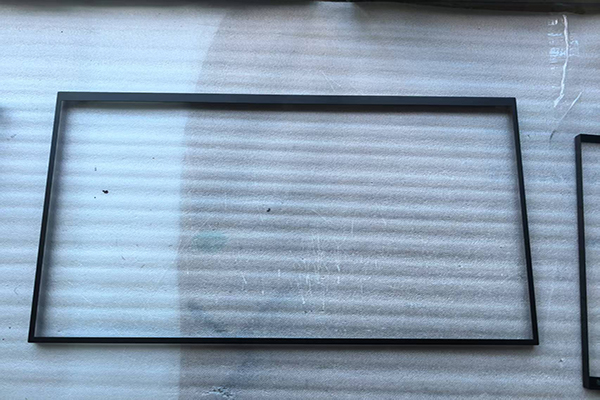

Electrical systems need strong protection to work well and stay safe. A sheet metal Electrical Equipment Enclosure acts as an important cover for delicate parts. It protects against dangers like dust, water, and physical damage. Made from tough materials, these enclosures stay strong and last a long time. They are designed to keep equipment safe and protect people using them. With smart engineering, these sheet metal Electrical Equipment Enclosures meet industry rules and help your systems last longer.

Key Takeaways

Sheet metal enclosures keep electrical systems safe from dust, water, and damage. This helps make them reliable and secure.

These enclosures manage heat, stopping systems from overheating and helping parts last longer.

Strong materials like stainless steel and aluminum don’t rust or wear out easily. This makes the enclosures tough and easy to care for.

Enclosures with high IP ratings stop dust and water. They work well in hard places like outdoors or factories.

Custom designs let enclosures fit different system needs. This boosts how they work and handles many challenges.

Protection from Environmental Factors

Electrical systems often face risks from the environment. A strong sheet metal Electrical Equipment Enclosure works like a shield. It keeps your equipment safe and running in tough conditions. Let’s see how these enclosures guard against dust, water, and temperature changes.

Keeping Dust and Debris Away

Dust and debris can harm electrical systems badly. When dirt builds up on parts, it can cause overheating or system failure. A sheet metal Electrical Equipment Enclosure blocks dust and debris from getting inside. This helps your equipment work well and lowers maintenance needs. By stopping dirt, you can make your systems last longer and stay reliable.

Protecting Against Moisture

Water is a big danger to electrical systems. Even small amounts can cause rust or damage parts. Sheet metal Electrical Equipment Enclosures have tight seals and coatings to stop water. They keep moisture out in wet or humid places. Whether it’s rain or spills, these enclosures prevent costly repairs and downtime.

Tip: Pick enclosures with high IP ratings for better water and dust protection.

Managing Temperature for Safety

Keeping the right temperature inside is very important. Too much heat can damage parts or cause fires. Good enclosures use vents or cooling systems to control heat. This keeps sensitive parts, like sensors, working properly.

The table below shows why temperature control matters:

By controlling temperature, you can make your systems last longer. A sheet metal Electrical Equipment Enclosure protects from outside dangers and creates a safe space for your parts to work.

Durability and Longevity of Sheet Metal Electrical Equipment Enclosures

Strength and Structural Integrity of Sheet Metal

Sheet metal enclosures are very strong and tough. They protect electrical systems in hard conditions. These enclosures can handle hits, shakes, and other stresses. Companies like Foxsen test them to make sure they last.

These tests prove that sheet metal enclosures stay strong in many situations. They keep your equipment safe and working well.

Resistance to Corrosion and Wear

Rust and damage can ruin enclosures, but sheet metal materials fight these problems. Stainless steel stops rust without extra coatings. Aluminum is light, strong, and naturally resists rust.

Stainless Steel: Stays strong and doesn’t rust, even in tough places.

Aluminum: Light and rust-proof, great for moving equipment.

Titanium: Very strong and resists rust in extreme conditions.

Using these materials means less fixing and better looks over time. Foxsen adds special coatings to their enclosures for extra protection. This keeps them working well in all kinds of environments.

Ensuring Long-Term System Performance

Sheet metal enclosures help systems work well for a long time. Unlike wood, which can bend or break, steel stays strong and keeps its shape. This helps save energy and keeps insulation steady.

Foxsen’s enclosures are built to last for years. Their strong design reduces damage and repairs. By choosing good enclosures, you protect your equipment and make it last longer.

Safety and Risk Mitigation with Sheet Metal Electrical Equipment Enclosures

Prevention of Electrical Hazards

Electrical dangers can harm both equipment and people. A strong sheet metal Electrical Equipment Enclosure acts as a shield. It keeps electrical parts safe from outside risks.

Insulation and Grounding: Grounding systems stop shocks and short circuits. Insulated panels help avoid touching live wires by accident.

Ingress Protection (IP): Enclosures with high IP ratings block dust and water. This keeps the electrical system safe from outside damage.

Tip: Pick enclosures with certified safety features to lower accident risks.

Using these enclosures makes your equipment safer. It also helps prevent costly problems caused by electrical failures.

Protecting Users and Maintenance Personnel

Safety isn’t just for equipment—it’s also for people. Sheet metal Electrical Equipment Enclosures are made to keep users and maintenance workers safe.

Secure Access: Lockable doors stop people from reaching live circuits. This lowers the chance of accidental exposure.

Ergonomic Design: Handles and hinges are placed for easy use. This helps workers avoid strain or injury during maintenance.

Warning Labels: Clear labels warn users about dangers. These markings help people handle the equipment safely.

Note: Check enclosures often to make sure safety features still work.

By focusing on user safety, these enclosures create a safer workplace. They also improve system reliability.

Fire Safety and Containment Features

Fires are a big risk for electrical systems. Sheet metal Electrical Equipment Enclosures use fire-resistant designs to reduce this danger.

Heat Dissipation: Vents and cooling systems stop overheating. This helps prevent fires from starting.

Fire-Resistant Coatings: Special coatings slow down flames. This gives more time to act during a fire.

Compartmentalization: Inside partitions keep fire from spreading. This protects other parts of the system.

Alert: Choose enclosures that meet fire safety rules for risky areas.

These fire safety features protect your equipment and nearby spaces. They help avoid major damage during emergencies.

Compliance with Industry Standards

Following Rules and Earning Certifications

Industry rules make sure electrical systems are safe and work well. Sheet metal enclosures follow these rules and earn important certifications. They meet standards like RoHS, which limits harmful materials, and IP ratings that show protection from dust and water. IK ratings also prove they can handle impacts.

Picking enclosures with these certifications keeps your systems safe and working in different places.

Proving Safety and Good Performance

Certifications show that sheet metal enclosures are safe and work well. They confirm the enclosures protect systems from dangers while staying efficient. For example, UL 50 and CSA C22.2.94.1 focus on safety for electrical equipment enclosures.

Choosing certified enclosures gives you trust in their ability to protect equipment and people.

Blocking Dust and Water with High IP Ratings

IP ratings measure how well enclosures stop dust and water. High ratings like IP55, IP65, and IP66 show strong protection for sensitive parts in tough conditions.

Sheet metal enclosures with high IP ratings keep systems running in dusty or wet places. This reduces downtime and saves on repairs.

Customization and Versatility of Sheet Metal Electrical Equipment Enclosures

Creating Designs for Specific System Needs

Each electrical system needs different things to work well. A sheet metal Electrical Equipment Enclosure can be changed to fit those needs. You can adjust it to improve safety, performance, and durability. For example:

Protection: Special designs keep parts safe from outside dangers.

Operational Efficiency: Custom features help equipment work better for specific tasks.

Long-term Reliability: Strong materials make enclosures last longer in tough conditions.

Real-life examples show how engineers change enclosures to match customer needs. They use tools like drills or printers to make designs that work well and look good. These changes also solve problems like making parts easier to reach or attach.

Handling Different Environmental Challenges

Sheet metal enclosures work well in many environments. You can adjust them to handle heat, cold, or moisture. Common changes include:

Corrosion Prevention: Coatings and sprays stop rust in wet areas.

Thermal Protection: Fans or heaters keep the inside temperature steady.

Insulation Methods: Foam layers save energy and keep parts safe.

These features make enclosures useful indoors and outdoors. Whether it’s rain, dust, or shaking, these enclosures protect your equipment and keep it running.

Flexible Designs for Special Uses

Sheet metal enclosures can be made in many shapes and sizes. You can pick features that fit your system perfectly. For example:

Built-in features like doors, panels, and cable holders make setup and repairs easier. These options let you change the enclosure as your project grows while keeping it safe and efficient.

A sheet metal Electrical Equipment Enclosure helps protect electrical systems. It is strong and lasts a long time. These enclosures can be adjusted for different environments. They follow safety rules to keep systems safe and reliable. Use them to protect delicate parts or improve system performance. Picking the right enclosure keeps equipment safe and working well for years.

FAQ

1. What materials are used for sheet metal enclosures?

Sheet metal enclosures are made from stainless steel, aluminum, or galvanized steel. These materials are strong, resist rust, and stay sturdy. They are great for keeping electrical systems safe in different places.

2. How do I pick the right IP rating for my enclosure?

Choose an IP rating based on how much dust and water your system faces. For outdoor use, IP65 or higher gives full dust protection and blocks water jets.

Tip: Check your system’s needs before deciding on an IP rating.

3. Can sheet metal enclosures be made for special uses?

Yes, you can change enclosures to meet specific needs. You can adjust the size, add cooling systems, or use special coatings for better protection.

4. Are sheet metal enclosures good for very hot or cold places?

Yes, they work well in extreme temperatures. Features like insulation, vents, and heat-resistant coatings help them handle both heat and cold.

5. How often should I check my sheet metal enclosure?

Check your enclosure every three months for rust, damage, or wear. Regular checks keep it working well and make your system last longer.