Complex Metal Stamping Components: Precision Engineered for Peak Performance

Complex Metal Stamping Components: Precision Engineered for Peak Performance

AT FOXSEN we specialize in producing complex metal stamping components designed to meet the highest industry standards. Our CNC metal stamping services offer precision sheet metal working, including punching. We use advanced CNC machines to create intricate parts that meet strict customer requirements. From prototypes to mass production, we can handle projects of various sizes and complexities and complexity.

| Item Description | complex metal stamping components |

| Material | Galvanized sheet 1.5MM; |

| Processing Technology | Stamping, riveting |

| Surface Treatment | True color |

| Unit Price | According to customer drawings |

| Remark | Accept customization |

Industrial Applications of Complex Metal Stamping Components

Industrial Applications of Complex Metal Stamping Components

Automotive Stampings

Building Products

Electronics

Solar BOS (balance of system) Components

LED Lighting LED

Roofing Products

Electronic Metal Forming Stamping Service Manufacturing Capabilities

Electronic Metal Forming Stamping Service Manufacturing Capabilities

FOXSEN in manufacturing high-quality punching process. Our team specializes in CNC metal stamping and is adept at crafting a wide array of complex sheet metal parts.

Whether you require thin gauge stamping, micro-hole punching, or irregular shape stamping, we deliver custom-tailored solutions of the highest quality.This allows us to assist the customer with valuable Design for Manufacturability advice. FOXSEN’s quality assurance team is driven by data and we strive for and achieve continuous improvement.

FOXSEN CNC Metal Stamping Process Involves

FOXSEN CNC Metal Stamping Process Involves

Material Selection: We carefully select premium-grade metals to ensure optimal performance.

Die Design and Fabrication: Our skilled engineers design and manufacture precision dies for accurate stamping.

Stamping Operation: Utilizing state-of-the-art CNC stamping presses, we create components with exceptional precision.

Secondary Operations: Additional processes such as bending, drilling, and tapping are performed as needed.

Surface Finishing: We offer a range of surface treatments, including plating, coating, and passivation.

Qualification Certificate &Finished product inspection

Qualification Certificate &Finished product inspection

Strictly inspect the quality of the finished goods, including visual inspection, dimensional measurement, strength testing, etc. Ensure that CNC metal stampings meets design requirements and customer needs.

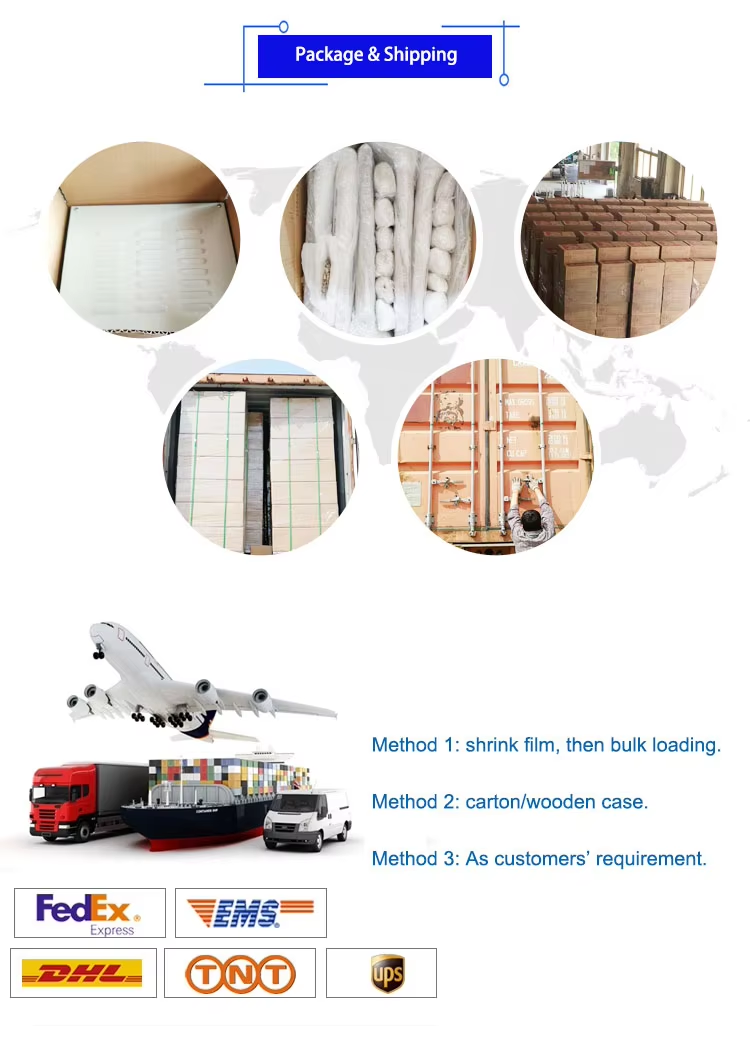

Shipping Packaging

Shipping Packaging

FAQ

FAQ

Q: Are you a trading company or manufacturer?

A: We are the manufacturer.Our advanced equipment ensures that every cut is accurate and consistent.

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or the sample of your product. Details below should be included,

A. Materials B. Surface Finish C. Tolerance D. Quantity

Q: How does the payment process work?

A: Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance before shipment.

Q: How do I know about the delivery?

A: Tracking number will be provided to you once we get it from shipping agent. Also we will keep updating the latest shipping information for you.

Q: Is it possible to know how my products are going without visiting your company?

A: We will provide a detailed production schedule and send weekly reports with digital pictures and videos showing machining progress.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness