Sheet metal medical equipment enclosures play a vital role in healthcare facilities. You rely on them to protect sensitive medical devices while ensuring a sterile environment. Their durability makes them ideal for handling the daily demands of hospitals and clinics. The smooth, non-porous surface allows you to clean them efficiently, maintaining hygiene standards. These enclosures adapt easily to various designs, offering precision and flexibility for your unique needs. Their ability to combine functionality with reliability makes them indispensable in modern healthcare settings.

Key Takeaways

Sheet metal enclosures are strong and last a long time. They can handle heavy use in busy hospitals and clinics.

The smooth surface of sheet metal is easy to clean. This helps keep medical tools and spaces germ-free.

Sheet metal can be shaped into custom designs. These designs fit the needs of different medical devices.

Sheet metal enclosures follow strict health rules. This makes them safe for patients and healthcare workers.

Using sheet metal enclosures saves money over time. They need less fixing and help equipment work better.

Durability of Sheet Metal in Medical Equipment Enclosures

Resistance to Wear and Tear

When you choose sheet metal for medical equipment enclosures, you gain a material that can handle constant use. Hospitals and clinics demand enclosures that endure frequent handling, movement, and exposure to various environmental conditions. Sheet metal resists scratches, dents, and other forms of physical damage. This durability ensures that your equipment remains protected, even in high-traffic areas. Unlike plastic or other materials, sheet metal maintains its structural integrity over time, reducing the need for frequent replacements.

Withstanding Harsh Sterilization Processes

Sterilization is a critical part of maintaining hygiene in healthcare environments. Medical equipment enclosures often undergo rigorous cleaning procedures, including exposure to high temperatures, chemical disinfectants, and steam. Sheet metal excels in these conditions. Its robust nature allows it to withstand repeated sterilization cycles without warping, cracking, or degrading. This makes it an ideal choice for environments where cleanliness is non-negotiable. You can rely on sheet metal to maintain its form and function, even under the most demanding sterilization protocols.

Longevity in Healthcare Applications

Sheet metal offers exceptional longevity, making it a cost-effective solution for medical equipment enclosures. Its durability stems from factors like the thickness of the metal plating and the quality of the fabrication process. Thicker plating acts as a strong barrier against corrosion, ensuring that your equipment remains functional for years. Additionally, the uniformity of the plating process and the type of metal used play a significant role in extending the lifespan of the enclosure. With proper sheet metal fabrication, you can trust that your enclosures will deliver consistent performance over the long term.

Key factors contributing to longevity include:

The thickness of metal plating, which enhances resistance to corrosion.

High-quality fabrication processes that ensure uniformity and durability.

The use of premium metals tailored for healthcare applications.

By investing in sheet metal enclosures, you ensure that your equipment remains protected and operational, reducing downtime and maintenance costs.

Hygiene Benefits of Sheet Metal Medical Equipment Enclosures

Non-Porous Surface for Easy Cleaning

Sheet metal enclosures feature a non-porous surface that simplifies cleaning. You can wipe away contaminants quickly without worrying about residue seeping into the material. This property is especially important in healthcare environments, where maintaining cleanliness is critical. Non-porous surfaces prevent the accumulation of dirt and grime, ensuring that medical equipment remains sterile and safe for use.

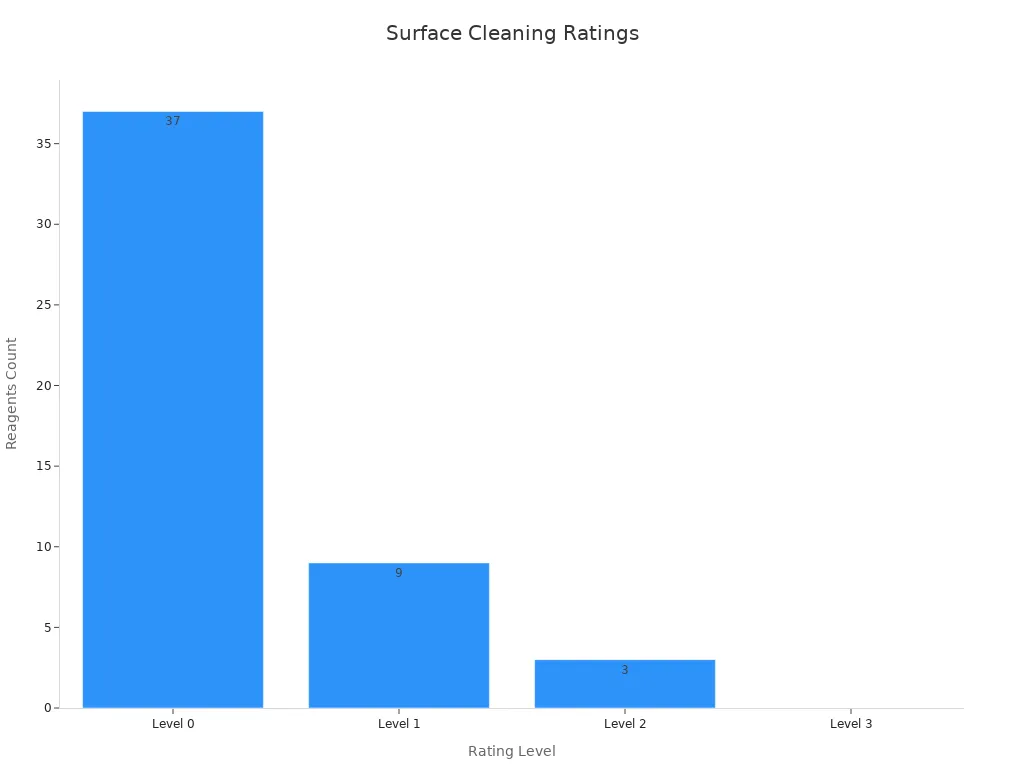

Laboratory tests have verified the effectiveness of non-porous sheet metal surfaces for easy cleaning. The results demonstrate how different reagents interact with the material:

These findings highlight the superior cleaning performance of sheet metal enclosures, making them a reliable choice for healthcare applications.

Resistance to Bacterial Growth

Sheet metal enclosures resist bacterial growth, ensuring a safer environment for patients and healthcare workers. The smooth, non-porous surface eliminates crevices where bacteria can thrive. You can trust this material to reduce the risk of contamination, even in high-touch areas.

Unlike porous materials, sheet metal does not absorb moisture, which is a key factor in bacterial proliferation. Its resistance to microbial growth makes it ideal for medical settings where hygiene is paramount. By choosing sheet metal fabrication for your enclosures, you enhance the overall cleanliness and safety of your equipment.

Compatibility with Sterilization Methods

Sheet metal enclosures are compatible with a wide range of sterilization methods. Whether you use chemical disinfectants, steam, or UV light, the material maintains its integrity. You can sterilize these enclosures repeatedly without worrying about damage or degradation.

This compatibility ensures that your equipment remains hygienic and functional, even under rigorous cleaning protocols. Sheet metal fabrication processes further enhance this durability, allowing the material to withstand high temperatures and harsh chemicals. With sheet metal enclosures, you can meet the strict hygiene standards required in healthcare environments.

Customization and Design Flexibility of Sheet Metal

Tailored Designs for Medical Equipment

Sheet metal offers unmatched flexibility when designing medical equipment. You can customize enclosures to meet specific requirements, ensuring they fit seamlessly with your devices. Materials like 304 and 316 stainless steel are commonly used due to their corrosion resistance and ability to withstand harsh sterilization processes. These materials also allow for intricate designs, making them ideal for surgical tools, implants, and diagnostic equipment.

For example, custom metal fabrication enables the creation of unique geometries for surgical instruments like scalpels and forceps. It also supports the development of patient-specific implants, such as hip or knee replacements, which improve healing outcomes. Diagnostic equipment, including MRI and CT machine components, benefits from precise manufacturing, ensuring reliable performance.

Customization also extends to finishing processes that enhance durability and hygiene. Techniques like passivation, electropolishing, and anodizing improve corrosion resistance and bacterial adhesion. Powder coating adds a protective layer while allowing for custom branding.

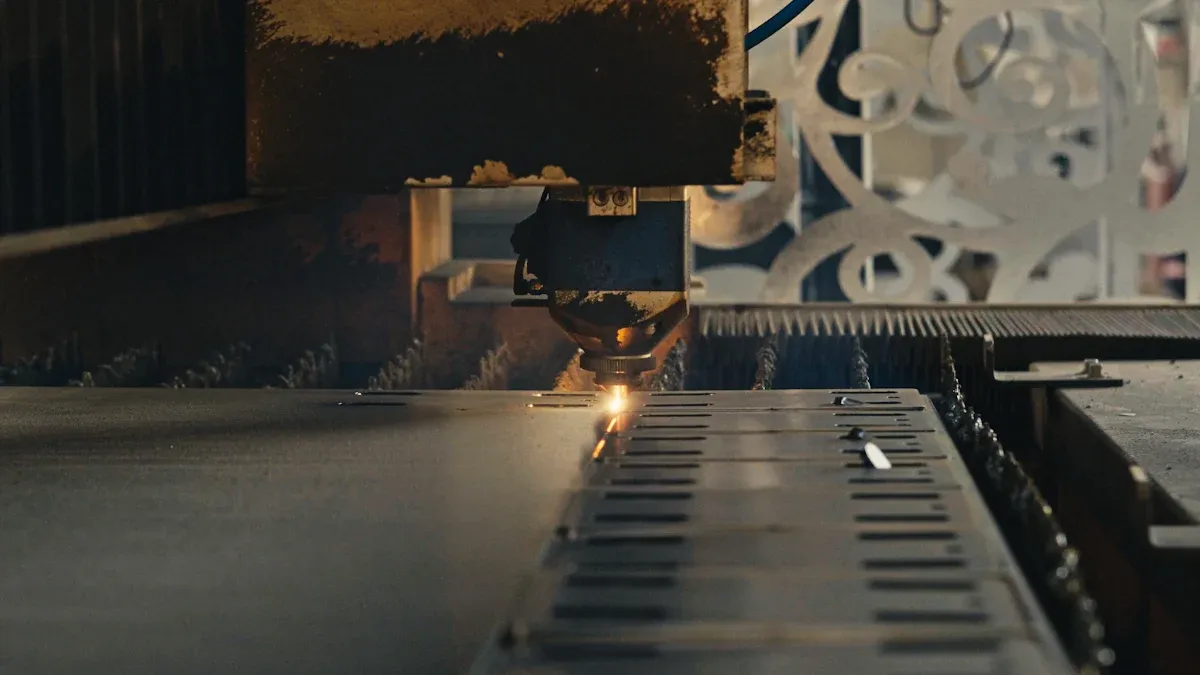

Precision Fabrication for Complex Features

Precision is critical in medical applications, and sheet metal fabrication delivers the accuracy you need. Advanced techniques like cutting, bending, and stamping ensure components meet exact specifications. This level of precision is essential for creating complex features in medical devices.

For instance, surgical instrument trays require intricate designs to hold tools securely during procedures. Similarly, high-tech imaging machine housings demand precise fabrication to ensure proper functionality. By choosing custom metal fabrication, you can achieve close tolerances and high accuracy, ensuring your equipment performs as intended.

Integration of Functional Elements like Ventilation

Medical enclosures often require functional elements like ventilation to maintain device performance. Sheet metal allows you to integrate these features seamlessly into your designs. For example, ventilation systems can protect sensitive components from overheating while preventing the entry of liquids and particulates.

Companies like Donaldson specialize in enclosure protection vents that offer advanced technological solutions. These vents ensure maximum performance by combining durability with protection against environmental factors. With sheet metal fabrication, you can incorporate such features without compromising the structural integrity of your enclosures.

Compliance with Medical Standards Using Sheet Metal

Meeting Regulatory Requirements (FDA, ISO)

When you work with medical enclosures, compliance with regulatory standards is essential. Sheet metal enclosures meet strict requirements set by organizations like the FDA and ISO. These standards ensure that medical equipment parts are safe, reliable, and effective. For example, ISO 13485 focuses on the quality management systems for medical device components, while FDA regulations emphasize safety and performance.

Sheet metal fabrication processes align with these standards by using approved materials and precise manufacturing techniques. This ensures that your enclosures meet the necessary specifications for healthcare applications. By choosing sheet metal, you can confidently meet regulatory demands and maintain the integrity of your equipment.

Ensuring Safety for Patients and Operators

Safety is a top priority in healthcare environments. Sheet metal enclosures provide robust protection for both patients and operators. Their durable construction shields sensitive medical device components from external damage, ensuring consistent performance. Additionally, the smooth, non-porous surface minimizes the risk of contamination, creating a safer environment for everyone.

You can also rely on sheet metal to prevent electrical hazards. Many enclosures feature grounding and shielding properties, which protect users from electrical shocks. This makes sheet metal an ideal choice for housing medical equipment parts that involve electronic components. By prioritizing safety, you enhance the overall reliability of your devices.

Approved Materials for Healthcare Applications

The materials used in sheet metal fabrication undergo rigorous testing to ensure they meet healthcare standards. Certifications like Certificates of Conformance (CoC) validate the suitability of these materials for medical applications. These certifications include details such as the type, grade, chemical composition, and mechanical properties of the material. They also confirm compliance with industry standards like ASTM and ISO.

Common certifications for healthcare materials include:

CoC for verifying compliance with national and global standards.

ASTM certifications for material quality and performance.

ISO certifications for ensuring safety and reliability.

By using certified materials, you ensure that your medical equipment parts meet the highest standards of quality and safety. This not only enhances the performance of your equipment but also builds trust with healthcare providers and patients.

Cost-Effectiveness and Sustainability of Sheet Metal

Affordable Manufacturing Costs

Sheet metal enclosures offer a cost-effective solution for medical equipment manufacturing. The affordability stems from efficient fabrication processes and the ability to produce enclosures at scale. Medical device companies rely on these enclosures to protect sensitive electronics while maintaining sterility. This dual functionality ensures that you get both protection and affordability in your applications.

Several factors influence the cost of manufacturing sheet metal enclosures:

By understanding these factors, you can optimize your manufacturing process to achieve the best balance between cost and quality.

Recyclability and Environmental Benefits

Sheet metal stands out as a sustainable choice for medical equipment enclosures. Metals like steel and aluminum are among the most recyclable materials, significantly reducing environmental impact. Recycling aluminum, for instance, saves up to 95% of the energy required for primary production. This not only conserves resources but also minimizes greenhouse gas emissions.

Aluminum is 100% recyclable, producing only 5% of the CO2 emissions compared to its initial production. By choosing recyclable materials, you contribute to a circular economy, reducing the demand for virgin resources. This makes sheet metal an environmentally responsible option for your equipment needs.

Long-Term Value in Medical Applications

Investing in sheet metal enclosures provides long-term value for your medical equipment. The durability of sheet metal ensures that enclosures last for years, reducing the need for frequent replacements. This longevity translates into lower maintenance costs and fewer disruptions in healthcare settings.

The growing demand for durable and corrosion-resistant materials in medical manufacturing highlights the value of sheet metal. The sheet metal fabrication market is projected to grow at a compound annual growth rate (CAGR) of 4-6% over the next seven years. This growth reflects the increasing reliance on sheet metal for customized, high-quality components. By choosing sheet metal, you secure a reliable and cost-effective solution for your equipment.

Sheet metal enclosures offer unmatched benefits for medical equipment. You gain durability, hygiene, and design flexibility, ensuring they meet the demands of healthcare environments.

Why choose sheet metal?

It complies with strict medical standards, ensuring safety and reliability.

Its cost-effectiveness and sustainability make it a smart choice for manufacturers.

By investing in sheet metal, you secure high-quality, long-lasting enclosures that enhance performance and meet healthcare needs. This decision ensures your equipment remains reliable and efficient for years to come.

FAQ

What types of sheet metal are commonly used for medical enclosures?

You often see stainless steel (304 and 316 grades) and aluminum used for medical enclosures. These materials resist corrosion, withstand sterilization, and meet hygiene standards. Their durability and versatility make them ideal for healthcare applications.

How does sheet metal ensure hygiene in medical environments?

Sheet metal has a smooth, non-porous surface. This prevents bacteria from growing and makes cleaning easy. It also withstands harsh sterilization methods like steam, UV light, and chemical disinfectants, ensuring a sterile environment.

Can sheet metal enclosures be customized for specific medical devices?

Yes, you can customize sheet metal enclosures to fit your device's unique requirements. Fabrication techniques like cutting, bending, and finishing allow for tailored designs, precise dimensions, and integration of functional features like ventilation or cable ports.

Are sheet metal enclosures environmentally friendly?

Absolutely! Sheet metal, especially aluminum and steel, is highly recyclable. Recycling these materials saves energy and reduces waste. By choosing sheet metal, you contribute to sustainability and support eco-friendly manufacturing practices.

How do sheet metal enclosures comply with medical standards?

Sheet metal enclosures meet strict standards like FDA and ISO certifications. These standards ensure safety, reliability, and quality. Approved materials and precise fabrication processes help you meet regulatory requirements for healthcare applications.

Tip: Always verify that your sheet metal supplier provides certifications for compliance with medical standards.