In industrial applications, protecting equipment from environmental hazards and mechanical impacts is crucial. A sheet metal electrical equipment enclosure offers an ideal solution. These enclosures shield sensitive systems like circuit boards and control panels, ensuring uninterrupted operations in challenging environments. Industries such as aerospace, automotive, and telecommunications rely on them for their unmatched durability and adaptability. For instance, in aerospace, they protect avionics from extreme conditions, while in telecommunications, they safeguard servers and communication devices. With a market forecast of USD 13.6 billion by 2033, their growing demand underscores their reliability and value.

Key Takeaways

Sheet metal enclosures protect equipment from weather and damage. This keeps the equipment safe and lasting longer.

You can customise and design these enclosures to fit needs. This makes them work better and adapt to different uses.

Buying strong metal enclosures saves money over time. They last longer and need less fixing than plastic ones.

These enclosures follow rules like NEMA and UL ratings. This ensures they are safe and work well in tough conditions.

Understanding Sheet Metal Electrical Equipment Enclosures

What are sheet metal enclosures?

A sheet metal electrical equipment enclosure is a protective housing made from materials like steel or aluminium. These enclosures are lightweight yet strong, offering excellent durability and resistance to harsh industrial environments. They are designed to shield sensitive components from external factors such as dust, moisture, and mechanical impacts. Their high strength and good electrical conductivity make them ideal for industrial applications.

Sheet metal enclosures provide excellent electromagnetic shielding for sensitive electronic components, as long as they are properly grounded. This makes them indispensable in industries like telecommunications, aerospace, and medical equipment manufacturing.

These enclosures are also cost-effective, offering long-term reliability at a lower price compared to alternatives like plastic or fibreglass. Their ability to dissipate heat efficiently prevents overheating, extending the lifespan of the equipment they protect.

Importance of enclosures in industrial applications

Enclosures play a critical role in safeguarding industrial equipment. They protect electrical components from environmental hazards, mechanical damage, and unauthorised access. This ensures operational integrity and reduces the risk of costly repairs or replacements.

Safety: High-quality enclosures prevent accidental contact with live electrical parts, reducing the risk of electrical shocks and fires.

Compliance: Many enclosures meet stringent safety standards set by organisations like NEMA, UL, and CSA, ensuring they are suitable for industrial use.

Longevity: By shielding equipment from harsh conditions, enclosures help extend the lifespan of industrial-grade systems.

Common uses of electrical enclosures in industry

Electrical enclosures are widely used across various industries. Their applications vary depending on the specific requirements of each sector.

From automotive to renewable energy, these enclosures are essential for protecting industrial equipment. For example, in the oil and gas sector, enclosures must comply with strict safety standards to ensure safe operations. In renewable energy, they protect solar and wind installations from environmental damage, supporting the growth of green energy solutions.

Benefits of Metal Enclosures for Industrial Applications

Durability and resistance to harsh conditions

When I think about industrial environments, I picture extreme temperatures, heavy vibrations, and exposure to water or chemicals. Metal enclosures, especially those made from aluminium or steel, excel in these conditions. Their durability ensures they can withstand mechanical impacts and environmental stress without compromising the equipment inside.

Testing methods confirm their resilience. For example:

These tests highlight the reliability of high-quality enclosures. I’ve seen aluminium enclosures with patented coatings that resist corrosion and UV radiation. They perform well in temperatures ranging from -40°C to 125°C and even withstand harsh chemicals like diesel fuel. Their ability to endure 3,000 hours of salt spray testing makes them ideal for long-term use in coastal or marine industries.

Protection against physical damage and electrical hazards

Industrial equipment often faces risks like accidental impacts, electrical surges, and exposure to moisture. Metal enclosures provide optimal protection and functionality by shielding sensitive electrical components from these hazards.

I’ve noticed how metal electrical enclosures act as a barrier against mechanical impacts. Their robust construction prevents damage to internal systems, ensuring uninterrupted operations. Additionally, their electromagnetic shielding capabilities protect equipment from interference, which is crucial in industries like telecommunications and aerospace.

Waterproof metal boxes, such as those rated IP67 or IP68, offer excellent protection against harsh environmental conditions. They keep out dust and water, making them suitable for outdoor installations. By preventing unauthorised access to live electrical parts, these enclosures also enhance safety and reduce the risk of electrical shocks or fires.

Customisation and modular design options

One of the standout features of metal enclosures is their adaptability. I’ve seen how custom sheet metal boxes can be tailored to meet specific industrial needs. For instance, the Eabel Load Center case study demonstrates how customisation reduces costs. Instead of using complex moulds, the customer opted for bending and laser cutting processes. This approach maintained a consistent appearance while minimising initial investment.

Modular designs further enhance the functionality of metal electronic enclosures. Prefabricated units simplify layouts and make it easier to identify problem areas. I’ve observed how modular designs allow for future additions without disrupting existing systems. This flexibility is invaluable in industries where equipment needs evolve over time.

Uncluttered electrical panel designs, achieved through distinct functional units, improve efficiency and safety. Whether it’s a manufacturing plant or a renewable energy installation, customisation and modularity ensure enclosures meet the unique demands of industrial applications.

Cost-effectiveness and long-term reliability

When I evaluate industrial investments, cost-effectiveness always stands out as a critical factor. Metal enclosures, such as those made from aluminium or steel, offer exceptional value over their lifespan. While the initial cost of these enclosures may be higher than alternatives like plastic, their long-term benefits far outweigh the upfront expense.

One of the key reasons for this is their durability. High-quality enclosures resist wear and tear, reducing the need for frequent replacements. I’ve seen how industries save significantly on maintenance costs by choosing durable materials. For instance, a custom sheet metal box designed for harsh environments can last decades with minimal upkeep. This longevity ensures that businesses avoid the recurring expenses associated with less robust options.

To understand the financial advantages better, I often refer to life cycle cost analysis (LCCA). This method compares the total cost of ownership for different materials. Studies reveal that while materials like EIFS on stud framing may seem cheaper initially, they incur higher maintenance costs over time. In contrast, metal enclosures, with their superior durability, require less frequent repairs or replacements. This makes them a more economical choice in the long run.

Key findings from LCCA:

Metal enclosures have a higher upfront cost but lower maintenance expenses.

Alternatives with lower initial costs often lead to higher life cycle costs due to frequent repairs.

Durability plays a significant role in reducing overall expenditure.

Another aspect I appreciate about metal enclosures is their ability to withstand extreme conditions without compromising performance. For example, aluminium enclosures with corrosion-resistant coatings perform exceptionally well in coastal or marine industries. This reliability minimises downtime, which can be costly in industrial settings. By ensuring uninterrupted operations, these enclosures contribute to long-term savings.

I’ve also noticed how modular designs enhance cost-effectiveness. Businesses can adapt these enclosures to evolving needs without replacing the entire system. This flexibility reduces the need for additional investments, making them a practical choice for industries with dynamic requirements.

In my experience, choosing high-quality enclosures is not just about immediate savings. It’s about investing in a solution that delivers consistent performance, reduces operational risks, and ensures long-term reliability. Whether it’s a steel enclosure for a manufacturing plant or a custom sheet metal box for a renewable energy installation, the financial benefits are undeniable.

Comparing Metal Enclosures to Other Materials

Advantages over plastic enclosures

When I compare metal enclosures to plastic alternatives, the differences are striking. Plastic enclosures may seem appealing due to their lower initial cost, but their performance often falls short in demanding industrial environments.

Heat Resistance: Metals endure high temperatures, up to 1000°F, without losing structural integrity. Plastic, on the other hand, can warp or melt under intense heat.

Chemical Resistance: Metals resist corrosive substances better over time, making them ideal for industries like oil and gas.

Conductivity: Metals conduct heat and electricity efficiently, which is essential for applications requiring effective transfer.

Strength Under Pressure: Metals handle immense pressure and force, ensuring durability in heavy-duty applications.

