Laboratory medical device enclosures:Housing Solutions for Surgical & Healthcare Equipment

Laboratory medical device enclosures:Housing Solutions for Surgical & Healthcare Equipment

Your medical devices need to be up to the challenge of meeting healthcare industry standards. FOXSEN can help.

FOXSEN can provide properly formulated, cost-effective materials for use as Medical device enclosure or other Medical enclosure to withstand short- and long-term challenges each piece of equipment faces during its service life in a constantly disinfecting maintenance condition,so that the housing or other enclosure resists crazing, cracking, and other structural threats.

| Item Description | laboratory medical device enclosures |

| Material | Aluminum 6061,5052 |

| Processing Technology | Laser cutting, bending, rivetin,spraying, silk screen,QC Inspection, Packaging/assembly, Shipment |

| Surface Treatment | Anodization,Mirror Polishing,Phosphating,Black Oxide Coating,Hot-dip Galvanizing,Sandblasting,Electroplating,Powder Coating,Spray Painting Electrophoretic Paint,Passivation |

| Unit Price | According to customer drawings |

| Remark | Accept customization |

When you're sourcing Laboratory Medical Device Enclosures, you’re looking for something that will stand up to demanding conditions and protect significant investment. Here’s how our approach, backed by hard data and years of experience, makes a genuine difference:

The Right Materials – Because Lab Environments Don’t Forgive:Let's be upfront: material selection for Laboratory Medical Device Enclosures isn't a casual choice; it's fundamental. We don’t guess; we use what works. That means certified, high-grade materials. For most lab applications, we’re looking at robust stainless steel – often you'll see us recommending grades like 304 for its all-around performance, or 316L if your work involves more aggressive chemicals and you need that extra corrosion resistance. Specific aluminum alloys also play a big role, especially when you need a good strength-to-weight ratio and excellent finishability. We don’t just take the mill certs at face value; we verify critical physical properties like material thickness and hardness to ensure they align perfectly with your design specifications. This isn't just any sheet metal; it's the foundation of your device's long-term integrity. And yes, for certain internal structural parts where it makes sense, we’re also experienced with materials like aluminized zinc plates or cold-rolled steel plates, always ensuring they meet the project's specific structural and environmental needs.

Manufacturing Precision – Where Our Numbers Become Your Assurance:Turning that carefully selected sheet metal into the precise forms needed for high-performance Laboratory Medical Device Enclosures is where our investment in technology and skill really pays off. We utilize advanced laser cutting, and when we say precise, we mean it – we consistently operate with tolerances of ±0.005mm. Why such a tight tolerance? Because in a lab instrument, every connection, every seal, every component alignment matters. Our CNC bending is no different; it’s a tightly controlled process where we aim for tolerances around ±0.1mm. These aren’t aspirational targets; these are figures we achieve daily. For more complex designs, we also use techniques like multi-station punching to ensure both accuracy and efficiency. A detail that might seem minor, but we’re obsessive about, is protecting the material's original surface protective film for as long as humanly possible during fabrication. The reason is simple: it’s the only way to guarantee that your Laboratory Medical Device Enclosures unit arrives with that smooth, flawless surface, absolutely free of burrs or scratches. This isn't just about looks; it’s critical for cleanability and preventing contaminant traps in a lab.

Designed for Real-World Lab Use – Functionality Meets Durability:Labs are demanding environments. Your Laboratory Medical Device Enclosures must be easy to clean – often with pretty potent chemicals – and they need to take the bumps and knocks of daily use. That’s why those impeccable sheet metal surfaces are so important. The surface treatments we use are selected for their durability and, crucially, their non-toxic nature, ensuring they comply with stringent medical and laboratory standards. When it comes to appearance, we get that a lab needs to look professional. We often discuss the "no more than three colors" guideline, and for Laboratory Medical Device Enclosures, this often translates to a primary color with subtle highlights, keeping in mind that low-purity colors are typically preferred for medical and lab equipment, fostering a calm, focused work environment.

