Product Link:

https://www.sheetmetalparts.net/products-telecommunication-sheet-metal-parts.html

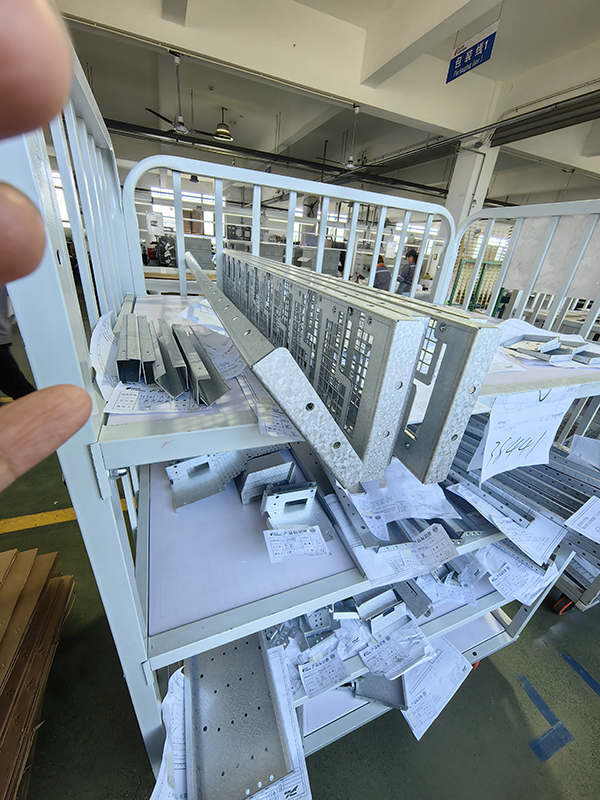

The quality of chassis and cabinets is directly affected by the quality of manufacturing process. The steel plate edge of the chassis with good process will not have burrs, sharp edges, burrs, etc., and the exposed corners are folded, which is not easy to scratch the installer's hands. The positioning of each card slot is also appropriate, and there will be no embarrassing situation that accessories cannot be installed or misplaced.

So how to choose chassis and cabinets?

Look at the structure layout

Generally speaking, there should be more baffles and heat dissipation holes. Some iron sheets used to fix cables should be wrapped to prevent pre-damage to the cables. Side wall fans should be installed on the back wall of the cabinet, because most of the heat is generated at the back of the equipment.

Look at the function

The first consideration should be stability.

Look at the material

To choose a sheet metal chassis and cabinet, the steel plate should be thick. You can feel which ones are thick and which ones are thin by tapping with your fingers. Its solid shell protects the board, power supply and storage device, and can prevent pressure, impact and dust. It can also play the role of preventing electromagnetic interference and radiation, and shielding electromagnetic radiation. Thirdly, it also provides many easy-to-use panel switch indicator lights, etc., so that the operator can operate the microcomputer or observe the operation status of the microcomputer more conveniently.

Look at the spray paint

For a qualified cabinet, all steel materials need to be sprayed, and the spray paint should be changed evenly, so that it can be well rust-proof and dust-proof.

Look at the heat dissipation

Estimate how much heat your equipment generates. Generally speaking, there are two to four fans on the top of the cabinet, and the more fans the better. There are also some screws and nuts used to fix the rack, which should be sufficient. Don't bring the trouble of insufficient accessories due to future expansion.

Look at the accessories

Since the device contains network cables, telecommunications cables and power cables, you need to buy hook-and-loop belts or toothed belts to fix the cables in the cabinet in an orderly manner. If the cabinet is equipped with a cable management module so that the cables can be directly fixed in the vertical installation rail, it would be better.

Look at the glass

The glass should be thicker, and you should also pay attention to whether there are cracks around the glass. If there are cracks, it means there are hidden dangers, and you should also pay attention to whether it is difficult.

In terms of heat dissipation technology, most of the cooling of chassis and cabinet equipment adopts the method of pushing cold air by the air conditioning system. In order to cool down the local high heat, the temperature of the entire air conditioning system is often very low, which increases the utilization rate of the power chassis and cabinet.

Easy to manufacture

On the basis of meeting the technical requirements at the same time, according to the actual production of each enterprise, priority should be given to sheet metal processing methods with simple manufacturing processes to reduce costs and increase production speed.

Minimize welding

Welding will cause deformation, and the welding surface treatment is not beautiful, which affects the production speed. In addition, the process can be changed to replace welding. 1. Use riveting instead of welding, which can save time and not deform. 2. Use stamping instead of welding, which is not easy to deform, but sometimes a simple mold should be used. 3. Cancel welding that has little effect. For welds with small force or only connecting functions, indirect disconnection welding can be used instead of continuous welding.

The materials should be selected correctly. The raw materials of cold-worked sheet metal are divided into alloy structural steel, carbon structural steel, aluminum copper, etc. According to the characteristics of the rolled cross-sectional shape, there are profiles, plates, wires, and profiles. When selecting, you should select correctly according to the following points:

1. Provide the utilization rate of raw materials. Sheet metal processing, under the premise of strength and technical requirements, its blanks are allowed to be small and large, so as to reduce scraps and reduce costs. According to the size of the plate, you can choose the plate of the specified size and length.

2. Correctly select materials according to working conditions. The flexibility of sheet metal processing design is large and has many advantages. The wall thickness of cold-worked parts can vary greatly. According to different stress conditions and working conditions, materials with different strengths, different properties, etc. can be selected.

3. Try to use rolled profiles. The rolled profiles are more accurate in size, high quality, smooth and smooth in appearance, and low in price. The use of rolled profiles can also reduce welding and forming processing costs, with good efficiency and good cost, so they can be widely used in structural parts.