Electrical Connection Aluminum Busbar:Custom Manufacturing, Quality Assurance

Electrical Connection Aluminum Busbar:Custom Manufacturing, Quality Assurance

Now we have aluminium horizontal-profiled busbars that connect vertically with a wider range of current ratings. This is good for OEMs.Foxsen is a busbar aluminum manufacturer specializing in busbar

| Item Description | Electrical Connection Aluminum Busbar |

| Material | Aluminum 6061,5052,1050A |

| Processing Technology | Raw Material Selection,Melting/Casting,Rolling/ Extrusion,Cutting,Drilling/Tapping,Bending,Welding,Surface Treatment,Quality Control,Assembly/Packaging,Shipment |

| Surface Treatment | Plating Options: Silver, Tin, Insulation Options:Heat Shrink ,Powder Coat |

| Unit Price | According to customer drawings |

| Remark | Accept customization |

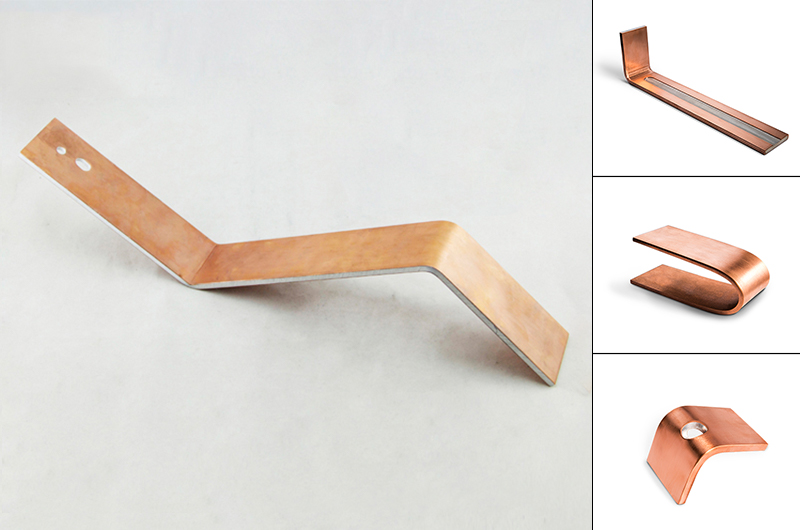

Looking for a dependable way to distribute electricity in your setup? The Electrical Connection Aluminum Busbar from Foxsen is built for the job. This isn’t just a chunk of metal—it’s a lightweight, high-performance conductor designed to carry power efficiently in places like factories, workshops, or any system needing solid electrical connections. With our top-notch sheet metal skills shaping its casing, it’s as practical as it is tough.

At its core, the Electrical Connection Aluminum Busbar is a rigid, rectangular bar made from high-purity aluminum, perfect for fixed installations where you need steady, reliable power flow. We craft its outer shell using advanced sheet metal techniques, ensuring it’s durable and easy to hook up. It’s all about getting electricity where it’s needed without the hassle.

Here’s what makes our Electrical Connection Aluminum Busbar a smart choice, starting with the materials we bring to the table:

High-Quality Aluminum:

We use aluminum with a purity of at least 99.50%, meeting strict electrical standards. That purity means better conductivity—less energy lost as heat. It’s light too, with a density of just 2.7g/cm³ (compared to copper’s 8.96g/cm³), so it’s easier to handle and cheaper than copper, without skimping on performance.

Rugged Sheet Metal Shell:

Our sheet metal work isn’t just for looks. We use automated riveting to assemble the casing—none of that shaky bolt stuff that can loosen over time. It’s a uniform, solid finish that keeps everything safe and stable, even under heavy use.

Corrosion Resistance:

Aluminum naturally forms an oxide layer that fights rust, and we kick it up a notch with optional anodizing—boosting heat resistance to 1500°C and durability for tough environments.

Practical Design:

Pre-punched holes and a flat shape make the Electrical Connection Aluminum Busbar a breeze to install. We stick to precise standards for hole spacing, so it lines up every time.

Wondering if this busbar’s the right fit? Here’s what you might ask, with straight answers backed by the data:

Is it strong enough?

You bet. Alloyed aluminum hits tensile strengths up to 310 MPa, so it holds up under load without bending or breaking.

Will it rust?

Nope. That natural oxide layer, plus optional anodizing, keeps corrosion away—even in damp or harsh spots.

How’s it stack up to copper?

It’s lighter (2.7g/cm³ vs. 8.96g/cm³) and cheaper, with conductivity at 61% of copper’s. For most jobs, it’s the practical pick.

Can it handle big currents?

Absolutely. Depending on size, it’s rated for up to 4000A—plenty for high-power needs.

Is it safe?

Yes. We follow strict electrical clearance rules, and the riveted sheet metal shell cuts the risk of shorts.

At Foxsen, we’ve got the sheet metal expertise and material smarts to make the Electrical Connection Aluminum Busbar a winner. With 99.50% pure aluminum, a lightweight 2.7g/cm³ build, and corrosion resistance that lasts, it’s all about delivering power you can rely on. Easy to install, tough as nails, and priced right—it’s the total package.

Here’s the quick take:

Built to Last: High-purity aluminum and a solid shell.

Efficient: Light, conductive, and cost-effective.

Safe: Precision design you can trust.

The Electrical Connection Aluminum Busbar is the no-fuss solution for serious power distribution. Get in touch with Foxsen today and see how our sheet metal know-how can power your project!

Aluminium busbar manufacturer Manufacturing Capabilitie

Aluminium busbar manufacturer Manufacturing Capabilitie

If requested, the moment a question or quote request comes to Storm Power, our engineering design team employs a process designed to make sure that each customer makes the right choice in metal, design and fabrication. If you need to create custom aluminum or copper bus bar, we work side-by-side with your engineers with the shared goal of making your part work from inception to completion.

HOW FOXSEN Produce aluminium busbar manufacturer

HOW FOXSEN Produce aluminium busbar manufacturer

One reason why the busbar has replaced hard-wired power distribution in industry is the rise of aluminium.And the rise of aluminium is due to its low cost, compared with copper. Recyclable aluminium is not prone to scarcity or to volatile commodity markets.

Process Flow: Raw Material Selection,Melting and Casting,Rolling and Extrusion,Cutting,Drilling and Tapping,Bending,Welding,Surface Treatment,Quality Control,Assembly and Packaging

Qualification Certificate &Finished product inspection

Qualification Certificate &Finished product inspection

Dimensional Inspection: Verifying that the busbars meet specified dimensions and tolerances.Electrical Conductivity Testing: Ensuring that the busbars have the required conductivity.

Mechanical Strength Testing: Checking for strength and durability.

Packaging&Shipping

Packaging&Shipping

FAQ

FAQ

Q: Are you a trading company or manufacturer?

A: We are the manufacturer.Our advanced equipment ensures that every cut is accurate and consistent.

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or the sample of your product. Details below should be included,

A. Materials B. Surface Finish C. Tolerance D. Quantity

Q: How does the payment process work?

A: Payment terms are flexible for us in accordance with specific conditions. Generally we advise 30%TT deposit, balance before shipment.

Q: How do I know about the delivery?

A: Tracking number will be provided to you once we get it from shipping agent. Also we will keep updating the latest shipping information for you.

Q: Is it possible to know how my products are going without visiting your company?

A: We will provide a detailed production schedule and send weekly reports with digital pictures and videos showing machining progress.

Rich experience:Over 16+ years experience in sheet metal fabration products

FOXSEN Strong QC team to ensure 100% inspection before shipment.

Our services include design, prototyping, tooling, and finishing, providing a one-stop solution for your sheet metal fabration parts needs.

Professional sheet metal production management MES ensure on-time delivery of products.

We have professinal experienced team of technicians and excellent processing equipment

Automation equipment and Softing tooling reduce production costs improve product cost-effectiveness