A sheet metal outdoor equipment enclosure is a protective housing designed to safeguard machinery and devices placed outdoors. Its primary purpose is to shield equipment from environmental factors like rain, sunlight, and dust, as well as physical damage caused by impacts or tampering. You rely on these enclosures to ensure the longevity and functionality of your outdoor systems. With their robust construction, they offer reliable protection from the elements, keeping your equipment secure and operational even in harsh conditions.

Key Takeaways

Sheet metal enclosures keep outdoor equipment safe from rain, dust, and sunlight. This helps them last longer and work well.

You can customize enclosures to fit your needs. This makes them more useful for different jobs.

Strong materials like stainless steel and galvanized steel stop rust. This makes the enclosures work well in tough weather.

These enclosures save money by lowering repair costs and helping your equipment last longer.

Picking a trusted maker like Foxsen gives you high-quality enclosures. They follow industry rules and protect your equipment well.

What Is a Sheet Metal Outdoor Equipment Enclosure?

Definition and Purpose

A sheet metal outdoor equipment enclosure is a protective structure designed to house and safeguard equipment used in outdoor environments. These enclosures serve as a barrier against environmental factors like dust, moisture, and chemicals, ensuring the equipment remains functional and safe. They also provide physical protection, preventing accidental contact with electrical components or damage from external impacts.

Manufacturers design these enclosures with durability in mind, often using materials like stainless steel or galvanized steel. This ensures long-lasting performance even in harsh conditions. Additionally, many enclosures are built with ease of installation and maintenance in mind, which helps improve operational efficiency. For instance, features like removable panels or hinged doors make accessing internal components straightforward.

Key Features

Sheet metal enclosures come with a variety of features that enhance their functionality and reliability. Some of the most notable features include:

Weather Resistance: Many enclosures are rated with IP standards, such as IP65, which indicates they are dust-tight and water-resistant. This makes them suitable for outdoor use in diverse climates.

Heat Dissipation: To prevent overheating, some enclosures include vents or built-in cooling systems. These features ensure that internal components operate within safe temperature ranges.

Durable Construction: Materials like stainless steel and aluminum provide excellent resistance to corrosion and physical wear, making the enclosures ideal for long-term use.

Customizable Design: Many manufacturers offer customization options, allowing you to tailor the enclosure to your specific needs. This includes size, shape, and additional features like cable entry points or mounting brackets.

These features make sheet metal enclosures a reliable choice for protecting sensitive equipment in outdoor settings.

Functionality in Outdoor Settings

In outdoor environments, equipment faces constant exposure to challenging conditions. A sheet metal outdoor equipment enclosure acts as a shield, ensuring your devices remain operational and safe. For example, these enclosures protect against rain, UV rays, and temperature fluctuations, which can otherwise degrade equipment over time.

Additionally, they provide a secure housing for electrical components, reducing the risk of accidents or tampering. Studies have shown that enclosures with high shielding effectiveness (SE) can minimize electromagnetic interference, ensuring optimal performance of internal components. This is particularly important for applications involving sensitive electronics, such as telecommunications or renewable energy systems.

The versatility of sheet metal enclosures also extends to their design. Many models include features like cable management systems or modular panels, which simplify installation and maintenance. This functionality not only saves time but also reduces operational costs, making these enclosures a cost-effective solution for outdoor equipment protection.

Uses of Sheet Metal Enclosures

Protecting Electrical Equipment

Sheet metal enclosures play a vital role in safeguarding electrical equipment. These enclosures shield sensitive components from environmental hazards such as moisture, dust, and extreme temperatures. For example, they prevent water ingress during heavy rains, ensuring uninterrupted operation of electrical systems. Additionally, their robust construction offers mechanical protection against impacts and accidental damage.

The effectiveness of sheet metal enclosures in protecting electrical equipment is supported by research. For instance, these enclosures provide excellent electromagnetic shielding, which is crucial for maintaining the performance of sensitive electronics. They also demonstrate high corrosion resistance, withstanding harsh environments without significant rust even after 72 hours of salt spray testing. This durability makes them a reliable choice for outdoor and industrial applications.

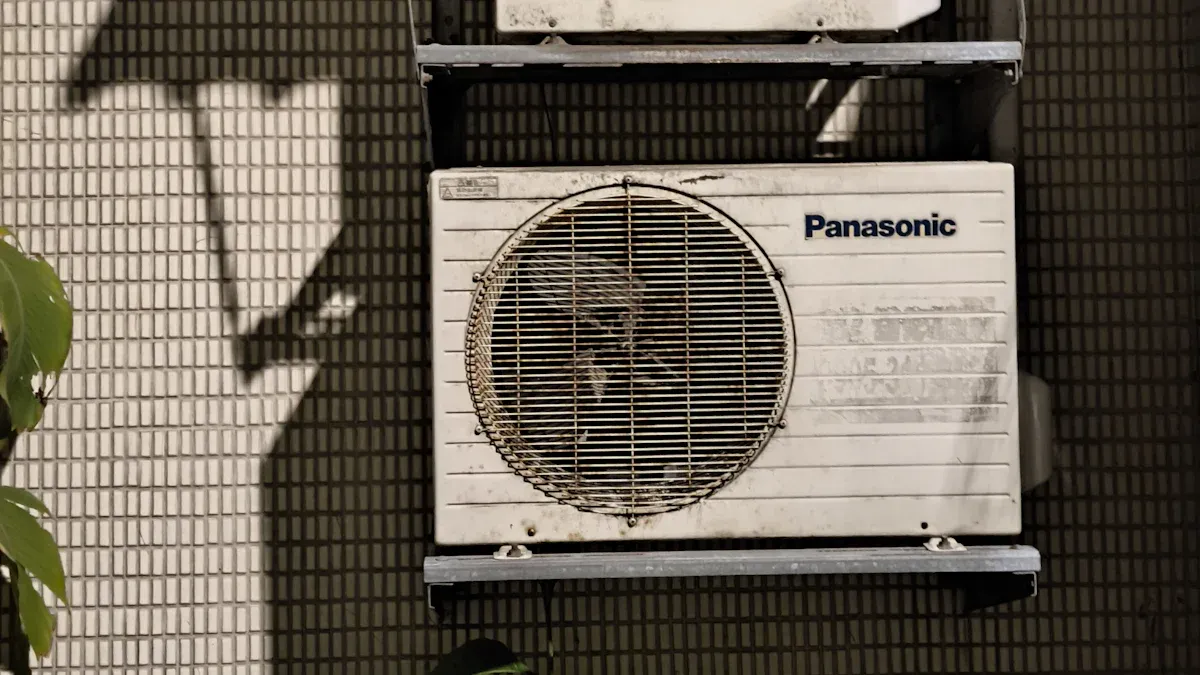

Housing HVAC Systems

Sheet metal enclosures are essential for housing HVAC systems. These systems often operate in outdoor environments, where they face exposure to rain, wind, and debris. A well-designed enclosure ensures the HVAC unit remains protected from these elements, extending its lifespan and maintaining its efficiency.

In addition to environmental protection, these enclosures help with noise reduction. By enclosing the HVAC system, they minimize the sound generated during operation, creating a quieter environment. Many enclosures also feature ventilation systems to promote heat dissipation, preventing the unit from overheating. This combination of protection and functionality makes sheet metal enclosures indispensable for HVAC applications.

Industrial and Machinery Applications

In industrial settings, sheet metal enclosures provide critical protection for machinery. They shield equipment from physical damage, environmental factors, and electromagnetic interference. This protection ensures the machinery operates efficiently and safely, reducing the risk of downtime or costly repairs.

Performance metrics highlight the importance of these enclosures in industrial applications. For instance, their ability to dissipate heat prevents overheating, which could otherwise lead to equipment failure. Electromagnetic shielding further enhances their functionality, safeguarding machinery from interference that could disrupt operations. When designing these enclosures, manufacturers prioritize protective functionality and production methods to ensure compliance with industry standards.

Sheet metal enclosures also offer customization options, allowing you to tailor the design to your specific needs. Whether you require additional cable entry points or modular panels, these enclosures can adapt to meet the demands of various industrial applications. Their versatility and durability make them a cornerstone of industrial and commercial metal enclosures.

Use in Renewable Energy and Telecommunications

Sheet metal enclosures play a vital role in renewable energy and telecommunications. You rely on these enclosures to protect sensitive equipment like solar inverters, battery storage systems, and communication devices. Their durable construction ensures that your equipment remains operational even in extreme weather conditions.

In renewable energy applications, these enclosures safeguard solar panels and wind turbine components from environmental hazards. For example, they prevent moisture and dust from damaging electrical connections. Many enclosures also feature heat dissipation systems, which help maintain optimal temperatures for energy storage units. This protection enhances the efficiency and lifespan of your renewable energy systems.

Telecommunications equipment also benefits from sheet metal enclosures. Outdoor communication devices, such as antennas and signal boosters, require shielding from rain, UV rays, and temperature fluctuations. These enclosures provide a secure housing that minimizes the risk of interference and physical damage. Some models include electromagnetic shielding, which ensures stable signal transmission and prevents disruptions.

Customization options make these enclosures even more versatile. You can choose designs tailored to your specific needs, such as modular panels or cable entry points. This flexibility allows you to optimize the performance of your equipment while maintaining ease of installation and maintenance.

Sheet metal enclosures are a cornerstone of commercial metal enclosures used in renewable energy and telecommunications. Their reliability and adaptability make them indispensable for protecting critical systems in outdoor environments.

Materials for Sheet Metal Enclosures

Stainless Steel

Stainless steel is one of the most reliable materials for a sheet metal enclosure. It protects your equipment from environmental hazards like moisture, dust, and physical damage. Its exceptional strength ensures durability, even in harsh outdoor conditions. You can rely on stainless steel to withstand physical impacts and wear over time. It also resists corrosion, making it ideal for environments with high humidity or exposure to chemicals.

This material performs well under extreme temperatures, maintaining its integrity up to 145°C. Its non-corrosive properties also make it suitable for hygienic storage of sensitive components. Stainless steel enclosures often meet NEMA and IP ratings, confirming their reliability for outdoor applications. These features make stainless steel a top choice for custom sheet metal fabrication.

Aluminum

Aluminum offers a lightweight yet durable option for outdoor enclosures. It is the lightest metal available for this purpose, making it easy to handle and install. Despite its low weight, aluminum provides excellent corrosion resistance, ensuring long-term performance in various environments. You can enhance its durability further with finishing options like anodizing or chem film.

Anodizing creates a tough oxide coating that increases the metal's longevity. Chem film, on the other hand, improves durability and is particularly useful for electrical contact. While aluminum requires a thicker gauge to match the stiffness of steel, its lightweight nature and adaptability make it a popular choice for many applications.

Galvanized Steel

Galvanized steel combines strength with excellent corrosion resistance. A protective zinc coating shields the steel from rust, making it suitable for outdoor use. Even if the surface gets scratched, the zinc layer acts as a sacrificial barrier, corroding first to protect the underlying steel. This feature ensures the material remains strong and reliable over time.

Unlike mild steel, which lacks this protective layer, galvanized steel resists oxidation and degradation. Its durability makes it a dependable choice for outdoor enclosures, especially in environments prone to moisture or salt exposure. You can count on galvanized steel to provide long-lasting protection for your equipment.

Choosing the Right Material

Selecting the right material for your sheet metal outdoor equipment enclosure is crucial. The material you choose directly impacts the durability, functionality, and cost-effectiveness of the enclosure. Each material offers unique advantages, so understanding your specific requirements will help you make an informed decision.

Factors to Consider

When choosing a material, you should evaluate several factors:

Environmental Conditions: Consider the climate and exposure to elements like moisture, UV rays, or chemicals.

Durability Needs: Assess how much physical wear and tear the enclosure will face.

Weight Requirements: Lightweight materials like aluminum may be ideal for portable applications.

Budget Constraints: Balance cost with performance to find the most economical option.

Decision-Making Frameworks

To simplify the selection process, you can use decision-making frameworks that rely on quantitative criteria. These frameworks evaluate materials based on various factors, ensuring you choose the most suitable option.

These frameworks provide a structured approach to material selection, helping you weigh the pros and cons of each option.

Customization and Material Choice

Custom sheet metal fabrication allows you to tailor the enclosure to your specific needs. Whether you require additional features like cable entry points or enhanced corrosion resistance, customization ensures the material aligns with your application. For instance, stainless steel offers unmatched durability, while aluminum provides a lightweight alternative. Galvanized steel, on the other hand, excels in environments prone to rust. By combining the right material with custom fabrication, you can achieve optimal performance and longevity.

Tip: Always consult with experts to ensure the material you select meets your operational and environmental requirements.

Benefits of Sheet Metal Outdoor Equipment Enclosures

Durability and Weather Resistance

A sheet metal outdoor equipment enclosure offers unmatched durability. Its robust construction ensures long-term reliability, even in harsh conditions. You can trust these enclosures to withstand physical impacts, extreme temperatures, and environmental wear. Materials like stainless steel and galvanized steel provide excellent resistance to corrosion, making them ideal for outdoor use.

Weather resistance is another key advantage. These enclosures protect your equipment from rain, snow, and UV rays. Many models meet IP ratings, such as IP65, which guarantees protection against dust and water ingress. This ensures your equipment remains operational, regardless of the weather.

The overall performance of sheet metal enclosures highlights their durability and weather resistance. For example, their mechanical strength and thermal conductivity prevent damage and overheating. This makes them a reliable choice for protecting sensitive equipment in outdoor environments.

Security and Protection

Security is a critical factor when housing outdoor equipment. A sheet metal enclosure provides superior protection against tampering and theft. Its sturdy design acts as a physical barrier, deterring unauthorized access. Many enclosures also feature locking mechanisms, adding an extra layer of security.

These enclosures excel in protecting sensitive equipment from environmental hazards. They shield your devices from dust, moisture, and chemicals, ensuring uninterrupted operation. Electromagnetic shielding is another benefit. It prevents interference from external signals, maintaining the performance of your equipment.

The enhanced security and protection offered by sheet metal enclosures make them indispensable for outdoor applications. Whether you are safeguarding electrical systems or telecommunications devices, these enclosures provide peace of mind.

Customization Options

Customization allows you to tailor a sheet metal enclosure to your specific needs. You can choose the size, shape, and features that best suit your application. For example, you might add cable entry points, ventilation systems, or mounting brackets. This flexibility ensures the enclosure meets your operational requirements.

Custom sheet metal enclosures also enhance functionality. You can optimize the design for heat dissipation, electromagnetic shielding, or noise reduction. This improves the performance and longevity of your equipment.

By choosing a custom enclosure, you gain a solution that aligns perfectly with your needs. This level of adaptability makes sheet metal enclosures a versatile and cost-effective choice for outdoor equipment protection.

Cost-Effectiveness

When choosing a solution for outdoor equipment protection, cost-effectiveness becomes a critical factor. Sheet metal enclosures offer a balance between affordability and long-term value. Their durability ensures that you save money on frequent replacements or repairs. By investing in a high-quality enclosure, you reduce maintenance costs over time.

The longevity of these enclosures contributes to their cost efficiency. Materials like stainless steel and galvanized steel resist corrosion and physical damage. This durability minimizes the need for constant upkeep. You can rely on these enclosures to protect your equipment for years, even in harsh outdoor conditions.

Another way sheet metal enclosures save money is through their energy efficiency. Many designs include features like heat dissipation systems, which prevent overheating. This reduces the risk of equipment failure, lowering repair expenses. Additionally, the electromagnetic shielding provided by these enclosures ensures optimal performance of sensitive electronics, avoiding costly disruptions.

Customization options also enhance cost-effectiveness. You can tailor a custom enclosure to meet your specific needs, ensuring you only pay for the features you require. For example, adding cable entry points or ventilation systems can improve functionality without unnecessary expenses. This flexibility allows you to optimize your investment.

Sheet metal enclosures also reduce operational costs. Their robust construction minimizes downtime caused by equipment failure. This reliability ensures that your systems remain operational, saving you money on repairs and lost productivity. Furthermore, their weather resistance eliminates the need for additional protective measures, further reducing expenses.

Why Choose Foxsen for Sheet Metal Enclosures?

Expertise and Quality

When it comes to sheet metal enclosures, Foxsen stands out for its unmatched expertise and commitment to quality. With years of experience in the industry, Foxsen has mastered the art of designing and manufacturing enclosures that meet the highest standards. You can trust their team of skilled professionals to deliver products that excel in durability, functionality, and precision.

Foxsen uses advanced manufacturing techniques and premium materials to ensure every enclosure performs reliably in outdoor environments. Their strict quality control processes guarantee that each product meets or exceeds industry standards. Whether you need enclosures for electrical equipment, HVAC systems, or renewable energy applications, Foxsen’s expertise ensures you get a solution you can depend on.

Did You Know? Foxsen’s enclosures often surpass standard IP and NEMA ratings, providing superior protection against dust, water, and environmental wear.

Customization Services

Foxsen understands that no two projects are the same. That’s why they offer extensive customization services to meet your unique requirements. You can choose from a wide range of options, including size, material, and additional features like cable entry points or ventilation systems. This flexibility allows you to create an enclosure tailored to your specific needs.

Their design team works closely with you to ensure the final product aligns perfectly with your operational goals. Whether you need a compact enclosure for a small device or a large, modular design for industrial machinery, Foxsen can bring your vision to life.

Customization Options Include:

Material selection (stainless steel, aluminum, galvanized steel)

Specialized coatings for added durability

Modular designs for easy installation

This level of adaptability makes Foxsen a top choice for businesses seeking personalized solutions.

Proven Reliability

Reliability is at the core of Foxsen’s reputation. Their enclosures are built to withstand the toughest conditions, ensuring your equipment remains protected and operational. You can count on Foxsen’s products to deliver consistent performance, even in extreme weather or demanding industrial settings.

Foxsen’s track record speaks for itself. Many businesses across industries, from telecommunications to renewable energy, rely on their enclosures to safeguard critical equipment. Their commitment to reliability extends beyond the product itself. Foxsen also provides excellent customer support, ensuring you have assistance whenever you need it.

Choosing Foxsen means investing in a partner you can trust to deliver reliable, high-quality enclosures for your outdoor equipment.

Sheet metal outdoor equipment enclosures provide essential protection for your outdoor systems. Their corrosion resistance ensures reliability in harsh environments, while their cost-effectiveness reduces maintenance expenses. These enclosures last decades, offering extended lifespans in both rural and urban areas. Their toughness withstands daily wear and transport, making them ideal for industrial applications.

Foxsen combines expertise, quality, and customization to deliver enclosures tailored to your needs. Their proven reliability ensures your equipment remains secure and operational. Choosing Foxsen means investing in durable solutions backed by industry-leading craftsmanship.

FAQ

What are the main advantages of using sheet metal enclosures outdoors?

Sheet metal enclosures offer durability, weather resistance, and security. They protect your equipment from environmental damage, such as rain or UV rays, and physical impacts. Their robust design ensures long-term reliability, making them ideal for outdoor applications.

How do I choose the right material for my enclosure?

Consider your environment, durability needs, and budget. Stainless steel resists corrosion, aluminum is lightweight, and galvanized steel offers cost-effective protection. Evaluate your specific requirements to select the best material for your application.

Tip: Consult with experts to ensure the material matches your operational needs.

Can sheet metal enclosures be customized?

Yes, you can customize sheet metal enclosures to fit your needs. Options include size, material, ventilation systems, and cable entry points. Customization ensures the enclosure meets your operational and environmental requirements.

Are sheet metal enclosures suitable for extreme weather?

Absolutely! Many enclosures meet IP ratings like IP65, ensuring protection against dust, water, and temperature fluctuations. This makes them reliable in harsh climates, from heavy rain to intense sunlight.

Why should I choose Foxsen for my enclosure needs?

Foxsen offers expertise, quality, and customization. Their enclosures meet high industry standards, ensuring durability and performance. With proven reliability and excellent customer support, Foxsen provides solutions tailored to your specific requirements.

Did You Know? Foxsen’s enclosures often exceed standard IP and NEMA ratings for superior protection.