Economic Viability: Metal fabrication remains cost-effective, even for small production runs.

The economic comparison further highlights the benefits of metal enclosures. While plastic enclosures have a lower upfront cost, their shorter lifespan and higher maintenance expenses make them less economical in the long run.

Benefits compared to fibreglass enclosures

Fibreglass enclosures offer certain advantages, such as lightweight construction and corrosion resistance. However, metal enclosures outperform them in critical areas.

Strength and Durability: Stainless steel enclosures withstand heavy loads and harsh environments without damage.

EMI Protection: Metal enclosures block electromagnetic interference, ensuring sensitive electronics maintain optimal performance.

Temperature Resistance: Metals perform reliably in extreme temperatures, making them suitable for diverse industrial applications.

Performance data further illustrates these differences:

Why metal enclosures are ideal for industrial-grade needs

Metal enclosures excel in industrial-grade applications due to their unmatched durability, environmental resistance, and protective features. I’ve seen how stainless steel enclosures enhance safety by shielding equipment from pollutants and electromagnetic interference. Their ability to withstand solvents, gasoline, and other harsh materials makes them indispensable in industries like manufacturing and telecommunications.

Metal enclosures are available in various sturdy materials, enhancing safety for industrial equipment.

They are suitable for both indoor and outdoor applications, with options for waterproof and hinged designs.

Their protective features shield equipment from pollutants and outside noise, crucial in industrial environments.

NEMA 4X enclosures demonstrate the superiority of metal enclosures. These models provide dust-tight protection and resist hose-directed water, making them ideal for harsh environments. Their corrosion-resistant design ensures reliability in industries dealing with corrosive materials.

In my experience, metal enclosures offer the perfect balance of strength, adaptability, and cost-effectiveness. Whether it’s a steel enclosure for a manufacturing plant or an aluminium box for renewable energy installations, their performance consistently meets industrial-grade requirements.

Key Factors in Choosing the Right Electrical Enclosure

Assessing environmental conditions and exposure

When selecting the right enclosures for industrial applications, environmental conditions play a pivotal role. I always start by evaluating the exposure risks that the enclosure might face. Factors like temperature extremes, humidity levels, and air cleanliness directly impact the performance and longevity of the enclosure. For instance, in coastal areas, high salt content in the air accelerates corrosion, making materials like aluminium with protective coatings a better choice.

Environmental assessment studies provide valuable insights into exposure risks. I’ve seen how lifecycle analysis (LCA) helps manufacturers choose sustainable materials for enclosures.

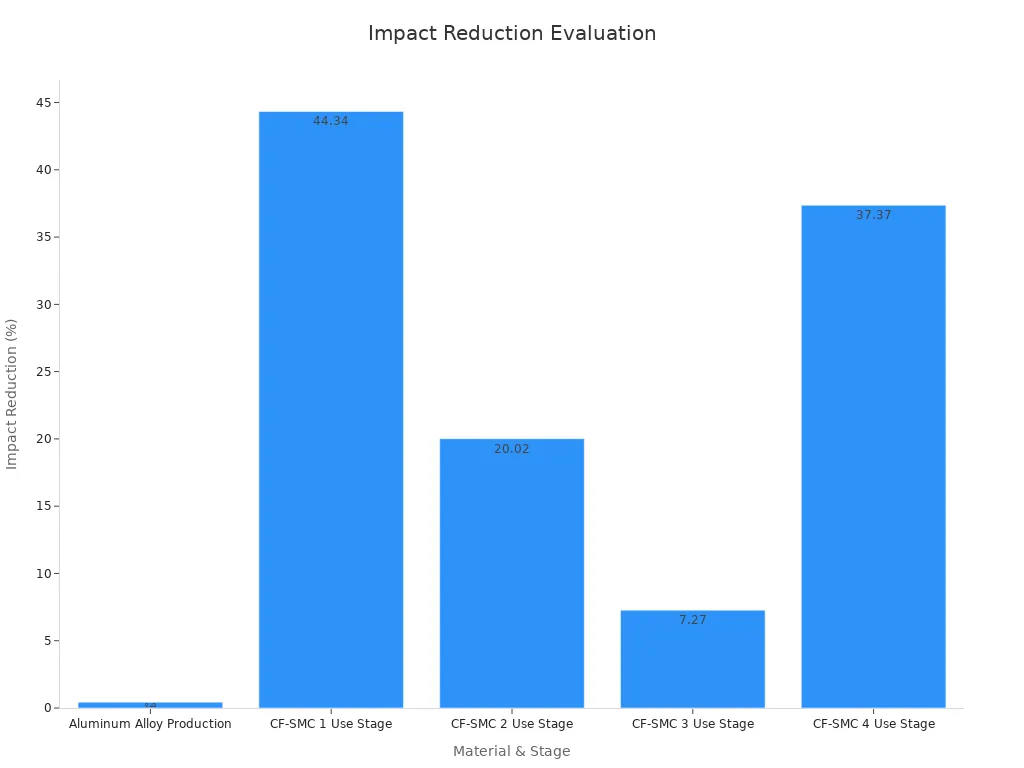

Quantitative evaluations further highlight the impact of environmental conditions on enclosure materials. For example, aluminium alloy shows a smaller reduction in environmental impact during production, while CF-SMC demonstrates significant reductions during the use stage.

I always recommend considering these factors early in the selection process to ensure the enclosure meets the demands of its environment.

Determining size, shape, and equipment compatibility

The size and shape of an enclosure must align with the equipment it houses. I’ve noticed that mismatched dimensions can lead to inefficiencies and even damage to sensitive components. To avoid this, I measure environmental conditions like temperature, humidity, and air velocity. These measurements help determine if the equipment is compatible with the enclosure.

Air cleanliness is another critical factor. Using an optical particle counter, I verify the cleanliness of the environment to ensure the enclosure meets ISO standards. This step is particularly important in industries like pharmaceuticals and electronics, where contamination can compromise operations.

Key considerations for compatibility:

Equipment dimensions and layout

Environmental conditions such as air cleanliness

Accessibility for maintenance and upgrades

Foxsen’s modular enclosures simplify this process. Their prefabricated designs allow for easy customisation, ensuring compatibility with a wide range of equipment. I’ve seen how these enclosures streamline operations in manufacturing plants and renewable energy installations.

Material selection and protective coatings

Material selection is the cornerstone of choosing the right enclosures. Metals like aluminium and steel offer durability and resistance to harsh conditions, but their performance depends heavily on the protective coatings applied. I’ve observed how coatings like powder and chromium plating enhance corrosion resistance and wear performance.

Foxsen’s enclosures utilise advanced coatings to ensure long-term reliability. For example, their aluminium enclosures feature corrosion-resistant layers that perform exceptionally well in marine environments. This makes them ideal for industries like oil and gas, where exposure to harsh chemicals is common.

I always emphasise the importance of matching the coating to the application. In nuclear settings, hard chromium plating remains the benchmark for wear resistance. In outdoor installations, powder coatings provide UV protection and durability. By selecting the right combination of material and coating, businesses can maximise the lifespan and efficiency of their enclosures.

Ensuring compliance with industry standards

When selecting electrical enclosures for industrial applications, compliance with industry standards is non-negotiable. These standards ensure that enclosures meet safety, durability, and performance benchmarks. I always prioritise enclosures that adhere to recognised certifications, as they guarantee reliability in demanding environments.

One of the most widely used standards is the NEMA rating system. It categorises enclosures based on their ability to protect against environmental hazards. For example, NEMA 1 enclosures are suitable for basic indoor use, while NEMA 4/4X models offer waterproofing and corrosion resistance for harsh outdoor conditions. Here’s a quick breakdown of common NEMA ratings:

I’ve found that understanding these ratings helps businesses choose enclosures that match their operational needs. For instance, a manufacturing plant with frequent hose-down cleaning would benefit from a NEMA 4X enclosure, while a marine installation might require a NEMA 6P model.

In addition to NEMA ratings, IP ratings provide a global standard for assessing an enclosure’s defence against dust and water. These ratings consist of two digits: the first indicates protection against solid particles (0-6), and the second measures resistance to liquids (0-8). For example, an IP67-rated enclosure offers complete dust protection and can withstand temporary water immersion. I always recommend checking these ratings to ensure the enclosure meets the specific environmental challenges it will face.

Beyond environmental protection, safety certifications like UL (Underwriters Laboratories) play a crucial role. UL certification verifies that an enclosure complies with stringent safety regulations and performs reliably under industrial conditions. I’ve seen how UL-certified enclosures instil confidence in industries like telecommunications and aerospace, where safety is paramount.

Mechanical durability is another critical factor. IK ratings measure an enclosure’s resistance to mechanical impacts. Higher ratings, such as IK08 and IK10, indicate robust protection against physical damage. This is particularly important in industries where equipment faces frequent handling or potential collisions.

Here’s a summary of key certifications to look for when evaluating enclosures:

UL Certification: Ensures compliance with safety regulations and verifies high performance.

IP Ratings: Indicates protection against dust and water, with ratings like IP54, IP66, and IP69 ensuring durability in various environments.

NEMA Certification: Confirms that enclosures meet specific protection standards against environmental hazards.

IK Ratings: Measures resistance to mechanical impacts, with higher ratings offering greater protection.

By focusing on these certifications, I ensure that the enclosures I recommend meet the highest standards of safety and reliability. Whether it’s a steel enclosure for a factory floor or an aluminium box for outdoor use, compliance with these benchmarks guarantees long-term performance and peace of mind.

Sheet metal electrical equipment enclosures excel in industrial applications due to their durability, adaptability, and superior protection. I’ve observed how their performance metrics consistently outshine alternatives like plastic and fibreglass.

Impact Resistance: Aluminium enclosures achieve an IK9 rating, enduring significant impacts without cracking. Stainless steel, with an IK8 rating, tends to crack under stress.

Corrosion Resistance: Aluminium forms a self-repairing protective layer, ensuring longevity in harsh environments. Stainless steel’s protective layer regenerates slower, making it less reliable in extreme conditions.

Thermal Management: Aluminium dissipates heat efficiently, maintaining stable internal temperatures, unlike stainless steel, which struggles with lower thermal conductivity.

Statistical comparisons further validate their advantages:

By evaluating environmental conditions and customisation needs, businesses can select industrial-grade enclosures that meet their requirements. These enclosures deliver unmatched reliability, making them the optimal choice for demanding environments.

FAQ

What are the most common materials used for sheet metal enclosures?

I’ve seen aluminium and steel as the most popular choices. Aluminium offers lightweight durability and corrosion resistance. Steel, especially stainless steel, provides excellent strength and impact resistance. Both materials perform well in industrial environments, depending on the specific application.

How do I determine the right size for an enclosure?

I always start by measuring the equipment dimensions and considering space for wiring and ventilation. Allowing extra room for future upgrades is essential. A snug fit ensures protection, but overcrowding can lead to overheating or maintenance challenges.

Are sheet metal enclosures suitable for outdoor use?

Yes, they are. I recommend enclosures with protective coatings like powder coating or anodising for outdoor applications. These coatings enhance corrosion resistance and weatherproofing. Models with IP67 or NEMA 4X ratings provide excellent protection against dust, water, and harsh weather.

Can sheet metal enclosures be customised?

Absolutely! I’ve worked with manufacturers who offer customisation options like size adjustments, additional cut-outs, and modular designs. These features allow businesses to tailor enclosures to their specific needs, ensuring compatibility and efficiency.

How do I ensure compliance with safety standards?

I always check for certifications like NEMA, IP, or UL ratings. These standards guarantee the enclosure meets safety and performance benchmarks. For example, NEMA 4X ensures waterproofing and corrosion resistance, while UL certification verifies electrical safety.