Structural Integrity – Because What’s Inside is Valuable:Let’s face it, Laboratory Medical Device Enclosures are often housing incredibly sensitive and expensive components – optics, fluidics, specialized electronics. These housings are not passive shells; they provide critical support, often making up 10-15% of the device's entire structural framework. Our designs always incorporate robust sheet metal frameworks, including intelligently placed load-bearing elements and absolutely secure connecting parts. We rely on professional welding techniques, such as TIG welding for its clean, strong bonds, and laser welding when pinpoint accuracy and minimal heat distortion are paramount. The choice of welding consumables is also critical – we select them for perfect compatibility with the parent sheet metal to maximize strength and ensure long-term corrosion resistance. For equipment that's particularly sensitive to contamination, main assembly and critical debugging stages are even performed in our dedicated cleanroom environments. We’re well-versed in different cabinet construction approaches, be it a column-beam type or an integral plate design, and we always use the most robust and appropriate connection methods for the application.

Compliance and Safety – Our Unshakeable Commitment:In the laboratory and medical fields, cutting corners on safety or compliance is simply not an option. Our entire manufacturing operation is governed by a strict quality management system, with ISO 13485:2016 (the specific standard for medical devices, which is highly relevant for advanced laboratory equipment) as a central pillar. But it goes beyond that. Any material that goes into our Laboratory Medical Device Enclosures, especially those with potential for contact or that might affect sensitive assays, is scrutinized. This includes adherence to RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), and, where applicable, the ISO 10993 series for biocompatibility. This isn't just about collecting certificates; it's about a deep-rooted commitment to ensuring the safety of lab personnel and the integrity of your scientific work. Our quality control doesn't stop at fabrication; post-finishing inspections include rigorous checks for color difference, corrosion resistance, and the adhesion of any coatings.

If you're specifying Laboratory Medical Device Enclosures, you have questions. Here are some we hear often, with the kind of practical answers you'd get from our engineering team:

Q: You talk about stainless steel and aluminum. For a typical lab, what specific grades of sheet metal do you find yourselves using most for Laboratory Medical Device Enclosures?

A: Good, practical question. For a lot of Laboratory Medical Device Enclosures, you'll find us working with stainless steel, typically 304 grade because it offers a great balance of corrosion resistance for general lab use and it’s very workable. If there's a known exposure to harsher chemicals, then 316L stainless steel is the upgrade we’d recommend for its superior resistance. For aluminum alloys, we select grades that give us good structural properties without adding unnecessary weight, and they can be finished to a very high standard. The final choice always comes down to the specific environment and the chemicals the sheet metal might encounter. And yes, if there’s any chance of interaction with biologicals, we’re looking at ISO 10993 compatibility.

Q: That ±0.005mm laser cutting tolerance is tight. Is that really necessary for a sheet metal housing in a lab?

A: It might seem like a tiny number, but for sophisticated laboratory instruments, that level of precision in the sheet metal is genuinely critical. Hitting that ±0.005mm with laser cutting and maintaining our ±0.1mm tolerance for CNC bending means that every panel aligns perfectly, every seal sits correctly, and every internal component mounts without stress. For Laboratory Medical Device Enclosures housing sensitive optics or microfluidics, this precision ensures everything functions as designed, experiment after experiment.

Q: Labs clean their equipment constantly, sometimes with pretty strong stuff. How do your Laboratory Medical Device Enclosures actually stand up to that?

A: That's a core design driver for us. That smooth, flawless surface, free from burrs or scratches isn't just for aesthetics; it's fundamental for effective cleaning and sterilization. It means fewer places for residues or microbes to hide. The sheet metal itself, especially the stainless steel grades we use, combined with the industrial-grade, non-toxic surface treatments, are specifically chosen to withstand the common cleaning agents and sterilization protocols found in labs without degrading, corroding, or leaching. We build them expecting rigorous cleaning.

Q: Our lab instruments are sensitive to dust, and occasionally, there might be a reagent spill. Can you build Laboratory Medical Device Enclosures to handle that?

A: Absolutely. Protecting the "brains" of your lab equipment is a top priority for Laboratory Medical Device Enclosures. We frequently design enclosures to meet specific IP (Ingress Protection) ratings based on what the lab environment might throw at it. This means careful sheet metal design of all joints, door seals, cable entry points, and any ventilation. For dust, we might use integrated dust cotton or nets, which are effective for ratings like IP5X. If you need something truly dust-tight (IP6X), we engineer a fully sealed design with specialized gaskets. For liquid ingress, we're using high-quality waterproof strips (made from materials like chemical-resistant rubber, silicone, PVC, or TPU), and incorporating smart waterproof structural designs like drip edges or internal channeling. We design for the occasional accident.

Q: Beyond ISO 13485, what assurance do we have that the materials in the Laboratory Medical Device Enclosures won't, say, leach something into a sensitive assay?

A: That’s a critical concern for many labs. While ISO 13485:2016 sets a strong quality system foundation, for material integrity in Laboratory Medical Device Enclosures, we also heavily rely on RoHS (to ensure we're avoiding restricted hazardous substances) and REACH (which means we understand the chemicals in our materials). For applications where outgassing or leaching could be an issue, especially with sensitive biological assays, we select materials known for their inertness and stability. If biocompatibility is a direct concern, then the ISO 10993 series guides our material choices. The goal is for the enclosure to be a completely neutral and protective element.

Choosing the right Laboratory Medical Device Enclosures is more than just ticking a box on a spec sheet. It’s about ensuring the long-term reliability, safety, and performance of your valuable laboratory instrumentation. With our deep, practical knowledge of sheet metal engineering, our insistence on using the right materials for the job, our documented manufacturing precision (you know the numbers: ±0.005mm laser cutting, ±0.1mm bending – these are real-world figures from our shop floor), and our unwavering commitment to standards like ISO 13485, we deliver enclosures that are genuinely built for the rigors of the modern laboratory.

Let's talk. Tell us about the specific challenges and needs of your lab equipment. We're confident we can engineer and build Laboratory Medical Device Enclosures that provide the exact protection and quality your critical work demands.

Laboratory medical device enclosures Manufacturing Capabilities

Laboratory medical device enclosures Manufacturing Capabilities

FOXSEN can provide assistance with the sale of our materials to help you determine how to achieve appropriate regulatory approvals.

Our Medical device enclosure and Medical enclosure are designed to meet the high standards of medical devices.

Manufactured using advanced production processes , our products offer superior durability, corrosion resistance, and biocompatibility.

HOW FOXSEN Produce Laboratory medical device enclosures

HOW FOXSEN Produce Laboratory medical device enclosures

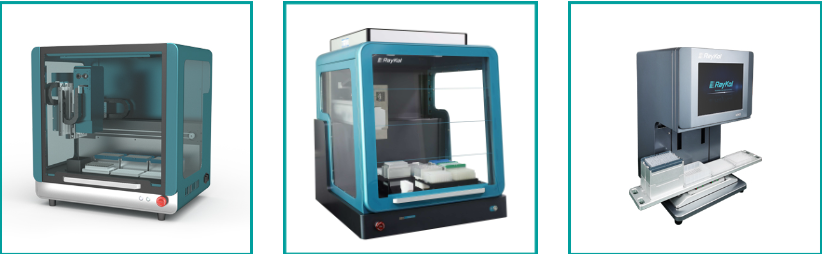

Our products are widely used in various medical equipment, including:Physical and chemical experimental analysis equipmen,medical imaging equipment, laboratory equipment, surgical instrumentsWhether it's small portable devices or large medical instruments, we can provide customized solutions to meet your unique needs.

Process Flow: Laser cuting,CNC punching,CNC bending,Stamping,Fitter (nailing/tapping),welding,polishing,Powder Coating,Silk screen,QC Inspection,Packaging/assembly,Shipment

Design and Development: Design products and molds according to customer needs.

Precision Cutting: Advanced CNC cutting technology ensures precise dimensions and a beautiful appearance.

Surface Treatment:Electroplating color zinc, powder coating, polishing, electroplating

Quality Inspection: strong QC team to ensure 100% inspection before shipment.

Qualification Certificate &Finished product inspection

Qualification Certificate &Finished product inspection

Strictly inspect the quality of the finished goods, including visual inspection, dimensional measurement, strength testing, etc. Ensure that medical enclosure meets design requirements and customer needs.

Packaging&Shipping

Packaging&Shipping

FAQ

FAQ

Q: Are you a trading company or manufacturer?

A: We are the manufacturer.Our advanced equipment ensures that every cut is accurate and consistent.

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or the sample of your product. Details below should be included,

A. Materials B. Surface Finish C. Tolerance D. Quantity

Q: How does the payment process work?

A: Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance before shipment.

Q: How do I know about the delivery?

A: Tracking number will be provided to you once we get it from shipping agent. Also we will keep updating the latest shipping information for you.

Q: Is it possible to know how my products are going without visiting your company?

A: We will provide a detailed production schedule and send weekly reports with digital pictures and videos showing machining progress.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness