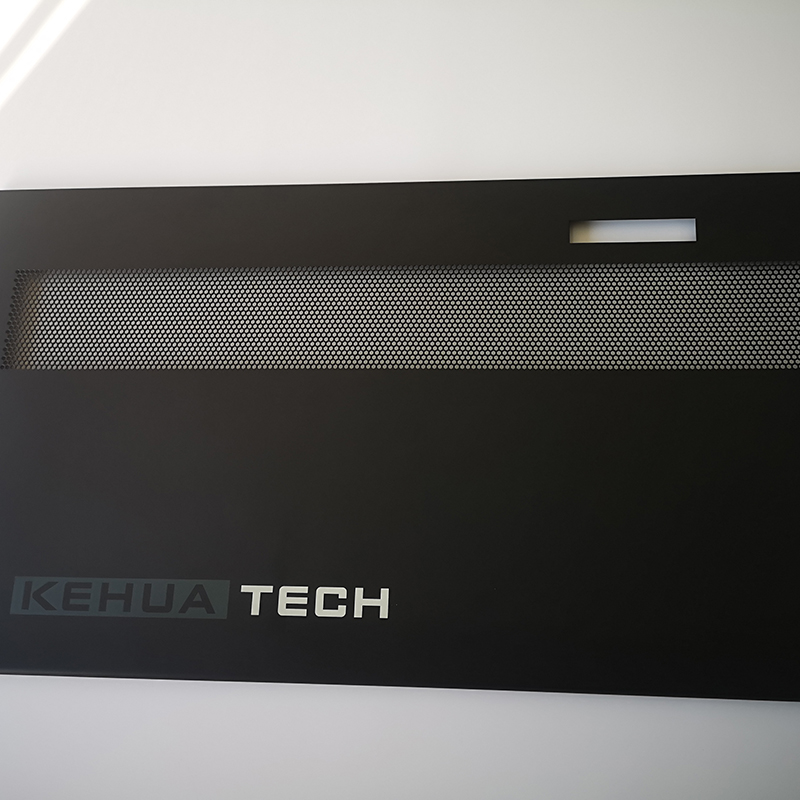

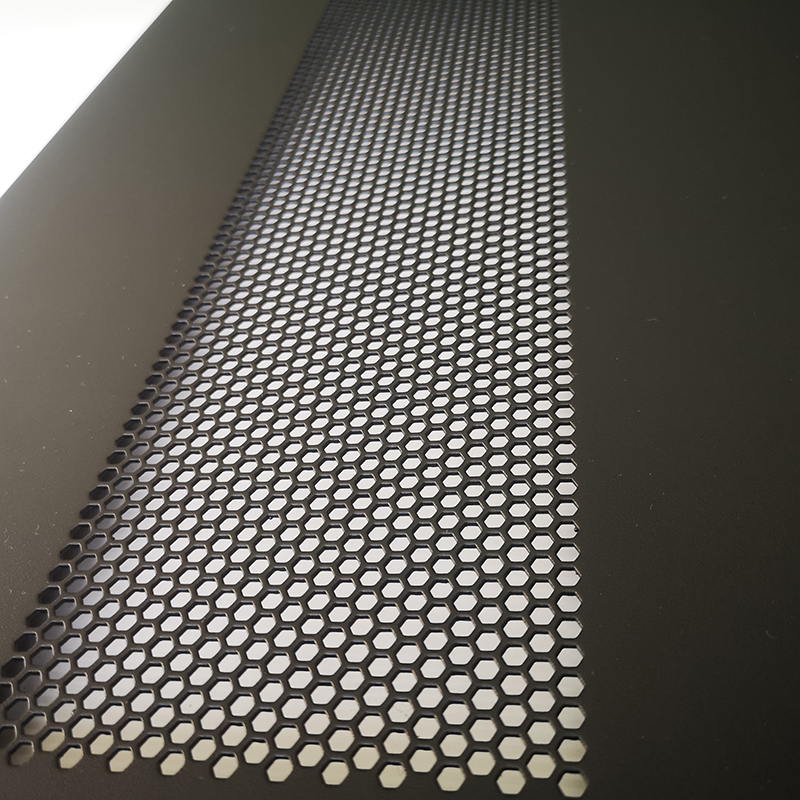

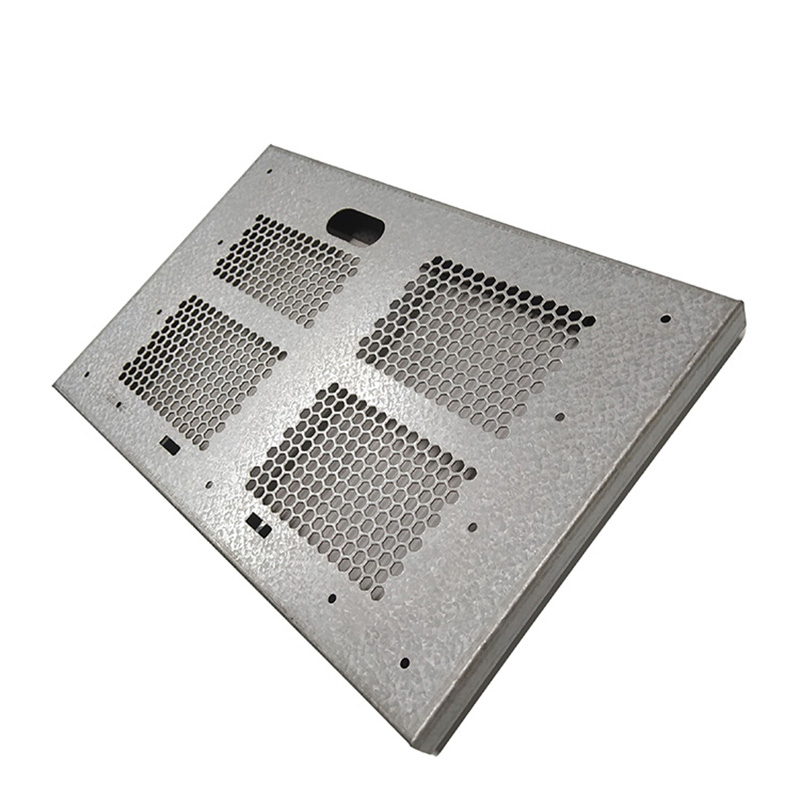

Think of a Sheet Metal Chassis as the custom-engineered skeleton for your product. Typically formed from high-quality sheet metal, it provides the essential mounting points, the necessary structural rigidity, and often, critical electromagnetic shielding. The "magic" behind creating these chassis with their intricate ventilation patterns, arrays of precisely located apertures, and unique formed features lies in the sophisticated process of CNC (Computer Numerical Control) Punching.

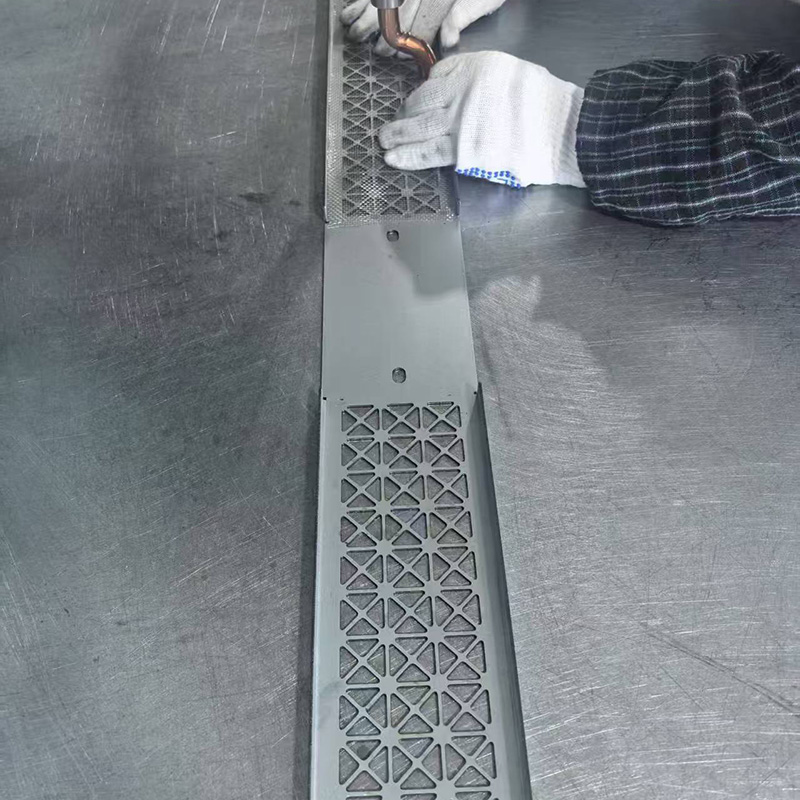

At its heart, CNC Punching is a highly automated manufacturing discipline. We take your digital blueprints and translate them into a precise sequence of commands. These commands meticulously direct the punch press, governing critical "mechanical quantities such as position, angle, speed, and even switch quantities related to the flow of mechanical energy." The machine then employs a diverse arsenal of tools to systematically create holes, louvers, embossments, and other complex features in the sheet metal. This process delivers exceptional accuracy and repeatability, part after part. The very possibility of such advanced fabrication "depends on the appearance of data carriers and binary data operations," a technological leap that has utterly transformed how Sheet Metal Chassis are conceived and produced, catapulting us from older, manual methods into an era of high-speed, digitally-driven precision.

When you entrust your Sheet Metal Chassis requirements to Foxsen, you're partnering with a team that possesses a deep, practical understanding of material science, coupled with a mastery of cutting-edge manufacturing technology.

Precision Born from Advanced CNC Punching: We harness the full capabilities of modern CNC punching technology – recognized as "key core equipment in modern manufacturing." This isn't just about automation; it's about achieving a level of precision that allows us to produce Sheet Metal Chassis featuring the most complex hole patterns, adhering to the tightest tolerances, and ensuring absolute consistency across production runs. The capabilities are so profound that these "high-end CNC punching machines" are indispensable in hyper-demanding sectors like aerospace and shipbuilding. This isn't just a fact; it's an indicator of the extreme reliability and pinpoint accuracy we bring to your project, regardless of its scale.

An Unwavering Commitment to Superior Materials: The integrity of a Sheet Metal Chassis is fundamentally tied to the quality of the sheet metal from which it's born. We don’t compromise here. We source and utilize only high-grade materials, carefully selected for their inherent durability, optimal formability, and proven suitability for the rigors of CNC punching and any subsequent manufacturing processes. This includes:

SPCC/SHCC (Cold-Rolled/Hot-Rolled Steel): The workhorses for robust, cost-effective chassis that demand excellent strength.

SECC/SGCC (Galvanized Steel): Chosen for their superior corrosion resistance, ensuring longevity even in challenging environments.

Aluminum Alloys: The go-to when your design prioritizes light weight and effective thermal conductivity.

Stainless Steel: Selected for applications where supreme corrosion resistance, hygienic properties, or a premium aesthetic finish are critical. Using materials of this caliber isn't just a preference; it's a prerequisite for achieving clean, burr-free punches, predictable behavior during forming (if your chassis design includes bends), and ultimately, a long and reliable service life for your Sheet Metal Chassis.

Engineered for Efficiency and Versatility: CNC Punching is an exceptionally efficient method for producing Sheet Metal Chassis, particularly those characterized by a high density of features or complex patterns. Tool changes can be fully automated, and once programmed, the machines can execute intricate tasks with minimal ongoing human intervention. For you, this translates into faster project turnaround times without any sacrifice in quality.

We Think Like You Do – The End-User Perspective: We never view a Sheet Metal Chassis as an isolated component. We understand it’s a critical part of a larger assembly. Does it facilitate easy integration of your electronics? Does it allow for adequate airflow? Will it withstand the rigors of its intended operational environment? Our design and manufacturing approach proactively considers these downstream needs right from the project's inception. This "close cooperation...to keep up with the latest user needs" is a philosophy we live by.

We know that when you're designing a critical component, you'll have detailed questions. Here are some of the common inquiries we receive, with answers grounded in our extensive manufacturing experience:

Q1: How can I be sure about the precision of my Sheet Metal Chassis when using CNC punching?

A: The inherent precision of CNC punching stems from its core principle: it "uses digital control methods to achieve automatic control of a specific work process." Every movement, every tool selection, every operation is dictated by the digital design, virtually eliminating the variables of manual intervention. Modern "high-end CNC punching machines" possess incredibly "high technical content," which translates directly into repeatable, verifiable accuracy for all features – from simple holes to complex contours – across the entire Sheet Metal Chassis.

Q2: What types of sheet metal are most compatible with CNC punching for a chassis application?

A: One of the great advantages of CNC punching is its versatility across a wide spectrum of sheet metal types. For Sheet Metal Chassis, we most frequently work with and recommend high-quality SPCC (cold-rolled steel), SHCC (hot-rolled steel), SECC/SGCC (galvanized steels), various Aluminum alloys, and different grades of Stainless Steel. The best choice always depends on your specific requirements for strength, weight, corrosion resistance, conductivity, and, of course, budget. The fundamental material characteristic we look for is its ability to shear cleanly under the punch, ensuring crisp, well-defined features.

Q3: My Sheet Metal Chassis design is fairly intricate, involving numerous hole sizes, specific ventilation slot patterns, and even some small formed elements. Can your CNC punching process handle this level of complexity?

A: Absolutely. This is precisely where modern CNC punch presses excel. They are engineered for versatility, equipped with extensive tool libraries that can hold a wide variety of punch shapes and sizes. Furthermore, they can create features beyond simple holes, such as louvers for ventilation, stiffening ribs through embossment, and knockouts for cable management. The "high-end CNC machine tools" we employ are specifically built for these complex tasks. It's no surprise that the general "demand for high-end CNC machine tools rose steadily" even during broader economic fluctuations – their capability to deliver complex, high-quality parts is proven and consistently sought after.

Q4: Can you give me an idea of the typical applications for the Sheet Metal Chassis you produce?

A: The Sheet Metal Chassis we manufacture find their way into an incredibly diverse range of applications. Thanks to the precision and consistent quality we achieve, they are ideally suited for demanding uses such as electronics enclosures, server racks and data center infrastructure, telecommunications equipment, sophisticated medical devices, industrial control panels, and much more. The fact that today's "high-end CNC machine tools" are seeing increasing use, even if in "small batches in high-end manufacturing enterprises such as aerospace and shipbuilding," clearly underscores the exceptional level of quality, reliability, and tight tolerances that are achievable and that we deliver.

Q5: You often mention "high-end CNC punching machines." What specific advantages do these bring to the quality and cost-effectiveness of my Sheet Metal Chassis?

A: Investing in and utilizing "high-end CNC punching machines" offers several tangible benefits that directly impact your Sheet Metal Chassis. These machines typically provide superior accuracy and repeatability, faster processing speeds (which can reduce lead times), extended tool life (reducing downtime), and a greater capacity to handle highly complex geometries with unwavering reliability. Their inherent "high technical content and high added value" mean they consistently produce Sheet Metal Chassis that not only meet but often exceed the most stringent quality standards. This reduces the likelihood of errors or rework, and often allows for more innovative and efficient chassis designs to be realized. This commitment to advanced technology is a cornerstone of our industry's move towards "industrial structure adjustment and achieving transformation and upgrading," ensuring we can meet increasingly sophisticated demands.

The Sheet Metal Chassis is more than just a component; it’s a fundamental enabler of modern technology. At Foxsen, we seamlessly blend our deep-rooted understanding of sheet metal behavior with the unparalleled precision and efficiency of state-of-the-art CNC Punching technology. We are acutely aware that this field is one of constant evolution, with a clear industry trajectory where "high-end CNC punching machines" are becoming the "preferred direction for industrial structure adjustment and transformation and upgrading." Our commitment is to remain at the vanguard of these advancements, ensuring that every Sheet Metal Chassis we deliver is not just fit for its intended purpose, but is truly engineered for excellence and represents a sound "guarantee for the industrialization and batch application" of your innovative products.

Let's engage in a detailed discussion about your next Sheet Metal Chassis project. We're confident our expertise can provide the perfect, precision-engineered foundation for your success.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness