Professional Stainless Steel Customization - Tailored Solutions, Premium Quality

Professional Stainless Steel Customization - Tailored Solutions, Premium Quality

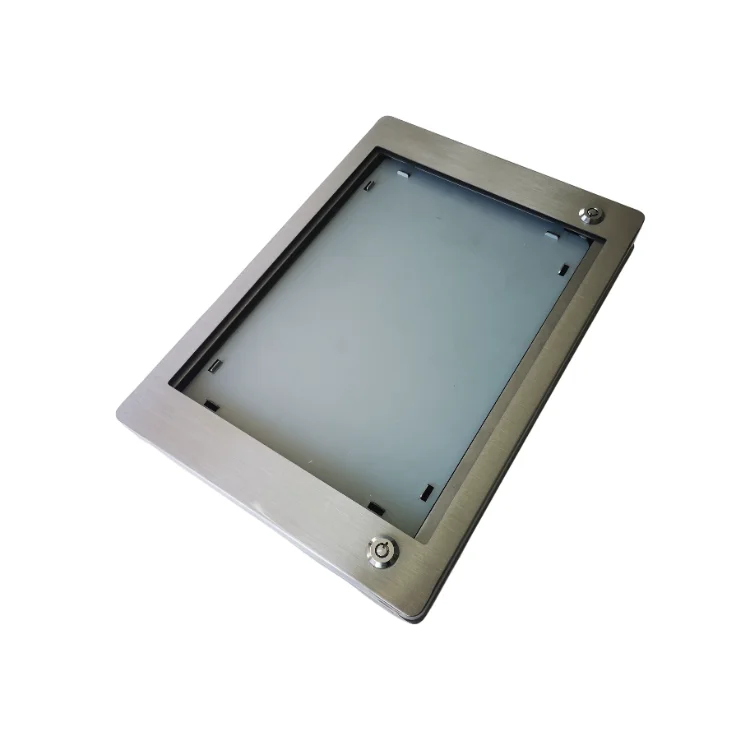

Looking for custom stainless steel solutions? Your search ends here!We offer professional custom stainless steel services, from design to production, every step is dedicated to excellence. Whether you need custom stainless steel products or complex stainless steel structures, we can meet your unique requirements.

| Item Description | Custom stainless steel products |

| Material | Stainless steel 304;316 |

| Processing Technology | stainless steel cutting, bending, rivetin,spraying, silk screen,QC Inspection, Packaging/assembly, Shipment |

| Surface Treatment | Polishing,polishing,Spray powder |

| Unit Price | According to customer drawings |

| Remark | Accept customization |

Hey there! At Foxsen, we’re all about making Stainless Steel Metal Products that you can rely on—think sturdy sheet metal parts for things like anti-theft windows, bus shelters, or custom racks. Based in Xiamen, we’ve got a knack for turning high-quality stainless steel into components that stand up to whatever you throw at them. Let’s dive into what makes our products special, using the good stuff: top-grade materials and solid craftsmanship.

Here’s the scoop on what makes Foxsen’s Stainless Steel Metal Products stand out:

Awesome Materials: We use the best 304 and 316 stainless steel for our sheet metal—no shortcuts here.

304 Stainless Steel: This one’s got 18-20% chromium and 8-10% nickel, which gives it solid corrosion resistance and makes it super easy to shape and clean. It’s a champ for things like decorative panels or kitchen gear.

316 Stainless Steel: With 16% chromium, 10% nickel, and 2-3% molybdenum, this grade’s a beast against corrosion—especially from chlorides like saltwater. That’s why it’s perfect for coastal projects or chemical plants. Plus, it can take the heat—up to 871°C (1600°F)—while 304 handles slightly less.

These aren’t just random metals; their high yield strength and hardness mean our Stainless Steel Metal Products can handle tough jobs without cracking under pressure.

Real Strength: Our sheet metal isn’t messing around. Grade 304 has a tensile strength of 515 MPa, and Grade 316 bumps it up to 580 MPa. That’s serious toughness for heavy-duty use. And because stainless steel hardens when worked (it’s got that cold work hardening effect), it resists dents and scratches like a pro.

Easy to Keep Up: You won’t be stuck scrubbing these forever. Thanks to stainless steel’s natural corrosion resistance—boosted by that molybdenum in 316—our Stainless Steel Metal Products stay rust-free with just a quick wash. No fancy coatings needed.

Made Your Way: We’ve got the tools to tweak our sheet metal to fit your project. Using stuff like laser cutting for precise edges, precision bending for exact angles, and argon arc welding for strong joints, we shape 304 and 316 stainless steel into whatever you need.

Smart Processing: Ever wonder how we get it so spot-on? We use heavy-duty machines to handle the big vibrations stainless steel kicks up during加工. For cutting, we pick high-speed steel (HSS) tools for smaller pieces (under φ40mm) and switch to hard alloy tools for bigger ones—keeps things efficient at a steady 60m/min cut speed.

I’ve thought about what I’d ask if I were buying Stainless Steel Metal Products. Here’s what came up, with answers packed with real info from our process:

How tough are they really?

Pretty darn tough. Grade 304’s got a tensile strength of 515 MPa, and 316 hits 580 MPa. Plus, with stainless steel’s high hardness and that cold work hardening, our sheet metal can take a beating—perfect for high-traffic spots or industrial setups.

Do they hold up in rough conditions?

Oh yeah. That 2-3% molybdenum in 316 makes it ace against chloride corrosion—think salty air or chemical spills. It’s why ships love it. 304’s great for general use, but 316’s your pick for the nasty stuff.

How much upkeep do they need?

Barely any. A wipe with soap and water keeps our Stainless Steel Metal Products looking good. No rust worries here, thanks to that 18-20% chromium in 304 and the extra kick from 316’s molybdenum.

Can you make them to my specs?

Sure can! We use CNC machining and laser cutting to nail exact sizes, and our bending accounts for stainless steel’s strong spring-back (it’s got a big rebound tendency). Need a weird shape? We’ve got it covered.

What about heat resistance?

They’re champs. 316 can handle 871°C, and 304’s close behind. Whether it’s a hot oven or a steamy engine room, our sheet metal won’t let you down.

How do you finish them?

We’ve got options—brushed, polished, or even electroplated for a sleek look. After processing, we might hit them with phosphating or spray coating to boost durability, depending on what you’re after.

Here’s a quick peek at how we turn raw stainless steel into top-tier Stainless Steel Metal Products:

Start with cutting the sheet metal to size using laser cutters or CNC machines.

Bend it with precision—stainless steel’s low stretch (low elongation) means we use extra force and bigger bend angles to avoid cracks.

Weld it up with argon arc or laser welding for joints that won’t quit.

Finish it off with surface treatments like electroplating or spray coating, then check every detail—dimensions, looks, the works.

We even tweak our tools to keep things smooth. For example, our cutting blades have a 0° rake angle to avoid chip jams, and we grind them sharp to cut down on wear—little tricks that make a big difference.

So, why go with us? Foxsen’s Stainless Steel Metal Products are built from the best 304 and 316 stainless steel, packed with chromium, nickel, and molybdenum for strength and corrosion resistance. We process them with care—think laser cutting, precision welding, and thorough quality checks—so you get sheet metal that’s ready for anything. Whether it’s a standard piece or a custom job, we’ve got the know-how to deliver.

Need something tough, reliable, and made just for you? Foxsen’s Stainless Steel Metal Products are where it’s at. Let’s make your next project shine!

Professional Stainless Steel Customization Service

Professional Stainless Steel Customization Service

FOXSEN provides custom service of Custom stainless steel products:

Customization: Tailored stainless steel products to fit your exact specifications.

Premium Materials: High-quality stainless steel for superior corrosion resistance, strength, and durability.

Expert Craftsmanship: Advanced equipment and skilled craftsmen ensure top-notch quality.

Wide Range of Applications: Suitable for construction, food, chemical, pharmaceutical, and more

Professional Stainless Steel Customization Manufacturing Capabilities

Professional Stainless Steel Customization Manufacturing Capabilities

In today's competitive market, selecting the right materials and components is crucial for enhancing product quality. Our stainless steel industrial components, crafted from high-quality premium stainless steel, specifically offer stainless steel CNC parts, ensuring precision and unparalleled durability.

HOW FOXSEN Produce Professional Stainless Steel Customization

HOW FOXSEN Produce Professional Stainless Steel Customization

Process Flow:

Design and Development: Design products and molds according to customer drawing.

Material Preparation: Select suitable metal materials:Stainless steel 316,Stainless steel 304,Stainless steel 201.

Stainless steel cutting: Use precision laser cutting equipment to metal sheets into the required shape.

Secondary Processing: Perform secondary processing such as bending, drilling, and tapping according to product requirements.

Surface Treatment: Electroplating color zinc, powder coating, polishing, electroplating

Quality Inspection: strong QC team to ensure 100% inspection before shipment.

Qualification Certificate &Finished product inspection

Qualification Certificate &Finished product inspection

Strictly inspect the quality of the finished goods, including visual inspection, dimensional measurement, strength testing, etc. Ensure that Custom stainless steel products meets design requirements and customer needs.

Packaging&Shipping

Packaging&Shipping

Why Choose our Professional Custom stainless steel products?

Why Choose our Professional Custom stainless steel products?

1: Rich experience:Over 16+ years experience in Custom stainless steel products

2.Professional Team: Experienced engineers and designers provide expert technical support.

3.Fast Delivery: Efficient production processes ensure timely delivery.

4.Competitive Pricing: Competitive prices to help you save costs.

FAQ

FAQ

Q: Are you a trading company or manufacturer?

A: We are the manufacturer.Our advanced equipment ensures that every cut is accurate and consistent.

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or the sample of your product. Details below should be included,

A. Materials B. Surface Finish C. Tolerance D. Quantity

Q: How does the payment process work?

A: Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance before shipment.

Q: How do I know about the delivery?

A: Tracking number will be provided to you once we get it from shipping agent. Also we will keep updating the latest shipping information for you.

Q: Is it possible to know how my products are going without visiting your company?

A: We will provide a detailed production schedule and send weekly reports with digital pictures and videos showing machining progress.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness