Custom sheet metal brackets are specialized components designed to meet your specific requirements. These brackets provide essential structural support, secure various components, or enhance the functionality of systems. Whether you need a custom metal bracket for industrial machinery or a sheet metal bracket for a consumer product, these solutions offer unmatched precision and adaptability. Their tailored designs ensure they fit seamlessly into your applications, delivering durability and reliability across diverse industries.

Key Takeaways

Custom sheet metal brackets are made to fit specific needs. They work well and are reliable in many industries.

These brackets are strong and last a long time. Materials like stainless steel and aluminum can handle tough conditions.

They come in many shapes and sizes to fit systems easily. This helps save materials and makes production faster.

Picking the right material and design is important. It helps the brackets hold weight and work in different environments.

Using recyclable materials and saving energy makes production eco-friendly. This helps protect the environment.

Unique Features of Custom Sheet Metal Brackets

Tailored Designs for Specific Applications

Custom sheet metal brackets are designed to meet the unique requirements of specific applications. This level of customization ensures that the brackets align perfectly with the intended purpose, whether it's for securing electronic components or providing structural support in industrial machinery. For example, in the electronics industry, these brackets play a critical role in maintaining the alignment and reliability of components in consumer electronics and telecommunications systems.

In the military and defense sector, the design process involves advanced fabrication techniques and materials that comply with stringent military specifications. These brackets are engineered to deliver maximum performance and reliability in demanding environments, such as aerospace and weapons systems. Materials like cold-rolled steel and aluminum are commonly used to meet MIL-SPEC standards, ensuring durability and strength under extreme conditions.

Did you know? Tailored designs not only improve functionality but also enhance the overall efficiency of systems. In aerospace applications, custom brackets have been shown to reduce installation time by 40% and improve holding strength by 15%.

Durability and Strength

Durability is a hallmark of custom sheet metal brackets. These components are built to withstand harsh environments, heavy loads, and prolonged use without compromising performance. The choice of material plays a significant role in ensuring durability. For instance, stainless steel offers excellent resistance to corrosion, while aluminum provides a lightweight yet strong alternative.

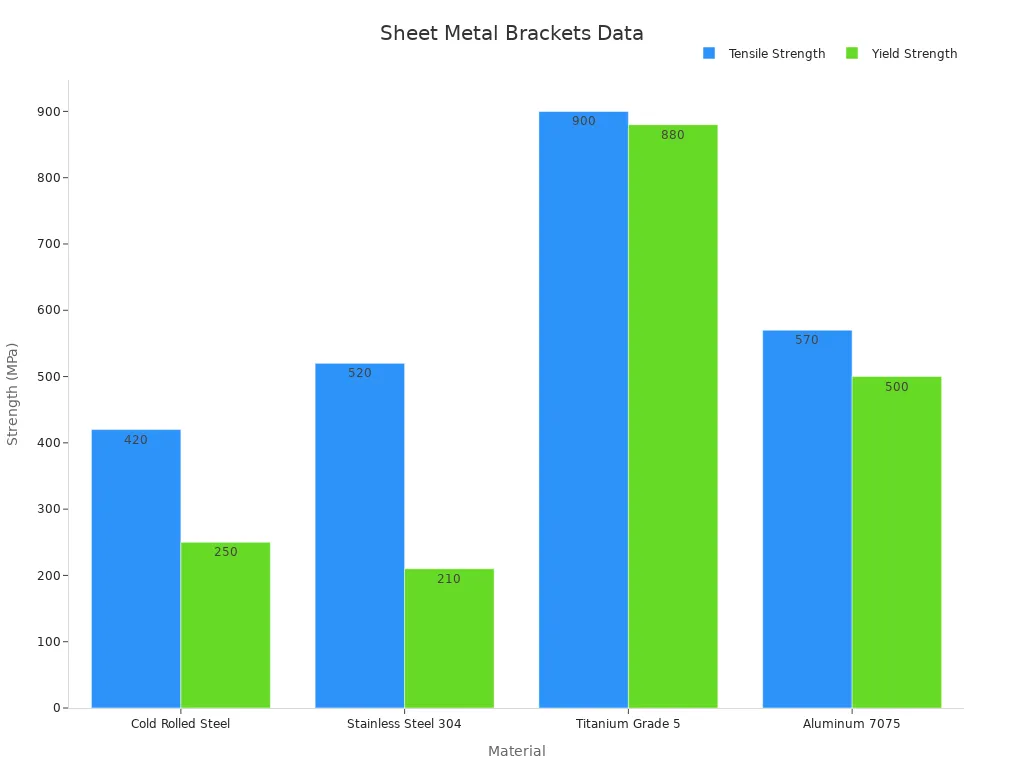

The strength of these brackets is often quantified through metrics like yield strength, ultimate tensile strength (UTS), and elongation. A study of sample stages reveals the following:

These figures highlight how different processes can impact the mechanical properties of the brackets, emphasizing the importance of selecting the right fabrication methods to maintain strength and durability.

