’ve become faster and smarter. They now handle tough materials and tricky designs easily.

Here’s what’s driving these changes:

AI-powered machines adjust settings automatically. They make sure every part is perfect. It’s like having a smart helper in the factory.

Hot Stamping for Stronger Steel

Hot stamping is great for shaping strong steel. The process heats steel to make it easier to form. After shaping, the steel cools quickly and becomes very strong. This method creates lightweight and durable parts.

Studies show its benefits:

Hot stamping isn’t just about strength. It also improves safety. Stronger car parts protect people better in crashes. This process is important for modern manufacturing.

Sheet metal stamping isn’t just making parts—it’s a big deal. It mixes accuracy, speed, and eco-friendly methods to create perfect pieces. From light car parts to detailed airplane components, it always delivers great results.

Here’s what makes it special:

It uses many metals, like strong steel and aluminum, for different jobs.

It makes thousands of parts every hour, saving time and money.

Light parts help cars use less fuel and are better for the planet.

From vehicles to gadgets, sheet metal stamping changes how things are made. Want to see how it can improve your ideas? Let’s work together and make it happen!

FAQ

What is sheet metal stamping?

Sheet metal stamping shapes flat metal sheets into parts. Dies, like metal cookie cutters, are used for this. It makes strong, exact pieces for cars, planes, and other industries.

Why is sheet metal stamping eco-friendly?

We cut waste and recycle leftover metal. Using materials wisely saves resources and helps the planet. It’s good for both businesses and the environment!

Can sheet metal stamping handle complex designs?

Yes! Tools like CAD and smart machines make tricky shapes easy. From detailed car parts to light airplane pieces, stamping gets it right every time.

What materials work best for sheet metal stamping?

We use metals like steel, aluminum, and brass. Each has special qualities, like being strong, flexible, or lightweight, to fit different projects.

How does automation improve the stamping process?

Automation makes stamping faster and more accurate. Machines repeat tasks perfectly, cutting mistakes and saving time. This means quick delivery and great quality for every part.