Versatility in Shapes and Sizes

One of the most remarkable features of custom sheet metal brackets is their versatility. These brackets can be fabricated in a wide range of shapes and sizes to suit various applications. Whether you need a compact bracket for an electronic device or a large, robust bracket for construction equipment, the possibilities are virtually endless.

Custom sheet metal brackets are widely used in industries such as automotive, aerospace, construction, and electronics.

Their designs cater to specific technical functions, making them indispensable across different sectors.

The adaptability of sheet metal machinery has further fueled the demand for custom components, showcasing the versatility of these brackets.

This flexibility allows manufacturers to create brackets and mounting plates that meet precise specifications, ensuring seamless integration into existing systems. The ability to customize shapes and sizes also reduces material waste and enhances the overall efficiency of production processes.

Pro Tip: When selecting types of metal brackets for your project, consider factors like load requirements, environmental conditions, and compatibility with other components to maximize their effectiveness.

Compatibility with Different Systems

Custom sheet metal brackets excel in their ability to integrate seamlessly with a wide range of mechanical systems. Their adaptability ensures that they meet the unique demands of various industries, from aerospace to construction. When you choose a custom bracket, you gain a solution that aligns perfectly with your system's requirements, enhancing both performance and reliability.

Material Versatility for System Integration

The choice of material plays a critical role in ensuring compatibility with different systems. Each material offers distinct properties that make it suitable for specific applications. Here's a breakdown of common materials and their key attributes:

By selecting the right material, you ensure that the bracket not only fits but also enhances the system's overall functionality. For example, aluminum brackets are ideal for aerospace applications due to their lightweight nature, while stainless steel brackets thrive in corrosive environments like marine or chemical industries.

Performance Metrics for Compatibility

When evaluating compatibility, performance metrics provide valuable insights. Load-bearing capacity stands out as a critical factor. You can assess this through weight balance and tensile strength tests, ensuring the bracket can handle the required loads without failure. Additionally, selecting materials tailored to your application enhances system performance.

Load-bearing capacity: Ensures the bracket can support the intended weight without deformation.

Tensile strength: Measures the bracket's ability to resist breaking under tension.

Environmental adaptability: Determines how well the bracket performs in specific conditions, such as high humidity or extreme temperatures.

These metrics help you identify the most suitable bracket for your system, ensuring long-term reliability and efficiency.

Seamless Integration Across Industries

Custom sheet metal brackets demonstrate exceptional compatibility across diverse industries. Their ability to adapt to different shapes, sizes, and materials makes them indispensable in:

Aerospace: Lightweight brackets reduce overall weight while maintaining structural integrity.

Automotive: Durable brackets withstand vibrations and heavy loads in vehicles.

Construction: Robust brackets provide essential support for infrastructure projects.

Electronics: Precision brackets secure delicate components in devices.

Pro Tip: Always consider the operating environment and system requirements when selecting a custom sheet metal bracket. This ensures optimal performance and longevity.

By prioritizing compatibility, you can achieve a seamless integration of custom brackets into your systems, enhancing both functionality and efficiency.

Materials Used in Sheet Metal Brackets

Common Materials

When selecting materials for manufacturing brackets, you encounter a wide range of options, each offering unique properties suited to specific applications. Common materials include aluminum, stainless steel, and carbon steel. Aluminum stands out for its lightweight nature and corrosion resistance, making it ideal for aerospace and automotive industries. Stainless steel provides exceptional durability and resistance to harsh environments, making it a preferred choice for marine and chemical applications. Carbon steel offers high strength and cost-effectiveness, making it suitable for heavy-duty industrial uses.

Other materials, such as brass and titanium, cater to specialized needs. Brass combines aesthetic appeal with long-lasting performance, while titanium excels in high-temperature and high-stress environments. These materials ensure that your metal brackets meet the demands of diverse industries and applications.

Factors Influencing Material Selection

Choosing the right materials for manufacturing brackets involves evaluating several factors. Performance requirements, such as load-bearing capacity and corrosion resistance, play a critical role. For example, stainless steel is ideal for environments with high humidity or exposure to chemicals, while aluminum is better suited for lightweight applications.

Manufacturing processes also influence material selection. Materials suitable for laser cutting, such as alloy steel, aluminum alloys, and titanium, offer advantages like fast delivery and consistent quality. Laser cutting minimizes heat-affected zones and maintains corrosion resistance, ensuring your sheet metal brackets perform reliably.

Cost considerations further impact your decision. While aluminum offers affordability for lightweight designs, titanium may be necessary for applications requiring superior strength and durability. Balancing these factors ensures your brackets meet both functional and budgetary needs.

Environmental Considerations in Material Choice

Environmental factors significantly affect the choice of materials for manufacturing brackets. Corrosive environments demand materials like stainless steel or brass, which resist degradation over time. For outdoor applications, aluminum provides excellent rust resistance, ensuring long-term durability.

Sustainability is another critical consideration. Recyclable materials, such as aluminum and steel, reduce environmental impact and align with eco-friendly manufacturing practices. By prioritizing sustainable options, you contribute to reducing waste and promoting greener production methods.

Temperature extremes also influence material selection. Titanium and stainless steel perform well under high heat, while aluminum maintains its integrity in colder conditions. Selecting materials that adapt to environmental challenges ensures your sheet metal brackets remain reliable in any setting.

Sheet Metal Fabrication Processes

Cutting Techniques

Cutting is the first step in sheet metal fabrication, where raw materials are shaped into precise dimensions. You can choose from various cutting methods depending on your project requirements. Laser cutting and plasma cutting are among the most efficient techniques. These methods deliver exceptional speed and precision, making them ideal for both prototyping and large-scale production.

Laser cutting uses a focused beam of light to slice through materials with remarkable accuracy. This technique minimizes waste and ensures clean edges, which reduces the need for additional finishing. Plasma cutting, on the other hand, employs ionized gas to cut through thicker materials like steel and aluminum. Both methods are adaptable and produce high-quality parts for industries such as aerospace and automotive.

Tip: When selecting a cutting technique, consider the material type, thickness, and desired level of precision to achieve the best results.

Forming Methods

Forming transforms flat sheet metal into three-dimensional shapes. This process involves bending, rolling, or stamping the material to meet specific design requirements. You can rely on forming methods to create complex geometries without compromising the material's integrity.

Bending is one of the most common forming techniques. It uses press brakes to fold the metal into precise angles. Rolling, another popular method, shapes the material into cylindrical or curved forms. Stamping, often used in mass production, presses the metal into molds to create intricate designs. These methods ensure versatility, allowing you to produce components for diverse applications of sheet metal fabrication, from automotive parts to construction brackets.

Joining and Finishing Processes

Joining and finishing processes complete the fabrication cycle by assembling and refining the components. Welding, riveting, and adhesive bonding are common joining methods. Welding creates strong, permanent bonds, while riveting offers a mechanical solution for parts that may need disassembly. Adhesive bonding provides a clean, seamless finish for lightweight applications.

Finishing processes enhance the appearance and durability of sheet metal products. Techniques like powder coating, anodizing, and polishing protect the surface from corrosion and wear. For example, anodizing aluminum brackets improves their resistance to environmental factors, ensuring long-lasting performance. These processes not only improve functionality but also add aesthetic value to the final product.

Pro Tip: Always choose finishing techniques that align with the operating environment and intended use of your product.

Applications of Sheet Metal Brackets

Custom sheet metal brackets play a pivotal role in various industries, offering tailored solutions for mounting, securing, and supporting components. Their versatility and reliability make them indispensable across diverse applications.

Automotive Industry

In the automotive sector, custom sheet metal brackets are essential for ensuring the structural integrity and functionality of vehicles. These brackets and mounting plates are used in applications ranging from securing automotive body panels to supporting critical components in electric and hybrid vehicles.

Precision Engineering: Automotive manufacturers demand brackets with high dimensional accuracy to meet the stringent requirements of modern vehicle designs.

Lightweight Materials: Aluminum brackets reduce overall vehicle weight, improving fuel efficiency and performance.

Corrosion Resistance: Stainless steel brackets withstand exposure to moisture and road salts, ensuring durability over time.

The growing focus on electric vehicles has further increased the demand for custom brackets. These components support battery enclosures, wiring systems, and other critical elements, enhancing safety and reliability.

Note: The automotive industry relies heavily on precision-engineered brackets to meet the evolving needs of electric and hybrid models, ensuring optimal performance and safety.

Aerospace and Defense

Custom sheet metal brackets are indispensable in aerospace and defense applications. Their ability to withstand extreme conditions, such as high temperatures and vibrations, makes them ideal for critical systems.

These brackets are used in aircraft structures, satellite systems, and defense equipment. Their lightweight properties reduce overall system weight, while their high strength ensures reliability in demanding environments.

Specialized Production: Aerospace brackets are manufactured using advanced techniques to achieve high precision and customization.

Extreme Conditions: These brackets perform reliably under harsh conditions, ensuring the safety and functionality of critical systems.

Tip: Engineers use a safety factor (SF) to ensure brackets can handle their load safely. For aerospace applications, SF values typically range from 2.5 to 3 to minimize the risk of failure.

Electronics and Technology

In the electronics industry, custom sheet metal brackets provide essential support for delicate components and enclosures. Their precision and adaptability make them ideal for applications in consumer electronics, telecommunications, and medical devices.

Compact Designs: Brackets are tailored to fit within tight spaces, ensuring seamless integration into electronic devices.

Sheet Metal Enclosures: These brackets secure enclosures, protecting sensitive components from environmental factors.

High Precision: Medical devices require brackets with exceptional accuracy to ensure patient safety and reliability.

Custom brackets also play a critical role in mounting circuit boards, securing wiring systems, and supporting displays. Their versatility allows manufacturers to create designs that meet specific technical requirements, enhancing the functionality of electronic systems.

Did you know? The medical device industry relies on custom brackets to ensure high precision and reliability, contributing to patient safety and the growth of this sector.

Construction and Infrastructure

Custom sheet metal brackets play a vital role in construction projects, offering tailored solutions for mounting, securing, and supporting structural components. Their adaptability ensures they meet the unique demands of modern infrastructure, from residential buildings to large-scale industrial facilities.

Enhanced Structural Performance

You can rely on custom brackets to improve the structural integrity of construction systems. These brackets provide robust support for beams, panels, and fixtures, ensuring stability under varying loads. For example, stainless steel brackets resist corrosion, making them ideal for outdoor applications exposed to moisture and pollutants. Aluminum brackets, on the other hand, offer lightweight solutions that reduce overall structural weight without compromising strength.

Case Studies in Construction Applications

The benefits of custom sheet metal brackets in construction are validated through real-world case studies. These examples highlight their versatility and performance across diverse projects:

These examples demonstrate how custom brackets enhance both functionality and aesthetics in construction projects. Whether you need brackets for lighting systems or structural supports, their tailored designs ensure seamless integration into your infrastructure.

Versatility Across Applications

Custom sheet metal brackets cater to a wide range of construction needs. You can use them for mounting HVAC systems, securing electrical conduits, or supporting architectural features. Their precision engineering ensures compatibility with existing systems, reducing installation time and costs.

Tip: When selecting brackets for construction, prioritize materials that align with environmental conditions and load requirements to maximize durability and efficiency.

Renewable Energy Systems

Renewable energy systems demand components that combine durability, precision, and environmental adaptability. Custom sheet metal brackets meet these requirements, offering reliable solutions for mounting solar panels, wind turbines, and other renewable energy equipment.

Optimized for Solar Energy

Solar panel installations benefit significantly from custom brackets. These brackets provide secure mounting on rooftops, ground arrays, or tracking systems. Aluminum brackets are particularly effective due to their lightweight nature and corrosion resistance, ensuring long-term performance in outdoor environments.

Wind Turbine Applications

Wind turbines require brackets that can withstand extreme conditions, including high winds and temperature fluctuations. Stainless steel brackets excel in these applications, offering the strength and durability needed to support turbine components. Their anti-corrosion properties ensure reliability in coastal or offshore installations.

Sustainability and Eco-Friendly Design

Custom sheet metal brackets align with the principles of sustainability. Many manufacturers use recyclable materials like aluminum and steel, reducing environmental impact. Additionally, these brackets contribute to the efficiency of renewable energy systems by ensuring optimal alignment and stability, which enhances energy output.

Did you know? Properly designed brackets can increase the efficiency of solar panels by maintaining their alignment with the sun, boosting energy production by up to 15%.

Versatility Across Renewable Energy Applications

You can use custom brackets in various renewable energy systems, including geothermal plants and hydroelectric facilities. Their adaptability ensures they meet the specific requirements of each application, from securing piping systems to supporting structural frameworks.

Pro Tip: When designing brackets for renewable energy systems, consider factors like wind load, temperature extremes, and corrosion resistance to ensure long-term reliability.

Design Principles for Custom Sheet Metal Brackets

Load-Bearing Considerations

Understanding load-bearing requirements is essential for designing effective custom sheet metal brackets. You must ensure the bracket can handle the intended weight without deformation or failure. Factors such as material thickness, shape, and properties like yield strength and tensile strength directly influence the bracket's performance. For instance, thicker materials increase load capacity, while triangular or curved shapes distribute stress more efficiently.

When designing for specific applications, you should calculate the required cross-sectional area to support the load. For example, if a bracket needs to support a 200kg load and the material's tensile strength is 250 MPa, the cross-sectional area must be at least 0.08 m², factoring in a safety margin. This ensures the bracket performs reliably under stress.

Tip: Collaborate with manufacturing teams early in the design process to identify potential issues and optimize load-bearing performance.

Dimensional Accuracy and Tolerances

Precision is critical in custom sheet metal brackets. Dimensional accuracy ensures the bracket fits seamlessly into your system, while tight tolerances minimize errors during assembly. Simplifying designs by eliminating unnecessary features and standardizing components, such as hole sizes and bend radii, enhances manufacturability.

You should also consider the material's gauge, which affects bending and forming processes. For example, aluminum and stainless steel are excellent choices for applications requiring high precision. By focusing on these aspects, you can reduce production costs and improve the bracket's overall quality.

Pro Tip: Use Design for Manufacturability (DFM) principles to simplify designs and ensure consistent results during fabrication.

Ease of Installation and Maintenance

Custom sheet metal brackets should be easy to install and maintain. Designs that prioritize accessibility and simplicity reduce installation time and labor costs. For example, brackets with pre-drilled holes or standardized mounting points streamline the assembly process.

Maintenance becomes more manageable when you choose corrosion-resistant materials like stainless steel or aluminum. These materials ensure the bracket remains functional over time, even in harsh environments. By focusing on ease of use, you enhance the bracket's long-term reliability and performance.

Note: Standardizing features not only simplifies installation but also improves compatibility with existing systems.

Aesthetic and Functional Integration

Custom sheet metal brackets excel in blending aesthetic appeal with functional performance. When designing these brackets, you must consider both visual harmony and practical utility to ensure they meet your project's requirements.

Enhancing Visual Appeal

A well-designed bracket can elevate the overall appearance of your product or system. Manufacturers often use finishing techniques like powder coating, anodizing, or polishing to achieve a sleek and professional look. These finishes not only enhance the bracket's appearance but also protect it from wear and corrosion.

For example:

Powder Coating: Adds a smooth, durable finish available in various colors.

Anodizing: Creates a metallic sheen while improving corrosion resistance.

Polishing: Provides a reflective surface for a premium aesthetic.

Tip: Choose finishes that align with your brand's visual identity to create a cohesive design.

Balancing Form and Function

While aesthetics are important, functionality remains the primary focus. You should prioritize designs that integrate seamlessly into your system without compromising performance. Features like pre-drilled holes, mounting slots, or curved edges enhance usability while maintaining a clean appearance.

Industry Applications

Aesthetic and functional integration is crucial in industries like consumer electronics, automotive, and architecture. In electronics, brackets must fit compact spaces while complementing the device's design. Automotive brackets often feature finishes that match the vehicle's interior or exterior. Architectural brackets combine structural support with decorative elements, enhancing the overall design of buildings.

Did you know? Aesthetic finishes can increase customer satisfaction by up to 30%, especially in consumer-facing products.

By focusing on both form and function, you can create custom sheet metal brackets that not only perform efficiently but also enhance the visual appeal of your projects.

Cost Factors in Custom Sheet Metal Brackets

Material Costs

The choice of material significantly impacts the cost of a metal bracket. High-strength materials, such as titanium or aerospace-grade aluminum, often command higher prices due to their superior properties. For example, stainless steel offers excellent corrosion resistance, making it ideal for applications in the automotive and construction industries. However, its cost is higher compared to carbon steel, which is more affordable but less resistant to environmental factors.

When selecting materials, you must balance performance requirements with budget constraints. Lightweight materials like aluminum are perfect for aerospace applications, where reducing weight is critical. On the other hand, heavy-duty brackets for industrial use may require carbon steel for its strength and cost-effectiveness.

Complexity of Design

The complexity of a metal bracket's design directly influences its production cost. Intricate designs often require advanced tooling, precision machining, and longer production times. For instance, brackets with multiple bends, custom cutouts, or tight tolerances demand specialized equipment and skilled labor, increasing overall expenses.

Simpler designs, such as flat brackets with standard holes, are more cost-effective and quicker to produce. However, if your application requires unique shapes or features, the added complexity is often unavoidable. In such cases, collaborating with manufacturers early in the design phase can help optimize the process and minimize unnecessary costs.

Key Cost Drivers in Design Complexity:

Advanced tooling for intricate shapes.

Additional machining time for tight tolerances.

Higher labor costs for custom fabrication.

Tip: Simplify your design wherever possible to reduce costs without compromising functionality.

Volume of Production

Production volume plays a crucial role in determining the cost per unit of metal brackets. Higher quantities typically result in lower per-piece costs due to economies of scale. For example, producing 1,000 brackets in a single batch is more cost-efficient than manufacturing 100 brackets across multiple smaller batches.

If you anticipate large-scale production, investing in efficient manufacturing processes, such as automated stamping or laser cutting, can further reduce costs. For smaller batches, consider modular designs that use standard components to minimize setup time and material waste.

Pro Tip: Plan your production volume carefully to take full advantage of cost savings from bulk manufacturing.

Additional Finishing or Coating Requirements

Finishing and coating processes play a vital role in enhancing the performance and appearance of custom sheet metal brackets. These treatments protect the brackets from environmental factors, improve durability, and add aesthetic value. Selecting the right finishing or coating option ensures your brackets meet both functional and visual requirements.

Common Finishing Techniques

You can choose from several finishing techniques based on your application needs. Each method offers unique benefits:

Powder Coating: Provides a durable, uniform finish resistant to scratches and corrosion. It is available in various colors, making it ideal for applications requiring aesthetic appeal.

Anodizing: Enhances the corrosion resistance of aluminum brackets while adding a sleek, metallic finish. This method also improves wear resistance.

Polishing: Creates a smooth, reflective surface, often used for decorative purposes or to reduce friction.

Galvanizing: Adds a protective zinc layer to steel brackets, preventing rust in outdoor or humid environments.

Tip: Match the finishing technique to the operating environment. For example, use anodizing for aluminum brackets in marine applications to prevent corrosion.

Factors to Consider

When selecting a finishing or coating process, consider these factors:

Benefits of Proper Finishing

Proper finishing extends the lifespan of your brackets and enhances their functionality. Coatings like powder or zinc plating protect against rust and wear, reducing maintenance costs. Aesthetic finishes improve the visual appeal of your products, making them more attractive to end users.

Did you know? Properly coated brackets can last up to 10 years longer in harsh environments compared to untreated ones.

By prioritizing the right finishing or coating process, you ensure your custom sheet metal brackets perform reliably and maintain their appearance over time.

Innovations in Sheet Metal Bracket Design

Use of Advanced Materials

Advancements in material science have revolutionized the design of metal brackets. You can now leverage materials like titanium, aerospace-grade aluminum, and high-strength alloys to achieve superior performance. Titanium offers unmatched strength-to-weight ratios, making it ideal for aerospace applications. Aluminum provides corrosion resistance and lightweight properties, ensuring durability in automotive and renewable energy systems. High-strength alloys enhance load-bearing capacity, making them indispensable in construction and industrial settings.

Modern machining processes, such as milling and turning, ensure precision when working with these advanced materials. Laser cutting and water jet techniques deliver clean edges and minimize waste, especially for aircraft components. Bending and forming methods further enhance structural integrity, allowing you to create brackets that meet rigorous industry standards.

Tip: When selecting materials for your metal brackets, prioritize those that align with your application’s environmental and performance requirements.

Integration of Smart Features

The integration of smart features into sheet metal brackets has opened new possibilities for functionality. You can now incorporate sensors, RFID tags, or IoT-enabled components into brackets to monitor performance and environmental conditions. For example, brackets used in renewable energy systems can include sensors to track alignment and optimize energy output.

Smart brackets also enhance safety and efficiency in industrial applications. By embedding temperature or vibration sensors, you can detect potential failures before they occur. This proactive approach reduces downtime and maintenance costs. Additionally, IoT-enabled brackets allow real-time data collection, enabling you to make informed decisions about system performance.

Did you know? Smart brackets equipped with sensors can increase operational efficiency by up to 25%, especially in automated manufacturing environments.

Automation in Manufacturing Processes

Automation has transformed the production of custom sheet metal brackets, ensuring precision and efficiency. CNC machines play a pivotal role in fabricating complex shapes with minimal human error. These machines enhance accuracy and reduce material waste, making them ideal for high-volume production.

Design for Manufacturability (DFM) principles streamline the production process. By optimizing bracket designs for automated fabrication, you can reduce costs and improve consistency. Advanced techniques like laser cutting and CNC punching further enhance efficiency, allowing you to create intricate designs without compromising quality.

Automation not only accelerates production but also ensures scalability. Whether you need a single prototype or thousands of brackets, automated processes adapt to your requirements, delivering consistent results every time.

Pro Tip: Collaborate with manufacturers who specialize in automated fabrication to maximize efficiency and reduce lead times.

Sustainable and Eco-Friendly Designs

Sustainability has become a cornerstone of modern manufacturing, and custom sheet metal brackets are no exception. By adopting eco-friendly designs, you can reduce environmental impact while maintaining high performance and durability. These designs not only align with global sustainability goals but also offer long-term cost savings and enhanced product value.

Use of Recyclable Materials

Many manufacturers now prioritize recyclable materials like aluminum and steel. These materials can be reused multiple times without losing their structural integrity. By choosing recyclable options, you contribute to reducing waste and conserving natural resources. For example:

Tip: Opt for brackets made from recyclable materials to support eco-friendly initiatives and lower your carbon footprint.

Energy-Efficient Manufacturing

Eco-friendly designs often incorporate energy-efficient manufacturing processes. Techniques like laser cutting and CNC machining minimize material waste and reduce energy consumption. These methods ensure precision while lowering the environmental impact of production.

Coatings and Finishes with Low Environmental Impact

Sustainable brackets use coatings and finishes that are free from harmful chemicals. Powder coating, for instance, is a popular choice due to its low emissions and minimal waste. This approach ensures your brackets remain durable and visually appealing without compromising environmental safety.

Benefits of Sustainable Designs

By choosing eco-friendly brackets, you gain more than just environmental benefits. These designs often result in lighter, stronger, and more efficient components. They also enhance your brand’s reputation by showcasing your commitment to sustainability.

Did you know? Using sustainable materials and processes can reduce manufacturing emissions by up to 30%, making a significant impact on global carbon reduction efforts.

Custom sheet metal brackets are essential components across industries, offering tailored solutions for diverse applications. Their versatility allows you to adapt them to unique requirements, while their durability ensures long-term performance in demanding environments. These brackets enable innovative designs by integrating seamlessly into modern systems, enhancing both functionality and efficiency.

Foxsen specializes in manufacturing high-quality custom sheet metal brackets. With expertise in advanced manufacturing techniques, Foxsen delivers solutions that meet your specific needs. Whether for aerospace, automotive, or renewable energy systems, Foxsen ensures precision and reliability in every application.

FAQ

What industries benefit the most from custom sheet metal brackets?

Custom sheet metal brackets serve industries like aerospace, automotive, construction, electronics, and renewable energy. You can use them for structural support, mounting, or securing components. Their adaptability ensures they meet the unique demands of each sector.

How do you choose the right material for your application?

Consider factors like load requirements, environmental conditions, and budget. For example, stainless steel resists corrosion, aluminum is lightweight, and carbon steel offers cost-effective strength. Match the material to your specific needs for optimal performance.

Are custom sheet metal brackets environmentally friendly?

Yes, many brackets use recyclable materials like aluminum and steel. Manufacturers also adopt energy-efficient processes and eco-friendly coatings. Choosing sustainable options reduces waste and aligns with green manufacturing practices.

What is the typical lead time for custom sheet metal brackets?

Lead times vary based on design complexity and production volume. Simple designs may take a few days, while intricate brackets require weeks. Collaborating with manufacturers early helps streamline the process and meet deadlines.

Can you integrate smart features into custom brackets?

Yes, you can incorporate sensors, RFID tags, or IoT components into brackets. These features monitor performance, enhance safety, and improve efficiency. Smart brackets are especially useful in industrial and renewable energy applications.